Professional Documents

Culture Documents

2 Marks Old QP

Uploaded by

Varun0 ratings0% found this document useful (0 votes)

9 views31 pagesgf

Original Title

2 MARKS OLD QP

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentgf

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views31 pages2 Marks Old QP

Uploaded by

Varungf

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 31

P.

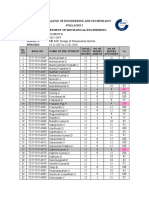

A COLLEGE OF ENGINEERING AND TECHNOLOGY, POLLACHI

DEPARTMENT OF MECHANICAL ENGINEERING

ME2027 - PROCESS PLANNING AND COST ESTIMATION

Two mark q!"#$o%" a%& a%"w!r"

'NIT-I ( )OR* ST'DY AND EROGONOMICS

+. D!,$%! m!#-o& "#&..

Method study is the systematic recording and critical examination of existing and

proposed ways of doing work as a means of developing and applying easier and more

effective methods and reducing cost.

2. )-a# ar! #-! o/0!1#$2!" o, m!#-o& "#&.3

(a) To present and analyze true facts concerning the situation.

(b) To examine those facts critically.

(c) To develop the best answer possible under given circumstances based on critical

examinations of facts.

4. )-a# ar! #-! 2ar$o" 1-ar#" "!& ,or m!#-o& "#&.3

(a). Out line process chart

(b). low process chart

(c). Two handed process chart

(d). Multiple activity chart

(e). !ang chart

(f). "imo chart

5. )r$#! "-or# %o#! o% o#6$%! 7ro1!"" 1-ar#.

The outline process chart gives an overall view of the process# from the beginning to

the end. $t is a graphic representation of the se%uence of all the operations and

inspections carried out in the entire process and the stage at which the materials are

introduced.

8. )r$#! "-or# %o#! o% ,6ow 7ro1!"" 1-ar#.

& flow process chart is a graphical representation of the se%uence of all operations#

transportations# inspections# delay and shortages occurring during a process and includes

information considered desirable for analysis such as time re%uired and distance moved.

9. )-a# ar! #-! 2ar$o" &$a:ram" "!& ,or m!#-o& "#&.3

(a) low diagram# b) "tring diagram# c) Travel chart

7. )r$#! "-or# %o#! o% ,6ow &$a:ram.

low diagram is a drawing# made to a scale of the workplace showing the location of

various e%uipment and machines# activities carried out and the followed by workers and

materials.

;. )r$#! "-or# o% "#r$%: &$a:ram.

"tring diagram is a scale layout drawing on which the length of string is used to

record the extent as well as pattern of movement of a worker for materials or e%uipment

working within limited area over a certain period time

<. )r$#! "-or# %o#! o% #ra2!6 1-ar#.

Travel chart is a tabular record for presenting %uantitative data about the movement

of workers# materials or e%uipment between any numbers of places over a given period

of time.

+0. D!,$%! Er:o%om$1".

The application of human biological sciences along with engineering sciences to

achieve optimum mutual ad'ustment of men and his work# the benefits being measured

in terms of human efficiency and well(being.

)rgonomics also known as human engineering and human factors engineering is the

scientific study of the relationship between man and his working environments.

++. )-a# ar! 7r$%1$76!" o, mo#$o% !1o%om.3

(a) *se of the human body.

(b) &rrangement of workplace.

(c) +esign of tools and e%uipment.

+2. )-a# ar! #-! 2ar$o" #!1-%$q!" o, work m!a"r!m!%#3

(a) Time study

(b) "ynthesis

(c) ,ork sampling

(d) &nalytical estimating

(e) -redetermined motion and time study

+4. D!,$%! #$m! "#&..

The application of techni%ues designed to establish the time for a %ualified worker to

carry out a specified 'ob at a defined level of performance.

+5. )-a# ar! #-! 2ar$o" #$m! "#&. !q$7m!%#3

(a) "top watch

(b) Time study board

(c) Time study forms

(d) Motion picture camera

+8. )-a# ar! #-! a776$1a#$o% o, work m!a"r!m!%# 2ar$o" #!1-%$q!"3

Techni%ues &pplications

a) Time study "hort cycle repetitive 'obs

(b) "ynthesis "hort cycle repetitive 'obs

(c) ,ork sampling .ong cycle 'obs

(d) &nalytical estimating "hort cycle repetitive 'obs.

(e) -redetermined motion. Manual operations confined to one work centre

time study.

.

+9. )-a# ar! #-! o/0!1#$2!" o, !r:o%om$1"3

(a). To enhance the efficiency and effectiveness with which the activities is carried out

so as to increase the convenience of use# reduced errors and increase in productivity.

(b). To enhance certain desirable human values including safety# reduced stress and

fatigue and improved %uality of life.

+7. )-a# ar! #-!r/6$:"3

Therbligs are the symbols used to denote the various activities and movements done

for different purposes.

Therbligs refer primarily to motions of the human body at the work place and to the

mental activities associated with them.

+;. Draw #-! ".m/o6" r!7r!"!%#$%: =a> I%"7!1#$o% a%& =/> S#ora:!.

$nspection ( /

"torage (

+<. D!,$%! work m!a"r!m!%#3

,ork measurement is the application of techni%ues designed to establish the time for

a %ualified worker to carry out a specified 'ob at a defined level of performance.

20. )-a# ar! #-! /!%!,$#" o, mo#$o% "#&.3

It eliminates unnecessary and wasteful motion.

It makes the work faster and better.

It increases productivity.

2+. M!%#$o% #-! $m7or#a%# a776$1a#$o%" o, work "#&.3

"cope of work study is not restricted to manufacturing industries only. $t can

effectively be used in service sector as well. $t can be applied in offices# hospitals# banks and

other service organizations.

22. M!%#$o% a%. #wo o/0!1#$2!" o, m!#-o& "#&.3

The work study is mainly carried out to fulfill the following ob'ectives0

i. To find the most economical way of doing the work.

ii. To simplify and standardize the methods# materials# tools and e%uipment.

24. M!%#$o% ,!w a776$1a#$o%" o, work "#&.3

1esides in manufacturing industries# the work study can also be applied in offices#

hospitals# banks# and other service organizations.

25. D!,$%! SIMO 1-ar#3

"$MO stands for "imultaneous Motion cycle chart.

"$MO chart is used to record simultaneously on a common time scale the activities

of two hands or other parts of workers body during the performance of a single cycle of

operation being investigated.

'NIT-II ( PROCESS PLANNING

+. D!,$%! 7ro1!"" 76a%%$%:.

$t is defined as the systematic determination of methods by which a product is to be

manufactured economically and competitively.

$t consists of selecting the proper machines# determining the se%uence of operations#

specifying the inspection stages# and tools# 'igs and fixtures such that the product can be

manufactured as per the re%uired specifications. The detailed process planning is done at

each component level.

2. )-a# ar! #-! 1o%"$&!ra#$o%" #o /! :$2!% w-$6! "!6!1#$%: a 7ro1!"" or ma1-$%!3

a. )conomic considerations

b. -roduction rate and unit cost of production.

c. +urability and dependability.

d. .ower process re'ection.

e. Minimum set(up and put away times.

f. .onger productive life machines or e%uipment.

g. functional versatility.

4. )-a# ar! #-! $%,orma#$o%?" r!q$r!& ,or 7ro1!"" 76a%%$%:3

a. &ssembly and component drawings and bill of materials

b. Machine or e%uipment details

c. The standard times for# operation and details of set(up time for each 'ob

d. &vailability of tooling.

