Professional Documents

Culture Documents

FDA 2013 Radhika Rajagopalan 1

Uploaded by

maneshdixit4312Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FDA 2013 Radhika Rajagopalan 1

Uploaded by

maneshdixit4312Copyright:

Available Formats

1

Further Stability

Considerations

Radhika Rajagopalan, Ph.D.,

Team Leader

Chemistry Division 2

Office of Generic Drugs, FDA

FDA-GPhA Workshop

June 4, 2013

2

Agenda

Common considerations

Q1D Bracketing and Matrixing Designs for

Stability Testing of New Drug Substances

and Products (presented at the FDA-GPhA Spring

workshop in 2012); additional

recommendations/information

Q1E Evaluation of stability data

considerations, recommendations

Summary

3

Common Considerations

The specification (tests, and criteria) proposed should be

the same for all 3 ANDA submission batches regardless

of Bracketing or Matrixing design chosen

Sterile drug product batches (supporting ANDA

submission) should be manufactured in a sterile facility;

sterility is a critical product quality attribute

Time points for various storage conditions:

Accelerated time points (4 points): 0, 3, 6, and one point

between 3 and 6 months ( 4 or 5 months)

Intermediate time points (0, 6, 9, and 12 months)

Long-term time points (0, 3, 6, 9, 12, 18, 24, 36 months)

0 = initial release

4

Q1D, and QIE Considerations

Q1D - Bracketing and Matrixing

reduced designs can be applied as a suitable

alternative to a full design when multiple factors are

involved; reduced designs based on different

principles; discuss additional considerations/

recommendations

Q1E Data analysis

All three ANDA submission batch data to be

presented; tabular form, graphs (critical product

attributes), narrative, and proposed expiration

5

Drug Product -Bracketing

No change from current policy for Bracketing

Test only the samples on the extremes of certain

design factors (container size/fill/strength) at all

time points as in a full design

Bracketing - experience is great!

Time-tested in OGD ANDA Products are already

following this concept

Reasonably safe design- multiple batches (3)

Extremes of design factors (strength/ fill volume/count

size) are tested at all times as in a full design

6

Considerations for Bracketing

Change in containers/void volume change/wall

thickness/geometry characteristics should be

comparable

If one of the extremes is no longer expected to be

marketed study design needs to be maintained to

support intermediates

The shelf-life of the intermediates should not exceed

that of the least stable extreme

Bracketed strength will need initial full release testing,

and Biowaiver request (if eligible)

7

Example of a Bracketing Design

Q1D

8

Matrixing Considerations

Matrixing can be implemented with out a pre-approved

protocol when ICH guidances are implemented.

Due to data coming from 3 batches, example tables

presented in the Q1D guidance can be adopted

Assumes stability of each subset of samples tested

represents the stability of all samples at a given time

point

Recommends full testing at certain time points (e.g., 0,

12, 24, 36 months etc..)

More suitable for long-term testing protocols than

accelerated, or intermediate testing

9

Matrixing Considerations

Degree of Reduction from Q1D- Matrixing

guidance depends on

Knowledge of data variability

Expected stability of the product

Availability of supporting data (including pre-formulation

studies/excipient compatibility studies/stress studies)

Stability differences in the product within factor or among factors

Number of combinations in the study

[1/2 reduction could be too much and 3/4 testing may be just enough]

10

Applicability

Factors that can be

matrixed

Batches common blend

Identical formulations

Container sizes

Fill sizes

Closely related

formulations (see Q1D)

colorants/flavors

Container closure suppliers

if justified

Factors that should not

be matrixed

Initial and final time points

Test parameters

(attributes)

(Dosage forms)

Storage conditions

Strengths w/ different

formulations (different

excipients or different

active/excipient ratios)

11

Q1D Guidance Example

12

Additional Considerations

ANDAs with several strengths (e.g., 3 or more than 3)

