Professional Documents

Culture Documents

NV MSTP 269 Multi Shot Tubing Punch TM 235 c207 003 09 Manual

Uploaded by

Diana Carolina Rojas Torres0 ratings0% found this document useful (0 votes)

74 views22 pagesThe Multi-Shot Tubing Punch (MSTP) is a tubular hydro-mechanical device designed for use in coil tubing well intervention. Designed to punch-perforate a multiple number of holes into the well completion tubing, in one coiled tubing run. Typical applications for the MSTP :provide access to casing annulus to circulate or to kill a well; provide emergency annular communication for separated water injector wells; bring in additional productive zones.

Original Description:

Original Title

Nv Mstp 269 Multi Shot Tubing Punch Tm 235 c207 003 09 Manual

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Multi-Shot Tubing Punch (MSTP) is a tubular hydro-mechanical device designed for use in coil tubing well intervention. Designed to punch-perforate a multiple number of holes into the well completion tubing, in one coiled tubing run. Typical applications for the MSTP :provide access to casing annulus to circulate or to kill a well; provide emergency annular communication for separated water injector wells; bring in additional productive zones.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

74 views22 pagesNV MSTP 269 Multi Shot Tubing Punch TM 235 c207 003 09 Manual

Uploaded by

Diana Carolina Rojas TorresThe Multi-Shot Tubing Punch (MSTP) is a tubular hydro-mechanical device designed for use in coil tubing well intervention. Designed to punch-perforate a multiple number of holes into the well completion tubing, in one coiled tubing run. Typical applications for the MSTP :provide access to casing annulus to circulate or to kill a well; provide emergency annular communication for separated water injector wells; bring in additional productive zones.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 22

TM 235 C207-003-09

Coil Tubing Conveyed

Multi-Shot Tubing Punch System

Rev.0 Page 2 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

INTRODUCTION

The PCE Multi-Shot Tubing Punch (MSTP) is a tubular hydro-mechanical device designed for use in coil

tubing well intervention to punch-perforate a multiple number of holes into the well completion tubing, in one

coiled tubing run; eliminating the need for returning to surface for re-setting.

The PCE MSTP is designed to perforate standard and heavy wall tubing, primarily J 55, L80, API tubing.

(Special modifications may be required to punch certain light-weight J 55 type tubing).

DESCRIPTION

The MSTP comprises the following purpose built tool sections:-

A flow activated control valve.

A hydraulic ram assembly.

A mechanical punch assembly.

A hydraulic cycling indexing tool, considered optional, may also be added to the MSTP tool string.

Much testing has been carried out in the development of this tool system.

The tool sub-sections have been designed to function together in such a way that permits the MSTP to carry

out its hole punching operation in a controlled sequence of actuations.

DESIGN FEATURES

Enables multiple holes to be punched during a single coiled tubing run.

Available as standard for 2 3/8, 2 7/8, 3 & 4 production tubing. (Other sizes available on

request).

Field proven mechanical tubing punch mechanism.

Operates hydraulically via an integral control valve in order to complete the perforating cycle.

Incorporates a safety release mechanism.

APPLICATIONS

Typical applications for the MSTP :-

provide access to casing annulus to circulate or to kill a well;

provide annular communication for gaslift straddles;

open up the annulus for separated water injector wells;

provide emergency annular communication for SSD opening failures;

bring in additional productive zones;

permit production through plugged tail pipe that cannot be opened using regular methods;

permit cement squeeze operations.

Rev.0 Page 3 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

Rev.0 Page 4 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

OPERATION

The MSTP operates on the application of internal hydraulic flow/ pressure.

A Hydraulic Control Valve provides linear control to a Hydraulic Ram Assembly.

The MSTP may be operated and returned to its original state by the surface control of hydraulic flow/

pressure differential.

The Hydraulic Ram Assembly, which is connected to the Tubing Punch Mechanism*, creates the force

necessary to punch a hole in the tubing and for returning it ready for the next perforating cycle.

*The Hydraulic Ram Assembly is connected to the Punch Mechanism in two places:-

a) Two tangential shear pins connecting the Hydraulic Ram Body to the Punch Housing.

b) One linking shear pin connecting the Hydraulic Ram Piston to the Punch Body at the safety shear sub.

The force required to shear out these pins can be referred to in individual tool data sheets.

The field proven wireline type Tubing Punch Mechanism is adapted to provide consistent and reliable

punch cycling.

The MSTP is capable of repeating its punch-perforating cycle, without removal from the well.

GENERAL OPERATING DESCRIPTION

At low (circulating) flow/ pressure differential, the MSTP remains inoperative.

As flow/ pressure differential is further increased, the Hydraulic Control Valve switches flow/ pressure to the

Ram Assembly pistons, creating a force to move them upward.

The Ram Assembly pistons extend the Punch Mechanism body, thereby making the punch expand.

The punch expands sufficiently to first engage the tubing wall and then pass through the tubing wall.

This action also has the effect of maintaining an opposite force on the housing outside diameter, which helps

prevent axial movement of the tool-string during the perforating operation.

The surface controlled flow/ pressure is now reduced back to low (circulating) pressure. This has the effect of

switching back the flow/ pressure supply (via The Hydraulic Control Valve), to return the Ram Assembly

pistons, to their original position and retract the punch.

Punch Orienter (optional)

At this point, if the MSTP Orienter is installed in the toolstring*, the punch will have automatically indexed

ready for the next punching flow/ pressure cycle.

*The Orienter tool would normally be positioned above the Hydraulic Control Valve.

Alternatively, the toolstring may now be moved to another tubing location ready for the perforating cycle to

begin again.

