Professional Documents

Culture Documents

2 9 4 Dissolution Test For Transdermal Patches

Uploaded by

api-2611249060 ratings0% found this document useful (0 votes)

258 views3 pagesOriginal Title

2 9 4 dissolution test for transdermal patches

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

258 views3 pages2 9 4 Dissolution Test For Transdermal Patches

Uploaded by

api-261124906Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

EUROPEAN PHARMACOPOEIA 5.0 2.9.4.

Dissolution test for transdermal patches

01/2005:20904

2.9.4. DISSOLUTION TEST FOR

TRANSDERMAL PATCHES

This test is used to determine the dissolution rate of the

active ingredients of transdermal patches.

1. DISK ASSEMBLY METHOD

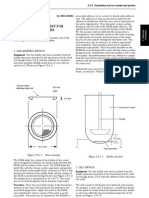

Equipment. Use the paddle and vessel assembly from the

paddle apparatus described in the dissolution test for solid

oral dosage forms (2.9.3) with the addition of a stainless

steel disk assembly (SSDA) in the form of a net with an

aperture of 125 m (see Figure 2.9.4.-1).

Figure 2.9.4.-1. Disk assembly

The SSDA holds the system at the bottom of the vessel

and is designed to minimise any dead volume between the

SSDA and the bottom of the vessel. The SSDA holds the

patch flat, with the release surface uppermost and parallel

to the bottom of the paddle blade. A distance of 25 2 mm

between the bottom of the paddle blade and the surface of

the SSDA is maintained during the test (see Figure 2.9.4.-2).

The temperature is maintained at 32 0.5 C. The vessel

may be covered during the test to minimise evaporation.

Procedure. Place the prescribed volume of the dissolution

medium in the vessel and equilibrate the medium to the

prescribed temperature. Apply the patch to the SSDA,

ensuring that the release surface of the patch is as flat

as possible. The patch may be attached to the SSDA by a

prescribed adhesive or by a strip of a double-sided adhesive

tape. The adhesive or tape are previously tested for the

absence of interference with the assay and of adsorption of

the active ingredient(s). Press the patch, release surface

facing up, onto the side of the SSDA made adhesive. The

applied patch must not overlap the borders of the SSDA.

For this purpose and provided that the preparation is

homogeneous and uniformly spread on the outer covering,

an appropriate and exactly measured piece of the patch

may be cut and used for testing the dissolution rate. This

procedure may also be necessary to achieve appropriate

sink conditions. This procedure must not be applied to

membrane-type patches. Place the patch mounted on the

SSDA flat at the bottom of the vessel with the release surface

facing upwards. Immediately rotate the paddle at 100 r/min,

for example. At predetermined intervals, withdraw a sample

from the zone midway between the surface of the dissolution

medium and the top of the blade, not less than 1 cm from

the vessel wall.

Perform the assay on each sample, correcting for any volume

losses, as necessary. Repeat the test with additional patches.

Figure 2.9.4.-2. Paddle and disk

2. CELL METHOD

Equipment. Use the paddle and vessel assembly from the

paddle apparatus described in the dissolution test for solid

oral dosage forms (2.9.3) with the addition of the extraction

cell (cell).

The cell is made of chemically inert materials and consists

of a support, a cover and, if necessary, a membrane placed

on the patch to isolate it from the medium that may modify

or adversely affect the physico-chemical properties of the

patch (see Figure 2.9.4.-3).

General Notices (1) apply to all monographs and other texts 231

2.9.4. Dissolution test for transdermal patches EUROPEAN PHARMACOPOEIA 5.0

Figure 2.9.4.-3. Extraction cell

Support. The central part of the support forms a cavity

intended to hold the patch. The cavity has a depth of 2.6 mm

and a diameter that is appropriate to the size of the patch to

be examined. The following diameters can be used: 27 mm,

38 mm, 45 mm, 52 mm, corresponding to volumes of 1.48 ml,

2.94 ml, 4.13 ml, 5.52 ml, respectively.