Matrixing designs possible as this example from previous slide

(#11) can be duplicated and used

Matrixing examples illustrated in the Q1D guidance are all based

on 3 batches (are made) for each strength

Multiple strengths are to be submitted at the same time in order

to use Matrixing designs

Multiple strengths divided among original submission and

unsolicited amendments may not qualify/be suitable for matrixing

protocol

Alternatively a suitable Bracketing design can be proposed to

be discussed in the next slide

13

Q1D Consideration

Case where common granulation/blend is used (tablet/capsule),

is there a need to make three batches of each strength

The following is our current thinking:

Three separate common granulation/blends to be made

one batch per ICH (at least of pilot scale) needs to be manufactured

comprising of all strengths (using one of the three common blend

batches); the other two batches of common granulation/blend can

be used for the highest and lowest strength alone; in the event BE

studies are done on a different strength (i.e., a strength that is

neither highest or lowest), that needs to be included also in the

manufacturing

Then a Bracketing design can be used to stability test strengths

and all (3) batches, where smallest and largest container fill size

alone can be subjected

14

Q1E Considerations

What are the expectations for data analysis and evaluation? Our

thinking is:

All three batches data to be presented

Use of Appendix A: Decision Tree for retest period or shelf life

estimation (excludes frozen Ds/Dp)

Use of tables, narrative, graphs, and analysis where needed to propose

expiration dating (DP), and retest date (DS)

Graphical format for assay, impurities/deg. p/total impurities, and other

critical attributes (e.g., pH), vs. time pts with upper and lower limits

Consideration of Significant Change from ICH Q1A(R2) section 2.2.7.1

At the time of submission 6 months accelerated data, and 6 months

long-term data to be provided for all 3 ANDA submission batches

Submission batches should be made under CGMP, and packaged using

automated/similar to commercial packaging lines, to provide adequate

protection for the DP

15

Q1 E Consideration

If 6 months accelerated data fails/significant

change occurs, ANDAs will need 6 months

30 C/65%RH intermediate data on batches at

filing time for all 3 ANDA submission batches

Narrative to be provided addressing the above

16

Appendix A Decision Tree for Data Evaluation

17

Q1 E Considerations

Statistical analysis need not be performed when 6

months accelerated data show no significant change and

long term data show no variability. A stable drug product

meeting the above will not require statistical analysis, per

Appendix A.

OGD will continue to grant 24 months tentative expiry

based 6 months accelerated, and 12 months ( or more if

available) long-term data (if the above is met)

Significant change occurs between 0 and 6 months,

long-term data needs to be used for analysis and

intermediate data are required (30 C/65% RH 6

months at the time of ANDA submission, and 12 months

to be amended)

18

Intermediate Data Evaluation

6 months at filing (0/initial, and 6)

If intermediate data also fails (meaning

significant change at that condition)

-No extrapolation of shelf-life/retest date

-Long-term data alone will take over

shelf-life/retest determination

19

Q1E Continued

General approach When stat. analysis is needed

Boxes in the Appendix A cite stat. evaluation, and

when data shows variability

Data evaluation approaches

Linear, logarithmic etc.; long-term data

-If the relationship is linear between attribute and time

then linear regression is a preferable mode

-Linear regression model is popular and applicable

when linear potency loss or increase in degradation

observed

20

Data Analysis Expectation

Plot the long-term data for a given attribute

(e.g. assay) vs. time (in months) for 3 batches

Determine the time when 95% confidence

interval intersects the proposed acceptance

criteria

Determine if data are poolable

Significance level (p) taken into account

Individual batches are to be used and shortest

expiry needs to be proposed

21

Graph Expectations

One-sided 95% Confidence limit curve

when time vs. acceptance criterion is

plotted; at times two-sided will be needed

Data poolable vs. non poolable

Small batch to batch variability = poolable

Large variability = not poolable

In general common slopes and a common

time-zero intercept may mean that data from

batches can be pooled

22

Data Presentation of Long-Term

Stability Data

23

Data Presentation

24

Data Presentation for Degradation Product

25

Q1E Continued

Setting Expiration (Drug product)