Rev.0 Page 5 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

OPERATION (cont.)

Prior to running

Where possible, the production tubing location site for the hole punching operation should be depth

correlated. This will help ensure that holes are punched in clean tubing and not into a tubing collar.

Where possible, the MSTP should be surface tested with similar tubing to that installed in the well, prior to

running in hole. Refer to Function Testing below.

The MSTP should be run in conjunction with a standard PCE coiled tubing bottom hole assembly; including a

twin flapper check valve and drop-ball disconnect).

A PCE mechanical or hydraulic jar can be included in the tool string.

A downhole screen or filter is recommended to keep debris from the hydraulic control valve.

Running

Refer to System Technical Data*

Whilst running in hole, normal circulation can be maintained.

At low (circulating) flow/ pressure differential, the perforator remains inoperative.

When the perforating depth is reached, to start the hole punching cycle, the circulating flow/ pressure

differential must be gradually increased to the MSTP operating pressure*.

Operating Pressure Note.

The differential pressure required for the MSTP to punch the hole varies according to the size of the

perforator being run and the weight per foot / material grade of production tubing being perforated.

Hole Punching

As flow/ pressure differential is further increased, the Hydraulic Control Valve switches flow/ pressure to The

Ram Assembly pistons, creating a force to move them upward and so extend the tubing punch.

The tubing punch, extends sufficiently to first engage the tubing wall and then pass through the tubing wall.

This action also has the effect of maintaining an opposite force on the tubing punch serrated housing, which

helps prevent axial movement of the tool-string during the perforating operation.

Operating pressure must be maintained until the tubing punch ruptures through the tubing.

The internal coiled tubing pressure is now reduced back to low (circulating) pressure. This has the effect of

switching back the flow/ pressure supply (via The Hydraulic Control Valve), to return the pistons to their

original position and retract the tubing punch.

The tool-string may now be moved to another tubing location ready for the perforating cycle to begin again.

Surface Indications Note.

Surface indications that the MSTP has perforated the tubing or casing will be:-

1) A tubing pressure drop will seen at surface.

2) An annular pressure gain or loss may be seen on the first punch, as circulation is established.

Rev.0 Page 6 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

Typical Multi-shot perforator operating sequence.

1. Start circulating through tools.

2. Increase pressure to 500psi.

3. Indexing tool rotates.

4. Increase pressure to 1000 psi.

5. low pressure side of control valve closes.

6. High pressure side of control valve opens.

7. Perforator punches hole.

8. Surface indication of tubing punched.

9. Stop pumping

10. High pressure control valve closes.

11. low pressure control valve opens.

12. Punch retracts into body.

13. Indexing tool piston returns ready to start next cycle.

14. Repeat procedure if indexing around the same plain.

15. If moving to new position keep pressure at 0 psi and pick up or set down.

Note:

This is a typical procedure for the Perforating system. The flow rates may vary slightly but

it is recommended that these should be kept to a minimum to reduce seal wear.

Rev.0 Page 7 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

Control Valve Operation.

The Flow Separation Control Valve provides flow control to the Multi-Shot Tubing Punch Hydraulic Ram

Assembly.

The Flow Separation Control Valve is designed to separate one main fluid supply into two distinct flow paths,

one operating at a low differential pressure (Low Dp.), the other at a higher differential pressure (High Dp.).

At low Dp., the Flow Separation Control Valve supplies fluid to the Hydraulic Ram Assembly and acts to

retract the Tubing Punch. Therefore whilst being run into the well, the Multi-Shot Tubing Punch, during low

Dp. fluid circulation, is normally retracted.

At high Dp., the Flow Separation Control Valve supplies fluid to the Hydraulic Ram Assembly and acts to

extend theTubing Punch.

If the flow is then reverted to low Dp, the Tubing Punch will automatically retract.

Description

Low Dp. The effective piston area upon which the pressure acts, creates a force against the resistance of a

stack of disc springs item (17), compressing said springs, until the nose (13) closes against the choke sub

(9) thereby closing the circulation path to the chamber and activating piston below the valve. The pressure at

which the valve operates is field adjustable by placing an O ring item (16 or 26) in one of the two positions

on the piston. Only one O ring should be installed at any given time.

High Dp. Once the Low Dp. has closed, the flow and pressure is concentrated on the check valve side of the

tool, which opens at its pre-set pressure, supplying the opposite side of the activating piston below, causing

the piston to traverse in its bore. The pressure at which the check valve operates is field adjustable by the

addition of a spring spacer.

Any adjustments should include both the High Dp & Low Dp valve configuration.

When the flow and pressure is reduced, the check valve closes, sealing the flow path to the lower side of the

piston.

As the Low Dp. piston to returns, under spring pressure to its start position, the fluid path to the activating

piston opens and returns said piston to its start position.

It is the responsibility of the individual or company running this device to ensure the down hole differential at

the tool can be achieved.

Recommendation

It is recommended that the Control Valve is stripped after each operation and all seals inspected and

replaced as necessary.

During operation the volume should not exceed 1BBl/min for best performance of the Valve.

Rev.0 Page 8 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

Dis-assembly

1. Break out Top sub (1) from Outer body (2).

2. Using gravity, invert the Body so the Top sub thread connection is lowermost and give a sharp tap on a

suitable surface (wood).

