Professional Documents

Culture Documents

Bab V NK Surabaya Ok

Uploaded by

Gita Marina Ahadyanti0 ratings0% found this document useful (0 votes)

11 views64 pagesBefore a ship or offshore structure can be registered, it must be surveyed in accordance with technical Rules and regulations of the Society. Classification of the ship is reviewed by the classification Commitee of the society, If approved, a certificate of classification or installation registration is issued. Basically, in the process of shipbuilding there are three mutually interested parties.

Original Description:

Original Title

Bab v Nk Surabaya Ok

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBefore a ship or offshore structure can be registered, it must be surveyed in accordance with technical Rules and regulations of the Society. Classification of the ship is reviewed by the classification Commitee of the society, If approved, a certificate of classification or installation registration is issued. Basically, in the process of shipbuilding there are three mutually interested parties.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views64 pagesBab V NK Surabaya Ok

Uploaded by

Gita Marina AhadyantiBefore a ship or offshore structure can be registered, it must be surveyed in accordance with technical Rules and regulations of the Society. Classification of the ship is reviewed by the classification Commitee of the society, If approved, a certificate of classification or installation registration is issued. Basically, in the process of shipbuilding there are three mutually interested parties.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 64

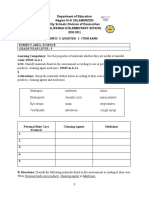

BAB V

CLASSIFICATION SURVEY FOR NEW KAPAL

5.1 Classification S!"#$s

Before a ship or offshore structure can be registered, it must be surveyed in

accordance with technical Rules and regulations of the Society. Once the ship has been

surveyed to the satisfaction of the surveyor, classification of the ship is reviewed by the

Classification Commitee of the Society. If approved, a certificate of classification or

installation registration, as appropriate, is issued and the ship id entered into ClassN!s

Registration of Ships.

Basically, in the process of shipbuilding there are three mutually interested

parties. "hey are the shipyard, ship owner, and classification. "hey perform control

function to ensure #uality of shipbuilding process.

Inspection during process of shipbuilding$

a% Inspection by shipyard

Shipyard!s #uality control standards

&uality assurance for customer

b% Inspection by ship owner

Owner!s specifications

Consideration to wards usability and maintenance

c% Classification Survey

Class re#uirements and international regulations

"o ensure the #uality of the ship is always associated with the survey. "his is

done not only when the ship was built, but it occurs througghout the lifetime of the ship

from the beginning design to operate the ship. "o e'plain it, we can loo( the chart life of

ship below.

Chart ).* +ife of Ship

Survey conducted during the building of new ship, including a survey for material and

e#uipment manufacturers. "o more clearly we can loo( at chart below$

Chart )., Construction Stage of Ship

Design

Construction

Service

Plan Approval

Classification

Surveys

Class Maintenance

Surveys

Fabrication

Shipyard

Equipment

Installation

Assembly

aunching

Manufacturers

Equipment !engine" propeller" etc#

purchas

e

Materials !steel plates#

Steel Ma$ers

Sea trials

Delivery

purchas

e

Chart ).- Outline of Classification Survey .uring Construction

Construction Stage

Inspection by S/Y, Owner

Inspection by

Surveyor

1. Building Contract

3. Material Order

. !abrication

". #sse$bly %eel

&ay

Steel

Cutting

'. (esign

Speci)ication

*lan #pproval

#cceptance Inspection

Surveys during !abrication and #sse$bly process

Bloc+ Inspection

*lan #pproval

Construction Stage

Inspection by S/Y, Owner

Inspection by

Surveyor

,. Out)itting

-. Bloc+ &oading

&aunc.ing

/. Out)itting

10. Sea 1rials (elivery

1ig.tness 1est and 2(1

!inal Inspection o) 3ull Co$part$ents

*er)or$ance 1est o) various 45uip$ent

Installation o) 6udder, %eel #lign$ent etc.

Sea 1rial

Stability 47peri$ents, i) necessary

Statutory Survey

(elivery

5.% Acc#&tanc# Ins&#ction

5.%.1 O'(#ct of ins&#ction

/late

/ropeller

Shaft

Safety e#uipment 0life buoy, life boat%

Navigation e#uipment

5.%.% Ot)oin) ins&#ction an* acc#&$anc# ins&#ction

"he ma(er or fabricator which producted plat, propeller, anchor, chain,

etc that used at ship must be approved by classification. 1nd then before

installed, the product must have certificate and stamp by classification. Chart

below can describe the steps of inspection.

C+a!t 5., Steps of Inspection 2#uipment

5.%.- P!&os# of Acc#&tanc# ins&#ction

*. "o confirm that the parts or material, which are outside manufacture,

have been inspection by the classification society or other appropriate

body.

,. "o confirm that they have not been damaged during transportation.

2'ample of acceptance inspection is shown picture below$

Fi)!#5.1 Chec( 3ill Sheet and "he /ate 3ar(ings

Confirm the stamp and the entry in the certificate then e'amine any damage

caused during transportation.

Fi)!# 5.% Stamp and Certificate

-. "o 4udge the ade#uacy of the installation of the delivered products to the

particular cessel.

5.- .ll St!ct!# Installation

5.-.1 Confi!/ation of scantlin) of /#/'#!s

Bloc( assembling system

5or #uic( building, hull construction is divided into the bigger

bloc(s

"he si6e of bloc(a depend on the crane capacity and si6e of

bloc( bay etc.

