Professional Documents

Culture Documents

Fire Suppression General Requirements

Uploaded by

Astri Ngent0 ratings0% found this document useful (0 votes)

150 views4 pagesThis document provides specifications for fire suppression systems for a Riyad Bank data center. It outlines general requirements, references applicable standards, requires submittals from the contractor, and specifies a one year warranty. It describes fire extinguishers, sprinkler systems, valves, pipe hangers and supports. Installation must comply with NFPA standards and the system must pass pressure and discharge tests according to NFPA requirements.

Original Description:

specification

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for fire suppression systems for a Riyad Bank data center. It outlines general requirements, references applicable standards, requires submittals from the contractor, and specifies a one year warranty. It describes fire extinguishers, sprinkler systems, valves, pipe hangers and supports. Installation must comply with NFPA standards and the system must pass pressure and discharge tests according to NFPA requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

150 views4 pagesFire Suppression General Requirements

Uploaded by

Astri NgentThis document provides specifications for fire suppression systems for a Riyad Bank data center. It outlines general requirements, references applicable standards, requires submittals from the contractor, and specifies a one year warranty. It describes fire extinguishers, sprinkler systems, valves, pipe hangers and supports. Installation must comply with NFPA standards and the system must pass pressure and discharge tests according to NFPA requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

RIYAD BANK DATA CENTER

FIRE SUPPRESSION GENERAL REQUIREMENT 21 00 00 - 1

SECTION 21 00 00

FIRE SUPPRESSION GENERAL REQUIREMENTS

PART 1 - GENERAL

1.1 DESCRIPTION:

A. The Work under this section shall include providing all materials, labors

and plants to furnish and install fire protection system as shown on the

drawings and specified herein. Fire water shall be connected with the

existing fire water network.

1.2 REFERENCES:

A. SASO Saudi Arabian Standards Organization

SASO 37 Steel carbon dioxide cartridges for fire extinguishers

SASO 38 Methods of test for steel carbon dioxide cartridges for fire

extinguishers

SASO 63 Fire extinguishers - Part 1: Steel portable carbon dioxide

fire extinguishers

SASO 64 Test methods for portable fire extinguishers

SASO 314 Industrial safety and health regulations Part 2: Buildings -

sections 2.7, 2.8 and 2.9 - fire protection

SASO 859 Threaded steel pipes

SASO 986 Electrical installation of buildings - Part 4: Protection for

safety - Section (482): protection against fire.

B. ANSI - American National Standard Institute:

ANSI B1.20.1 Pipe Threads

ANSI B16.1 Cast Iron Flanges and Flanged Fittings class 25, 125, 250

and 800

ANSI B16.3 Malleable-Iron screwed Fittings 150 and 300 Pound

C. ASTM - American Society for Testing and Materials:

ASTM A 53 Pipe, Steel, Black and Hot-Dipped, Zinc Coated

(Galvanized), Welded and Seamless.

D. NFPA - National Fire Protection Association:

NFPA 10 Portable Fire Extinguishers

NFPA 13 Installation of Sprinkler Systems.

RIYAD BANK DATA CENTER

FIRE SUPPRESSION GENERAL REQUIREMENT 21 00 00 - 2

NFPA 14 Standpipe and Hose Systems.

NFPA 20 Fire Protection Equipment.

NFPA 101 Life Safety Code.

NFPA 1961 Fire Hose.

NFPA 1963 Screw Threads and Gaskets for Fire Hose Connections.

E. UL - Underwriters Laboratories, Inc.

UL 299 Dry-Chemical Fire Extinguishers.

UL 711 Rating and Fire Testing of fire extinguishers.

F. UBC Uniform Building Code.

Section 905 Smoke Control.

Section 906 Smoke and Heat Venting.

1.3 SUBMITTALS:

A. Material and equipment information: Shall include catalog cuts and technical

data for each component or device used in the system.

B. The contractor shall provide information outlining the operation and maintenance

procedures that will be required by Engineer.

C. Sequence of operation, electrical schematics and connection diagrams shall be

provided.

D. Shop Drawings: Shop drawings shall indicate locations, installation details and

operation details of all equipment associated with the fire protection systems.