3. The inner assemblies can now be separated into individual items.

4. The Nose (13) is threaded to the Piston (12).

Assembly

1. Assemble Disc springs (17) to Piston (12).

2. Fit Oring (20) to thread on Nose (13) and make up the Piston (12) capturing the Disc springs (17).

3. All other Orings can be now fitted, selecting the preferred Oring (16 or 26) for the Piston.

4. Fit Choke sub (9) to Nose body (6).

5. Assemble Nose body (6) with Choke sub (15) to Piston (12), Disc springs and Nose. Insert Piston (12),

Disc springs and Nose into Upper insert (5)

6. Fit Valve seat (14) into Inner Body (7) and secure with set screws (15).

7. Assemble into Inner Body (7) Check valve body (8) spring spacer (10) and Coil spring (11)

Rev.0 Page 9 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

8. Make up Seal sub (28) with Slipper seal (21) to Fluid separation sub (3) and connect to Fluid separation

body (4) locate Alignment pins (33) into face holes of Fluid separation sub (3).

9. Locate Inner body (7) Check valve body (8) etal, onto Alignment pins (33) in face of Fluid separation sub

(3).

10. Insert Nose body (6) with Choke sub (9) onto Inner body (7).

11. Make up Outer body (2) to Fluid separation sub (3).

12. Make up Top sub (1) to Outer Body (2) to complete assembly.

Note

After every operation in the tool should be stripped, thoroughly cleaned and be re-assembled with new O

rings and when necessary disc springs.

Rev.0 Page 10 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

SURFACE FACTORY SETTINGS

CONTROL VALVE 3.5

E

B C

D F

A

A: 1.125 PISTON

B: 18 CARBON DISC SPRINGS

C: NO CHOKE FITTED

D: COIL SPRING C/W SPACER

E: 0.25 CHOKE FITTED

F: IF PORT PRE-DRILLED, BLANK CHOKE FITTED

Rev.0 Page 11 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

HYRAULIC RAM ASSEMBLY 3.5

G

I

H

G: .187 CHOKE FITTED

H: .4375 MILD STEEL PIN FITTED

I : 2 X 0.125 MILD STEEL TAMNGENTIAL PINS FITTED

Rev.0 Page 12 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

HYDRAULIC RAM ASSEMBLY

NOTE: Make sure parts are clean, in good working order, are lightly oiled and work freely. Seals should be

greased prior to assembling. Particular attention should be paid to the condition of the hydraulic cylinder

bores and piston mandrels. They should be straight and free of wear or score marks. Also, o-ring seals

should be closely inspected to make sure they are free from cuts.

1. Assemble the Punch Mechanism as per instructions above.

2. Screw Shear Sub (5) to the top male thread connection on the Punch Mechanism.

3. Fit all o-rings and backup rings (12, 13, 14, 15, 16) and lubricate using molybdenum grease.

4. Take Lower Body (4) and hold in a suitable vice.

5. Fit Plug (17) into Connector Mandrel (10).

6. Push Connector Mandrel (10) through Lower Body (4) and turn until the assembly holes in each part

align. Put a 3/8 diameter screwdriver or similar pin punch through the hole to temporarily retain the two

parts.

7. Screw Lower Piston (9) onto the Connector Mandrel (10) using spanner flats provided.

8. Screw Connector Sub (6) into the Middle Body (3) at the port holed end. Slide this assembly over the

Lower Piston (9) and screw onto the Lower Body (4).

9. Screw Piston Mandrel (8) to Upper Piston (7). Then screw the Upper Piston (7) onto the protruding

thread of the Lower Piston (9).

10. Slide the Upper Body (2) over the Upper Piston (7) and screw onto the Connector Sub (6).

11. Withdraw the screwdriver from the hole and push Piston (4) down so that the Connector Mandrel (5)

shear pin holes align with the slots in the Lower Body (3).

Rev.0 Page 13 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

ASSEMBLY (cont.)

12. Take the Control Valve, (previously assembled), and screw it into the end of the Upper Body (2).

13. Take the Punch Mechanism and slide it into the end of the Lower Body (4). The Shear Sub (5) should

locate into the end of the Connector Mandrel (10). Turn the Connector Mandrel (10), through the slots in

the Lower Body (4), so that the shear-pin holes in it align with the hole in the Shear Sub (5). Fit the

Shear Pin (19) and lock it by fitting the Locking Screw (18), again, through the slot in the Lower Body (4).

14. Align the tangential grooves in the Punch Mechanism Body with the mating holes in the Lower Body (4).

Fit the tangential pins (20).

Rev.0 Page 14 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

Mechanical Tubing Punch

INTRODUCTION

The PCE Mechanical Tubing Punch assembly provides the punching mechanism for the Coiled Tubing Multi-

shot Tubing Punch System.

This established mechanism is a variant of the field proven Wireline Tubing Punch which has seen

successful service for many years.

The PCE Mechanical Tubing Punch is designed to be coupled to the Multi-Shot Hydraulic Ram Assembly,

which supplies power to the punching mechanism.

The PCE Mechanical Tubing Punch is capable of punching through most weights 2 3/8, 2 7/8, 3 & 4

API tubing in grades J 55, L80 & P110.

DESCRIPTION

The PCE Mechanical Tubing Punch assembly consists of the following main parts:- a body , a tubing punch,

a punch holder and a housing.

The tubing punch is located within a tapered track in the body and is retained by the punch holder. This

punch mechanism is positioned in a housing which has gripping serrations machined on its outside diameter.

The serrated section of the housing helps keep the perforator securely in position in the tubing as the punch

drives through the tubing.

The PCE Mechanical Tubing Punch is coupled to the Multi-Shot Hydraulic Ram Assembly in two places:-

1) Dual tangential pins tying the Hydraulic Ram Body to the Punch Housing.