7or(ing drawings 0name and information of members,

se#uence of assembling%

Importance of control for building schedule

Increase of building rotation and leveling of amount of building

Scantling of members including thic(ness and steel garde. 2specially

primary members such as web frame and girders.

3issing members $ Collar plates, carlings, stiffeners and small brac(ets,

etc.

If abnormality such as imbalance of structure and discontinuity of strength

are found, even if they are built as per drawings, surveyor is to discuss with the

shipyard and suggest correcting them.

Fi)!# 5.- 3issing Brac(ets

).-., Confirmation of assembly accuracy

3isalignment at cross 4oint 0fillet welding%. 2specially counter

members to primary members.

3issalignment at butt 4oint

.istortion members

Fi)!# 5., Inapproriate 2dge /reparation and 3isalignment

Fi)!# 5.5 3isalignment at Bloc( 8oint

Fi)!# 0.0 3isalignment at Bloc( 8oint

Fi)!# 5.1 3isgnment at Brac(et

3isalignment can cause damage

Fi)!# 5.2 .amage .ue to 3isalgnment

Ripair for misalignment $

Fi)!# 5.3 Repair for 3isalignment

5.-.- W#l*in)

Chec( point $

*. 7elder #ualigication

,. 1pproved welding procedure specification

-. 7elding shall be done properly in accordance with above ,.

9. .efect e'ceeding the critical the limit are to be repaired and re:

chec(ed.

/roper welding is to be done in accordance with 7/S

*. Confirmation of edge preparation

a% Same thic(ness

Fi)!# 5.14 2dge /reparation for Butt 8oint without ;rooving

Fi)!# 5.11 2dge /reparation for Butt 8oint with < and = "ype of ;rooving

b% .ifferent "hic(ness

Fi)!# 5.1% .ifferent "hic(ness of Butt 8oint

ClassN rule re#uires this tapering not more than *>- when there is the

difference in the thic(ness over 9 mm.

Fi)!# 5.1- "apering for .ifferent "hic(ness 8oint /reparation

Fi)!# 5.1, Confirmation of 2dge /reparation with 7elding ;auge

,. Run:off tab

"abs should be provided at both ends of butt welding,

because defects are li(ely to occur here.

"abs should be cut after completion of welding and

surface should be inspected for defects.

Fi)!# 5.15 Run:off tab

Fi)!# 5.10 <arious "ype of Run:off tab

-. 7elding se#uence

In case of wrong welding se#uence,

Butt 4oint will be deformed due to heat

2nd of butt 4oint overlaps on the seam, and defect is

li(ely to occur

N." of welding 4oint

"o (now discontinuity in weld metal in surface and subsurface

Fi)!# 5.11 .iscontinuity in 7eld 3etal and "he N." 3ethod

ind of N."

7e can loo( at table below for (inds of N."

"able ).* inds of N."

1fter completin of welding wor(s, the surveyor is to decide locations for N." and

indicate them in the bloc( plan.

Fi)!# 5.12 +ocation for N."

).-.9 Other inspection

Confirmation of welding and remaining wor(s

3issing welding and bac( gouging of critical points

.efects such as under cut, blow hole, lac( of leg length, distortion at

welding 4oint, etc.

Inspection around bloc(s

5inished surface of edge preparation and treatment of craters

Sufficient penetration of automatic welding

Scallops on internal members at welding line of plates

Others

/enetration of internal members through water>oil tight bul(head

/roperly arranged ?cut:water scallop@

1ir holes and drain holes in tan(s

Inspection in special bloc( 0stern frame%

Chec( point

7elding between steel plate and cast>forged steel

Slot welding

"ightness test

1lignment of stern frame

Fi)!# 5.13 Inspection of Stern frame for ?1@ "ype Rudder

Inspection inspecial bloc( 0shoe piece%

Fi)!# 5.%4 Shoe /iece

Bloc( inspection and final inspection

Ta'l# 5.% 1dvantages of Bloc( Inspection and 5inal Inspection

5., Ins&#ction B#fo!# Lonc+in)

5.,.1 Ti)+tn#ss t#st an* st!ct!al t#st

*% Confirmation of tightness and strength

C+a!t 5.5 Confirmation of "ightness and Strength

,% /lan of Structure "est

C+a!t 5.0 /lan of Structure "est

-% Aydrostatic test

Aydrostatic test

5illing water up to a suitable water head

Confirmation of tightness

Confirmation of strength of structure

Ob4ects to be tested

.ouble bottom tan(s

.eep tan(s

Cargo oil tan(s and cofferdams of tan(ers

1/"

5/"

Chain +oc(ers

etc.

/rocedure of hydrostatic test

7here it is impracticable to carry out the hydrostatic test on the berth with the

specified test head, the test may be carried out as followsB

*. Aydrostatic test for each compartment on berth under the water head to the level

of ballast water line

,. 1fter that, hydrostatic test for each compartment under the water head specified

above, when ship is afloat

7hen hydrostatic test for certain compartments is replaced by air test on berthB

a% Some of them including 5/", 1/", all CO" ad4acent to cofferdam and pump

room and ones selected by the surveyor are to be sub4ect to hydrostatic test

in float condition under the water head as specified above.

b% 1ll ballast tan(s other than the above selected ones are to be sub4ect to the

hydrostatic test during sea trial with the head of water to the top of the air

pipe.