5. )-a# ar! #-! ,a1#or" #-a# $%,6!%1$%: 7ro1!"" 76a%%$%:3

a. 2olume of production.

b. +elivery date for components or products.

c. &ccuracy and process capability of machines.

d. The skill and expertise of manpower.

f. Materials specifications.

g. &ccuracy re%uirements of components or parts.

8. E@76a$% #-! 7ro1!"" 76a%%$%: "-!!#.

The whole information determined by the process planning is recorded in a tabular

form in a sheet.

9. L$"# #-! 7ro1!"" 76a%%$%: a1#$2$#$!"3

&nalyse# determine# select# calculate# document# communicate.

7. )-a# ar! #-! 7aram!#!r" ,or ma#!r$a6 "!6!1#$o%3

unction# &ppearance# 3eliability# "ervice life# environment# compactability# cost

;. )-a# ar! #-! #.7!" o, CAPP3

a. 3etrieval 4&-- system

b. !enerative 4&-- system

<. )-a# ar! #-! ,a1#or" a,,!1#$%: 7ro1!"" 76a%%$%:3

2olume of production# Man -ower# +elivery dates of products# Material

specification# accuracy of process and machines.

+0. )-a# ar! #-! a77roa1-!" ,or 7ro1!"" 76a%%$%:3

a) Manual process planning b) 4omputer &ided process planning.

++. L$"# #-! /!%!,$#" o, CAPP.

a) -rocess standardization. b) -roductivity improvement.

c) -roduct cost reduction. d) )limination of human error

e) 3eduction in time. f) 3educed paper work.

+2. )-a# $" PMTS3

& work measurement techni%ue whereby times established for basic human motions

are used to build up the time for a 'ob at the defined level of performance.

+4. )-a# $" #-! $%,orma#$o% r!q$r!& ,or 7ro1!"" 76a%%$%:3

i) &ssembly and component drawings and bill of materials.

ii) Machine or e%uipment details.

iii) The standard times for operation and details of set(up time for each 'ob.

iv) &vailability of tooling.

+5. L$"# #-! &!m!r$#" o, r!#r$!2a6 CAPP S."#!m.

a) The components to be planned are limited to similar components previously planned.

b) )xperienced process planers are still re%uired to modify the standard plan for specific

component.

+8. L$"# #-! a&2a%#a:!" o, :!%!ra#$2! CAPP.

$t can generate consistent process plans rapidly.

5ew components can be planned as easily as existing components.

+9. )-a# ar! #-! #oo6" ,or a1q$r$%: a%& &o1m!%#$%: a%& *%ow6!&:!3

low charts# +ecision tables# experts system shells.

+7. E@76a$% #-! #!rm %orma6 #$m!.

5ormal time is the time for carrying out a work or an element of work at standard

rating.

+;. )-a# ar! #-! 2ar$o" a66owa%1!" a&&!& $% %orma6 #$m!3

a. 3elaxation allowance.

b. atigue allowance.

c. -ersonal allowance.

d. -rocess delay allowance.

e. "pecial allowance such as interference and contingency allowance.

+<. Ar$!, a/o# "1o7! o, 7ro1!"" 76a%%$%:3

6. -rocess rationalization and standardization.

7. aster response to engineering changes.

8. "tandard plans leads to achieve six sigma levels.

20. D!,$%! #-! #!rm ro#! "-!!#3

The route sheet# also known as operation sheet or instruction sheet or planner or

traveler# lists the production operations and associated machine tools for each

component and subassembly of the product.

2+. )-a# &o .o %&!r"#a%& /. 7ro1!"" 76a%%$%:3

-rocess planning is the systematic determination of the methods by which a product

is to be manufactured# economically and competitively.

22. )-a# ar! #-! #.7!" o, 7ro&1#$o%3

Job shop production

Batch production

Mass production

24. )-a# ar! #-! ma#!r$a6" "!6!1#$o% 7aram!#!r"3

Function

Appearance

Reliability service life

Environment

ompatibility.

25. )-a# ar! #-! ,%1#$o%" o, 7ro1!"" 76a%%$%:3

-rocess planning# through route sheet# provides0

i. part identification

ii. operation se%uence and machine.

45. )-a# $" "!q!%1$%:3

"e%uencing can be defined as the selection of an order for a series of 'obs to

be done on a finite number of service facilities (machines).

28. )-a# ar! #-! #.7!" o, 7ro1!"" 76a%%$%:3

Manual process plannin!.

omputer aided process plannin!

Retrieval A"" system

#enerative A"" system

29. )-a# $" 1om7#!r A$&!& Pro1!"" P6a%%$%:3

$n 4&--# the -rocess plan is prepared with the use of computers. 4&-- overcomes

the drawbacks of manual process planning.

27. )-a# &o!" #-! #!rm 7ro1!"" 76a%%$%: m!a%3

-rocess planning is an act of preparing a detailed processing documentation for the

manufacture of a piece part or assembly.

2;. )-a# ar! a66 #-! &o1m!%#" %!1!""ar. ,or 7ro1!"" 76a%%$%:3

i. &ssembly and component drawings.

ii. 1ill of materials.

iii. Machine and e%uipment details.

2<. )-a# ar! #-! &o1m!%#" "!& $% 7ro1!"" 76a%%$%:3

"rocess sheet

$peration sheet

Route sheet.

'NIT-III ( INTROD'CTION TO COST ESTIMATION

6. +efine cost estimating.

4ost estimating is the estimation of the expected cost of producing a 'ob or

manufacturing order before the actual production is taken up or predicting what new

things will cost# before they are made. The expected expenditure on all the items used to

make a product is added to give the estimated cost of final product.

7. +efine cost accounting.

4ost accounting means classify# recording and allocating the appropriate expenditure

for determining the cost of production and is achieved by keeping a continuous record of

all the costs involved in manufacturing.

8. ,rite the common method costing.

a. 9ob costing

b. 1atch costing

c. -rocess costing

d. Operating cost method

e. *nit cost method

f. Multiple cost method

:. +efine 9ob costing.

The is method is concerned with finding the cost of each individual 'ob or contracts.

$n this method# the total cost for each order is obtained from the daily cost sheet. The

method is adopted in 'ob order industries such as ship building# machine manufacturing#

fabrication# building contract.

;. ,hat are the components of a cost estimate<

a. 4ost design

b. 4ost drafting

c. 4ost of research and development

d. 4ost of materials.

e. 4ost of labour

f. 4ost of inspection.

g. 4ost of tools# 'igs and fixtures.

=. +efine overhead expenses.

Overhead expenses include all other expenditure made on the product except direct

materials cost# direct labour charges and direct other expenses. &dministrative expenses#

sales and advertisement costs etc.# form a part of overhead expenses.

>. ,hat are the two ma'or groups of total cost of the product<

a. +irect costs b. $ndirect costs

?. ,hat are the usual three elements of costing<

a. Material cost.

b. .abour cost.

c. Other expenses.

6@. ,rite short notes on direct labour cost.

+irect labourer is one who actually works and processes the materials to convert it

into the final shape. The cost associated with direct labour is called direct labour cost.

66. ,rite short notes on indirect labour cost.

$ndirect labourer is one who is not directly employed in the manufacturing of the

product but his services are used in some indirect manner. The indirect labour includes

supervisors# inspectors# foremen# storekeeper gatekeeper# maintenance staff crane driver

etc. The cost associated with indirect labour is called indirect labour cost.

67. ,hat are the direct expenses<

4ost of special 'igs# patterns# tooling made for 'ob# or cost of research and

development work done for that specific 'ob.

68. ,hat are the indirect expenses<

a. actory expenses

b. &dministrative expenses.

c. "elling and distribution expenses.