E. Certification and Guarantees:

1. Manufacturer's Guarantees for all proprietary equipment in brochure

2. Certificate of Compliance.

3. Test Reports.

F. Operation and Maintenance Instructions:

1. For all proprietary equipment and assemblies

2. Valve Identification Brochure.

RIYAD BANK DATA CENTER

FIRE SUPPRESSION GENERAL REQUIREMENT 21 00 00 - 3

1.4 WARRANTY:

A. The Contractor shall furnish a written guarantee covering the

satisfactory operation of the fire protection system in all its parts for a period of

one (1) year after date of acceptance. During this period, the

Contractor shall repair or replace any defective work and pay for any repair or

replacement costs.

1.5 QUALITY ASSURANCE:

A. All the work specified in this section shall be installed in accordance with the

applicable provisions of the following codes and standard:

1. Factory Mutual Laboratories (FM)

2. Underwriter's Laboratories (UL)

3. National Fire Protection Association (NFPA)

PART 2 - PRODUCTS

2.1 PIPES AND FITTINGS:

A. 1. FOAM FIRE EXTINGUISHING: refer to Section 21 13 39, paragraph 2.1

2. DRY PIPE SYSTEM: refer to Section 21 13 19, paragraph 2.2

3. CLEAN-AGENT FIRE-EXTINGUISHING SYSTEMS (NOVEC-1230): refer to

section 21 22 00, paragraph 2.2

2.2 MULTI-PURPOSE PORTABLE FIRE EXTINGUISHERS:

A. Multi-purpose portable fire extinguishers shall be of red enamel steel shell, SASO

64 and SASO 647 compliant, UL Listed, FM approved, 4.5 kg (10 lbs.)

capacity, Class C, multi-purpose dry chemical (Ammonium phosphate

base) complete with squeeze grip discharge horn, pressure gauge and wall-

mounted bracket.

2.3 CARBON DIOXIDE PORTABLE FIRE EXTINGUISHERS:

A. Portable fire extinguishers shall be red glossy polyester-coated

aluminum cylinder, SASO 63 compliant, UL Listed, 4.5 kg (10 lbs.) capacity,

carbon dioxide agent used to provide protection against Class B and C

fires, complete with squeeze grip, discharge horn and wall-mounted bracket.

2.4 SPRINKLER SYSTEM:

A. 1. FOAM FIRE EXTINGUISHING: refer to Section 21 13 39, paragraph 2.5

2. DRY PIPE SYSTEM: refer to Section 21 13 19, paragraph 2.3

3. CLEAN-AGENT FIRE-EXTINGUISHING SYSTEMS (NOVEC-1230):

refer to section 21 22 00, paragraph 2.7

2.5 VALVES:

A. Refer to Section - VALVES.

RIYAD BANK DATA CENTER

FIRE SUPPRESSION GENERAL REQUIREMENT 21 00 00 - 4

2.6 PIPE HANGERS AND SUPPORTS:

A. Refer to Section - HANGERS AND SUPPORTS.

PART 3 - EXECUTION

3.1 INSTALLATION:

A. Installation shall be made in accordance with the applicable National

Fire Protection Association Standards. All equipment and devices used

shall be listed in either the UL Fire Protection List or the Factory Mutual

Approval Guide.

B. Installation of the fire protection systems shall be made in strict accordance

with NFPA 12A, 70, 72A, 72E and 2001. The fire protection system shall be

installed by an experienced firm regularly engaged in the installation of fire

extinguishing systems; firm shall be subject to Engineer's approval.

Installation shall also comply with the requirements of Section - BASIC

PIPING MATERIALS AND METHODS.

C. Seal all pipe penetrations of fire barriers (walls and slabs) using fire

barrier penetration seals as specified in relevant Section of the

Specifications or as approved by the Engineer.

D. System Inspection and Checkouts:

1. After installation is complete the system shall be inspected by

factory- trained personnel in accordance with the manufacturer's

recommended procedures, in the presence of Engineer.

3.2 INSPECTION AND TESTING:

A. Tests shall demonstrate that entire system functions as intended. Tests shall

be carried out in accordance with applicable requirements of NFPA. Discharge

tests shall be conducted for each area; each area shall be tested separately.