2'ample of hydrostatic test 0.eep tan(%

7ith the greatest one of followings $

a% +oad waterline

b% "op of overflow pipe

c% ,.9)m above tan( top

0d% ,>-A from tan( top

where A is the highest from tan( top to upper end of .

Fi)!# 5.%1 Aydrostatic "est 0+ea(age and Strenth test%

9% 1ir test$

Charge compressed air in the tan( up to the re#uired pressure,

Spray lea( indicator solution 0a (ind of soapy water%,

In case of any lea(age from defective spots, bubbles will be found on it.

Fi)!# 5.%% 1ir "est 0Only +ea(age "est%

Fi)!# 5.%- Chec( point for tightness test

1ir "est 0+ocal% <acuum "est

If the gauge pressure doesn!t decrease, lea(age of the bo'>>gas(et should be chec(ed.

Fi)!# 5.%, <acum "est

1ir "est 0+ocal% 1ir In4ection "est

"his test may be carried out during ?in:shop fabrication@ or ?bloc( inspection@,

in accordance with the approved procedure.

If the gauge pressure doesn!t go up, the ?tunnel@ or ?gap@ is stuffed by any

reason. In this case, air tightess should be chec(ed by the other methods.

Fi)!# 5.%5 1ir In4ection "est

)% Aose "est

/ressure 0in no66le%$ C.,3pa

.iameter of no66le$ *,mm or more

3a'imum distance$ *.)m

Fi)!# 5.%0 Aose "est

Aose test is applicable to shell plating, water:tight dec(, water:tight bul(head,

shaft tunnel, hatchway, etc.

5or shell plating of fully welded construction being inspected from both sides

visually, the hose test may be dispensed at the discretion of the surveyor.

5.,.% 5#as!#/#nt of P!ici&al 6i/antions

Confirmation of accuracy to the design dimensions

5latness of (eel

Fi)!# 5.%1 Standard for 5latness of eel

+ength

Standard for error accordance 8apan Standard &uality of Shipyard 08S&S% is D

)C mm 0per *CC m%

Breadth

Standard for error according 8apan Standard &uality of Shipyard 08S&S% is D *)

mm.

.ept

Standard for error according 8apan Standard &uality of Shipyard 08S&S% is D

mm.

Fi)!# 5.%2 Standard for 2rror

Chec( points B

Calibartion of the measurement tool

Record of water

"emperature

"ime during measurement

Fi)!# 5.%3 5latness of (eel, 3easurement of +

3easurement of Breadth

a% Set up a pole along the side shell

b% 3ar( the height of the lower face of (eel to the pole

c% 3easure the height from the dec( line to the lower face of (eel

d% 3easure the breadth at bottom

Fi)!# 5.-4 3easurement of Breadth

).9.- 3ar(ing

+oad lines 0I++C%

/osition of +oad line mar(, dec( line

1ccuracy 0DC.) mm%

/ermanent mar(ing 0welding of thin steel plate or punching%

Color 0in contrast with the color of the shell%

3easurement of load lines

1llowable error is C.)mm

/ermanent mar(ing 0welding of thin steel plate or punching, Color in

contrast with the color of the shell%

"his 3ar(ing is on the starboard side

,. .raught Scale SO+1S II:*

3ar(ed at fore, aft and midship on both port> starboard side, every ,C cm of

draught. "he height of each letter is to be *C cm.

"he lower edge of the letter should coincide with the actual draught line

0standard D* mm, limit D, mm%

Fi)!# 5.-% .raught Scale

-. Ship!s identification number 0I3O Number% 0SO+1S =I>-.9%

Stern, both sides of hull at midship, both sides or front of superstructure

1ftermost bul(head or hatchway in the machinery space

Fi)!# 5.-- I3O Number at 5ront of Superstructure

5igurr ).-9 I3O Number at 3achinery Space

9. Cargo Compartment 3ar( 0"3 EF%

Characters ?CC@ should be permanently mar(ed at the compartments

included in the calculation of net tonnage

+ocation of the mar(ing is in principle as follows$

Cargo ship $Outside of hatch coaming

"an(er $Outside of cargo hatch

/CC $Outside of entrance to the hold

+/; carrier$Coaming of tan( on upper dec(

Fi)!# 5.-5 CC 0Cargo Compartment% 3ar(

5.,., Co!!osion P!#"#ntion

5.,.,.1 Paintin)

C+a!t 5.1 Corosion /revention

*. Surface /reparation

Surface preparation

"o remove mill scale, rust, G other contaminations on steel surface, as

well, as to provide proper roughness for ensuring better adhesion with

coating

1utomated blassting

Below figure shows general layout of shop primer coating machine

3anual blasting

1pplicable for various shapes of the ob4ects

1cid pic(ling

1pplicable for pipes and small pieces by using phoshoric acid, etc.

,. Shop /rimer

1pplied for corrosion protection of steel materials at construction stage, as well

as for reducing wor( load of surface preparation at painting stage.

Inorganic 6inc shop primer

3ost propular shop primer due to good durability and a little adverse

defects to the welds.

Hinc epo'y primer

/opular primer used as touch up paint for the surface applied shop

primer due to good durability and #uic( drying.

7ash primer

/rimer used previously due to good adhesion to various (ind of coatings

and a little adverse defects to weld.