2) A single shear pin tying the Hydraulic Ram Arm to the Punch Body.

These pins enable the Mechanical Tubing Punch to function with the other system tools that make up the

PCE Multi-Shot Tubing Punch as a single unit.

They also enable, in the event of an emergency, the ability to disconnect the Mechanical Punch from the

remainder of the coiled tubing tool-string.

The PCE Mechanical Punch has an external fishing neck allowing it to be fished using conventional fishing

tools.

OPERATION

As hydraulic pressure is fed to the Hydraulic Ram, the tubing punch body automatically strokes, extending

the tubing punch into the tubing.

Once the punch has been driven through the tubing, pump flow/ pressure is reduced in order to reverse the

Hydraulic Ram and therefore retract the tubing punch, ready for the another cycle.

Rev.0 Page 15 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

DISASSEMBLY

To disassemble the PCE Mechanical Punch Perforator for cleaning, inspection, and repairs, follow the steps

listed below:

1) Remove Shear Pins (2) and (11).

2) Remove Set Screw (10) and Dowel Pin (6).

3) Body (1) and Punch Holder (3) can now be removed from the housing (6). If Catch (7) stops in the

upper port whilst removing parts from the Housing, depress slightly with adjustable tool.

4) Remove Catch (7) and Spring (8) form the Body (1).

5) To disassemble the Body (1) and Punch holder (3) pry apart using a screw driver until the Bushing

(6) comes free from the Punch (5) and can be removed. Remove Punch from the Body by sliding it

to the lower most position. Remove Bush (4).

ASSEMBLY

1) Attach Punch (5) to Body (1) at the lower most position and slide up along the incline. Assemble

Bush (4) with split face up in the Body (1).

2) Assemble the Body (1) and the Punch Holder (3) by loading the Punch (5) over the Bushing and

using a Soft Headed Hammer to force Punch into Bush (4).

3) Place Catch (7) and Spring (8) into Body (1) and slide assembly into Housing (6). If Catch stops in

upper port whilst locating in Housing depress slightly with a suitable tool. 4) Insert Dowel Pin (9)

and tighten Set Screw (10).

4) Insert Shear pins (2) and (11).

MAINTAINANCE

NOTE: Make sure parts are clean, in good working order, are free of burrs and work freely. Particular

attention should be paid to the Housing serrated section, making sure the serrations are clean and sharp.

The tapered track within the Body should be clean, unrestricted and thoroughly greased.

The punch face should be closely inspected to make sure it is straight and the cutting edge sharp. It is

possible to reface the punch within the minimum punch length guidelines.

The base of the punch is surface coated to allow a smooth transition along the body track whilst under load.

It should be checked for smearing and possible recoating. Serious wear will reduce the effectiveness of the

Punch.

Rev.0 Page 16 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

TROUBLE-SHOOTING

If there is no surface indication that the MSTP has perforated the tubing the operating sequence should be

repeated a further 3 cycles.

If still no surface indication, the tool-string should be removed from the well.

If a resistance load is seen during this operation, the operator should revert to manual over-ride

Manual Over-ride

As mentioned earlier, the Hydraulic Ram Assembly is shear pinned to the Punch Mechanism as follows:-

Two tangential shear pins connecting the Hydraulic Ram Body to the Punch Housing.

One link shear pin connecting the Hydraulic Ram Piston to the Punch Body at the safety shear sub.

(The force required to shear out these pins can be referred to in individual tool data sheets).

If the tool-string remains stuck, by over-pulling a set amount (ref technical data sheet) the tangential release

shear pins will break.

This, in effect, converts the MSTP to manual over ride.

Over-pull will stroke the Hydraulic Ram manually, and should continue to extend the punch to finish the hole

punching and then allow the tool-string complete to be removed from the well.

Emergency Release

If the MSTP still fails to release itself , continuation of an overpull to the set amount (ref technical data

sheet), will break the link shear pin, linking the hydraulic ram to the tubing punch.

This will enable the retrieval of the MSTP BHA , leaving the Tubing Punch behind.

The released Tubing Punch that remains in the well has an external fishing neck looking up and can be

retrieved using standard pulling/ fishing tools.

During the fishing of the Tubing Punch, once latched, the operator can complete the punching operation by

jarring up. However, the punch will only retract when the punching operation is completed.

If the operator cannot complete the punching operation, he can abort it by jarring down.

This will lock out the Punch Body into the abort position. In this position the punch is retracted and the tool

string may be retrieved.

Rev.0 Page 17 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

PRESSURE CONTROL ENGI NEERI NG PRODUCT DATA SHEET

____________________________________________________________________________

| Pr od No: C103- 028 Rev: 0 ( 17 Dec 02) Dr g No: C103- AS- 01 S |

| TUBI NG PUNCH 3 1/ 2" |

| MULTI SHOT TUBI NG PUNCH Si ze Ref : 3 1/ 2" |

| ____________________________________________________________________________|

| Max O. D: 2. 690" | Fi sh Neck: 2. 313" | Ser vi ce: |

| Mi n I . D: | Top Con: 1 1/ 16- 10 P | ________________|

| Lengt h: 30" | Lower Con: NA | Wei ght : 16. 0|

| Ot her : | Ot her : | ( Kg) |

| __________________________| ________________________________| ________________|

| W. Pr ess: | W. Tensi l e: 50000 LB | Tech Manual |

| T. Pr ess: | Cal c Tens: 76300 LB | |

| | Ot her P/ L: | TM- 007 |

| __________________________| ________________________________| ________________|