6:. ,hat are the components of -rimary cost<

a. +irect material cost# b. +irect labour cost# c. +irect expenses.

67. ,hat are the components of -roduction cost<

a. actory cost# b. &dministrative expenses.

6;. .ist any two ob'ectives of cost estimation .

a. To establish the selling price of product.

b. To veryfiy the %uotations submitted by vendors.

c. To take make or buy decisions.

d. To prepare production budget.

6=. 5ame the types of material cost .

a. +irect materials cost b. $ndirect material cost.

6>. ,ho are called indirect lab our <

$ndirect lab our are the non productive staff who helps the productive lab our in

performing their duties..

6A. ,hat are the knowledge re%uired for cost estimation.

a. +esign time. b. amount and cost of materials re%uired.

c) production time re%uird. d) labour charges.

e) cost of machinery f) previous estimates

g) volume h) change of cost.

6?. ,hat are the types of estimates <

a) preliminary estimates b) final estimates.

7@. ,hat is meant by indirect material<

$ndirect material is the one which cannot be traced as a part of the product. $t is the

material re%uired for maintaing and operating the plant and e%uipment but cannot be the

part of product.

76. !ive examples for indirect materials.

!rease# lubricating oil used to lubricate the e%uipments# coolants# cotton wastes#

kerosene.

77. ,hat is indirect labour cost<

$t is the wages paid to the indirect labour.

78. ,hat are the types of expenses<

+irect expenses# $ndirect expenses.

7:. .ist the factory expenses.

actory on cost# works on cost# factory overhead# production overhead.

7;. ,hat is selling expenses<

These are the expenses which are incurred for creating and enhancing the demand

for the products.

'NIT-IB ( COST ESTIMATION

6. ,hat are the data re%uired for estimation of cost of any product<

a. Machining operations

b. Machining time re%uired for each operation

7. ,hat are the elements consisting of estimating total time re%uired to perform an

operation.

a. "et(up time b. Bandling time c. Machining time

d. Tear down time e. +own time f. &llowance

8. )xplain the term set(up time.

This is the time taken to prepare the machine for operation.

:. )xplain the term unit time operation.

The sum of handling time and machining time for a 'ob is called unit operation time.

;. ,rite short note on machining time.

$t is the time for which the machine works on the components# i.e. rom the time

when the tool touches the work to when the tool leaves the component after completion

of operation.

=. ,rite short note on tear down time.

$t is the time taken to remove the tools# 'igs fixtures from the machine and to clean

the machine and tools after the operation has been done on the last component of batch.

>. ,rite short note on down time.

$t is the time wasted by the operator due to break down# non(availability or delay in

supply of tools and materials etc.

A. ,hat are the various allowances in estimation<

a. -ersonal allowance b. atigue

c. Tool sharpeningC4hange allowance d. 4hecking allowance

?. +efine the term fatigue allowance.

The long working hours and poor working conditions such as poor lighting# poor

ventilation etc.# causes fatigue and effect the efficiency of worker i.e. fatigue decreases

the workers capacity to work.

6@.,rite short note on tool sharpeningCchange allowance.

This allowance is provided for the time taken by the operator to get the tool changed

or to resharpen the tool when it becomes dull. This time varies from machine to machine

and depends upon the type of tool being used.

66. +efine design cost.

The cost of design of a product is estimated by ascertaining the expected time for the

design of the that product.

67.+efine drafting cost .

&fter the completion of the design the drawing have to be prepared by drafts man.

68..ist the components of 'ob estimate.

+esign cost # drafting cost# 3D+ cost# Materials cost # labour cost # $nspection cost.

Overhead cost# cost of tools and 'igs and fixtures.

6:. 5ame the types of estimate.

a. preliminary estimation. b. inal estimation.

6;. ,hat are the method of estimation<

a. 4onference method.

b. 4omparision method.

c. +etailed analysis method

6=. ,hat is cost of research<

4onsiderable time and money has to be spent on research and development work.

6>. ,hat is tool cost per unit produced <

)stimated cost C number of 'ob.

6A. +efine inspection cost .

)stimating the inspection cost # one should consider the cost of inspection

e%uipments# gauges and consumables# wages to the $nspectors.

6?. ,hat is overhead cost <

Overhead expenses are those which cannot be charged directly to a particular

product manufactured.

7@. ,hat is prime cost <

The sum of direct labour cost and direct material cost and direct expenses.

76. ,hat is total cost<

The sum of prime cost and factory overheads and administrative expenses and

selling and distribution expenses.

77. ,hat is unit cost method<

This method is adopted by the firms #which supply a uniform product rather than a

varity of products such as mines#%uries#etc.

78. ,hat is manufacturing cost<

"um of factory cost and administrative expenses.

7:. ,hat is selling price<

Total cost E profit.

7;. ,hat is market price <

"elling price E discount.

'NIT-B ( PROD'CTION COST ESTIMATION

6. ,hat are the various elements considered while calculating the cost of a welded 'oint<

a. +irect material cost. b. +irect labor cost.

c. +irect other expenses. d. Overheads.

7. )xplain the terms direct material in costing of welded 'oint.

a. 4ost of base materials to be welded i.e.# sheet# plate# rolled section# casting or

forging.

This cost is calculated separately.

b. 4ost of electrodesCfiller materials used. The electrode consumption can be estimated

by using the charts supplied by the suppliers. ¬her way to find the actual weight

of weld metal deposited is to weigh the component before and after the welding and

making allowance for stub end and other losses during welding.

&lso the weight of weld metal F 2olume of weld G +ensity of weld material.

8. )xplain the terms direct other expenses in costing of welded 'oint.

The direct other expenses include the cost of power consumed# cost of fixtures used

for a particular 'ob etc.

:. )xplain the terms overheads expenses in costing of welded 'oint.

The overheads include the expenses due to office and supervisory staff# lighting

charges of office and plant# inspection# transport# cost of consumables and other charges.

The cost of e%uipment is also apportioned to the individual components in the form of

depreciation.

;. ,hat are the various losses considered while calculating the materials cost for a forged

component.

a. "hear loss. b. Tonghold loss.

c. "cale loss. d. lsh loss. e. "prued loss.

=. )xplain the term "hear loss.

The blank re%uired for forging a component is cut from billet or long bars. The

material e%ual to the product of thickness of sawing blade and cross(section of bar is lost

for each cut. "imilarly# if the small pieces left at the end are not of full length# these also

go as waste. "hear loss is generally taken as ;H of net weight.

>. )xplain the term Tonghold loss.

+rop forging operations are performed by holding the stock at one end with the help

of tongs. & small length# about 7.@(7.;cm and e%ual to dia of stock is added to the stock

for holding.

A. )xplain the term "cale loss.

&s the forging process is performed at very high temperature# the oxygen from air

forms iron oxide by reacting with hot surface. The iron oxide forms a thing film called

scale# and falls off from surface at each stroke of hammer. "cale loss is taking as =H of

net weight.

?. )xplain the term lash loss.

,hen dies are used for forging# some metals come out of the die at the parting line

of the top and bottom halves of the die. This extra metal is called flash. lash is

generally taken as 7@mm wide and 8mm thick. The circumference of component at

parting line multiplied by cross(sectional area of flash gives the volume of flash. The

flash lioss is then calculated by multiplying the volume of flash by density of the

material.

6@. )xplain the term sprue loss.

,hen the component is forged by holding the stock with tongs# the tonghold and

metal in the die even when metal is s%ueezed in dies# are in contact through a portion of

metal called sprue or runner. The cut off when product is completed. "prue loss taken as

>H of net weight.

66. )xplain the terms direct material cost in costing of forged component.

a. 4alculate the net weights of forging.