-. Control of Coating 5ilm "hic(ness

7et film gauge

"o be used during application and before curing. .ry film thic(ness

0.5"% can be estimated from wet film thic(ness 075"% based on wet>dry

film thic(ness ratio of the material in the specification.

.ry film gauge

"o be used after curing. By using the change in the strength of magnetic

field depending on the distance between steel plate and probe, .5" is

measured.

Fi)!# 5.-0 "ype of Control Coating

9. "iming of Coating

3ain coating is not to be applied until the completion of tightness test.

7elds, which are passed tightness test 0e.g. in4ection test% at bloc( stage,

can be applied with main coating.

Notwithstanding the above, shop primers can be applied prior to

ti)+tn#ss t#st.

5.,.,.% Cat+o*ic P!ot#ction

;alvanic anode system

Corrosion protective method by fitting less noble metals such as Hinc, aluminum,

magnesium, etc. as sacrificial anode. ;enerally, outer hull and ballast tan( surfaces are

protected by this system in cooperation with coatings.

Impressed current system

Corrosion protective method by using insoluble metal anodes such as /b or "i,

which are to be (ept in anode potential applied by .C power source installed in 2>R

generally. "his anode potential wor(s to protect corrosion.

1nodes of aluminum and magnesium generate higher anode potential than 6inc, that

loo(s more effective than 6inc. But magnesium anodes are not used for ships in general

due to the ris( of hydrogen e'plosion. 1nd aluminum anodes are not used for ballast

tan(s in considering spar( ha6ard and corrosion product from anode itself.

Ta'l# 5.- inds of Cathodic /rotection

Fi)!# 5.-1 Hinc 1nnode as Cathodic /rotection

5.5 .ll Otfits

5.5.1 R**#!

5.5.1.1 T$&# of R**#!

Fi)!# 5.-2 "ype of Rudder

5.5.1.% Installation of !**#!

1. Confirmation of material and welding procedure

%. Internal and e'ternal inspection

-. 5itting of sleeve, pintle, bush etc.

,. Coupling of rudder plate and rudder stoc(

5itting condition of coupling bolts

+oc(ing of nut

5. 1lignment of rudder and stern frame

0. 5itting of rudder

1. 3easurement of clearance

Between sleeve and bush of each bearing

Between shoe:piece and rudder lower pintle or

Between rudder horn and rudder

2. Swing test

5.5.1.- 5at#!ial an* const!ction of !**#!

*. Confirmation of material and welding procedure

3aterial of rudder stoc(, pintles, rudder plates, frames,

coupling bolts, etc.

3aterial of sleeve and bush

welding procedure

,. Internal inspection

Scantling and arrangement of rudder plates, frames, main pieces, etc.

7elding condition

No gap between rudder plate and strap for slot welding

.imension and pitch of slots

Confirmation of internal coating

.rain plug on the bottom

-. 2'ternal inspection

Slot welding

"ightness test

5.5.1., Ali)n/#nt of !**#! an* st#!n f!a/#

Rudder carrier

I 3aterial of rudder carrier and bearing

I Completion of all the construction wor(s around the dec(

I 5inished surface, dimension and install angle of rudder carrier and liner plate

I 1rrangement and dimension of reamer bolts or stoppers

1lignment of rudder

I 5ore>aft direction, athwart ship direction 0allowanceJC.-mm, limitJC.)mm%

1lignment of stern frame

I Completion of construction wor(s and hydrostatic test in the vicinity

I 3easurement of pre:alignment prior to boring

I 5i'ing of rudder carrier

I 5inal boring

Slot welding is applied for rudder plate because of drum panelling.

Fi)!# 5.-3 Construction of "ype 1 rudder

Fi)!# 5.,4 Slot 7eld

5.5.1.5 Pintl# an* Sl##"#

Fi)!# 5.,1 Steps of /intle and Sleeve Installation

5.5.1.0 Colo! fit of &intl#

a% /ut red lead on the tapered part

b% Insert the pintle into the gudgeon

c% Confirm the contact by the colour remained on the gudgeon

Standard is E)K, and the contact should be uniform

Fi)!# 5..,% Colour 5it of /intle

5.5.1.0 Wat#! S#al fo! Pintl#

Fi)!# 5.,- /intle

If water soa(s, it will lead to $

*% Rust of pintle

,% Slac(ness of sleeve

5.5.1.1. C#nt#!in) of R**#!

1llowable error is C.)mm 0standard is C.-mm%

Fi)!# 5.,, Centering of Rudder by 3easurement of fore:aft direction and

3easurement of 1thwartship .irection

5.5.1.1 C#nt#!in) of st#!n f!a/#

Centering shall be carried out after hydrostatic test of aft construction is finished

0to avoid its effect%

1llowable error is C.)mm 0standard is C.-mm%

Fi)!# 5.,5 Steps of Centering of Stern 5rame

).).*.L 3easurement of clearance

"o be measured at top, middle and bottom, and the average to be calculated.

Fi)!# 5.,0 Report of Clearance Calculation

5.5.% .atc+ Co"#!