Cover. The cover has a central opening with a diameter

selected according to the size of the patch to be examined.

The patch can thus be precisely centred, and its releasing

surface limited. The following diameters may be used:

20 mm, 32 mm, 40 mm, 50 mm corresponding to areas of

3.14 cm

2

, 8.03 cm

2

, 12.56 cm

2

, 19.63 cm

2

, respectively. The

cover is held in place by nuts screwed onto bolts projecting

from the support. The cover is sealed to the support by a

rubber ring set on the reservoir.

Extraction cell. The cell holds the patch flat, with the

release surface uppermost and parallel to the bottom of

the paddle blade. A distance of 25 2 mm is maintained

between the paddle blade and the surface of the patch

(see Figure 2.9.4.-4). The temperature is maintained at

32 0.5 C. The vessel may be covered during the test to

minimise evaporation.

Procedure. Place the prescribed volume of the dissolution

medium in the vessel and equilibrate the medium to the

prescribed temperature. Precisely centre the patch in the

cell with the releasing surface uppermost. Close the cell, if

necessary applying a hydrophobic substance (for example,

petrolatum) to the flat surfaces to ensure the seal, and

ensure that the patch stays in place. Introduce the cell flat

into the bottom of the vessel with the cover facing upwards.

Immediately rotate the paddle, at 100 r/min for example. At

predetermined intervals, withdraw a sample from the zone

midway between the surface of the dissolution medium and

the top of the paddle blade, not less than 1 cm from the

vessel wall.

Perform the assay on each sample, correcting for any volume

losses, as necessary. Repeat the test with additional patches.

Figure 2.9.4.-4. Paddle over extraction cell

3. ROTATING CYLINDER METHOD

Equipment. Use the assembly of the paddle apparatus

described in the dissolution test for solid oral dosage forms

(2.9.3). Replace the paddle and shaft with a stainless steel

cylinder stirring element (cylinder) (see Figure 2.9.4.-5). The

patch is placed on the cylinder at the beginning of each

test. The distance between the inside bottom of the vessel

and the cylinder is maintained at 25 2 mm during the test.

The temperature is maintained at 32 0.5 C. The vessel is

covered during the test to minimise evaporation.

Procedure. Place the prescribed volume of the dissolution

medium in the vessel and equilibrate the medium to the

prescribed temperature. Remove the protective liner from

the patch and place the adhesive side on a piece of suitable

inert porous membrane that is at least 1 cm larger on all

sides than the patch. Place the patch on a clean surface with

the membrane in contact with this surface. Two systems for

adhesion to the cylinder may be used:

apply a suitable adhesive to the exposed membrane

borders and, if necessary, to the back of the patch,

apply a double-sided adhesive tape to the external wall

of the cylinder.

Using gentle pressure, carefully apply the non-adhesive side

of the patch to the cylinder, so that the release surface is in

contact with the dissolution medium and the long axis of the

patch fits around the circumference of the cylinder.

The system for adhesion used is previously tested for absence

of interference with the assay and of adsorption of the active

ingredient(s).

Place the cylinder in the apparatus, and immediately rotate

the cylinder at 100 r/min, for example. At determined

intervals, withdraw a sample of dissolution medium from a

zone midway between the surface of the dissolution medium

and the top of the rotating cylinder, and not less than 1 cm

from the vessel wall.

Perform the assay on each sample as directed in the

individual monograph, correcting for any volume withdrawn,

as necessary. Repeat the test with additional patches.

232 See the information section on general monographs (cover pages)

EUROPEAN PHARMACOPOEIA 5.0 2.9.5. Uniformity of mass of single-dose preparations

Figure 2.9.4.-5. Cylinder stirring element

Dimensions in centimetres

Interpretation. The requirements are met if the quantity

of active ingredient(s) released from the patch, expressed

as the amount per surface area per time unit, is within the

prescribed limits at the defined sampling times.

