Professional Documents

Culture Documents

Parts of A Differential

Uploaded by

Jeff Regor Ebalo100%(1)100% found this document useful (1 vote)

15 views6 pagesfor automotive servicing nc2

Original Title

parts of a differential

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfor automotive servicing nc2

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

15 views6 pagesParts of A Differential

Uploaded by

Jeff Regor Ebalofor automotive servicing nc2

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

The Suspension System

When to replace struts and shocks on your car.

Your suspension soaks up the bumps in the road, keeping you comfortable and safe by allowing your brakes and tires to work as designed. Let's look at the major components and

then talk a little about what can go wrong.

Spring:

Springs allow your car to absorb the energy of a bump or pothole, without jarring the occupants of the car. Most cars have 4 springs made from spring steel (huh imagine that!) and

wound in a spiral shape. Some cars (Corvette) have transverse (across) springs and are made from fiberglass or other composite materials. Made to last the lifetime of the vehicle,

properly sized springs seldom need to be replaced.

Shock:

Shocks work to dampen the springs natural tendancy to oscillate. A good way to test your shocks is to push on a corner of your car and observe how many times the car bounces.

More than twice and your shocks are worn. The shock is designed with fluid and internal passages to control the movement of the wheel and dampen the spring, over time the fluid

can leak, degrade or the valving can become damaged.

Strut:

Just a fancy unit that combines the spring and shock in to one unit. Usually a little more labor to remove the spring when replacing the shock (strut cartridge).

MacPherson Strut:

Just a fancier version of the Strut which also serves as the upper pivot point for the suspension.

Sway or Roll Bar:

When cornering the forces want to roll your car's body to the outside of the turn. You feel this same force sitting inside the car. The Sway Bar counteracts this force and helps to

keep the inside wheel in contact with the ground. Stiffer Sway Bar rates give a firmer ride, but better handling.

Ball Joints:

Your suspension is designed to move up and down with the road. This is accomplished with control arms which are connected to the spindle by ball joints. They are what they sound

like, a ball and socket joint which allows movement in two dimensions. Most modern ball joints are lubricated with grease, and are sealed. Older ball joint and some newer truck ball

joint do have a grease fitting to allow adding grease.

Spindle:

The spindle serves as the center point for your wheel, and rotor to rotate around. The spindle also connects to the lower control arm and upper control arm or MacPherson Strut.

Through the travel of your suspension the spindle should remain as parallel to the road as possible. Suspension geometry is designed to keep as much of the tire in contact with the

road as possible.

Common Problems:

o Shocks and struts can wear out and affect handling. If you car bounces excessively over bumps and leans hard in corners, your shocks could be warn. Look behind the wheel for the

shock or strut and look for leaking oil. This is a sure sign of a worn shock or strut. Also check your owners manual, some will give a mileage estimate for shock or strut life. As a

general rule somewhere in the 60,000 - 75,000 mile range depending on your driving style and road conditions.

o Ball joints. Ball joints wear and can cause your car to wander while driving down the road. This is dangerous as they can separate and cause you to lose control.

o Sway bar bushings can wear out over time and will allow the sway bar to clunk when turning corners or at low speeds. A fairly inexpensive part to replace, but gaining access can be

tricky depending on the vehicle.

Preventive maintenance:

o Check your shocks or struts for leakage frequently. Also pay attention to how your car handles. If you notice the ride deteriorating take your car in to have the struts checked.

o Ball joints should be checked when your car is inspected, if not, have your mechanic check them at least twice a year.

o At each oil change make sure you or your mechanic lubricates the ball joints and any other suspension components. Some components can not be lubricated as they are sealed

from the factory.

Clutch Removal and Installation

Please see our Clutch-Related Procedures.

~~~

Note: Any time the engine is removed, check the clutch for wear and replace worn components as necessary. The

relatively low cost of the clutch components compared to the time and trouble spent gaining access to them warrants

their replacement -- unless they are new or in near perfect condition -- anytime the engine is removed.

~~~

Clutch Removal

1. Remove the engine from the car (see our Engine Removal and Installation procedure).

Note: The pressure plate assembly and clutch disk remain on the flywheel when you remove the engine. The

clutch release (throw-out) bearing and related parts stay in the transmission.

Pressure Plate Clutch Disc

2. If the old pressure plate is to be reused, scribe or paint alignment marks on the pressure plate and the flywheel

to ensure proper realignment of the pressure plate during reassembly.

3. Hold the pressure plate securely and completely, then loosen the pressure plate-to-flywheel bolts by turning

each bolt only a little at a time. Work in a criss-cross pattern until all spring pressure is relieved. Then remove

the bolts, followed by the pressure plate and the clutch disc.

Caution: The pressure plate is under a great deal of spring pressure. If you work your way around the plate,

removing each bolt one at a time, it will warp.

4. Clean the friction surface on the flywheel and inspect it for wear, cracks, heat checking, grooves, and other

obvious defects. Alternating brigt and dull areas indicate a warped plate. A machine shop can machine the

surface flat and smooth (highly recommended, regardless of the surface appearance). Light glazing can be

removed with medium grit emery cloth.

5. Inspect the diaphragm spring fingers for excessive wear and make sure they are not distorted.

6. Shake the pressure plate assembly and verify that the diaphragm spring, which should be under tension, does

not rattle. If the pressure plate is defective in any way, replace it.

7. If you will be reinstalling the engine you removed, clean the flywheel and pressure plate friction surfaces with

lacquer thinner or acetone.

Caution: DO NOT use oil or grease on these surfaces or on the clutch disk lining. And clean your hands before

handling the parts.