| Not es: FOR 3 1/ 2" TUBE #7. 70 #9. 20 #10. 2 #12. 70 |

| STROKE 14. 72" HOLE PUNCH 7/ 16" DI A |

| PUNCH EXTENDED 3. 344" |

| ____________________________________________________________________________|

____________________________________________________________________________

| I t em| Qt y| Par t No Rev | Descr i pt i on | Spar e |

| ____| ____| ______________| ______________________________________| ____________|

| 1 | 1 | 00- 05340 A| BODY | |

| 2 | 1 | FXP0- 094 0| PI N | KS |

| 3 | 1 | 00- 05341 0| PUNCH HOLDER | |

| 4 | 1 | 00- 05345 A| BUSH | KR |

| 5 | 1 | 00- 05343 B| PUNCH | KR |

| 6 | 1 | 00- 30005 0| HOUSI NG | |

| 7 | 1 | 00- 05346 0| CATCH | |

| 8 | 1 | MSS0- 211 A| COI L SPRI NG | KR |

| 9 | 1 | 00- 05344 0| DOWEL PI N | KR |

| 10 | 1 | FSH7- 027 | HEX SOCKET SET SCREW | KS |

| 11 | 1 | FXP0- 038 | PI N | KS |

| 12 | 1 | 00- 29710 0| BULL NOSE BOTTOM SUB | |

| ____| ____| ______________| ______________________________________| ____________|

Recommended Spar es: KS ( Gener al Spar es Ki t ) KR ( Ot her Recommended Spar es)

Rev.0 Page 18 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

Rev.0 Page 19 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

PRESSURE CONTROL ENGI NEERI NG PRODUCT DATA SHEET

____________________________________________________________________________

| Pr od No: C103- 014 Rev: 0 ( 17 Dec 02) Dr g No: C103- AS- 17 |

| HYDRAULI C RAM ASSEMBLY 3 1/ 2" |

| MULTI - SHOT TUBI NG PUNCH Si ze Ref : 3 1/ 2 |

| ____________________________________________________________________________|

| Max O. D: 2. 650 | Fi sh Neck: NA | Ser vi ce: |

| Mi n I . D: . 39 | Top Con: 2 7/ 16- 12UN BOX | ________________|

| Lengt h: 51. 9 | Lower Con: 1 1/ 16- 10 UN BOX | Wei ght : |

| Ot her : NA | Ot her : | ( Kg) |

| __________________________| ________________________________| ________________|

| W. Pr ess: 1600PSI OPERATE | W. Tensi l e: 23000LB SAFETY | Tech Manual |

| T. Pr ess: 5000 PSI | Cal c Tens: RELEASE | |

| | Ot her P/ L: 13KPSI I N. YI ELD | TM- 119. 2 |

| __________________________| ________________________________| ________________|

| Not es: BRASS TAN. SHEAR PI NS TO RETRACT PERFORATOR= 8000LB OVERPULL |

| OPERATI NG PRESSURE 1600- 2000 PSI |

| |

| ____________________________________________________________________________|

____________________________________________________________________________

| I t em| Qt y| Par t No Rev | Descr i pt i on | Spar e |

| ____| ____| ______________| ______________________________________| ____________|

| 2 | 1 | 00- 30010 0| UPPER BODY- MULTI - SHOT PERF | |

| 3 | 1 | 00- 30009 A| MI DDLE BODY- MULTI - SHOT PERF | |

| 4 | 1 | 00- 30003 0| LOWER BODY- MULTI - SHOT PERF | |

| 5 | 1 | 00- 20577 A| SHEAR SUB | |

| 6 | 1 | 00- 30015 0| CONNECTOR SUB | |

| 7 | 1 | 00- 30013 0| PI STON UPPER- MULTI - SHOT PERF | |

| 8 | 1 | 00- 30012 A| PI STON MANDREL, MULTI - SHOT PERF | |

| 9 | 1 | 00- 30016 0| LOWER PI STON- MULTI - SHOT PERF | |

| 10 | 1 | 00- 30014 A| C' NCTR MANDREL MULTI - SHOT PERF | |

| 11 | 3 | HV04- 034 | O- RI NG | KS |

| 12 | 2 | P0- 17982 0| SLI PPER SEAL | KS |

| 13 | 2 | 00- 29898 0| LOAD BEARI NG GUI DE TAPE | KS |

| 14 | 2 | P0- 17998 0| SLI PPER SEAL | KS |

| 15 | 2 | 00- 30021 0| LOAD BEARI NG GUI DE TAPE | KS |

| 16 | 1 | HV03- 023 | O- RI NG | KS |

| 17 | 1 | FEH8- 002 | PLUG - HEX SOCKET | KS |

| 18 | 1 | FSH7- 025 | HEX SOCKET SET SCREW | KS |

| 19 | 1 | FXP0- 051 | PI N | KS |

| 20 | 2 | FZP0- 007 | PI N | KS |

| ____| ____| ______________| ______________________________________| ____________|

Recommended Spar es: KS ( Gener al Spar es Ki t ) KR ( Ot her Recommended Spar es)