01/2005:20905

2.9.5. UNIFORMITY OF MASS OF

SINGLE-DOSE PREPARATIONS

Weigh individually 20 units taken at random or, for

single-dose preparations presented in individual containers,

the contents of 20 units, and determine the average mass.

Not more than 2 of the individual masses deviate from the

average mass by more than the percentage deviation shown

in Table 2.9.5.-1 and none deviates by more than twice that

percentage.

For capsules and powders for parenteral use, proceed as

described below.

CAPSULES

Weigh an intact capsule. Open the capsule without losing

any part of the shell and remove the contents as completely

as possible. For soft shell capsules, wash the shell with a

suitable solvent and allow to stand until the odour of the

solvent is no longer perceptible. Weigh the shell. The mass

of the contents is the difference between the weighings.

Repeat the procedure with another 19 capsules.

Table 2.9.5.-1

Pharmaceutical Form Average Mass Percentage

deviation

80 mg or less 10

More than 80 mg and

less than 250 mg

7.5

Tablets (uncoated and

film-coated)

250 mg or more 5

Less than 300 mg 10 Capsules, granules

(uncoated, single-dose)

and powders (single-dose)

300 mg or more 7.5

Powders for parenteral use*

(single-dose)

More than 40 mg 10

Suppositories and pessaries All masses 5

Powders for eye-drops and

powders for eye lotions

(single-dose)

Less than 300 mg

300 mg or more

10

7.5

* When the average mass is equal to or below 40 mg, the preparation

is not submitted to the test for uniformity of mass but to the test for

uniformity of content of single-dose preparations (2.9.6).

POWDERS FOR PARENTERAL USE

Remove any paper labels from a container and wash and dry

the outside. Open the container and without delay weigh

the container and its contents. Empty the container as

completely as possible by gentle tapping, rinse it if necessary

with water R and then with alcohol R and dry at 100-105 C

for 1 h, or, if the nature of the container precludes heating

at this temperature, dry at a lower temperature to constant

mass. Allow to cool in a desiccator and weigh. The mass of

the contents is the difference between the weighings. Repeat

the procedure with another 19 containers.

General Notices (1) apply to all monographs and other texts 233

You might also like

- 2.9.4. Dissolution Test For Transdermal Patches PDFDocument3 pages2.9.4. Dissolution Test For Transdermal Patches PDFRani RubiyantiNo ratings yet

- Uniform mass test for single-dose preparationsDocument3 pagesUniform mass test for single-dose preparationsSandeep KumarNo ratings yet

- ASTM D 1436 - 97 (Reapproved 2002) Application of Emulsion Floor Polishes To Substrates ForDocument3 pagesASTM D 1436 - 97 (Reapproved 2002) Application of Emulsion Floor Polishes To Substrates Foralin2005No ratings yet

- LS-297 R26 123Document6 pagesLS-297 R26 123Gourav GoelNo ratings yet

- 2.9.1. Disintegration of Tablets and CapsulesDocument3 pages2.9.1. Disintegration of Tablets and CapsulesPikiy PutriNo ratings yet

- L Disso SeminarDocument11 pagesL Disso SeminarRavindra TupeNo ratings yet

- Dissolution Test For Solid Oral Dosage FormsDocument8 pagesDissolution Test For Solid Oral Dosage FormsPedro Marcelo Alva PlasenciaNo ratings yet

- Disintegration test ensures tablets and capsules break down properlyDocument3 pagesDisintegration test ensures tablets and capsules break down properlyasrielisabetNo ratings yet

- European Pharmacopoeia Disintegration Test ProceduresDocument3 pagesEuropean Pharmacopoeia Disintegration Test ProceduresCarlos Gómez100% (1)