5et weight F 2olume of forging G +ensity of materials.

b. 4alculate the gross weight.

!ross weight F 5et weight E Materials loss in the process.

c. +irect materials cost F !ross weight G -iece per Ig.

67. +iscuss the various constituents of cost of a forged component.

a. 4ost of direct materials.

b. 4ost of direct labour.

c. +irect expenses such as due to cost of die and cost of press.

d. Overheads.

68. )xplain the terms direct labour cost in costing of forged component.

+irect labout cost is estimated as follows.

+irect labour cost F tG l

,here t F Time for forging per piece (in hours)

l F .abour rate per hour

6:. )xplain the distribution of die cost on individual components.

&pportioning of +ie cost0

.et cost of die F 3s. G

5o. of components that can be produced using this die F J components.

4ost of dieCcomponent F 3s. GCJ

6;. )xplain the terms overheads expenses in costing of forged component.

The over heads include supervisory charges# depreciation of plant and machinery#

consumable# power and lighting charges# office expenses etc. The overheads are

generally expressed as pKpercentage of direct labour cost.

6=. )xplain the distribution of machine cost on individual components.

&pportioning of Machine 4ost0

.et cost of press F 3s. &

.ife of press F 1 F n year F nG67G:G;GA F 6?7@n hours

Bourly cost of production F&C1

5o. 4omponents produced per hour F 5

4ost of using press per component F &C15 3s.

6>. +efine bending.

1ending is the operation by which a metal rod or pipe can be bent to form various

shapes without damaging its internal gain structure.

6A. ,hat is drifting <

&fter a hole is punched it may be opened out to any size and shape by driving a

tapered drift through it .this operation is known as drifting .

6?. +efine swaging.

"waging is the process of removing the irregularities on the surface of the work

piece produced by the process of drawing down.

7@. ,hat is net weight of forging<

2olume of forging G density of material used.

76. ,hat is filler material <

The filler material has a similar composition and melting point as the base metal.

The filler rod is used to make up losses during welding.

77. ,hat is flux <

& flux is re%uired for the welding process# so as to remove the oxide layers in the

form of fusible slag which floats on the molten metal.

78. ,hat is non pressure welding <

$n fusion welding the metal at the 'oint is heated to molten state. Then it is allowed

to solidify. -ressure is not applied in welding process.

7:. ,hat is butt 'oint <

1utt 'oint is used to 'oin the ends of two sheets or plates kept in the same plane.

7;. ,hat is lap 'oint <

$t is used to 'oin two overlapping sheets or plates.

7=. ,hat is welding cost <

$t is the cost of labor in actual welding operation.

PART A ( C'ESTIONS

'NIT-I

6. )xplain the significance# construction and applications of the following recording

techni%ues0

(i). Out line process chartL

(ii). low process chartL

(iii). Two handed process chartL and

(iv). Multiple activity chart.

7. )xplain the various techni%ues of work measurement.

8. ,hat is meant by ergonomics< +escribe the ob'ectives of the study of ergonomics.

'NIT-II

6. +efine 4&--. )xplain the various types of 4&-- approaches.

7. ,hat is process planning< ,hat are the activities associated with it.

8. 4ompare and contrast the features of variant and generative 4&-- systems.

:. 5ame the three commonly used tools for ac%uiring and documenting knowledge.

;. ,hat are the re%uirements to analyze finished parts.

'NIT -III

6. ,hat the main functions of estimation<

7. ,hat is meant by preparation of a realistic estimate<

8. +efine floor to floor time.

:. ,hat is aim of costing<

;. +ifferentiate costing and estimation.

=. +escribe with a block diagram how the selling price of a product is arriving at<

>. $llustrate the relationship between Melements of costN and Mcomponent costN with the help

of a block diagram.

'NIT-IB

6. ,hat are the causes for depreciation<

7. Bow is the gross weight in forging operation determined<

8. ,hat are the various allowances re%uired in pattern making operation<

:. Bow can you determine the size of the stock in forging<

;. +iscuss the various constituents of cost of forged components.

=. Bow can you estimate the grinding time for a cylindrical grinding operation<

>. )xplain the procedure on estimating the machining time for plain milling a flat

surface when the width of the 'ob to be milled is more than the width of the plain milling

cutter.

'NIT-B

6. ,hat are the various losses in forging<

7.. ,hat are the different types of labour cost involved welding<

8. )stimate the milling time to cut =@ teeth on a gear blank =@mm thick# 8;mmCmin and

take

overall set up time as 6@ minutes.

:. Bow can you estimate the cost of the wooden pattern for sand molding<

ME+0+8 - PROD'CTION PLANNING AND CONTROL

'NIT-I INTROD'CTION

6. ,hat is production<

-roduction consists of a series se%uential operations to produce a desirable product

acceptable to customer and meets the customer demand# with respect to the %uality and

intended function.

7. +efine the term production planning and control.

+irection and coordination of firmNs resources towards attaining the prefixed goals.

:. ,hat are the functions of production planning and control<

a. Material function# b. Machines and e%uipment# c. Methods# d. 3outing#

e. )stimating f. .oading and scheduling# g. +ispatching# h. )xpediting i. $nspection.

=. +efine the term durability.

+urability refers to the length of the active life of the product under given working

condition.

>. +efine the term dependability.

+ependability refers to the reliability with which the product serves its intended

function.

A. +efine the term "tandardization.

"tandardization is a process of defining and applying the conditions necessary to ensure

that given range of re%uirements can normally be met with a minimum of variety and in

a reproducible and economic manner on the basis of the best current techni%ues.

?. ,hat are the ob'ectives of "tandardization<

i) $nterchangeability of parts# components# etc.

ii) Ieeping the variety minimum.

iii) Belps to achieve a better control due to reduced variety.

6@. ,hat are the advantages of "tandardization<

i)3eduction of waste and obsolescence.

ii)3eduction in inventory

iii)3educed efforts in book keeping and accounting.

iv)"tandardization reduces the price because of economy of scale.

v) )ase in procurement because of availability.

66. ,hat is simplification<

$t is a process of reducing types of products within a definite range.

67. ,hat is specialization<

$t is a process where in particular firms concentrate on the manufacture of limited

number of product types.

68. ,hat are the disadvantages of simplification<

i) 5ot able to meet the needs of wide range of customer preferences.

ii) -ossibility of loosing orders to competitors

iii) 4reates a constant source of conflict between marketing and production.

6:. +efine the term break(even point.

1reak(even point refers to the level of sales at which the sale income e%ual the total

costs.

6;. ,hat is margin of safety<

$t is the difference between the existing level of output and the level of output at 1)-.

6=. ,hat are the levels of production palnning <

factory planning # process planning # operation planning.

6>.what are the factors control the production planning <

volume production # nature of process# nature of operations.

6A.,hat are the phases involves in --4 <

a. pre planning phase . 7. planning phase. 8. control phase.

6?.,hat is meant by productivity<

-roductivity is measure of how effectively the resources of an enterprise are being

managed. $t is defined as the ratio of output to the input.

7@.,hat are methods for determining the financial feasibility<

-ayback period# rate of return# present worth# and uniform annual cost

76.,hat is meant by payback period<

The payback period is the time during which benefits from the investment e%ual to

the cost of investment. $t can be expressed as

-- F 4 C ("(&)# where 4Fre%uired investment

"Fannual savings

&Fannual cost of utilizing the investment

77.,hat are the methods available to improve the productivity<

$ncreasing the output for a given input

+ecreasing the input for a given output

2arying both the output and input in such a way that their ratio increases

78.,hat is meant by mass production<

$n mass production of discrete parts or assemblies# the production volume is high.