Retest date (Drug substance)

Long-term data to be used for stat. analysis

Data amenable to statistical analysis (2 times LT

but not more than 12 months, and if refrigerated

NMT 6 months)

Data not-amenable to statistical analysis (1.5 times

LT, but not more than 6 months and if refrigerated

NMT 3 months)

26

Summary

Key considerations

Developing a stability protocol utilizing Q1 D (Bracket or Matrix)

guidance is essential to a successful program

Application of significant change, generation of ICH intermediate

condition data (when needed), and utilization of all 3 batches

stability data

Stable drug product (6 months 40 C/75%RH, and no variability

at long-term) will not need data analysis

Narrative, and graphical presentation of data (in addition to

tables, where assay, impurities can be plotted individually),

needed

Data analysis needed as indicated by Appendix A when

products experience significant change, using long-term data

tentative expiration is to be proposed

27

Acknowledgements

Stability WG members: Drs. Atwal, Patankar,

Murali, Takiar, and Rajagopalan

Drs. L. Yu, K. Webber, & Mr. Clark

Drs. Holcombe, Jr., Raw, Skanchy, Schwartz,

Sayeed, and Rosencrance; Mr. Smith, and Mr.

Iser

Dr. Christensen

FDA, & GPhA

You might also like

- Calibration ProcedureDocument2 pagesCalibration ProcedureSairam Edupuganti100% (1)

- Journal of Drug Discovery and Therapeutics 1 (9) 2013, 13-19Document7 pagesJournal of Drug Discovery and Therapeutics 1 (9) 2013, 13-19anandhra2010No ratings yet

- Zeta Potential - An Introduction in 30 MinutesDocument6 pagesZeta Potential - An Introduction in 30 MinutesFA AyNo ratings yet

- Downloadable Solution Manual For Information Technology Auditing 3rd Edition James Hall Solutions 1Document4 pagesDownloadable Solution Manual For Information Technology Auditing 3rd Edition James Hall Solutions 1Diane Lorenzo0% (1)

- Foto StabilityDocument14 pagesFoto StabilityDalton WattsNo ratings yet

- EstaBiliDad FdaDocument41 pagesEstaBiliDad FdazombiecorpNo ratings yet

- 15 - M. PH Drugs Regulatory AffairsDocument10 pages15 - M. PH Drugs Regulatory AffairsMehak LubanaNo ratings yet

- ANDA ChecklistDocument12 pagesANDA Checklistmaneshdixit4312No ratings yet

- How To Identify Critical Quality Attributes and Critical Process ParametersDocument40 pagesHow To Identify Critical Quality Attributes and Critical Process ParametersNicolas Mateo Gonzalez LopezNo ratings yet

- Data Validation, Processing, and Reporting Data ValidationDocument8 pagesData Validation, Processing, and Reporting Data ValidationNaga Ajay Kumar DintakurthiNo ratings yet

- Research Article: Jack Cook, Maria T. Cruañes, Manish Gupta, Steve Riley, and John CrisonDocument9 pagesResearch Article: Jack Cook, Maria T. Cruañes, Manish Gupta, Steve Riley, and John CrisonnarendragcpNo ratings yet

- Quality Metrics Poster PDA March 2016Document1 pageQuality Metrics Poster PDA March 2016Anthony CollierNo ratings yet

- Metrology and Calibration in GLPDocument30 pagesMetrology and Calibration in GLPNicolas Quero Carvajal100% (1)

- 4 EI FDAperspectivedPQRIDocument22 pages4 EI FDAperspectivedPQRIsudheerbabu nadendlaNo ratings yet

- Chemistry, Manufacturing and Controls (CMC) Regulation of PharmaceuticalsDocument66 pagesChemistry, Manufacturing and Controls (CMC) Regulation of PharmaceuticalsDiti ShahNo ratings yet