Piping system shall be capped and subjected to minimum static water

pressure of 1.5 times designed working pressure and maintained for two

hours with no leaks or loss of pressure. After performance test, complete the

necessary adjustments and reset the control and equipment.

END OF SECTION

You might also like

- Automatic Fire Sprinkler SystemDocument16 pagesAutomatic Fire Sprinkler SystemArnel ArnaoNo ratings yet

- Jci 2017072Document15 pagesJci 2017072Toretta AdrianNo ratings yet

- Fire-Suppression Piping System-13915 PDFDocument21 pagesFire-Suppression Piping System-13915 PDFMohammad Jugnu100% (1)

- Section 15310 Fire Protection PipingDocument8 pagesSection 15310 Fire Protection PipingkdpmansiNo ratings yet

- Kidde AE Spec - ADS Using Novec 1230-01-2015Document6 pagesKidde AE Spec - ADS Using Novec 1230-01-2015kuraimundNo ratings yet

- Basic Framework For Submission of Performance-Based SolutionsDocument83 pagesBasic Framework For Submission of Performance-Based Solutionsahmed abdohNo ratings yet

- Falar CajiligDocument5 pagesFalar CajiligRamil S. ArtatesNo ratings yet

- General Fire Safety ReportDocument48 pagesGeneral Fire Safety ReportBalgo BalgobinNo ratings yet

- Report of Inspection, Testing & Maintenance: of Fire Pump AssembliesDocument6 pagesReport of Inspection, Testing & Maintenance: of Fire Pump AssembliesMatel Franklin AnastaNo ratings yet

- Documentation AnsulDocument40 pagesDocumentation AnsulkdsessionsNo ratings yet

- Mechanical Plan Evaluation and Review OutlineDocument11 pagesMechanical Plan Evaluation and Review OutlineEngelbert CasanovaNo ratings yet

- Sprinklers PDFDocument43 pagesSprinklers PDFpil7194No ratings yet

- HVAC Ductwork SpecificationDocument4 pagesHVAC Ductwork SpecificationhvacwallyNo ratings yet

- Alarmline Linear Heat Detection Power PointDocument27 pagesAlarmline Linear Heat Detection Power PointCris Javicho100% (1)

- T&C of Fire Supression SystemDocument5 pagesT&C of Fire Supression Systemamg007100% (1)

- Isle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingDocument18 pagesIsle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingcaptalaaNo ratings yet

- 7-BOQ & Estimate Fire ProtectionDocument26 pages7-BOQ & Estimate Fire ProtectionTransitpoint Holiday BungalowNo ratings yet

- Specification For Fire Water MonitorsDocument6 pagesSpecification For Fire Water MonitorsThiru AnanthNo ratings yet

- Automatic Fire Suppression SystemsDocument1 pageAutomatic Fire Suppression Systemsnvenkat.narayanNo ratings yet

- KFD Test Paper Sample Questions 1Document25 pagesKFD Test Paper Sample Questions 1ragulNo ratings yet

- Viking Residential Sprinkler Installation GuideDocument18 pagesViking Residential Sprinkler Installation Guidesina_84No ratings yet

- Fire Pump Compliance MatrixDocument5 pagesFire Pump Compliance Matrixshakil612No ratings yet

- Questions in Interview For Fire FightingDocument1 pageQuestions in Interview For Fire FightinglguetaNo ratings yet

- List of NFPA Codes & StandardsDocument1 pageList of NFPA Codes & StandardsSahil PalNo ratings yet

- Deluge enDocument8 pagesDeluge enHuynh Phuc Phung100% (1)

- Ansul R-102Document4 pagesAnsul R-102heliopintoNo ratings yet

- Clean Agent System Test Report-1Document96 pagesClean Agent System Test Report-1bayrammtnNo ratings yet

- NFPA13 - Pt1 - Handout Cambios Nfpa 13Document33 pagesNFPA13 - Pt1 - Handout Cambios Nfpa 13Eden FriasNo ratings yet

