Professional Documents

Culture Documents

Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part48

Uploaded by

linghuchong0 ratings0% found this document useful (0 votes)

17 views4 pagesEmbedment length requirements in the current ACI Building Code (2) for the reinforcement are based on the hypothesis that the tension force T that can be developed in a bar is a function of the perimet er bond stresses uo, the perimeter of the bar to be developed Eo and the embedment length of the bar. The straight embedment length in order to develop a tension force of 32 kips is L = T / uoLo = 32 / (0.534)(3.53) = 17

Original Description:

Original Title

Proposed Design Procedures for Shear and Torsion in Reinforced and Prestressed Concrete Ramirez_part48

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEmbedment length requirements in the current ACI Building Code (2) for the reinforcement are based on the hypothesis that the tension force T that can be developed in a bar is a function of the perimet er bond stresses uo, the perimeter of the bar to be developed Eo and the embedment length of the bar. The straight embedment length in order to develop a tension force of 32 kips is L = T / uoLo = 32 / (0.534)(3.53) = 17

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part48

Uploaded by

linghuchongEmbedment length requirements in the current ACI Building Code (2) for the reinforcement are based on the hypothesis that the tension force T that can be developed in a bar is a function of the perimet er bond stresses uo, the perimeter of the bar to be developed Eo and the embedment length of the bar. The straight embedment length in order to develop a tension force of 32 kips is L = T / uoLo = 32 / (0.534)(3.53) = 17

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

173

The embedment length requirements in the current ACI Build ing

Code (2) for the reinforcement are based on the hypothesis that the

tension force T that can be developed in a bar is a function of the

perimet er bond stresses uo,the perimeter of the bar to be developed

Eo, and the embedment length of the bar such that

(4.27)

where the ultimate perime ter bond stress U

o

is a function of the

concrete strength ~ and the bar diameter db

(4.28)

For this design example U

o

is 9 5 ~ 1 1 2 5 = 534 psi, since T = 32

kips and LO for a 119 bar is 3.53 in. The required straight embedment

length in order to develop a tension force of 32 kips is

L = T/uoLo = 32/(0.534)(3.53) = 17" (4.29,)

Thus, the straight embedment length of 6" is not enough. Therefore, it

is necessar y to prov id e the 119 corner bar s at the bottom of the

reinforced concrete box beam with a standard 90 degree hook at the ends.

If a standard 90 degree hook in accordance with the requirements given

in the ACI Building Code (2) is provided, then the stress that can be

developed by the hook fh is

(4.30)

174

where k = 540 for #9 bar. Thus, fh = = 34 ksi. The

required stress is 32 kips divideJ by the area of a 119 bar (1 in.2) or

32 ksi. Hence, if a 90 degree standard hook is provided, the 32 kip

force would be adequately developed.

For the case of the 2 #8 compression bars only the 20 kip force

due to the presence of and torsion would have to be developed.

However, as illustrated in Sec. 2.2.2 of Report 248-2, due to the

presence of the compression fan in the support region no longitudinal

tension reinforcement is required due to the effects of shear in the top

compression face of the member within a distance [(ZLcota)/2] from the

centerline of the support. Thus, at the support region only that area

of longitudinal reinforcement required for torsion would have to be

developed to its full yield strength. From Eq. 4.24 taking Vn = 0, the

resultant area required only for torsion is

(4.31)

Thus, T = 0.11 (60) = 6.8 kips, Uo is given as 9.5 ,.foOO'0/1 = 601 psi and

L = T/uoLD = 6.8/(.601)(3.1415) = 3.60". Since it is a top bar Ld =

1.4(L) = (1.4)(3.6) = 5.0". The 6 in. straight embedment length

provided past the centerline of the support is then adequate to develop

the required tension force.

Finally, the anchorage of the top compression reinforcement has

to be evaluated at (zLcota)/2 = 6.5 in. from the centerline of the

support.

175

The area of longitudinal reinforcement required for shear and

torsion can be evaluated using Eq. 4.24, AL(T,V) =

[(176)(51.64)/4(166.7) + 51.3/2]/(2)(60) = 0.32 in.

2

, hence T =

(0.32)(60) = 19 kips. The compression force produced by the applied

moment can be evaluated using as C = T = Mu/z. Mu at a distance

zcot 12 from the centerline of the support is 289 in.-k, thus C = 289/12

= 24 kips. Therefore, the net resultant tension at the section is zero.

Therefore, the theoretical required embedment length would equal to

zero.

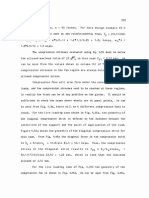

The final detailing of the longitudinal reinforcement at the

support region is shown in Fig. 4.27.

4.3.8 Design of the Reinforced Concrete Box Section Following

the ACI/AASHTO Design Procedure. In order to show the difference in

design procedures, the same example used in Section 4.3.7 is reworked

using current design procedures.

The first step in the design procedure is to evaluate the

magnitude of the torsional moment to find out if torsional effects can

be neglected. The ACI/AASHTO design procedure (1,2) states that torsion

effects shall be included with shear and flexure where the factored

torsional moment Tu exceeds (0.5 J ~ L: X

2

y). Otherwise, the torsion

effects may be neglected. In this design example Tu = 150 in.-kip and

~ = 4000 ps i. The term L: X

2

y represents the torsional section

properties, where x is the shorter overall dimension of the rectangular

part of the cross section and y is the longer overall dimension of the

retangu1ar part of the cross section. For this design example, x = y =

176

IS"

<l

I

3in.