Fi)!# 5.,1 Aatch Cover

Chec( point

.imensions + G B $ D)mm, Aeight $ D-mm as a standard

.istortion )mm as a standard

;as(et and e#uipment

"ightness 0for drum panel type%

Note"he standard is for pontoon hatch covers for container carrier

5.5.- Pi&in)

5.5.-.1 5at#!ial of &i&#

Steel pipe

Carbon steel pipe

Carbon steel pipe for pressure piping 0S"/;% is the most commonly used pipes

in ship

Cast steel pipe

Corrosion:resistant. /ipes of large thic(ness are used in large scale for cargo oil

line and ballast line of tan(ers

Stainless steel pipe

5or piping, where less:maintenance and corrosion:resistance are re#uired

Copper and copper alloy pipe

2asy for bending and corrosion:resistant. 5or dec( steam line

Other material

Synthetic resin, /<C, etc.

5.5.-.% Pi&# (oint

Fi)!# 5.,2 "ype of /ipe 8oint

7eld 4oint 0a%

5lange 4oint 0b%

Screw 4oint 0c%

Bite 4oint 0d%

Mnion 4oint 0e%

2'pansion 4oint 0f%

0a% G 0b% are the most common 4oints for hull part

5.5.-.- T$&# of "al"#

;ate valve 0a%

;lobe valve 0b%

Butterfly valve 0c%

Non:return valve 0d%

5.5.-., Class#s of Pi&#s

Ta'l# 5., Classes of /ipes

Kin* of 5#*i/ 6#si)n P!#ss!# 0P% and 6#si)n T#/&#!at!# 0T%

7!o& I 7!o& II89: 7!o& III

Steam / N *.E3/a or

" N -CCOC

/ *.E3/a and " -CCOC / C.P3/a and "

*PCOC

"hermal oil / N *.E3/a or

" N -CCOC

/ *.E3/a and " -CCOC / C.P3/a and "

*)COC

5uel oil, lubricating

oil and flammable

hydraulic oil

/ N *.E3/a or

" N *)COC

/ *.E3/a and " *)COC / C.P3/a and "

ECOC

1ir, carbon dio'ide

gas, water and non:

flammable hydraulic

oil

/ N 9.C3/a or

" N -CCOC

/ 9.C3/a and " -CCOC / *.E3/a and "

,CCOC

).).-.) /ressure test

"est ob4ects

/ipes in ;roup I and II

Steam pipes, feed water pipes, compressed air pipes and fuel oil pipes with the

design pressure e'ceeding C.-)3/a 0e.g. 5.O. pipes and heating pipes%

Cargo oil pipes, crude oil washing pipes for oil tan(er

Chec( point

Aydrostatic test with pressure of *.) times 0*.,) time for cargo oil pipes% of

the design pressure. "he test may be replaced by airtight test with prior

consultation

"est pressure is to be chec(ed by properly calibrated 8IS>ISO approved

pressure gauge

7elding of pipe is to be e'ecuted by #ualified welders. 8oints of pipes in

;roup I G II with a diameter of )C1 or more is to be of butt welding type

Others

/enetration of air pipes, sounding pipes, etc. is to be confirmed at the time of

pressure test of tan(s

Not applicable to the pipes with opening end in tan(s

5.5.-.0 P!ot#cti"# a!!an)#/#nt of &i&#s

Fi)!# 5.54 /iping 1rrangements

5.5.-.1 Kin*s of Ai! Pi&# .#a*

*. 3anual closing type

;oosenec( type

3ushroom type

,. Self Closing type

Ball float type

.isc float type

Note B Aead of air pipe located on the e'posed dec( of a ship, the (eel of which is laid

on or after *>*>,CC), should be of self closing type

0ngga( ada gambar%

5.5.-.2 N/'#! an* S#ctional A!#a of Ai! Pi&#

*% "an(s having top plates are to be provided with two or more pipes arranged

at suitable distance from each other

,% Aowever, small tan(s having inclined top plate may be provided with one air

pipe located at the highest part of the top plate

Fi)!# 5.5- Number and Sectional 1rea of 1ir /ipe

5.5.-.3 .#i)+t of Ai! Pi&#

1 corrosion resistant &!ot#ction ;i!# n#t is re#uired for the air pipes of oil tan(s

Fi)!# 5.5, Aeight of 1ir /ipe

Note$ "he height of air pipe head is re#uired depending on (inds of dec(

5.5.-.14 T$&#s an* Position of Son*in) Pi&#

In principle, the pipes should lead to positions above the bul(head dec(, which

is readily accessible at all times, and are to be provided with effective closing

appliance at their upper ends

Re#uirements for name plates of air pipes, protections and insulations are also

applied to sounding pipes

Special devises such as self:closing device are re#uired for sounding pipes

which open in 2>R

Fi)!# 5.55 "ype and /position of Sounding /ipe

5.5.-.11 Bil)# Lin# S$st#/

7hen pipes pass through cargo holds, they must be protected against damage

Fi)!# 5.0 3anifold System or Independent System and /ipes /ass "hrough Cargo

Aolds

5.5.-.1% A!!an)#/#nt of Bil)# W#ll

2'cept for the aft of propeller shaft, Qa! should be less than Qd

4

>,! and Qb! should

be more than 9EC mm

Capacity of Bilge well should be C.*P m

-

or more

Fi)!# 5.52 1rrangement of Bilge 7ell

5.5., Fi!# Saf#t$ 5#as!#s

5.5.,.1 Fi!# P!ot#ction

1. Fi!# P!ot#ction 5at#!ials

Non:combustible material

?1@ and ?B@ class division

5ire retardant base material 0for divisions, groundsills%

5ire retardant veneers

5ire retardant surface floorings

/rimary dec( covering

5ire retardant coating

.oor 0?1@ and ?B@ class%

Side scuttle 0?B@ class%

Classes 1 and B mean e#uivalent performance as the division where they are

installed. 0On the other hand, Class B of side scuttle means a category of strength%

7here an asteris( appears in the table, the division is re#uired to be of steel or

other e#uivalent material but is not re#uired to be of ?1@ class standard.