- Testing & Commissioning Checklist Fire HydrantDocument2 pagesTesting & Commissioning Checklist Fire HydrantTorre 11 Departamento 1808No ratings yet

- Fire AlarmDocument39 pagesFire AlarmNisha LambaNo ratings yet

- Installation of Sprinkler Piping SystemDocument6 pagesInstallation of Sprinkler Piping SystemJosef MadronaNo ratings yet

- Fire Suppression SystemDocument26 pagesFire Suppression SystemLawrence Ting0% (3)

- Fire Fighting - Information From AnswersDocument12 pagesFire Fighting - Information From AnswerslearnafrenNo ratings yet

- Fire Fighting - QatarDocument21 pagesFire Fighting - QatarrajeshjamesNo ratings yet

- Fire Suppression Systems UL 300: Length of HoodDocument3 pagesFire Suppression Systems UL 300: Length of Hoodkdsessions100% (2)

- Microsoft PowerPoint - 2. Design Inert Gas System - HDocument54 pagesMicrosoft PowerPoint - 2. Design Inert Gas System - HBidang KK3L Unit PLTP Gunung Salak100% (1)

- Nfs2-8 Instal Manual WebDocument0 pagesNfs2-8 Instal Manual WebDota NgNo ratings yet

- HydrantDocument2 pagesHydrantHarikrishnaNo ratings yet

- Linear Heat Detection Cable - Digital Linear Sensor Cable-NitenDocument6 pagesLinear Heat Detection Cable - Digital Linear Sensor Cable-Nitenkhalidwy6342100% (1)

- Kidde FM-200 SpecDocument5 pagesKidde FM-200 SpecreregilaNo ratings yet

- For Fire SuppressionDocument28 pagesFor Fire SuppressionAmjathkhan Shiekusman100% (1)

- Foam System Specification PDFDocument22 pagesFoam System Specification PDFpequenita34No ratings yet

- Asd 640Document2 pagesAsd 640RICHI100% (1)

- MECH QCDD Exam Questions KIC by Amr SaadDocument4 pagesMECH QCDD Exam Questions KIC by Amr SaadSHERIF KHATTABNo ratings yet

- Passive Fire ProtectionDocument28 pagesPassive Fire ProtectionBFP PANGLAONo ratings yet

- Clean Agent Suppression SystemDocument14 pagesClean Agent Suppression Systemhendrik wibowoNo ratings yet

- R5.0 Signature Series Detector Application BulletinDocument60 pagesR5.0 Signature Series Detector Application BulletinOmar Alfredo Del Castillo0% (1)

- Et 321 06-23-15Document2 pagesEt 321 06-23-15Shishan AhmadNo ratings yet

- 3.1 Design BriefDocument5 pages3.1 Design BriefRaj KamalNo ratings yet

- Royal Oman Police (English)Document191 pagesRoyal Oman Police (English)Khizer ArifNo ratings yet

- Level 1Document121 pagesLevel 1Jerry RdzNo ratings yet

- Louth County Council Fire and RescueDocument56 pagesLouth County Council Fire and Rescuesetyawan punkNo ratings yet

- Fire Alarm Design PDFDocument19 pagesFire Alarm Design PDFzafar.ucNo ratings yet

- Fire Extinguisher Placement and Design ProcedureDocument16 pagesFire Extinguisher Placement and Design ProcedureDIEGOZafNo ratings yet

- MX Argotec With Carbon Dioxide PDFDocument7 pagesMX Argotec With Carbon Dioxide PDFNarendra Reddy BhumaNo ratings yet

- 21 12 00 Fire Protection SystDocument16 pages21 12 00 Fire Protection SystMichel CorrêaNo ratings yet

- Fire Detection/Total Flooding Carbon Dioxide Suppression System Engineering Specifications Part 1 - General 1.01 Description of WorkDocument17 pagesFire Detection/Total Flooding Carbon Dioxide Suppression System Engineering Specifications Part 1 - General 1.01 Description of Work張哲僑No ratings yet

- 21 05 00 - Common Work Results For Fire Suppression PDFDocument4 pages21 05 00 - Common Work Results For Fire Suppression PDFmasoodaeNo ratings yet