Rev.0 Page 20 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

Rev.0 Page 21 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

PRESSURE CONTROL ENGI NEERI NG PRODUCT DATA SHEET

____________________________________________________________________________

| Pr od No: C180- 024- 09 Rev: B ( 20 J an 03) Dr g No: C180- AS- 09 |

| FLOWSEPARATI ON CONTROL VALVE |

| FOR USE WI TH HYD PERFORATOR Si ze Ref : 3 1/ 2 |

| ____________________________________________________________________________|

| Max O. D: 2. 65 | Fi sh Neck: | Ser vi ce: STD |

| Mi n I . D: | Top Con: 1 1/ 2 AMMT BOX | ________________|

| Lengt h: 26" | Lower Con: 2 7/ 16- 12UN PI N | Wei ght : |

| Ot her : | Ot her : | ( Kg) |

| __________________________| ________________________________| ________________|

| W. Pr ess: 5000 PSI | W. Tensi l e: 85, 000 LBS | Tech Manual |

| T. Pr ess: | Cal c Tens: | |

| | Ot her P/ L: | TM- 235. 1 |

| __________________________| ________________________________| ________________|

| Not es: LOWDp VALVE OPENS 600 OR 1050 PSI SELECT O' RI NG |

| HI GH Dp VALVE OPENS 1300 PSI OR 1500 PSI |

| |

| ____________________________________________________________________________|

____________________________________________________________________________

| I t em| Qt y| Par t No Rev | Descr i pt i on | Spar e |

| ____| ____| ______________| ______________________________________| ____________|

| 1 | 1 | 00- 30027 0| UPPER CONNECTI ON | |

| 2 | 1 | 00- 30028 A| OUTER BODY | |

| 3 | 1 | 00- 30029 B| FLUI D SEPARATI ON SUB | |

| 4 | 1 | 00- 30030 B| FLUI D SEPARATI ON BODY | |

| 5 | 1 | 00- 30031 0| UPPER I NSERT | |

| 6 | 1 | 00- 30948 0| NOSE BODY | |

| 7 | 1 | 02- 30884 A| I NNER BODY ( 1 PI ECE) | |

| 8 | 1 | 00- 30674 0| CHECK VALVE BODY | KR |

| 9 | 1 | 00- 30947 0| CHOKE SUB | KR |

| 10 | 1 | 00- 30952 0| SPRI NG SPACER | KR |

| 11 | 1 | MSS0- 577 0| COI L SPRI NG | KR |

| 12 | 1 | 02- 30759 0| PI STON | KR |

| 13 | 1 | 00- 30760 A| NOSE | KR |

| 14 | 1 | 00- 30883 A| VALVE SEAT 0. 375 | KR |

| 15 | 2 | FSH7- 038 0| HEX SOCKET SET SCREW | KS |

| 16 | 2 | HV02- 026 | O- RI NG | KS |

| 17 | 18 | MSS0- 434 0| DI SC SPRI NG | KR |

| 18 | 3 | HV03- 047 | O- RI NG | KS |

| 19 | 1 | HV04- 034 | O- RI NG | KS |

| 20 | 2 | HV02- 018 | O- RI NG | KS |

| 21 | 1 | P0- 49007 0| SLI PPER SEAL | KS |

| 22 | 1 | 00- 31409 0| BACK UP RI NG ( PEEK) | KS |

| 23 | 1 | HV03- 016 | O- RI NG | KS |

| 24 | 1 | HV03- 026 | O- RI NG | KS |

| 25 | 0 | SEE I TEM 16 | I NCLUDED I N I TEM 16 | |

| 26 | 3 | HV02- 028 | O- RI NG | KS |

| 27 | 2 | HV03- 020 | O- RI NG | KS |

| 28 | 1 | 02- 30738 A| SEAL SUB | |

| 29 | 1 | HV03- 023 | O- RI NG | KS |

| 30 | 2 | BU03- 023 | SEAL BACKUP RI NG | KS |

| 31 | 2 | MV03- 047 0| O- RI NG | KS |

| 33 | 2 | FXP0- 035 | PI N | KS |

| ____| ____| ______________| ______________________________________| ____________|

Recommended Spar es: KS ( Gener al Spar es Ki t ) KR ( Ot her Recommended Spar es)

Rev.0 Page 22 of 22 TM 235 Multi-Shot Tubing Punch System

Pressure Control Engineering Tel: +44 0 1202 631817 - Fax: +44 0 1202 631708 - E-Mail: sales@pce.co.uk

You might also like

- CHAMP® XHP PackerDocument2 pagesCHAMP® XHP PackerservicemenruNo ratings yet

- TopTools Catalog 20170906Document49 pagesTopTools Catalog 20170906JoséManuelOvandoNo ratings yet

- Collect Accurate HP/HT Reservoir Samples: Production OptimizationDocument2 pagesCollect Accurate HP/HT Reservoir Samples: Production OptimizationAngel GuamánNo ratings yet

- Gryphon Product OverviewDocument51 pagesGryphon Product OverviewTaras ByloNo ratings yet

- M60es54 Na549y QC Man 001Document29 pagesM60es54 Na549y QC Man 001Riski Kurniawan67% (3)

- Full Flow Type Reverse Circulation Junk Basket: Instruction Manual 3105Document10 pagesFull Flow Type Reverse Circulation Junk Basket: Instruction Manual 3105Foros IscNo ratings yet

- Casing Cutting Procedure - WFDDocument5 pagesCasing Cutting Procedure - WFDprateek132106No ratings yet

- Casing Head Housings 01Document1 pageCasing Head Housings 01arianaseriNo ratings yet

- Ubsurface Lickline Ools S S TDocument2 pagesUbsurface Lickline Ools S S Tbreynner100% (1)

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDocument8 pagesBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNo ratings yet

- 2 Bridge PlugsDocument9 pages2 Bridge PlugsaaaNo ratings yet

- DST Slip Joint PDFDocument8 pagesDST Slip Joint PDFcrni rokoNo ratings yet

- Thread Make-Up ProcedureDocument5 pagesThread Make-Up ProcedureVova PanchenkoNo ratings yet

