Professional Documents

Culture Documents

RTDInstall Op Maint

Uploaded by

Arunava Basak0 ratings0% found this document useful (0 votes)

5 views1 pagehi

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageRTDInstall Op Maint

Uploaded by

Arunava Basakhi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Edmonton, Alberta T6E 5K3

Telephone: (780) 463-7035

Fax: (780) 462-0017

Head Office: 9328-37 Ave

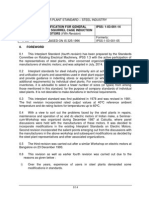

INSTALLATION-OPERATION-MAINTENANCE

FOR RTD (RESISTANCE TEMPERATURE DETECTOR)

Handling:

There are many variations of RTD and RTD assemblies.

Even though some may appear to have heavy duty

protecting tubes or thermowells, the internal parts can be

delicate. Care in handling is a must to insure the sensor

integrity. DO NOT DROP. RTDs are carefully packed at the

factory. Inspect the package for indications of shipping

damage. If shipping damage is noticed report it immediately

to the shipping company and make the necessary reports.

ships on a factory basis

therefore it is your responsibility to file any claims. Hidden

shipping damage can occur (no evident sign of mishandling).

If after carefully opening the package, damage is discovered

save all product and shipping material. Notify and file the

proper claims with the shipping company immediately.

Store in a dry, clean place. Avoid areas where dropping or

stacking may occur.

The RTDshould , as close as possible, what the product

in the process is experiencing in order to get meaningful

temperature measurements. Locate the RTD as close to the

product as possible. Arule of thumb is to have at least 10 tube

diameters immersion in the hot zone. Avoid direct flame

impingement or stagnant areas.

ALLTEMP SENSORS

SEE

FOB

Storage:

Location:

Installation:

DONOTATTEMPTto mechanically connect the assembly in

the process by tightening at the terminal or connection head.

USE ONLY THE PROCESS FITTING OR THE

THERMOWELL FLATS FORTHIS PURPOSE. Terminals or

connection heads that are twisted can be damaged or cause

short circuits that can adversely affect the operation of the

RTD. DONOTBENDTHERTDELEMENT(within six inches

of the end sheath). Bending will break the element that is in

the metal sheath and the sensor will be rendered inoperative.

If the thermowell or protection tube must be welded into the

process, carefully remove RTD sensor before welding and

be sure to handle carefully. Keep clean and replace without

forcing or stressing any components.

Wire Extension:

Maintenance :

See general operation parameters and job wiring diagrams.

Regularly scheduled maintenance procedures should

include inspection and calibration intervals so that life and

reliability of the instrumentation is improved and the

likelihood of sudden serious failure is reduced. These

procedures should be set up by the responsible engineering

department and performed by personal that are familiar with

the operating principles upon which the systemis based. DO

NOTLUBRICATE.

PROCESS CONNECTION

You might also like

- PIX-36 - Manual - VDRB05981-01 33kV Switchgear PDFDocument94 pagesPIX-36 - Manual - VDRB05981-01 33kV Switchgear PDFaman kumar jhaNo ratings yet

- Crane & Earth Moving Vehicles Inspection ReportRev 00 PDFDocument1 pageCrane & Earth Moving Vehicles Inspection ReportRev 00 PDFArunava BasakNo ratings yet

- Relay Coordination 132kW MCPDocument2 pagesRelay Coordination 132kW MCPArunava BasakNo ratings yet

- Specification For Motorized Gear Units (Mgus) IPSS:1-03-008-03Document8 pagesSpecification For Motorized Gear Units (Mgus) IPSS:1-03-008-03HEMANTKHERANo ratings yet

- MRS-opgw a1.sor.pdf Print Date 15/10/2020 12:18 pm SmartOTDR Test ResultsDocument1 pageMRS-opgw a1.sor.pdf Print Date 15/10/2020 12:18 pm SmartOTDR Test ResultsArunava BasakNo ratings yet

- 1 03 001 14Document14 pages1 03 001 14umashankarsinghNo ratings yet

- CEA Transmission Line Upload Format - 1Document1 pageCEA Transmission Line Upload Format - 1Arunava BasakNo ratings yet

- Crane & Earth Moving Vehicles Inspection ReportRev 00 PDFDocument1 pageCrane & Earth Moving Vehicles Inspection ReportRev 00 PDFArunava BasakNo ratings yet

- Crane & Earth Moving Vehicles Inspection ReportRev 00 PDFDocument1 pageCrane & Earth Moving Vehicles Inspection ReportRev 00 PDFArunava BasakNo ratings yet

- CEA Transmission Line Upload Format - 2Document1 pageCEA Transmission Line Upload Format - 2Arunava BasakNo ratings yet

- Transmission Line Sag CalculationDocument14 pagesTransmission Line Sag CalculationArunava BasakNo ratings yet

- Battery Charger DC LoadDocument6 pagesBattery Charger DC LoadArunava BasakNo ratings yet

- Lowmain Tech ManualDocument30 pagesLowmain Tech ManualArunava BasakNo ratings yet

- Code of Practice For Overhauling of DC Motors With Antifriction / Sliding Bearings IPSS: 1-03-033-03Document9 pagesCode of Practice For Overhauling of DC Motors With Antifriction / Sliding Bearings IPSS: 1-03-033-03GopalMahantaNo ratings yet

- 33KV Switchboard Panel DetailsDocument3 pages33KV Switchboard Panel DetailsArunava Basak100% (1)

- Standard Phrases For Business EmailsDocument29 pagesStandard Phrases For Business EmailsArunava BasakNo ratings yet

- Positive IsolationDocument10 pagesPositive IsolationArunava Basak0% (1)