Bere the dedicated special purpose machine can be used for mass production.

)g. Manufacturing of bicycles# washing machines# and video games

7:.,hat is meant by batch production<

$n batch production of parts or assemblies# the volume is lower# and variety higher

than in mass production. Bere goods are manufactured in batches that be repeated as

re%uired. $t is some times referred to as mid volume# mid variety operation.

)g. 1ooks# apparels etc

7;.,hat is meant by 'ob shop production<

The 'ob shop represents the most versatile production facility. ,ith in the limitations

of machine and the operators# it can manufacture almost any product. ,ith a low

production volume # the cost of product design and set up time is high.

)g -roduction facilities for aircrafts# ships# and special machine tools.

7=. ,hat is meant by product life cycle<

&n expression to describe the length of time a product lasts in the market. $t

comprises the period of conception# design# production# use# and finally termination when

not needed by the market. lexible technologies allow shorter product life cycles# which

mean more fre%uent design and model changes

'NIT-II )OR* ST'DY

6. ,hat is method study<

$t is the systematic recording and critical examination of existing and proposed ways of

doing work# as a means of developing and applying easier and more effective method

reduced costs.

7. ,hat are the ob'ectives of method study<

i) To present and analyze true facts concerning the situation.

ii) To examine those facts critically.

iii) To develop the best answer possible under given circumstances based on critical

examination of facts.

8. ,hat are the charts used for method study<

i) Operation process chart# ii). low process chart. iii). Multiple activity chart#

iv) Two handed process chart# v). Travel chart# vi). "imo chart.

:. ,hat are the diagrams used for method study<

i) low and string diagram# ii). Models and templates# iii). 4ycle graph and chronocycle

graph.

;. ,hat is outline process chart<

The chart gives the birdNs(eye view of the whole process by recording only the ma'or

activities and inspections involved in the process.

=. ,hat is time study<

The application of techni%ues designed to establish the timer for a %ualified worker to

carry out a specified 'ob at a defied level of performance.

>. ,hat is work sampling<

& techni%ue in which a statistically competent number of instantaneous observations are

taken# over a period of time# of group of machines# process or workers. )ach

observations recorded for a particular activity or delay is a measure of the percentage of

time observed by the occurrence.

A. ,hat is multiple activity chart<

$t is a chart on which the activities of more than one sub'ect are each recorded on a

common time scale to show their interrelationship.

?. ,hat is "imo chart<

$t is used to record simultaneously on a common time scale the activities of two hands or

other parts of workerNs body during the performance of single cycle of operation being

investigated.

6@. ,hat are therbligs<

Therbligs are the symbols used to denote the various activities and movements done for

different purposes.

66. ,hat is memo motion study<

Memo motion study is a form of time(lapse photography which records activity by the

use of cine camera adapted to take picture at longer intervals than normal.

67. ,hat is -MT"<

& work measurement techni%ue whereby times established for basic human motions are

used to build up the time for a 'ob at the defined level of performance.

68. ,hat are the various templates and models used for method study<

(a) 7(dimensional templates

(b) 7(dimensional models

(c) 8(dimensional models

6:. ,hat are principles of motion economy<

(a) *se of the human body.

(b) &rrangement of workplace.

(c) +esign of tools and e%uipment.

6;. ,hat are the various techni%ues of work measurement<

(a) Time study

(b) "ynthesis

(c) ,ork sampling

(d) &nalytical estimating

(e) -redetermined motion and time study

6=. )xplain the term normal time.

5ormal time is the time for carrying out a work or an element of work at standard

rating.

6>. ,hy some allowances have to be added in normal time<

There is no provision# in the normal time# for the interruptions that occur on every

'ob each day# such as time re%uired by the workers for personal needs and rest and for

delay due to reasons beyond his control. To compensate for theses delays# the normal

time is increased by adding some allowances.

6A. ,hat are the various allowances added in normal time<

a. 3elaxation allowance.

b. atigue allowance.

c. -ersonal allowance.

d. -rocess delay allowance.

e. "pecial allowance such as interference and contingency allowance.

6?. ,hat are the various time study e%uipment<

(a) "top watch

(b) Time study board

(c) Time study forms

(d) Motion picture camera

7@. ,hat are the application of work measurement various techni%ues<

Techni%ues &pplications

a) Time study "hort cycle repetitive 'obs

(b) "ynthesis "hort cycle repetitive 'obs

$ ,ork sampling .ong cycle 'obs

(d) &nalytical estimating "hort cycle repetitive 'obs.

(e) -redetermined motion. Manual operations confined to one work centre

time study.

76. +efine process allowances

These are allowances provided to compensate for enforced idleness during a process.

77. 5ame the special allowances .

i) startup allowances. ii) shut down allowances.

iii) 4leaning allowances. iv) Tool allowances.

v) 4hangeover allowance.

78. what are the basic procedure for method study <

select# record # examine# develop# define# install# maintain.

7:. .ist the ob'ectives of work measurements <

To reduce or eliminate non productive time.

To fix standard time for doing a 'ob.

To develop standard data for future reference.

To improve methods.

7;. ,hat is work study <

work study is generic term for the techni%ues of method study and work measurement .

These techni%ues are used in the examination of human work in all its contexts.

'NIT-III PROD'CTION PLANNING AND PROCESS PLANNING

6. ,hat is production planning<

$t is the determination# ac%uisition and arrangement of all facilities necessary for future

production products.

7. ,hat are the factors affecting production planning<

i) 5on(availability of materials

ii) -lant# e%uipment and machine breakdown

iii) 4hanges in demand and rush orders.

iv) &bsenteeism of workers.

v) .ack of coordination and communication between various functional areas of

business.

77. ,hat is value analysis<

2alue analysis is the systematic application of recognized techni%ues which identify the

function of a product or service# establish a monetary value for the function and provide

the necessary function reliably at that lowest overall cost.

:. ,hen to apply value analysis<

i) 4ompanyNs products are loosing in the market and there is a decline in sales.

ii) 4ompnyNs products are priced higher than the competitors.

iii) 5ew design of products being undertaken.

iv) "ymptoms of disproportionate increase in cost of production.

v) +ecreasing profitability and return on investment.

vi) 4ompany failing to meet its delivery commitment.

;. ,hat is process planning<

$t is defined as the systematic determination of methods by which a product is to be

manufactured economically and competitively.

=. ,hat are the activities associated with process planning<

O .ist of operations to be performed and their se%uence.

O "pecifications of the machines and e%uipment re%uired

O 5ecessary toolings 'igs and fixtures.

O !ives the manufacturing details with respect to feed# speed# and depth of cut for each

operation to be performed.

O $t gives the estimated or processing times of operations.

>. ,hat is the information re%uired for process planning<

i) &ssembly and component drawings and bill of materials.

ii) Machine or e%uipment details.

iii) The standard times for operation and details of set(up time for each 'ob.

iv) &vailability of toolings.

A. ,hat are the factors affecting process planning<

i) 2olume of production

ii) +elivery dates for components

iii)&ccuracy and process capability of machines.

iv) The skill and expertise of manpower.

v) Material specifications

vi) &ccuracy re%uirements of components or parts.

?. ,hat are the steps in process planning<

i) +etailed study of the component drawings# process and machine selection# inspection

stages and toolings re%uired.

ii) .ist the surfaces to be machined.

iii) +etermine the work centre# tools# cutting tools# 'igs and fixtures and inspection

stages and e%uipment re%uired.

iv) +etermine the speed# feed and depth of cut for each operation.

v) )stimate the operation time.

vi) ind the total time to complete the 'ob.

vii) 3epresent the details on the process sheet.