8. Inspect the clutch release (throw-out) bearing. If it feels gritty when you turn it, or if it has been making noise,

replace it. Never wash the bearing in solvent since this will remove the factory-installed lubricant. If the bearing

is unserviceable, replace per the procedure.

9. Inspect the lining on the clutch disk for wear. There should be at least 2mm of friction material remaining above

the rivet heads.

10. Check the clutch disk for loose rivets, distortion, cracks, broken springs and other obvious damage.

Note: As mentioned above, ordinarily the clutch disk is routinely replaced, so if in doubt the condition, replace it

with a new one. If you're planning to re-use the old clutch disk, it's a good idea to check it for runout.

11. Carefully inspect the splines inside the hub of the clutch disk and the splines on the transmission input

shaft. They must not be broken or distorted. Lubricate the splines in the disk hub and the splines on the input

shaft with graphite or molybdenum disulfide powder (Rob's last replacement clutch plate came with a tiny tube

of special "spline" grease to be smeared sparingly on the splines).

12. Verify that the clutch disk slides freely on the drive shaft splines without excessive radial play. If the

clutch disk is in any way unservicable, replace it.

Note: You're probably replacing the clutch disk anyway, but if the splines on the input shaft are damaged, you'll

have to replace the input shaft as well.

Note: If you are replacing the main oil seal, remove the flywheel at this point and replace the clutch after the

flywheel has been reinstalled.

Servicing CV Joints

Step 1: Removing the axle shaft

Step 2:Remove the boot & mark all parts

Step 3: Remove the joint from the shaft

Step 4: Disassembly and cleaning of the CV Joint

Step 5: inspection of the joint parts

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Special Tuning For 948Document14 pagesSpecial Tuning For 948aakk75No ratings yet

- 1966 1978model Recognition Manual PDFDocument129 pages1966 1978model Recognition Manual PDF秦龙No ratings yet

- Volvo s40v40 With 19 Diesel EngineDocument3 pagesVolvo s40v40 With 19 Diesel EnginemilerinNo ratings yet

- Carter Carbureter Alphabetical Application SheetsDocument9 pagesCarter Carbureter Alphabetical Application Sheetsisland14No ratings yet

- Service Manual Cars: Section Wiring Diagram Late EditionDocument186 pagesService Manual Cars: Section Wiring Diagram Late EditionArvis ŽigalovsNo ratings yet

- Bomba SPV 25 Manual de ServicioDocument22 pagesBomba SPV 25 Manual de Serviciogustavo rivasNo ratings yet

- Chrysler Dodge CALIBER Service Manual (2007) # - IntroducciónDocument17 pagesChrysler Dodge CALIBER Service Manual (2007) # - IntroducciónKart MichelNo ratings yet

- LubricantsDocument1 pageLubricantsShivaraj JadhavNo ratings yet

- G9190FDocument4 pagesG9190Fvicky khanNo ratings yet

- 0 Agd0026797 0 0729033119P106964809Document1 page0 Agd0026797 0 0729033119P106964809sharoon ahamadNo ratings yet

- R1.4 2.5 D435 TG 04 2021 EMEA Rev00 EN v1 PDFDocument16 pagesR1.4 2.5 D435 TG 04 2021 EMEA Rev00 EN v1 PDFGilo MonterrubioNo ratings yet

- FUCHS Product Program Automotive LubricantsDocument72 pagesFUCHS Product Program Automotive Lubricantsmk61100% (1)

- HeroMotoCorp Is Now WorldDocument2 pagesHeroMotoCorp Is Now Worldp.sankaranarayananNo ratings yet

- Adil Khan STP MahindraDocument98 pagesAdil Khan STP Mahindragopal.leathers23No ratings yet

- L 20258Document2 pagesL 20258Enrique MurgiaNo ratings yet

- Dmax V3.5 Coverage ChartDocument16 pagesDmax V3.5 Coverage ChartSeun AlhassanNo ratings yet

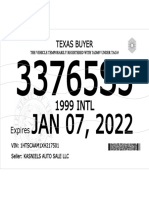

- 1999 INTL: Texas BuyerDocument3 pages1999 INTL: Texas BuyerJshjssNo ratings yet

- Mitsubishi PDFDocument16 pagesMitsubishi PDFSmelpirogok KosNo ratings yet

- Lamborghini IprDocument30 pagesLamborghini IprMandal SouvikNo ratings yet

- Astra Valve Cover GasketDocument2 pagesAstra Valve Cover GasketHernanNo ratings yet

- Honda Civic Del Sol 1997Document42 pagesHonda Civic Del Sol 1997Mac Pirx100% (1)

- Akebono Report 2016en 08Document3 pagesAkebono Report 2016en 08Raajeswaran BaskaranNo ratings yet

- Pecifications Igging Iagram: DimensionsDocument2 pagesPecifications Igging Iagram: DimensionsRAMON TEIXIDORNo ratings yet

- Camber AnglesDocument8 pagesCamber AnglesAbhishek Sharma100% (1)

- NOV Gill Services Handling Tools BrochureDocument8 pagesNOV Gill Services Handling Tools BrochureAnonymous VNu3ODGavNo ratings yet

- Diagrama Electronico EGED 285Document2 pagesDiagrama Electronico EGED 285Carlos Juarez Chunga100% (1)

- MM Term Paper 01 Spring 2023Document3 pagesMM Term Paper 01 Spring 2023Fahim Ahmed YeaminNo ratings yet

- Canton FairDocument3 pagesCanton Fairrgrao850% (1)

- Gauge & SensorDocument31 pagesGauge & SensorDario OliveiraNo ratings yet

- Indice EuropeusDocument65 pagesIndice EuropeuskrilinX0No ratings yet