- Petroline RNQN Standing ValveDocument16 pagesPetroline RNQN Standing Valveabbas1368No ratings yet

- Arrow Set Ficha TecnicaDocument3 pagesArrow Set Ficha TecnicaOscar GuaricalloNo ratings yet

- NCS SpotFrac Saves Troubled Flossie Lake Horizontal CompletionDocument9 pagesNCS SpotFrac Saves Troubled Flossie Lake Horizontal CompletionMauro LozanoNo ratings yet

- M60es44 NX449L Man 001Document24 pagesM60es44 NX449L Man 001Riski KurniawanNo ratings yet

- CT WKM Powrseal GateDocument28 pagesCT WKM Powrseal GatemoonanbuNo ratings yet

- Texas Oil Tools: Packer Inserts & EnergizersDocument12 pagesTexas Oil Tools: Packer Inserts & Energizersshahrol effendy rodziNo ratings yet

- C200-019-23 TM-210.1 2.875 Motorhead AssemblyDocument13 pagesC200-019-23 TM-210.1 2.875 Motorhead AssemblysamanNo ratings yet

- WPCE Venting-Glycol Injection ValveDocument1 pageWPCE Venting-Glycol Injection ValveMARIONo ratings yet

- Drilltech Services (USA) Inc: Spiro-TorqDocument10 pagesDrilltech Services (USA) Inc: Spiro-TorqDante Cabrera GuzmanNo ratings yet

- PB Valve Brochure - 243Document11 pagesPB Valve Brochure - 243Nwakile Chukwuebuka100% (1)

- 1PackerSystem PackerAccessories&tools PDFDocument21 pages1PackerSystem PackerAccessories&tools PDFAnand aashishNo ratings yet

- M60eh44 Man 001Document40 pagesM60eh44 Man 001Riski KurniawanNo ratings yet

- Hydraquaker: Hydraulic Drilling Jar Delivers High ImpactDocument4 pagesHydraquaker: Hydraulic Drilling Jar Delivers High ImpactPavin PiromNo ratings yet

- Norris Polished Rods (P004-V02-072208) - 1Document5 pagesNorris Polished Rods (P004-V02-072208) - 1Rodrigo RuizNo ratings yet

- Rupture Disk FUL-FLO Sampler: HalliburtonDocument2 pagesRupture Disk FUL-FLO Sampler: Halliburtonsaeed65No ratings yet

- Drill Stem Testing RD Sampler: SmartstarDocument1 pageDrill Stem Testing RD Sampler: SmartstarDenier RubianoNo ratings yet

- PPS Catalogue 2016v4 (English)Document44 pagesPPS Catalogue 2016v4 (English)Kamry AhmadNo ratings yet

- Coiled Tubing Pressure Control CapabilitiesDocument8 pagesCoiled Tubing Pressure Control CapabilitiesGuido100% (1)

- DL Bop BrochureDocument4 pagesDL Bop BrochureIRWIN_DSOUZANo ratings yet

- D&L Double Grip Pkr-Asi-Xpacker1c PDFDocument2 pagesD&L Double Grip Pkr-Asi-Xpacker1c PDFMoh Syamsul BahriNo ratings yet

- CPST Pressure Setting Tool PDFDocument1 pageCPST Pressure Setting Tool PDFmahsaNo ratings yet

- Technical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Document16 pagesTechnical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Riski KurniawanNo ratings yet

- Botil Model BTCN Mechanical Set PackerDocument2 pagesBotil Model BTCN Mechanical Set PackerReivaj JavierNo ratings yet

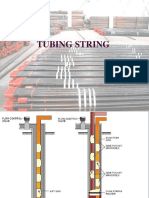

- Tubing StringDocument32 pagesTubing StringKAORU AmaneNo ratings yet

- RB2 Standing Valve Parts and Sizes GuideDocument3 pagesRB2 Standing Valve Parts and Sizes GuideLuis ChavarroNo ratings yet

- Powerstroke Drilling Jar: Instruction Manual 4250Document24 pagesPowerstroke Drilling Jar: Instruction Manual 4250Foros IscNo ratings yet

- TIC CatalogDocument424 pagesTIC Catalogmglsite1No ratings yet

- Seal Bore Packer System - RetrievableDocument8 pagesSeal Bore Packer System - RetrievableFabio ParceroNo ratings yet

- Casing Cup TesterDocument3 pagesCasing Cup TesterWei ShangNo ratings yet

- Well-Vac v.2 2-18Document133 pagesWell-Vac v.2 2-18Nerymar Coromoto Parra BustamanteNo ratings yet

- Series 150 Overshots: Instruction Manual 1150Document25 pagesSeries 150 Overshots: Instruction Manual 1150Ragui StephanosNo ratings yet

- Top-Co - AutoFill - BV & HF ValvesDocument4 pagesTop-Co - AutoFill - BV & HF ValvesJuan LacorteNo ratings yet

- Black Max Downhole Motors PDFDocument52 pagesBlack Max Downhole Motors PDFGeorge BoafoNo ratings yet

- A Series Tubing StopDocument1 pageA Series Tubing StopFabio ParceroNo ratings yet

- DSQ4 10M SidedoorDocument15 pagesDSQ4 10M SidedoorДудла СтаніславNo ratings yet

- 1887 125HP Union TD 120 Triplex Sour Pump PackageDocument11 pages1887 125HP Union TD 120 Triplex Sour Pump PackageIvan Jojic100% (1)

- Choke Manifold JHCDocument31 pagesChoke Manifold JHCahouaNo ratings yet

- Pressure Independent Control ValveDocument12 pagesPressure Independent Control Valvekya_leyNo ratings yet