- TRS961 Annex7Document25 pagesTRS961 Annex7Tahir KhanNo ratings yet

- GLP Protocols and Study Conduct-It Just Takes A Little PlanningDocument11 pagesGLP Protocols and Study Conduct-It Just Takes A Little PlanningSofia BlazevicNo ratings yet

- EDQM PAT Proceedings, 2004Document141 pagesEDQM PAT Proceedings, 2004huynhhaichauchauNo ratings yet

- PointersDocument4 pagesPointersCatholica Fidei Defensoris100% (1)

- CDER's Quality Management Maturity Program: Fda/Cder/Opq/OqsDocument26 pagesCDER's Quality Management Maturity Program: Fda/Cder/Opq/OqsAmbadas RautNo ratings yet

- Current Good Manufacturing Practice & Drug Manufacturing QualityDocument54 pagesCurrent Good Manufacturing Practice & Drug Manufacturing QualityGopinath GopiNo ratings yet

- FDA Perspective - QBD Considerations For Analytical MethodsDocument20 pagesFDA Perspective - QBD Considerations For Analytical MethodssamxuNo ratings yet

- DA NUT2013 B4 Rune Frederiksen PDFDocument56 pagesDA NUT2013 B4 Rune Frederiksen PDFMaheshNo ratings yet

- Inspecciones - CasosDocument25 pagesInspecciones - CasoszombiecorpNo ratings yet

- Enhancing ANDA Submissions-A GPhA White PaperDocument23 pagesEnhancing ANDA Submissions-A GPhA White Papermaneshdixit4312No ratings yet

- Cleaning Validation: JANUARY 2013Document11 pagesCleaning Validation: JANUARY 2013dhimas06No ratings yet

- FDA 483 and Warning LetterDocument38 pagesFDA 483 and Warning LetterOmar FaruqNo ratings yet

- Events Presentations Raci 121126Document22 pagesEvents Presentations Raci 121126mokhtari asmaNo ratings yet

- ACPS CP S1 01 FDA SlidesDocument78 pagesACPS CP S1 01 FDA SlidesBlueSagaNo ratings yet

- CDRHLearn ProductionandProcessControls Slides PDFDocument53 pagesCDRHLearn ProductionandProcessControls Slides PDFmailtorubal2573No ratings yet

- Fda'S Question-Based Review (QBR) : A Risk-Based Pharmaceutical Quality Assessment ToolDocument50 pagesFda'S Question-Based Review (QBR) : A Risk-Based Pharmaceutical Quality Assessment Toollalooprasad15No ratings yet

- Forced Degradation Studies-DDT June2010-Rd3Document4 pagesForced Degradation Studies-DDT June2010-Rd3Prem GoelNo ratings yet

- Drug Shelf LifeDocument27 pagesDrug Shelf LifeAurora SavageNo ratings yet

- Workshop - Specifications in Early Development (Regulatory Perspective-Stephen Miller, FDA)Document30 pagesWorkshop - Specifications in Early Development (Regulatory Perspective-Stephen Miller, FDA)lhthang1990No ratings yet

- Analytical Control Strategies of VaccineDocument20 pagesAnalytical Control Strategies of VaccineDimitris PapamatthaiakisNo ratings yet

- Day2.4 - Mozzachio - Post-Approval and Surveillance InspectionDocument30 pagesDay2.4 - Mozzachio - Post-Approval and Surveillance InspectionMarkbot1999No ratings yet

- TM-4 Use of Animals in Research and EducationDocument37 pagesTM-4 Use of Animals in Research and EducationAnita Maulinda Noor100% (1)

- R/.. 1-.fltvt : Ts L RR I I IDocument6 pagesR/.. 1-.fltvt : Ts L RR I I IBrian WilliamsNo ratings yet

- QBD Approach To Analytical Method PDFDocument21 pagesQBD Approach To Analytical Method PDFAsti Destilia SafrudinNo ratings yet

- UCM471276Document30 pagesUCM471276EckhardNo ratings yet

- Blend UniformityDocument16 pagesBlend UniformitySagi Nguyen100% (1)