- ASTM D 452 - 91 (Reapproved 1997) Sieve Analysis of Surfacing For Asphalt Roofing ProductsDocument2 pagesASTM D 452 - 91 (Reapproved 1997) Sieve Analysis of Surfacing For Asphalt Roofing Productsalin2005No ratings yet

- Á701Ñ Disintegration: 584 Á699ñ Density of Solids / Physical Tests USP 40Document3 pagesÁ701Ñ Disintegration: 584 Á699ñ Density of Solids / Physical Tests USP 40Long ManNo ratings yet

- Standard Practice For Reducing Samples of Aggregate To Testing SizeDocument7 pagesStandard Practice For Reducing Samples of Aggregate To Testing Sizejun floresNo ratings yet

- Particle Size AnalysisDocument31 pagesParticle Size Analysisحبيبه بيبيNo ratings yet

- LS-297 - Rev 34 - May 2020Document9 pagesLS-297 - Rev 34 - May 2020ming_zhu10No ratings yet

- 5.3 Disintegration Test For Tablets and Capsules: Final Text For Revision ofDocument4 pages5.3 Disintegration Test For Tablets and Capsules: Final Text For Revision ofM. S. ChikkamaniNo ratings yet

- Dissolution Test-2554700864Document12 pagesDissolution Test-2554700864Aanchal DeviNo ratings yet

- QCtabletDocument9 pagesQCtabletapi-3742263100% (3)

- PSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressDocument6 pagesPSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressChung LeNo ratings yet

- Disintegration Test for Tablets and CapsulesDocument4 pagesDisintegration Test for Tablets and CapsulesRed DiggerNo ratings yet

- PosiTestAT-v4 0 PDFDocument45 pagesPosiTestAT-v4 0 PDFcentaury2013No ratings yet

- D 2041 - 00Document4 pagesD 2041 - 00harisahamedNo ratings yet

- Scope: CautionDocument0 pagesScope: Cautionandy981No ratings yet

- Sieve Analysis of Surfacing For Asphalt Roofing Products: Standard Test Method ForDocument2 pagesSieve Analysis of Surfacing For Asphalt Roofing Products: Standard Test Method ForNuMbNo ratings yet

- ABAA T0002 Pull Strength TestDocument4 pagesABAA T0002 Pull Strength Testzaheerahmed77No ratings yet

- Iso 2781 TraducidaDocument5 pagesIso 2781 TraducidaRenato Moises Rosales SaraviaNo ratings yet

- TMH-6 - ST10Document10 pagesTMH-6 - ST10ATHOLSCHWARZNo ratings yet

- Determine Soil Shear Parameters with Triaxial TestDocument8 pagesDetermine Soil Shear Parameters with Triaxial TestTenzinKesangNo ratings yet

- Astm E965Document11 pagesAstm E965Luis CabreraNo ratings yet

- Mud Lab Manual - NewDocument32 pagesMud Lab Manual - Newfisco4ril67% (6)

- Aashto T27-T11Document14 pagesAashto T27-T11Rifki Aulia50% (4)

- Keur 00821-029 201906Document5 pagesKeur 00821-029 201906erik0007No ratings yet

- Astm d2726Document26 pagesAstm d2726mzaimNo ratings yet

- T 826Document6 pagesT 826burucuNo ratings yet

- 2.9.40. Uniformity of Dosage Units 20940eDocument4 pages2.9.40. Uniformity of Dosage Units 20940ecupidvishu123No ratings yet

- Successful particle size analysis of dry powdersDocument3 pagesSuccessful particle size analysis of dry powderssiswantoNo ratings yet

- Disintegration Test and Apparatus - Pharmaceutical GuidelinesDocument2 pagesDisintegration Test and Apparatus - Pharmaceutical Guidelinesmannuu00No ratings yet

- 11111Document3 pages11111Praful N KNo ratings yet

- test-09(1)Document6 pagestest-09(1)Ateafac Anastasia NjuafacNo ratings yet

- Filtration Tests: Test ProcedureDocument4 pagesFiltration Tests: Test ProcedureAbdulHameed H. AlalwanNo ratings yet