- Fire Suppression PipingDocument22 pagesFire Suppression Pipingadel rihanaNo ratings yet

- Duct Silencers and Acoustic TreatmentDocument8 pagesDuct Silencers and Acoustic TreatmentShabbir WahabNo ratings yet

- Design of Welded ConnectionsDocument8 pagesDesign of Welded ConnectionsAstri NgentNo ratings yet

- D Value CalcDocument5 pagesD Value CalcAstri NgentNo ratings yet

- Bekomat Produk DisplayDocument4 pagesBekomat Produk DisplayAstri NgentNo ratings yet

- 10 11Document9 pages10 11PrashannaNo ratings yet

- Plate and Box Girder DesignDocument60 pagesPlate and Box Girder DesignKrishna ChandranNo ratings yet

- Data Dial IndikatorDocument2 pagesData Dial IndikatorAstri NgentNo ratings yet

- ZX 100 K-Truss Support PadDocument4 pagesZX 100 K-Truss Support PadAstri NgentNo ratings yet

- Slide Bearing PTFE Tes ReportDocument6 pagesSlide Bearing PTFE Tes ReportAstri NgentNo ratings yet

- Beam Desain1Document2 pagesBeam Desain1Astri NgentNo ratings yet

- Gantry Crane CalculatedDocument1 pageGantry Crane CalculatedAstri NgentNo ratings yet

- Assy Joint Pipa Line 1Document1 pageAssy Joint Pipa Line 1Astri NgentNo ratings yet

- ValveDocument4 pagesValveAstri NgentNo ratings yet

- Mud Barge Sea ChestDocument1 pageMud Barge Sea ChestAstri NgentNo ratings yet

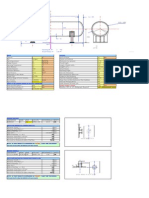

- Surge TankDocument4 pagesSurge TankAstri NgentNo ratings yet

- NTN Pillow BlockDocument54 pagesNTN Pillow BlockteguheafNo ratings yet

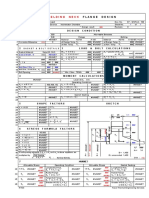

- Flange Example CalcDocument14 pagesFlange Example CalcAstri NgentNo ratings yet

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Spherical Roller Thrust Bearing PDFDocument16 pagesSpherical Roller Thrust Bearing PDFAstri NgentNo ratings yet

- Over Head Water Tank DesignDocument5 pagesOver Head Water Tank DesignAstri Ngent100% (1)

- Bearing Layout PDFDocument1 pageBearing Layout PDFAstri NgentNo ratings yet

- Plugin Bushes PDFDocument3 pagesPlugin Bushes PDFAstri NgentNo ratings yet

- Motor Selection, Inertia PDFDocument6 pagesMotor Selection, Inertia PDFIswar Rauf Aboo 'AqilahNo ratings yet

- Reinforced PadDocument3 pagesReinforced PadAstri NgentNo ratings yet

- Weld Analysis-IC Method v1.1Document5 pagesWeld Analysis-IC Method v1.1jefersonpimentelNo ratings yet

- 6000 EN 00 04 Friction BearingDocument30 pages6000 EN 00 04 Friction BearingAstri NgentNo ratings yet

- Calculating The Time Required To Empty A Vessel: ExamplesDocument1 pageCalculating The Time Required To Empty A Vessel: ExamplesKabir KhanNo ratings yet

- Hydroelectric Hydro Power 4 3 1 DesignDocument28 pagesHydroelectric Hydro Power 4 3 1 DesignLouise UmaliNo ratings yet

- Limit State DesignDocument26 pagesLimit State DesignAstri NgentNo ratings yet

- Hammer Product Data SheetDocument2 pagesHammer Product Data SheetAstri NgentNo ratings yet

- Gang SawDocument55 pagesGang SawAstri NgentNo ratings yet

- Fuel System Components 1. Fuel TanksDocument6 pagesFuel System Components 1. Fuel TanksRebecca Lepon LegaspiNo ratings yet

- FLK DMS 2021 0110 01 00Document235 pagesFLK DMS 2021 0110 01 00mohanadsamaraNo ratings yet