- Well PreparationDocument16 pagesWell PreparationfarajNo ratings yet

- Water Hammer ReferenceDocument5 pagesWater Hammer ReferenceAmit SawantNo ratings yet

- 4.oil Hydraulic Circuit Trainer KitDocument13 pages4.oil Hydraulic Circuit Trainer KitAlmas 1710No ratings yet

- Application Note: Improving Primary Pumping in Pri/Sec. Pumping SystemsDocument5 pagesApplication Note: Improving Primary Pumping in Pri/Sec. Pumping SystemsJose David SanchezNo ratings yet

- Downwhole Deployment Valve Specification - (CNPC) Option1Document13 pagesDownwhole Deployment Valve Specification - (CNPC) Option1RobertNo ratings yet

- Grundfos BMQE Constant Pressure System Product GuideDocument48 pagesGrundfos BMQE Constant Pressure System Product GuidealbertoNo ratings yet

- New Choke Controller For Managed Pressure DrillingDocument8 pagesNew Choke Controller For Managed Pressure Drillingermaiez100% (1)

- Triple Screw PumpsDocument2 pagesTriple Screw PumpsSaravanan SelvaNo ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- S600P Slag Hauler Parts ManualDocument133 pagesS600P Slag Hauler Parts ManualAdi PutraNo ratings yet

- 11yz61180199 (SSRD180)Document229 pages11yz61180199 (SSRD180)Thein Htoon lwin0% (1)

- Hydraulic Excavator: - 5G - 5G - 5G - 5GDocument13 pagesHydraulic Excavator: - 5G - 5G - 5G - 5Gnugraha kurniawanNo ratings yet

- Catalogo Vedações TrelleborgDocument536 pagesCatalogo Vedações TrelleborgFabio CarrascoNo ratings yet

- Oilgear Type "PVG" Pumps 150 (SERIES A1) Service InstructionsDocument28 pagesOilgear Type "PVG" Pumps 150 (SERIES A1) Service InstructionsAngel Mendoza RodríguezNo ratings yet

- Owners Manual for Auto Crane 4004EH CraneDocument61 pagesOwners Manual for Auto Crane 4004EH CraneAdamNo ratings yet

- Pneumatic AutomationDocument3 pagesPneumatic AutomationLuis MoreiraNo ratings yet

- CPP ReportDocument34 pagesCPP Reporthash electrolabsNo ratings yet

- Review and Development Trend of Digital HydraulicDocument30 pagesReview and Development Trend of Digital HydraulicalenjuNo ratings yet

- 525B MTM V2 PDFDocument278 pages525B MTM V2 PDFstjepan100% (3)

- Mining Excavator: Operating Weight With Backhoe Attachment: Shovel Attachment: Engine: Bucket Capacity: Shovel CapacityDocument10 pagesMining Excavator: Operating Weight With Backhoe Attachment: Shovel Attachment: Engine: Bucket Capacity: Shovel CapacityWita ManaluNo ratings yet

- Hydraulic 4 Roller Rolling Machine W12-12x3000Document4 pagesHydraulic 4 Roller Rolling Machine W12-12x3000EnriqueMiguelPriceNo ratings yet

- ZX 50u2 PDFDocument8 pagesZX 50u2 PDFIvanNo ratings yet

- 6.1 - SL2006-469 PDFDocument15 pages6.1 - SL2006-469 PDFValeriy DomashenkoNo ratings yet

- 0106-7 Section C-DDocument129 pages0106-7 Section C-DPartsGopher.comNo ratings yet

- Hydraulic Bolt Tensioning 10022-1817-C-0002-SC17-00027Document40 pagesHydraulic Bolt Tensioning 10022-1817-C-0002-SC17-00027lemuel bacsaNo ratings yet

- Camless Two Stroke Main Propulsion engine-B&W ME - CDocument21 pagesCamless Two Stroke Main Propulsion engine-B&W ME - CNarayana Prakash96% (52)

- Como Instalar Sellos Cat 2Document2 pagesComo Instalar Sellos Cat 2jhonNo ratings yet

- Volkswagen Polo Mk4 Brake System Technical ManualDocument126 pagesVolkswagen Polo Mk4 Brake System Technical Manualsssf-dobojNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- KMT Waterjet 2012 Product Catalog - L PDFDocument12 pagesKMT Waterjet 2012 Product Catalog - L PDFRamaditya Putera KlesindoNo ratings yet

- Abel 1Document30 pagesAbel 1Robel KebedeNo ratings yet

- Hydraulic Pulley PullerDocument4 pagesHydraulic Pulley PullerTanvi KhuranaNo ratings yet

- 1 User Manual Ad-R v04Document83 pages1 User Manual Ad-R v04Emerson TerrelNo ratings yet

- Page 1 Section Dimensions Car dataDocument5 pagesPage 1 Section Dimensions Car dataAlexandra SterescuNo ratings yet

- W01 358 3407Document29 pagesW01 358 3407MROstop.comNo ratings yet

- Paper or Digital: Get Your Manuals The Way You Need Them!Document363 pagesPaper or Digital: Get Your Manuals The Way You Need Them!Abigail DeclerNo ratings yet

- Champion Log Splitter 22tonDocument25 pagesChampion Log Splitter 22tonChuck CharlesNo ratings yet

- Simrit 03 - Hydraulics (Technical Manual 2007)Document312 pagesSimrit 03 - Hydraulics (Technical Manual 2007)jo_rz_57No ratings yet

- R9350 EN New PDFDocument123 pagesR9350 EN New PDFSubairi bain100% (1)