- Liquid Strike-Through Time 150.4-99Document5 pagesLiquid Strike-Through Time 150.4-99S6001964No ratings yet

- Determining The Outgassing Potential of Sealant Backing: Standard Test Method ForDocument5 pagesDetermining The Outgassing Potential of Sealant Backing: Standard Test Method ForRufo CascoNo ratings yet

- USP 2040 Disol y Desint SotaxDocument4 pagesUSP 2040 Disol y Desint Sotaxpatricia MedinaNo ratings yet

- Triaxial Test (UC)Document3 pagesTriaxial Test (UC)Aisha MalikNo ratings yet

- UNCONSOLIDATED UNDRAINED TRIAXIAL TEST (QUICK TESTDocument14 pagesUNCONSOLIDATED UNDRAINED TRIAXIAL TEST (QUICK TESTSi Rerumpai LautNo ratings yet

- Sampling and Fabrication of 50-mm (2-In.) Cube Specimens Using Grout (Non-Shrink) or MortarDocument5 pagesSampling and Fabrication of 50-mm (2-In.) Cube Specimens Using Grout (Non-Shrink) or MortarWaleed AhmedNo ratings yet

- Ring Crush of Paperboard (Rigid Support Method) (Five-Year Review of T 822 Om-02)Document8 pagesRing Crush of Paperboard (Rigid Support Method) (Five-Year Review of T 822 Om-02)ArjuLana Van MaulaNo ratings yet

- ASTM D 814 - 95 (Reapproved 2000) Rubber Property-Vapor Transmission of Volatile LiquidsDocument2 pagesASTM D 814 - 95 (Reapproved 2000) Rubber Property-Vapor Transmission of Volatile Liquidsalin2005No ratings yet

- Tablet EvaluationDocument5 pagesTablet EvaluationsudhansupNo ratings yet

- AASHTO T84 (Specific Gravity & Absorption of Fine Aggregate) PDFDocument12 pagesAASHTO T84 (Specific Gravity & Absorption of Fine Aggregate) PDFKhant Linn AungNo ratings yet

- Resistance of Nonporous Paper To Passage of Air: Standard Test Method ForDocument3 pagesResistance of Nonporous Paper To Passage of Air: Standard Test Method Forjamaljamal20No ratings yet

- Estimating Water Sorptivity as a Durability Index for Ultra-High Strength RPCDocument4 pagesEstimating Water Sorptivity as a Durability Index for Ultra-High Strength RPCyeshwanthvkumarNo ratings yet

- Houghton 1998Document15 pagesHoughton 1998_meiantiNo ratings yet

- USP FriabilityDocument2 pagesUSP Friabilityshdph100% (1)

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationSantosh KumarNo ratings yet

- Absorbency Under PressureDocument3 pagesAbsorbency Under PressureMOHAMED DawiNo ratings yet

- Experiment No: Dry Shrinkage Test For MortarDocument13 pagesExperiment No: Dry Shrinkage Test For Mortarruba.qammarNo ratings yet

- F1536 1479757-1Document5 pagesF1536 1479757-1Thaweekarn ChangthongNo ratings yet

- Section Cutting and Staining: A practical introduction to histological methods for students and practitionersFrom EverandSection Cutting and Staining: A practical introduction to histological methods for students and practitionersNo ratings yet

- Flow charts of pharmaceutical quality control tests for different dosage formsFrom EverandFlow charts of pharmaceutical quality control tests for different dosage formsNo ratings yet

- Eye C GasDocument3 pagesEye C GasLuis ReyesNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument3 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Install Medium Voltage Lines SafelyDocument106 pagesInstall Medium Voltage Lines Safelyajayi micheal sunday100% (1)