.I

Sin.

I

25I

#S

I

16.1"

I

#9 corner bars

12 db =13.5"

bend diameter=Sdb =9"

~ r o ~ I

2.6" I

7\

",." ,." ,. ,. 777 /

Sin.

.,1

Fig. 4.27 Detailing of the longitudinpl reinforcement

at the support region

You might also like

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part22Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part22linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part17Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part17linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part12Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part12linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part14Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part14linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part23Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part23linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part7Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part7linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part20Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part20linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part19Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part19linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part21Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part21linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part18Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part18linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part15Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part15linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part16Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part16linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part10Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part10linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part13Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part13linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part9Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part9linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part4Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part4linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part11Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part11linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part8Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part8linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part2Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part2linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part5Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part5linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part3Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part3linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part6Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part6linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part61Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part61linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part67Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part67linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part1Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part1linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part60Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part60linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part66Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part66linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part68Document2 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part68linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part65Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part65linghuchongNo ratings yet

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part59Document4 pagesProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part59linghuchongNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Diagrame AburDocument4 pagesDiagrame AburhbcbmwtuningNo ratings yet

- Endogenic ProcessesDocument36 pagesEndogenic ProcessesShannel Kate NuñezNo ratings yet

- Corelation For Laboratory Test ParametersDocument36 pagesCorelation For Laboratory Test ParametersCEG BangladeshNo ratings yet

- Creep and Shrinkage Calculation Using The Model Code 1990: Benchmark Example No. 2Document8 pagesCreep and Shrinkage Calculation Using The Model Code 1990: Benchmark Example No. 2Sri RamNo ratings yet

- Failure Theories..Document93 pagesFailure Theories..adnanmominNo ratings yet

- Mechanical Properties of Mild Steel, Copper and Aluminum under Tensile TestingDocument9 pagesMechanical Properties of Mild Steel, Copper and Aluminum under Tensile TestingAdarsh BujadeNo ratings yet

- Course Title: Thermal System DesignDocument27 pagesCourse Title: Thermal System DesignhailemebrahtuNo ratings yet

- Psychrometry ProblemsDocument33 pagesPsychrometry Problems19R21A0334 MATTA SHASHANKNo ratings yet

- AsahimasDocument10 pagesAsahimasfirzaasaNo ratings yet

- Assignment 2 - 2023 - SolutionsDocument23 pagesAssignment 2 - 2023 - SolutionsLinhan ChuNo ratings yet

- Questoin Paper JEN Civil Diploma Exam 2016Document29 pagesQuestoin Paper JEN Civil Diploma Exam 2016erparshotamNo ratings yet

- Solar Water HeatingDocument2 pagesSolar Water HeatingCatherine Diccion LaciapagNo ratings yet

- Latihan Kelompok Mekanika Fluida Dan PartikelDocument2 pagesLatihan Kelompok Mekanika Fluida Dan PartikelrizkaNo ratings yet

- Cryogenic Piping DesignDocument19 pagesCryogenic Piping Designsatishchemeng80% (10)

- Properties of Air and Other GasesDocument52 pagesProperties of Air and Other GasesNereo SpenglerNo ratings yet

- IJETR041973Document5 pagesIJETR041973erpublicationNo ratings yet

- Design Calculation of Shock Absorber (Landcruiser) : AbstractDocument4 pagesDesign Calculation of Shock Absorber (Landcruiser) : AbstractDr. Aung Ko LattNo ratings yet

- Is800 2007Document2 pagesIs800 2007S S HARISHNo ratings yet

- ADDAX PETROLEUM HYDRAULIC PROGRAMDocument1 pageADDAX PETROLEUM HYDRAULIC PROGRAMAderobaki GbengaNo ratings yet

- From Boltzmann to Navier-StokesDocument7 pagesFrom Boltzmann to Navier-StokesDago EspañaNo ratings yet

- Nonlinear Analysis & Performance Based Design FundamentalsDocument86 pagesNonlinear Analysis & Performance Based Design FundamentalsvinujohnpanickerNo ratings yet

- CEC2017 After Revision Final VersionDocument9 pagesCEC2017 After Revision Final VersionAli GhavamiNo ratings yet

- ThesisDocument24 pagesThesisBiswajit GhoshNo ratings yet

- Chapter 5 Steam TurbineDocument13 pagesChapter 5 Steam TurbineHalil İbrahim KüplüNo ratings yet

- This Study Resource Was: Problem #1 A Sharp-Edge Orifice, 50 MMDocument6 pagesThis Study Resource Was: Problem #1 A Sharp-Edge Orifice, 50 MMJemuel FloresNo ratings yet

- SPE 106855 Phase Envelopes From Black-Oil Models: DefinitionsDocument9 pagesSPE 106855 Phase Envelopes From Black-Oil Models: DefinitionsEstefany Marcela DiazNo ratings yet

- 04 PDFDocument42 pages04 PDFAla ThajilNo ratings yet

- The Radiant Time Series Cooling Load Calculation ProcedureDocument14 pagesThe Radiant Time Series Cooling Load Calculation ProcedureNor Firdaus Yunus100% (1)

- TYPICAL STEEL - UB Design ReportDocument3 pagesTYPICAL STEEL - UB Design ReportHenry DiyokeNo ratings yet

- Lesson 4 - Heat TransferDocument16 pagesLesson 4 - Heat TransferJoanna Ruth SeproNo ratings yet