Refer to SO+1S and relevant chapter of /art R of the Rules for more details as

there are some other applicable provisions.

5.5.,.% Ins&#ction '#fo!# C#ilin)< Pan#lin) an* Linin)

5ollowing parts are to be inspected before ceiling, paneling and lining.

"reatment at intersection of bul(head or dec(, and e'tension of insulation

Construction of bul(head or dec( at penetration of pipe, duct or electric cable

1rrangement and construction of ventilation duct including damper

1rrangement and construction of draught stop behind ceiling, paneling and

lining

Non:combustible materials 0especially for 3ethod IC%

5.5.,.- 5at#!ials of O"#!'oa!* Fittin)s

Fi)!# 5.53 3aterial of Overboard 5ittings

3aterials readily rendered ineffective by heat, such as /<C, 5R/, aluminium alloys,

lead, copper and copper alloys, should not be used for overboard scuppers and sanitary

discharges at following parts$

0*% "he parts below the freeboard dec(

0,% "he parts in the space above freeboard dec( having the open end located at

a height of *)Cmm or less from the +7+

0-% "he parts in the spaces directly above the freeboard dec(, when the distance

between freeboard dec( and the +7+ is *)Cmm or less

In addition to confirmation of the cerificate including its validity and label on the

articles, proper use of the items should be confirmed according to the approved

drawing.

% Class Of 6i"ision

Class Const!ction Ris# of t#/&#!at!#

of n#=&os#* si*#

Passa)# of s/o># an*

fla/#

A I 5ormed by bul(heads and dec(s

I Constructed of steel or e#uivalent material

I Suitably stiffened

I Insulated with approved non:combustible

material

I 1verage$ *9C

I 1ny point$ *LC

I "ime$ C, *), -C, EC

minutes

/revent the passage of

smo(e and flame for *

hour

B I 5ormed by bul(heads, dec(s, ceiling or linings

I Constructed of approved non:combustible

materials. 1ll materials used in the construction

and erection shall be non:combustible

I 1verage$ *9C

I 1ny point$ ,,)

I "ime$ C, *) minutes

/revent the passage of

flame for -C minutes

C I Constructed of approved non:combustible

materials

: :

Ta'l# 5.5 Class of .ivision 5ire /rotection

? Non:combustible material is a material which neither burns nor gives off flammable

vapors in sufficient #uantity for self:ignition when heated to appro'imately P)C C@

- Fi!# Int#)!it$ of Bl>+#a*s 8Ca!)o S+i&s ot+#! t+an Tan>#!s:

Ta'l# 5.0 5ire Integrity of Bul(heads

- "he parts inn the spaces directly above the freeboard dec(, when the distance between

freeboard dec( and the +7+ is *)C mm or less.

5.5.,., S&ac# fo! E/#!)#nc$ Fi!# P/&

Confirm that there is no direct passage between space for emergency fire pump G

machinery spaces

Fi)!# 5.04 Space for 2mergency 5ire /ump

5.5.,.5 S#lf?Closin) 6oo!

*. Starways accessible to other dec(s not going out of the starways enclosures

,. Starways with open steps. Only starways are surrounded by an enclosure and acces to

other dec(s is made through outside the enclosure at each dec( level and each end of

stair.

Fi)!# 5.01 Self:Closing .oor

5.5.,.0 Inslation at P#n#t!ation &a!ts 8Pi&#:

2'tend the insulation at least 9)Cmm 0in principle%

Regardless of the class of partition

If the pipe is made of material having low:heat conductivity character 0e.g. ?B@

class division% and a diameter of less than *)Cmm, the insulation may be

terminated at the end of penetration piece or sleeve

5.5.,.1 Inslation at P#n#t!ation &a!ts 8Ca'l#:

Fi)!# 5.0- Insulation at /enetration Cable ?1@ Class division

Fi)!# 5.0, Insulation at /enetration Cable ?B@ Class .ivision

5.5.5 Closin) 6#"ic#

3eans that in any sea condition water will not penetrate into the ship 0IC++%

.oors IC++ Reg.*,

/osition of hatchways, doorways and ventilators IC++ Reg.*-

Cargo and other hatchways IC++ Reg.*9,*) and *E

3achinery space openings IC++ Reg.*P

3iscellaneous openings in freeboard and superstructure dec(s

IC++ Reg.*L

<entilators IC++ Reg.*F

1ir pipes IC++ Reg.,C

Cargo ports and other similar openings IC++ Reg.,*

Scuppers, inlets and discharges IC++ Reg.,,

Spurling pipes and cable loc(ers IC++ Reg.,,:,

Side scuttles, windows and s(ylights IC++ Reg.,-

5.5.5.1 Position of o&#nin)s

/osition I$ Mpon e'posed freeboard and raised #uarterdec(s, and upon e'posed

superstructure dec(s situated forward of a point located a #uarter of the ship!s

length from the forward perpendicular

0Note$ "hose superstructure dec(s located at least two standard height of

superstructure above the freeboard dec( are categori6ed as /osition II%

/osition II$ Mpon e'posed superstructure dec(s situated abaft a #uarter of the

ship!s length from the forward perpendicular and located at least one standard

height of superstructure above freeboard dec(

Fi)!# 5.0 /osition of Opening

5.5.5.% Closin) /#ans fo! acc#ss o&#nin)s in S&#!st!ct!# En* Bl>+#a*s

"o be made of steel or other e#uivalent materials

"o be rigidly fitted to the bul(heads

"o be rigidly constructed, to be of e#uivalent strength to that of intact bul(head