- Global Energy Balance in The Exchanger and Losses StudyDocument4 pagesGlobal Energy Balance in The Exchanger and Losses StudyJames Clerk MaxwellNo ratings yet

- Asme CCase N-432Document4 pagesAsme CCase N-432julianmorantesNo ratings yet

- As 1463-1988 Polyethylene Pipe Extrusion CompoundsDocument6 pagesAs 1463-1988 Polyethylene Pipe Extrusion CompoundsSAI Global - APACNo ratings yet

- 4261 CombustorsDocument29 pages4261 CombustorsLakshman Reddy LuckyNo ratings yet

- Non-Ferrous Metals and AlloysDocument58 pagesNon-Ferrous Metals and AlloysPradeep Kumar BagadiNo ratings yet

- 48,3x5,08 824000Document2 pages48,3x5,08 824000Mehmet ŞaHanNo ratings yet

- Culasi Phase 1 (BOX CULVERT) - Recover-ModelDocument1 pageCulasi Phase 1 (BOX CULVERT) - Recover-ModelEmman De los ReyesNo ratings yet

- Toshiba Auxiliary-CatalogueDocument28 pagesToshiba Auxiliary-CatalogueSuresh Chandra SharmaNo ratings yet

- Canadian VsgeneratorsDocument24 pagesCanadian VsgeneratorsStan AndreiNo ratings yet

- Agitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDocument1 pageAgitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDeepikaNo ratings yet

- Document PDFDocument136 pagesDocument PDFMargarita KianidouNo ratings yet

- Ausmelt SmeltingDocument6 pagesAusmelt SmeltingMarcelo SerranoNo ratings yet

- Valorizing Spent Coffee GroundsDocument15 pagesValorizing Spent Coffee GroundsJorge ZapataNo ratings yet

- As 3585-2008 End Fittings For Synthetic Flat-Webbing and Round SlingsDocument7 pagesAs 3585-2008 End Fittings For Synthetic Flat-Webbing and Round SlingsSAI Global - APAC0% (1)

- MSDS Fused SilicaDocument6 pagesMSDS Fused SilicaJi ChemNo ratings yet

- 5 431529563391000589Document1 page5 431529563391000589mNo ratings yet

- Cooling: Operating Temperature Arrhenius Equation Radiation Transformer Oil Mineral Oil PaperDocument2 pagesCooling: Operating Temperature Arrhenius Equation Radiation Transformer Oil Mineral Oil PaperVishnu PillaiNo ratings yet

- Capral - WERS BookletDocument58 pagesCapral - WERS BookletLEONARDONo ratings yet

- TM620 LeafletDocument4 pagesTM620 LeafletÖzgürMetinNo ratings yet

- STEEL & PIPES for AFRICA price listDocument1 pageSTEEL & PIPES for AFRICA price listWynand Van ZylNo ratings yet

- 350 MW Power Plant Technical SpecificationsDocument7 pages350 MW Power Plant Technical SpecificationsEricGaringanaoNo ratings yet

- Cutting RoomDocument45 pagesCutting RoomSuchismitaShauryaNo ratings yet

- 01 Heating PL 2017 Rs v03 Svu 5.4 FinalDocument77 pages01 Heating PL 2017 Rs v03 Svu 5.4 FinalKajak Klub DrinaNo ratings yet

- CBR PLUS Soil Stabilizer and Dust Control English CatalogueDocument4 pagesCBR PLUS Soil Stabilizer and Dust Control English CataloguecbrplusmexicoNo ratings yet

- New DataDocument872 pagesNew DataRoomman ArifNo ratings yet

- Kia Sorento 2015 Service ManualDocument20 pagesKia Sorento 2015 Service ManualMaria100% (56)

- Enhanced Oil Recovery (EOR) - Schlumberger GlossaryDocument66 pagesEnhanced Oil Recovery (EOR) - Schlumberger GlossaryDiana La CruzNo ratings yet