- Taticek-Product Monitoring & Post-Approval Lifecycle Management of Biotech ProductsDocument36 pagesTaticek-Product Monitoring & Post-Approval Lifecycle Management of Biotech Products刘朝阳No ratings yet

- GMPs Workshop - Analytical Method Validation (Regulatory Perspective - Linda NG, FDA)Document31 pagesGMPs Workshop - Analytical Method Validation (Regulatory Perspective - Linda NG, FDA)Helena DordioNo ratings yet

- 587-7556 Indust Information Gov/oc/industry T England Union: ObservationDocument3 pages587-7556 Indust Information Gov/oc/industry T England Union: ObservationBrian WilliamsNo ratings yet

- Sap Fico ConsultantDocument3 pagesSap Fico ConsultantNanda AmbatiNo ratings yet

- CMC July 09 Patricia HughesDocument30 pagesCMC July 09 Patricia HughesSteven Correa MNo ratings yet

- Long-Term Stability (Zone IV) 30-75%RHDocument6 pagesLong-Term Stability (Zone IV) 30-75%RHমোঃ এমদাদুল হকNo ratings yet

- Parts of A Research PaperDocument8 pagesParts of A Research Paperdiane ganzaganNo ratings yet

- D1S02 Kopcha PDFDocument39 pagesD1S02 Kopcha PDFHemant SankhalaNo ratings yet

- Interpreting Qualitativa DataDocument24 pagesInterpreting Qualitativa DataFernanda Belarmino De Santana ScainiNo ratings yet

- Freeze Thaw StudiesDocument15 pagesFreeze Thaw StudiesIsabelLópezNo ratings yet

- ICH Q1 Stability Training Program MY 2019 - Brochure - 07 2019 PDFDocument4 pagesICH Q1 Stability Training Program MY 2019 - Brochure - 07 2019 PDFSih AtiiNo ratings yet

- 04 Breakout B-Control Strategy-Key MessagesDocument21 pages04 Breakout B-Control Strategy-Key MessagesOskar LazaroNo ratings yet

- Article-22855 Lynn D. Torbeck PDFDocument2 pagesArticle-22855 Lynn D. Torbeck PDFe1717y8653No ratings yet

- Analytical Method Validation ModuleDocument60 pagesAnalytical Method Validation ModuleGaoussou TimitéNo ratings yet

- Validation of Analytical ProceduresDocument15 pagesValidation of Analytical ProceduresildamonalisaNo ratings yet

- USFDA Guidelines For PharmaceuticalsDocument5 pagesUSFDA Guidelines For PharmaceuticalsemranNo ratings yet

- EMA - Reflection Paper For Laboratories That Perform The Analysis or Evaluation of Clinical Trial SamplesDocument19 pagesEMA - Reflection Paper For Laboratories That Perform The Analysis or Evaluation of Clinical Trial Samplesrpg1973No ratings yet

- Iupac Oos Oot PDFDocument33 pagesIupac Oos Oot PDFGATOMICONo ratings yet

- 10.dissolution Comparison As Per IpbpuspepDocument5 pages10.dissolution Comparison As Per IpbpuspepNitinPrachiJainNo ratings yet

- GMP For Facility Design References April06Document17 pagesGMP For Facility Design References April06madhubiochemNo ratings yet

- QC Supervisor or QC Manager or QA Supervisor or QA Manager or ReDocument2 pagesQC Supervisor or QC Manager or QA Supervisor or QA Manager or Reapi-77380607No ratings yet

- A Case For Alpha-Lipoic Acid As An Alternative Treatment For Diabetic PolyneuropathyDocument8 pagesA Case For Alpha-Lipoic Acid As An Alternative Treatment For Diabetic PolyneuropathyKorry Meliana PangaribuanNo ratings yet

- Omgoing Stability Testing - Innovations - in - Pharmaceutical - TechnologyDocument3 pagesOmgoing Stability Testing - Innovations - in - Pharmaceutical - TechnologyJuan RojasNo ratings yet