6@. ,hat is machine capacity<

M4( Machine capacity

M-(Max production

*4(*tilization capacity

5 P 5umber of machines

"T("tandard time

M4 F "T G M-C5 G *4.

66. ,hat is *se value <

$t is the measure of properties# %ualities# and features which make the product accomplish a

use.

use value is the fundamentals form of economic value.

67.what is cost value <

$t is the measure of sum of all costs incurred in producing the product.

68.what are the reasons for unnecessary costs <

failure to utilize specialized knowledge.

poor design of the component.

lack of ideas and relevant information.

lack of standardization and exaggerated specification.

unavoidable delivery constraints.

&dvances in technology is not considered.

6:.what are the steps involved in value analysis <

1lastQ(i) $dentify the product. (ii) 4ollect relevant information (iii) +efine different

functions.

createQiv) 4reate different alternatives. v) critically evaluate alternatives.

refineQvi) +evelop the best alternative. vii) implement the alternative.

6;.what are factors affecting the selection of batch sizes <

6 setup costs of machines and other costs of preparation for the run.

7.consumption rate.

8.production rate.

:.interest charges per piece per unit time.

;.&verage storage costs.

=.sales price per unit.

6=.what are the criteria for slection of batch sizes <

6.minimum costs per piece.

7.maximum profit for the batch.

8.maximum ration of profit to cost of production.

:. maximum rate of return per unit time.

6>. ,hat is meant by machine loading <

machine loading is the process of the assigning specific 'obs to machines # men or work

centers based on relative priorities and capacity utilization.

6A. list the information re%uired for machine loading <

i) 5umber and identification of work order.

ii) symbol and identification of part.

iii)number of parts in each lot.

iv) list of operations to be performed.

v) se%uences in which operations.# specifications of machines.

6?.what is master production program<

The various informationNs re%uired for machine loading and se%uence are usually presented

in a graphical form known as master production programme.

7@.+efine machine output

machine output is inversely proportional to cycle time.

76. what is meant by balancing <

balancing refers to the procedure of ad'usting the times at work centers to conform as much

as possible to re%uired cycle time.

77.,hat are the process planning techni%ues used in the modern manufacturing

technologies<

Manual approach

4omputer aided process planning techni%ues

3etrieval type 4&-- system (2ariant type 4&-- system)

!enerative type 4&-- system

78.,hat is meant by 4&--<

4omputer aided process planning system offers the potential for reducing the routine

clerical work of manufacturing engineers. $t provides the opportunity to generate

routings which are rational# consistent and perhaps even optimal.

7:.,hat is meant by retrieval type 4&-- (2ariant type) systems<

or each part family a standard process plan is established and stored in computer

files and then it is retrieved for new work parts which belong to that family. 1ecause of

the alterations that are made in the retrieved process plan# the 4&-- system is known as

variant system.

7;.,hat is meant by generative 4&-- system<

!enerative process planning involves the use of computer to create an individual

process plan automatically without human assistance. The computer would employ a set

of algorithms to progress through the various technical and logical decisions toward a

final plan.

7=.,hat are the types of variant type process planning systems<

4&--# M$-.&5# M$T*35# M$&--# *5$2&T$O5# 4$5T*35# and 4OM4&--2.

7>.,hat are the types of generative type process planning systems<

M)T4&--# 4---# &*T&-# and &--&"

7A.,hat are the steps involved in the design for manufacturing<

!uidelines for the general approach to +M

"election of manufacturing processes (4hoice of production process)

!uidelines for particular processes

!uidelines for assembly

7?.,hat are the benefits of computer aided process planning (4&--)<

6. -rocess rationalization

7. $ncreased productivity of process planners

8. 3educed turn around time

:. $mproved legibility

;. $ncorporation of other application program.

'NIT-IB PROD'CTION SCHED'LING

6. ,hat is loading<

$t is defined as the assignment of work to a facility. The facility may be men# machine# a

department# a group of men# group of machines of a plant.

7. ,hat is scheduling<

$t is time phasing of loading. $t is defined as the assignment of work to a facility

specifying the particular se%uence of the work and the time of actual performance.

>. ,hat is line balancing<

&ssembly line balancing is associated with a product layout in which products are

processed as they pass through a line of work centers. &n assembly line can be

considered as a production se%uence where parts are assembled together to form an end

product. The operations are carried out at different workstations situated along the line.

A. ,hat are the advantages of assembly line<

i) *niform rate of production. ii) .ess material handling

iii) .ess work(in(process. iv))asy production control.

v) )ffective use of facilitiesClabour. vi) .ess congesting.

?. ,hat are the disadvantages of assembly line<

i) More capital intensive.

ii) .ow flexibility.

iii) Monotony of work for operators.

6@. ,hat are the steps in solving line balancing problems<

i) +efine task

ii) $dentify precedence re%uirements.

iii) 4alculate minimum number of workstations re%uired to produce desired output.

iv) &pply heuristics to assign task to each station.

v) )valuate effectiveness and efficiency.

vi) "eek futher improvement.

66. ,hat are the advantages of !antt load chart<

i) This system is %uite simple.

ii) This could be maintained even by electrical staff after some training.

iii) Overall cost of operation is small.

67. ,hat are the disadvantages of !antt load chart<

rom the load chart it is not possible to learn the exact time of a work. $t tells only the

total load ahead of a department or a facility.

6:. ,hat is production se%uencing<

+etermining the order of processing of all 'obs at each work centre.

6;. ,hat is expediting<

Monitoring progress# taking corrective actions to minimize deviations.

6=.,hat is lot splitting <

$n which a 'ob order is split and only part of it is processed now and others are processed

later.

6>. what is operations splitting <

processing part of the 'ob in one work centre and the rest at another.

6A.what are the criteria for se%uencing <

setup cost# process inventory# idle time# average time to complete 'ob.# average number of

'obs waiting in %ue# average time the 'obs are late.

6?. ,hat is .-T <

longest processing time.

7@.what is -4O <

-referred customer order.

76.what is critical ration for scheduling <

critical ratio F +emand time C supply lead time.

77. what are the advantages of critical scheduling <

To fix up relative 'ob priorities for scheduling .

status of each 'ob is determined.

schedule can be ad'usted automatically when there are changes in 'ob demand and progress.

78. ,hat is forward scheduling <

set forward is commonly used in 'ob shops where customers place their orders on needed as

soon as as possible basis. forward scheduling determines start and finish times of next

priority 'ob by assigning it the earliest available time slot and form that time# determines

when the 'ob will be finished in the work center.

7:.what is 'ob cards<

card authorize the work man to sart the work on certain material# indicate what to do and

also serves as a means of production progress.

7;.what is shortage chasing <

$t is the 'ob of comparing the actual availability of material and parts with the %uantities

re%uired for production and of reporting any shortages so that they can be produced %uickly.

7=.what is inventory turn over <

$f the company maintains inventories e%ual to three months consumption. $t means that

inventory turnover is : times a year. The entire inventory is used up and replaced : times a

year.

'NIT-B INBENTORY CONTROL AND RECENT TRENDS IN PPC

6. ,hat are the types of inventories<

i) 3aw materials# ii) 1ought out parts# iii) ,ork(in(process inventories# iv) inished

goods inventories v) Maintenance# repair and operating stores.

7. ,hat are the benefits of inventory control<

i) $mprovement in customerNs relationship because of the timely delivery of goods and

services.

ii) "mooth and uninterrupted production and hence no stock out.

iii) )fficient utilization of working capital.

iv) Belps in minimizing loss due to deterioration# obsolescence damage and preliferage.

v) )conomy in purchasing.

vi) )liminates the possibility of duplicate ordering.