"he means for securing weathertightness to be provided

"o permanently fit gas(ets and clamping devices or other e#uivalent devices

"o be operated from both sides of the bul(heads

"he height of sills of access openings shall not be less than -LCmm

Fi)!# 5.00 Closing 3eans for 1cces Openings in Superstructure 2nd Bul(heads

5.5.5.- .atc+;a$s

Coaming heightIC++ Reg.*9:*

ECC mm/osition I

9)C mm/osition II

Fi)!# 5.01 Aatchway Beams and 7ooden Aatchway Covers

5.5.5., B&n*a!i#s of 5ac+in#!$ S&ac# an* Co/&anion;a$s Coa/in) .#i)+t of

O&#nin)s

*. Boundaries of machinery space

;eneral $ECC mm 0/osition I%, -LC mm 0/osition II%

Ship having a reduced freeboard 0"ype 1, "ype B:EC, B:*CC%$ In ships having a

reduced freeboard, doorways in the e'posed machinery casings on the freeboard

or raised #uarter dec( shall lead to a space or passageway which is of a strenght

e#uivalent to that of the casing and is separated from the stairway to the

machinery spaces by a second steel weathertight door of which the doorway still

be at least ,-C mm in height.

,. Companionways

5or dec( houses or companionways which provides acces to a space below the

freeboard dec( or a space within an enclosed superstructure, the coaming height of

openings shall not be less than ECC mm in /osition I and -LC mm in /osition II.

5.5.5.5 5isc#llanc#os O&#nin) in F!##'oa!* na* S&#!st!ct!# 6#c>s

3anholes and flush scuttles within superstructures other than enclosed

superstructures shall be closed by subtantial covers capable of being made watertight.

Mnless secured by closely spaced bolts, the covers shall be permanently attached.

5.5.5.0 V#ntilato!s

<entilators in position I, the coamings of which e'tend to more than 9.)m

above the dec(, and in position II, the coamings of which e'tend to more than ,.-m

above the dec(, need not be fitted with closing arrangement

Note$ 5ire damper may be re#uired according to the usage

Fi)!# 5.03 "ype of <entilator

Coaming height

/osition I $ FCC mm

/osition II$ PEC mm

<entilator openings shall be provided with weathertiight closing appliance of

steel or other e#uivalent

5.5.5.1 Ai! Pi&#s

Aeight

On the freeboard dec( PEC mm

On the superstructure dec( 9)C mm

Note$ 5or the ship constructed on and after *st 8anuary ,CC), air pipes shall be provided

with automatic closing devices

Fi)!# 5.14 1ir /ipes

5.5.5.2 Ca!)o Po!ts

Chec( point$

Opening>Closing device, Securing device and Roc(ing device

Operational test, Aose test

Indicator lights to show the door condition 0Open>Close% , <isual and audible

alarms

1pproved ?Operation and 3aintenance 3anual@

5.5.5.3 S&!lin) Pi&#s an* C+ain Loc>#!s

"o be provided with permanently attached closing appliances to minimi6e water ingress

Fi)!# 5.11 Spurling /ipes and Chain

5.5.5.14 Si*# Scttl#s

Side Scuttles at spaces below freeboard dec( or within the first tier of enclosed

superstructures shall be fitted with hinged inside deadlights which are capable of being

closed and secured watertight.

Fi)!# 5.1% Side Scuttles below 5reeboard .ec(

5.0 Sta'ilit$ E=&#!i/#nts

5.0.1 Inclinin) T#st

/rior to the measurement, the surveyor is to confirm that the ship!s condition,

test circumstances and test devices conform to the re#uirements in ?1nne'

B,.-.,:, ;uidance for Inclining "est@ of the guidance

.uring the measurement, the surveyor is to confirm that sufficient data is

gathered to determine the particulars of stability information of the ship

If the ship!s construction wor( is not completed, the weights and positions of

items which are to be added, removed or relocated should be recorded by the

shipyard and confirmed by the surveyor 0within D,K of final lightweight%

7hen the test report incorporating the data is submitted, the surveyor is to

ensure that the data given in the report is consistent with that gathered during the

test

Note$

*% Small heel angle may result in deviation over tolerance limit

0e'pected heel *O to 9O%

,% . 3ooring lines are to be free of transverse tension

Fi)!# 5.1- .raught 3easurement and .raught 3easurement Specific ;ravity of Sea

7ater.