- BACPACDocument50 pagesBACPACkavya nainitaNo ratings yet

- A Guide To Blend Uniformity: Overview of Blending Process and EquipmentDocument6 pagesA Guide To Blend Uniformity: Overview of Blending Process and Equipmentmailtorubal2573100% (1)

- Canada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1Document34 pagesCanada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1atulbsNo ratings yet

- The APIC Audit Programme Version 6Document18 pagesThe APIC Audit Programme Version 6Ngoc Sang HuynhNo ratings yet

- Metronidazol 500 MGDocument12 pagesMetronidazol 500 MGAbou Tebba SamNo ratings yet

- Federal Cleanroom StandardsDocument6 pagesFederal Cleanroom StandardsmarkNo ratings yet

- Critical Cleaning Guide: How To Select and Use Detergents For Critical Cleaning ApplicationsDocument20 pagesCritical Cleaning Guide: How To Select and Use Detergents For Critical Cleaning Applicationsmaneshdixit4312No ratings yet

- Critical Cleaning Guide: How To Select and Use Detergents For Critical Cleaning ApplicationsDocument20 pagesCritical Cleaning Guide: How To Select and Use Detergents For Critical Cleaning Applicationsmaneshdixit4312No ratings yet

- Taking The Mystery Out of The Maximum Allowable Carryover (MAC) Calculations For Cleaning ValidationDocument2 pagesTaking The Mystery Out of The Maximum Allowable Carryover (MAC) Calculations For Cleaning Validationjljimenez1969100% (3)

- MAPP 5016.6 - Change in Hard Gelatin Capsule SupplierDocument2 pagesMAPP 5016.6 - Change in Hard Gelatin Capsule Suppliermaneshdixit4312No ratings yet

- Brochure - LPI (Liberty)Document2 pagesBrochure - LPI (Liberty)maneshdixit4312No ratings yet

- Supac GuidelineDocument30 pagesSupac GuidelineSalman ShaikhNo ratings yet

- RTR Guidance 2015 MayDocument25 pagesRTR Guidance 2015 Maymaneshdixit4312100% (1)

- Estab Conditions Reporting by US FDADocument17 pagesEstab Conditions Reporting by US FDAmaneshdixit4312No ratings yet

- Animal Draft - GFI 234 - QBR For CMC Technical Section - 02242016 - Final - V2Document56 pagesAnimal Draft - GFI 234 - QBR For CMC Technical Section - 02242016 - Final - V2maneshdixit4312No ratings yet

- ANDA Litigation BasicsDocument27 pagesANDA Litigation Basicsmaneshdixit4312No ratings yet

- Impurity Guidance Table FDADocument4 pagesImpurity Guidance Table FDAmaneshdixit4312No ratings yet

- AquaSolve As HandbookDocument16 pagesAquaSolve As Handbookmaneshdixit4312No ratings yet

- FDA 2012 Biosimilar Quality ConsiderationDocument20 pagesFDA 2012 Biosimilar Quality Considerationmaneshdixit4312No ratings yet

- Abuse Deterrent MarketDocument6 pagesAbuse Deterrent Marketmaneshdixit4312No ratings yet

- Aegis Patent US20140162965Document45 pagesAegis Patent US20140162965maneshdixit4312No ratings yet

- Alconox Applications in Pharmaceutical ManufacturingDocument12 pagesAlconox Applications in Pharmaceutical Manufacturingmaneshdixit4312No ratings yet

- Polyox Form Peo MatricesDocument7 pagesPolyox Form Peo Matricesmaneshdixit4312No ratings yet

- Stability Q ADocument16 pagesStability Q Amaneshdixit4312No ratings yet

- European Biosimilars Handbook enDocument54 pagesEuropean Biosimilars Handbook enmaneshdixit4312No ratings yet