8. ,hat is inventory turnover<

$f the company maintains inventories e%ual to 8months consumption. $t means that

inventory turnover is : times a year# i.e.# the entire inventory is used up and replaced :

times a year.

:. +efine the term 3e(order level.

$t is the point at which the replenishment action is initiated. ,hen the stock level

reaches 3.O...# the order is placed for the item.

;. +efine the term 3e(order %uantity.

This is the %uantity of material to be ordered at the re(order level. 5ormally this %uantity

e%uals the economic order %uantity.

=. ,hat is demand<

$t is the number of items re%uired per unit of time. The demand may be either

deterministic or probabilistic in nature.

>. +efine the term order cycle.

The time period between two successive orders is called order cycle.

A. ,hat is lead time<

The length of time between placing an order and receipt of items is called lead time.

$t is the time that elapses between placing of an order and the receiving the material to stock.

$t an order to placed today and material is received after one month# then the lead time is one

month. the lead time determines the amount of material to be kept in stock.

?. ,hat are the various costs associated with inventory<

i) -urchase cost# ii) 4apital cost# iii) Ordering cost# iv) Bolding costs# v) "hortage cost.

6@. ,hat is an )conomic order %uantity<

$t is the %uantity to be ordered is one that strikes a balance between the inventory

carrying cost and the inventory carrying cost. This %uantity is referred to as )conomic

order %uantity.

66. ,hat is safety stock<

The additional stock of material to be maintained in order to meet the unanticipated

increase in demand arising out of uncontrollable factors.

67. ,hat are the advantages of &14 analysis<

This approach helps the manager to exercise selective control and focus his attention

only on a few items.

68. ,hat are the limitations of &14 analysis<

&14 analysis is a fundamental tool for exercising selective control over numerous

inventory items but in present for do not precise consideration of all relevant problems

of inventory management.

$t is not one time exercise and items are to be reviewed and recategorised periodically

6:.+ifferentiate between M3- and 4apacity planning<

Materials 3e%uirement -lanning is used to plan the materials# while the capacity

planning is used to determine the man power and machine capacities re%uired to meet

the production schedule as well as long term future production need of the firm.

6; ,hat is the use of order progress<

The order progress is used to provide data for work(in(progress status report# shop

order status and capacity control.

Order progress collects data from shop floor and generates reports to assist

production management.

6=. what are the classification of inventory <

Transit inventories

cycle inventories

buffer inventories.

decoupling inventories.

$nventory can also classified according to nature of items stocked namely raw materials# in

process inventories# finished goods inventories and spare part inventories.

6>. what are the factors affecting inventory control policy <

6.4haraecteristics of the manufacturing system.

7.amount of production against shortages.

8.organizational factors.

6A. $nventory carrying or holiday or storage cost <

cost of maintaining inventory.

rent for the space# cost of depreciation.

$nterest on the capital.

the wages and salaries of staff.

$nsurance# deterioration# obsolence cost etc.

6?. ,hat is "hortage cost <

$t is the cost that arises due to unfailing of demand in the stock out period.

7@. ,hat is setup cost <

This is the cost incurred in changing the inventory.

76. ,hat is procurement cost <

These are the costs incurred by inventory system itself in making a procurement of items or

in receving the items to stock. $ncludes inspection costs also.

78. .ist the application of &14 analysis.

To evolve useful recording strategy.

stock records.

$nformation of items which re%uire higher degree of control.

priority treatment for different items.

determination of safety stock limits.

stores layout.

value analysis.

7:. ,hat is -$4" <

-roduction $nventory and control system.

7;.,hat is waste of motion <

study motion for economy and consistency. economy improves productivity and

consistency improves %uality. first improve the motions # then mechanize or automate

otherwise there is danger of automating waste.

7=.what are the basic components of M3- system <

i) Master production schedule.(M-") ii) 1ill of materials (1OM) iii) $nventory status

ile.

)3O+) ")5!*5TB&3 )5!$5))3$5! 4O..)!)

TB*+*-&TB$# )3O+)(;>

+)-&3TM)5T O M)4B&5$4&. )5!$5))3$5!

ME-+0+8 PROD'CTION PLANNING AND CONTROL

&ssignment 6 Ruestions

'NIT + INTROD'CTION TO PROD'CTION PLANNING AND CONTROL

)numerate the activities involved in production planning and control function under ten

convenient points<

)xplain the different types of production systems. +ifferentiate between them.

+iscuss the ten functions of production planning cycle<

)xplain 1rake )ven analysis.

,rite detailed notes on

6. standardization

7. simplification

8. "pecification.

)3O+) ")5!*5TB&3 )5!$5))3$5! 4O..)!)

TB*+*-&TB$# )3O+)(;>

+)-&3TM)5T O M)4B&5$4&. )5!$5))3$5!

ME-+0+8 PROD'CTION PLANNING AND CONTROL

&ssignment $$ Ruestions

'NIT 2 )OR* ST'DY

)xplain the various types of time study<

+iscuss pre determined time standards<

)xplain micro motion time study<

)xplain the work sampling process.

,hat are therbligs < )xplain any five therbligs with symbols<

)3O+) ")5!*5TB&3 )5!$5))3$5! 4O..)!)

TB*+*-&TB$# )3O+)(;>

+)-&3TM)5T O M)4B&5$4&. )5!$5))3$5!

ME-+0+8 PROD'CTION PLANNING AND CONTROL

&ssignment $$$ Ruestions

'NIT 4 PROD'CT PLANNING AND PROCESS PLANNING

+iscuss in detail the different phases of applying value analysis<

)xplain the steps involved in product planning and process planning<

,hat do you mean by minimum cost batch size< &lso derive an expression for it<

,hat is mean by machine loading< &lso enumerate the vriious methods to the cycle time to

minimum<

4ompare and contrast the manual and computer aided process planning<

)3O+) ")5!*5TB&3 )5!$5))3$5! 4O..)!)

TB*+*-&TB$# )3O+)(;>

+)-&3TM)5T O M)4B&5$4&. )5!$5))3$5!

ME-+0+8 PROD'CTION PLANNING AND CONTROL

&ssignment $2 Ruestions

'NIT 5 PROD'CTION SCHED'LING

+escribe the information flow for master scheduling<

)xplain !antt chart with an example<

,hat is a priority se%uence< )xplain six priority rules used for 'ob se%uencing<

,rite a detailed notes on flow production scheduling and batch production scheduling<

,hat is progressing< )xplain its functions<

)xplain the factors affecting scheduling .

)3O+) ")5!*5TB&3 )5!$5))3$5! 4O..)!)

TB*+*-&TB$# )3O+)(;>

+)-&3TM)5T O M)4B&5$4&. )5!$5))3$5!

ME-+0+8 PROD'CTION PLANNING AND CONTROL

&ssignment 2 Ruestions

'NIT 8 INBENTORY CONTROL AND RECENT TRENDS IN PPC

+iscuss the different costs associated with inventory<

+erive an expression for )OR with uniform date of demand with out shortages<

+iscuss in detail of 9$T and )3-<

,hat is &14 analysis< )xplain its significance in inventory control with a suitable

example<

+escribe the fixed period %uantity inventory model then compare the - and R system<

)xplain M3- P$$ in +etail.

)xplain the ob'ectives of M3-.