- Neumatico - Ingersoll-Rand-FA5A-Parts-ManualDocument4 pagesNeumatico - Ingersoll-Rand-FA5A-Parts-ManualJaimeAlbertoCardonaSaavedraNo ratings yet

- Aquatherm Blue Pipe PDFDocument164 pagesAquatherm Blue Pipe PDFAnonymous 4MwmDaNbNo ratings yet

- Orque Rench AnualDocument36 pagesOrque Rench AnualmohamedNo ratings yet

- Atlas Copco Oil and Gas LeafletDocument8 pagesAtlas Copco Oil and Gas Leafletchristophe BardouilNo ratings yet

- Bill of Quantities: 1 Provisional SumDocument12 pagesBill of Quantities: 1 Provisional SumbibekNo ratings yet

- City Gas Distribution Project in East & West Godavari Districts of Andhra PradeshDocument11 pagesCity Gas Distribution Project in East & West Godavari Districts of Andhra PradeshAnil KumAr MoteNo ratings yet

- GR Rapid SL Pour WCDocument2 pagesGR Rapid SL Pour WCMohamed KhaldiNo ratings yet

- Manual Parts - Ir - Compresor - XP375 Wcu T2 PMDocument94 pagesManual Parts - Ir - Compresor - XP375 Wcu T2 PMAhbdi Torres100% (2)

- Section 2 - INSTALLATION LAYOUT DESIGNDocument111 pagesSection 2 - INSTALLATION LAYOUT DESIGNAnoop PrajapatiNo ratings yet

- National Plumbing CodeDocument20 pagesNational Plumbing CodeDonixNo ratings yet

- Piping Engineer SyllubusDocument3 pagesPiping Engineer SyllubusbalajivangaruNo ratings yet

- NCR - SampleDocument7 pagesNCR - SamplecamycaxNo ratings yet

- IPSS Draft Handbook 2014Document45 pagesIPSS Draft Handbook 2014soumenhazraNo ratings yet

- Weldolet CatalogueDocument44 pagesWeldolet Cataloguehwdyang100% (2)

- Brochure HYDRAULIC Hose Quick Camlock Valve HIC India 04Document4 pagesBrochure HYDRAULIC Hose Quick Camlock Valve HIC India 04Tithi Kuldeep ChauhanNo ratings yet

- Telelift 4017 - 4514 - 19296Document212 pagesTelelift 4017 - 4514 - 19296FranciscoOliveiraNo ratings yet

- Catalog Tevi Fitinguri Pvcu PlassonDocument41 pagesCatalog Tevi Fitinguri Pvcu PlassonzenogredinaNo ratings yet

- Prowirl 77Document60 pagesProwirl 77Capacitacion TodocatNo ratings yet

- Tyco Alarm ValveDocument22 pagesTyco Alarm ValveMohammed BaquarNo ratings yet

- 04BR05Document6 pages04BR05martiguada1No ratings yet

- General Requirements For Flares and Flare StacksDocument9 pagesGeneral Requirements For Flares and Flare StacksReza100% (1)

- Cromc 0299 UsDocument64 pagesCromc 0299 UshacenescribdNo ratings yet

- Bolt 10022-1817-C-0002-SC17-00026Document9 pagesBolt 10022-1817-C-0002-SC17-00026lemuel bacsaNo ratings yet

- Envy Walk in Tub Manual 1-12-2011Document15 pagesEnvy Walk in Tub Manual 1-12-2011Morris Taylor100% (1)

- Awwa c604-2006Document48 pagesAwwa c604-2006trieu75% (4)

- RFF Delivery ProgrammeDocument4 pagesRFF Delivery Programmekad-7No ratings yet

- 394M - Parr - 4540 High Pressure Reactor Inst PDFDocument32 pages394M - Parr - 4540 High Pressure Reactor Inst PDFlorenzoNo ratings yet

- Harmonized Standards Under PED - Pressure Equipment - European Standards - Enterprise and IndustryDocument12 pagesHarmonized Standards Under PED - Pressure Equipment - European Standards - Enterprise and IndustryKetan Choukekar0% (1)