- Magnesium Sterate Mixing in V BlenderDocument12 pagesMagnesium Sterate Mixing in V Blendermaneshdixit4312No ratings yet

- QBD ACE Case HistoryDocument92 pagesQBD ACE Case Historymaneshdixit4312No ratings yet

- Anatel PDFDocument4 pagesAnatel PDFmaneshdixit4312No ratings yet

- Guidance For IndustryDocument7 pagesGuidance For IndustryYash PatelNo ratings yet

- Hovercraft-Lab ReportDocument2 pagesHovercraft-Lab ReportRudi HartonoNo ratings yet

- Ps SecurityDocument27 pagesPs SecurityMaster RajaNo ratings yet

- Moving Charges and MagnetismDocument41 pagesMoving Charges and Magnetismkapil100% (2)

- Project On: Apollo HospitalDocument20 pagesProject On: Apollo HospitalMoheuddinMayrajNo ratings yet

- Benefits of Social Media To Us As An IndividualDocument12 pagesBenefits of Social Media To Us As An IndividualFe Marie ApaNo ratings yet

- Hilton - Maher - SeltoDocument21 pagesHilton - Maher - Seltoareep94No ratings yet

- Assesment RiskDocument69 pagesAssesment RiskAhmad MaulidiNo ratings yet

- Shsa1105 - Unit-III Course MaterialDocument57 pagesShsa1105 - Unit-III Course MaterialMaadhavaNo ratings yet

- Proposal Body Shaming The Age of Social Media, New DraftDocument13 pagesProposal Body Shaming The Age of Social Media, New DraftMunashe GoromonziNo ratings yet

- My Lovely ResumeDocument3 pagesMy Lovely ResumeJanicz BalderamaNo ratings yet

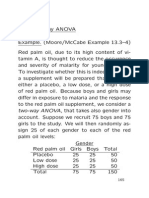

- 2 Way AnovaDocument20 pages2 Way Anovachawlavishnu100% (1)

- Translation and Validation of The Amsterdam Preoperative Anxiety and Information Scale (Apais) Into Hausa LanguageDocument23 pagesTranslation and Validation of The Amsterdam Preoperative Anxiety and Information Scale (Apais) Into Hausa LanguageGlobal Research and Development ServicesNo ratings yet

- Topik 1 - Pengenalan Kepada KeusahawananDocument13 pagesTopik 1 - Pengenalan Kepada Keusahawananhas6744332No ratings yet

- CSRP07 ProceedingsDocument90 pagesCSRP07 ProceedingsGuadalupe EMNo ratings yet

- IA Recomendaciones UnescoDocument51 pagesIA Recomendaciones UnescoIsa PhoinixNo ratings yet

- Economic System Design OutlineDocument11 pagesEconomic System Design OutlineLDaggersonNo ratings yet

- Psych - Chapter 23 Into To Milieu ManagementDocument4 pagesPsych - Chapter 23 Into To Milieu ManagementKaren かれんNo ratings yet

- Literature Review: Prof M. Sandada 0772363753 Msandada@uzbusinessschool - Uz.ac - ZW Uzbusiness School Office No. 7Document12 pagesLiterature Review: Prof M. Sandada 0772363753 Msandada@uzbusinessschool - Uz.ac - ZW Uzbusiness School Office No. 7Tinotenda FredNo ratings yet

- Jadwal NEAT SG 1Document5 pagesJadwal NEAT SG 1sangkertadiNo ratings yet

- Sbioclimatic MarketDocument14 pagesSbioclimatic MarketdetailsNo ratings yet

- Etextbook 978 0205985807 CognitionDocument61 pagesEtextbook 978 0205985807 Cognitionbenjamin.vega423100% (45)

- Thesis Ibanag) )Document17 pagesThesis Ibanag) )Rahc Engam Gahyadap100% (20)

- The Nature and Psychology of Reading: What Is Reading? DR1Document5 pagesThe Nature and Psychology of Reading: What Is Reading? DR1Harol AcallarNo ratings yet