- Basak, Arunava IN CCU MT: From: Sent: To: SubjectDocument1 pageBasak, Arunava IN CCU MT: From: Sent: To: SubjectArunava BasakNo ratings yet

- PT Burden Calculations 01 PDFDocument4 pagesPT Burden Calculations 01 PDFArunava Basak100% (2)

- CT_Burden_Calculations_01 Excel VA CalculationDocument1 pageCT_Burden_Calculations_01 Excel VA CalculationArunava Basak100% (1)

- PT Burden Calculations 01 PDFDocument4 pagesPT Burden Calculations 01 PDFArunava Basak100% (2)

- DC Load Calc PDFDocument8 pagesDC Load Calc PDFArunava BasakNo ratings yet

- C, Basic Safety RulesDocument28 pagesC, Basic Safety RulesArunava BasakNo ratings yet

- 3AK6 VCB Tech Description PDFDocument3 pages3AK6 VCB Tech Description PDFArunava Basak50% (2)

- CT_Burden_Calculations_01 Excel VA CalculationDocument1 pageCT_Burden_Calculations_01 Excel VA CalculationArunava Basak100% (1)

- Design Verification Form Rev 00Document1 pageDesign Verification Form Rev 00Arunava BasakNo ratings yet

- DC Load Calc PDFDocument8 pagesDC Load Calc PDFArunava BasakNo ratings yet

- 3AK6 VCB Tech Description PDFDocument3 pages3AK6 VCB Tech Description PDFArunava Basak50% (2)

- Design Input Form Rev 00Document1 pageDesign Input Form Rev 00Arunava BasakNo ratings yet

- Customer Satisfaction Feedback Rev 00 PDFDocument1 pageCustomer Satisfaction Feedback Rev 00 PDFArunava BasakNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- VDP08 Technical CatalogueDocument47 pagesVDP08 Technical CatalogueAdal VeraNo ratings yet

- Hino 500S Catalog LR PDFDocument8 pagesHino 500S Catalog LR PDFZulNo ratings yet

- Suvarnabhumi Airport Trial OperationDocument4 pagesSuvarnabhumi Airport Trial Operationfwmching0% (1)

- Micron Ezeprox Access Control KeypadDocument4 pagesMicron Ezeprox Access Control KeypadThuy VuNo ratings yet

- Bilge Alarm Monitor OMD 11Document22 pagesBilge Alarm Monitor OMD 11Lucian Iftemie100% (3)

- Duet CE-3301 Geotechnical Engineering - IDocument37 pagesDuet CE-3301 Geotechnical Engineering - IShekh Muhsen Uddin AhmedNo ratings yet

- 13 - Principles of Flight - QuestionsDocument80 pages13 - Principles of Flight - QuestionsEdgar Muñoz Fernández50% (4)

- ETN2A ElectromechanicsDocument64 pagesETN2A ElectromechanicsEinstein's VanderbijlparkNo ratings yet

- Chapter 2 Cast IronDocument9 pagesChapter 2 Cast IronHelen AdugnaNo ratings yet

- Simucube 2 Quick Release GuideDocument7 pagesSimucube 2 Quick Release Guideemyrs12No ratings yet

- Experiment 3: Temperature Measurement MethodDocument12 pagesExperiment 3: Temperature Measurement Methodmohamad munzirNo ratings yet

- Hanson G209 (SW Valves)Document12 pagesHanson G209 (SW Valves)AKSHEYMEHTANo ratings yet

- STN Cat Novelties Vol.i 2023Document89 pagesSTN Cat Novelties Vol.i 2023ruba herbawiNo ratings yet

- Partlist Smsport 110RDocument74 pagesPartlist Smsport 110RThai YunNo ratings yet

- Amphenol Musician Range PDFDocument8 pagesAmphenol Musician Range PDFtrc_wmNo ratings yet

- New Schedule For Sunset Limited Benefits Passengers and Improves Financial PerformanceDocument3 pagesNew Schedule For Sunset Limited Benefits Passengers and Improves Financial Performanceapi-26433240No ratings yet

- Control Fixed Bed ReactorsDocument4 pagesControl Fixed Bed ReactorsAddison JuttieNo ratings yet

- Procedure Installation of Lighting - LABUAN BAJO PDFDocument6 pagesProcedure Installation of Lighting - LABUAN BAJO PDFWika Djoko ONo ratings yet

- DR System ConciseDocument37 pagesDR System ConciseJiten KarmakarNo ratings yet

- AMS Thread Size ChartDocument4 pagesAMS Thread Size Chartarunvelu_1250% (2)

- Determining The Redundancy FactorDocument6 pagesDetermining The Redundancy FactorEdris Salehi GolsefidiNo ratings yet

- Hit-Re 500 With Hit-V Has RodsDocument3 pagesHit-Re 500 With Hit-V Has RodsMKNo ratings yet

- CED 426 Quiz # 2 SolutionsDocument26 pagesCED 426 Quiz # 2 SolutionsMary Joanne AninonNo ratings yet

- Studio GPGL LogDocument5 pagesStudio GPGL LogCarlos Julian LemusNo ratings yet

- Cassette toilet spare parts guide for models C2, C3 and C4Document21 pagesCassette toilet spare parts guide for models C2, C3 and C4georgedragosNo ratings yet

- 3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFDocument6 pages3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFRene ParedesNo ratings yet

- ITU ISUP Release Cause CodesDocument5 pagesITU ISUP Release Cause Codesdelgado08No ratings yet

- QADocument170 pagesQASudama KhatriNo ratings yet

- Case Study Cracked Oil Tanks Investigations Web PDFDocument2 pagesCase Study Cracked Oil Tanks Investigations Web PDFyamakunNo ratings yet

- Sodium Citrate AUDocument3 pagesSodium Citrate AUKrishna OgotNo ratings yet