5.0.- Oscillation T#sts

Inclining "ests "o locate the center of

gravity of the ship

Oscillation "ests "o determine rolling

period of the ship

0appro'imate calculation%

Rules /art M assume that rolling angle * is proportionate to the root of s, which is a

function of " 0rolling period%

+ =

*CC

C9- . C C,- . C -P- . C

,

C

wl

m

L

d

B

M G

B

T

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Bulk Carriers PicDocument24 pagesBulk Carriers PicGita Marina AhadyantiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Hull Form Improvement For SPXB Operated in Shallow Draft WaterDocument9 pagesHull Form Improvement For SPXB Operated in Shallow Draft WaterGita Marina AhadyantiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Abstract Submission Gita MarinaDocument1 pageAbstract Submission Gita MarinaGita Marina AhadyantiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Paper ICSOT 3nov2015 PDFDocument6 pagesPaper ICSOT 3nov2015 PDFGita Marina AhadyantiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Wartsila Energyefficiency Presentation19sep08 WasisDocument69 pagesWartsila Energyefficiency Presentation19sep08 WasisGita Marina AhadyantiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Response-Based Metocean Criteria For The Optimization of Floating Production Facility For Marginal Oil Field at Java SeaDocument6 pagesResponse-Based Metocean Criteria For The Optimization of Floating Production Facility For Marginal Oil Field at Java SeaGita Marina AhadyantiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Altair 4X: Operating ManualDocument68 pagesAltair 4X: Operating ManualjackNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Master Deed SampleDocument29 pagesMaster Deed Samplepot420_aivan0% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- MSDS DimethylglyoximeDocument6 pagesMSDS DimethylglyoximeMia BarzagaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- For Golf Cars - Safety and Performance Specifications: ANSI/ILTVA Z130.1-2012Document34 pagesFor Golf Cars - Safety and Performance Specifications: ANSI/ILTVA Z130.1-2012Shahram GhassemiNo ratings yet

- Enclosed Space Entry and Rescue Drill PDFDocument15 pagesEnclosed Space Entry and Rescue Drill PDFKlemens Bonggo Suhartono100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- CAPSTONEDocument5 pagesCAPSTONETricia Maxine DomingoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- NOVOAIR - View Reservation ShiedDocument2 pagesNOVOAIR - View Reservation ShiedMd Abdur RahimNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Karl Fisher MSDSDocument6 pagesKarl Fisher MSDSmshabanero2359No ratings yet

- Kaye Manual Ctr-40Document83 pagesKaye Manual Ctr-40Juan Francisco Velazco DiazNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Material Safety Data Sheet (MSDS) Butane Please Ensure That This MSDS Is Received by An Appropriate PersonDocument3 pagesMaterial Safety Data Sheet (MSDS) Butane Please Ensure That This MSDS Is Received by An Appropriate Personmalaya tripathyNo ratings yet

- Msds CMC PDFDocument5 pagesMsds CMC PDFSitra AdnanNo ratings yet

- Code of Practice For Health and Safety in Dock Work PDFDocument84 pagesCode of Practice For Health and Safety in Dock Work PDFmanuelNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Inspection of and Leak Detection in Liquid Ammonia PipelinesDocument52 pagesInspection of and Leak Detection in Liquid Ammonia PipelinesPedro Juan Vergara Velez100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Script FinalDocument19 pagesScript FinalyetyetNo ratings yet

- Laser JetDocument140 pagesLaser Jetcarlos marNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Science-5 Quarter - 1 - Item Bank: Overview of Deped Mis and BeisDocument8 pagesScience-5 Quarter - 1 - Item Bank: Overview of Deped Mis and BeisChelleyOllitro100% (1)

- Product Overview: Ethylene Oxide Handling SafetyDocument3 pagesProduct Overview: Ethylene Oxide Handling Safetymanojkp33No ratings yet

- Fire Hand BookDocument35 pagesFire Hand BookManojkumar kondaveetiNo ratings yet

- Module2 Safety and R M 2017 FinalDocument19 pagesModule2 Safety and R M 2017 FinalvukNo ratings yet

- Gas Cylinder Rules 1981 PDFDocument50 pagesGas Cylinder Rules 1981 PDFRMK BrothersNo ratings yet

- HAAGEN Fire CatalogDocument52 pagesHAAGEN Fire CatalogForum PompieriiNo ratings yet

- Copressed Gas Cylinder HandlingDocument18 pagesCopressed Gas Cylinder HandlingWaelNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Cat Natural Gas Engine Oil (Ngeo) Advanced 40Document9 pagesCat Natural Gas Engine Oil (Ngeo) Advanced 40Nazrul IslamNo ratings yet

- Carquest Wearever Non Chlorinated Brake Parts Cleaner W7341 PDFDocument12 pagesCarquest Wearever Non Chlorinated Brake Parts Cleaner W7341 PDFYoutube For EducationNo ratings yet

- Hot Work Protocol 6 25 19Document24 pagesHot Work Protocol 6 25 19Victor EgharevbaNo ratings yet

- Fireworks Safety Data ReportDocument10 pagesFireworks Safety Data ReportClint MuscatNo ratings yet

- Long#2 (18) (GHS) MSDSDocument8 pagesLong#2 (18) (GHS) MSDSEduardo GarzaNo ratings yet

- Utv Gamma CF Moto 625Document135 pagesUtv Gamma CF Moto 625maximchacaNo ratings yet

- As 2359.2-1985 Industrial Trucks (Known As The SAA Industrial Truck Code) OperationDocument9 pagesAs 2359.2-1985 Industrial Trucks (Known As The SAA Industrial Truck Code) OperationSAI Global - APAC0% (1)

- W18ke00-Workshop Manual PDFDocument549 pagesW18ke00-Workshop Manual PDFRavinder SinghNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)