You might also like

- Get FileDocument10 pagesGet FileGanesh DongreNo ratings yet

- GL On CM - Internal CirculationDocument2 pagesGL On CM - Internal CirculationVarunNo ratings yet

- Table FormatDocument16 pagesTable FormatVarunNo ratings yet

- Absentees StatementDocument3 pagesAbsentees StatementVarunNo ratings yet

- Syllabus MetrologyDocument2 pagesSyllabus Metrologyvijayakumar rNo ratings yet

- College of Engineering and Technology: Criteria 7Document14 pagesCollege of Engineering and Technology: Criteria 7VarunNo ratings yet

- 18.12.17 To 12.01.18 DTS 'B'Document4 pages18.12.17 To 12.01.18 DTS 'B'VarunNo ratings yet

- Yuva IremosDocument9 pagesYuva IremosVarunNo ratings yet

- OneDocument15 pagesOneVarunNo ratings yet

- The Six Sigma Dmaic Methodology in LogisticsDocument6 pagesThe Six Sigma Dmaic Methodology in LogisticsVarunNo ratings yet

- Order FormDocument1 pageOrder FormVarun KumarNo ratings yet

- Stroboscope: Non-Contact Speed Measurement High Intensity Flashes Direct Speed Reading in RPM No Shaft ModificationDocument1 pageStroboscope: Non-Contact Speed Measurement High Intensity Flashes Direct Speed Reading in RPM No Shaft ModificationVarunNo ratings yet

- Awards HonorsDocument2 pagesAwards HonorsVarunNo ratings yet

- Impact of Six-Sigma DMAIC Approach OnDocument6 pagesImpact of Six-Sigma DMAIC Approach OnVarunNo ratings yet

- Entrepreneurial Orientation, Managerial Networking, and New Venture Performance in ChinaDocument21 pagesEntrepreneurial Orientation, Managerial Networking, and New Venture Performance in ChinaVarun KumarNo ratings yet

- Design Process Improvement Through TheDocument35 pagesDesign Process Improvement Through TheVarunNo ratings yet

- A SDLC Developed Software Testing Process UsingDocument9 pagesA SDLC Developed Software Testing Process UsingVarunNo ratings yet

- Document30 pagesVarunNo ratings yet

- Evaluating Environmental Performance Using Statistical Process Control TechniquesDocument16 pagesEvaluating Environmental Performance Using Statistical Process Control Techniqueskuko111No ratings yet

- An Application of DMAIC Methodology For Increasing The Yarn Quality in Textile IndustryDocument16 pagesAn Application of DMAIC Methodology For Increasing The Yarn Quality in Textile IndustryVarunNo ratings yet

- Yildirim 2006Document7 pagesYildirim 2006VarunNo ratings yet

- JSBM 12073Document17 pagesJSBM 12073VarunNo ratings yet

- Identifying and Differentiating Key Employees From Owners and Other Employees in SmesDocument17 pagesIdentifying and Differentiating Key Employees From Owners and Other Employees in SmesVarun KumarNo ratings yet

- JSBM 12086Document21 pagesJSBM 12086VarunNo ratings yet

- Audit ReportDocument24 pagesAudit ReportVarunNo ratings yet

- Self Study Report 1Document315 pagesSelf Study Report 1VarunNo ratings yet

- Academic CalendarDocument2 pagesAcademic CalendarVarunNo ratings yet

- EOA Report 2014-15.Document3 pagesEOA Report 2014-15.Tanmay MohantyNo ratings yet

- Annexure VI List of Publications in Last Five Years International JournalsDocument79 pagesAnnexure VI List of Publications in Last Five Years International JournalsVarunNo ratings yet

- Published Paper of IJCAS in 2012-2014Document114 pagesPublished Paper of IJCAS in 2012-2014VarunNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Value Stream Mapping Machine ShopDocument19 pagesValue Stream Mapping Machine ShopVinoth VinoNo ratings yet

- SQL ALL QueriesDocument33 pagesSQL ALL QueriesAjimNo ratings yet

- Calender IngDocument4 pagesCalender IngchrisgargeNo ratings yet

- Cellular and Flexible Manufacturing SystemDocument3 pagesCellular and Flexible Manufacturing SystemGhani RizkyNo ratings yet

- Lean Equipment Design Guide 2nd PrintDocument73 pagesLean Equipment Design Guide 2nd PrintcristianpetriceanNo ratings yet

- Total Productive Maintenance Review: A Case Study in Automobile Manufacturing IndustryDocument7 pagesTotal Productive Maintenance Review: A Case Study in Automobile Manufacturing Industryswathi aradhyaNo ratings yet

- GAO Schedule Assessment GuideDocument220 pagesGAO Schedule Assessment GuidemirakulNo ratings yet

- Financial Planning and Analysis: The Master BudgetDocument15 pagesFinancial Planning and Analysis: The Master BudgetAlyaYusof100% (2)

- 15etn153 - Quality Control & Quality Assurance - GeDocument4 pages15etn153 - Quality Control & Quality Assurance - GeDeepak PooranachandranNo ratings yet

- Work Study PDFDocument8 pagesWork Study PDFmann20No ratings yet

- Production Function - Handwritten Notes - (Aarambh 2024)Document10 pagesProduction Function - Handwritten Notes - (Aarambh 2024)Pranjal GuptaNo ratings yet

- Bpo2 PPT 2Document17 pagesBpo2 PPT 2Mary Lynn Dela PeñaNo ratings yet

- Asiedu+ ProductLifeCycleCostAnalysis - 201412102295156Document27 pagesAsiedu+ ProductLifeCycleCostAnalysis - 201412102295156MenaNo ratings yet

- Standard Costing and Variance AnalysisDocument99 pagesStandard Costing and Variance AnalysisHaroon ZafarNo ratings yet

- Aa025 KMKT - QN Pra1920Document9 pagesAa025 KMKT - QN Pra1920JOSEPH LEE ZE LOONG MoeNo ratings yet

- Instructor Lecture Powerpoints: Operations Management and QualityDocument25 pagesInstructor Lecture Powerpoints: Operations Management and QualityvegasusNo ratings yet

- Project Management Handbook TemplateDocument10 pagesProject Management Handbook TemplatesociatteNo ratings yet

- Workholders Work Piece ControlDocument16 pagesWorkholders Work Piece ControlRam WaingankarNo ratings yet

- DL & SIDL Calculation (NH-130A)Document18 pagesDL & SIDL Calculation (NH-130A)amitNo ratings yet

- Chapter 3 - SCMDocument45 pagesChapter 3 - SCMMatee Khan0% (1)

- Itp Concrete CoatingDocument4 pagesItp Concrete Coatingkaml100% (1)

- 5S ClassDocument36 pages5S ClasspradabkNo ratings yet

- Inventory Management, Supply Contracts and Risk PoolingDocument96 pagesInventory Management, Supply Contracts and Risk PoolingdhiarNo ratings yet

- Isoquant and IsocostDocument9 pagesIsoquant and Isocostsangeet_srichandan75% (4)

- QMS Awareness TrainingDocument108 pagesQMS Awareness TraininggilangadiNo ratings yet

- Relevant CostingDocument7 pagesRelevant CostingTERRIUS AceNo ratings yet

- Software Eng..Document116 pagesSoftware Eng..manjeet_dahiya419910% (1)

- Agenda 2013 PrintDocument6 pagesAgenda 2013 PrintJeferson GevinskiNo ratings yet

- Lecture 12 - Agile Processes-ScrumDocument31 pagesLecture 12 - Agile Processes-ScrumSarathy ParthaNo ratings yet

- BS en 1317-5-2007+A1-2008 Road Restraint Systems Part 5 Product Requirements and Evaluation of Conformity For Vehicle Restraint SystemsDocument36 pagesBS en 1317-5-2007+A1-2008 Road Restraint Systems Part 5 Product Requirements and Evaluation of Conformity For Vehicle Restraint Systemsmingul33% (3)