Professional Documents

Culture Documents

ENG-TIPS de Vessel Circular Section Single Diametral Staying Member Rev 000c-3

Uploaded by

RomeoMendoza0 ratings0% found this document useful (0 votes)

79 views1 pageENG-TIPS de Vessel Circular Section Single Diametral Staying Member Rev 000c-3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentENG-TIPS de Vessel Circular Section Single Diametral Staying Member Rev 000c-3

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

79 views1 pageENG-TIPS de Vessel Circular Section Single Diametral Staying Member Rev 000c-3

Uploaded by

RomeoMendozaENG-TIPS de Vessel Circular Section Single Diametral Staying Member Rev 000c-3

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

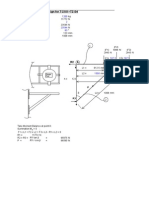

vessel circular section single diametral staying member ASME VIII div 1 chap 13-13

ASME VIII - DIVISION 1 SA 240 TP304L <100F 16700 PSI

Mandatory appendix 13-13

see fig. 13-2(c) fill in yellow cells only

b 25,4 (using mm)

t1 10 mm shell thickness

R 197,2 mm shell internal radius

Lv 350 mm shell (vessel) length

t3 6,4 mm plate thickness

P1 0,3 MPa P =P1-P2 0,155 MPa 3 bar

P2 0,145 MPa

Ratio 1,12685714 ratio of long to short side of plate element

J

1 0,05965771

check plate parameter table 13-13 c below

c shell 5 mm half thickness of shell

c plate 3,2 mm half thickness of plate

I

1 2116,66667 mm4

I

3 554,871467 mm4

Design stress

S 115,1 MPa from ASME II part D; table 1A

E 1 weld coefficient 13-5: E =joint efficiency factor as required by UW-12 for all Category A

to any Category C or D butt

1

joints. The joint efficiency factor is used as

note 1 from 13-5: ' Use E = 1.0 far Category C and D joints that are no

UW-12: E has N/A value for angle joint

13-1(d): N/A (d) In 13-18 special consideration is given to the calculation

(1) Membrane stresses (1) Membrane stresses

Shell Section Shell Section

S

m 5,9 MPa (1) S

m 5,9 MPa (6) primary membrane stress allowable

5% S allowable =S 115,1 MPa 5% 13-4(b) "Membrane stresses due to pressure and m

Diametral Plate Diametral Plate

S

m 0,0 MPa (2) S

m 0,0 MPa (7) primary membrane stress allowable

0% S allowable =S 115,1 MPa 0% 13-4(b) "Membrane stresses due to pressure and m

(2) Bending stresses (2) Bending stresses

Shell Section Shell Section

S

b 0,6 MPa (3) (S

b

)

A 58,4 MPa (8)

1%

Diametral plate

Lv =<2R

S

b 165,9 MPa (9) or (10) weld =S.E = 115,1424419 144% 13-4(b)

UG-23(e) ? Sps =3.S

(3) Total stresses (3) Total stresses

Shell Section Shell Section

S

T 6,6 MPa (4)=(1)+(3) (S

T

)

A 64,3 MPa (11)=(6)+(8) 13-4(b) Any combination of membrane plus bending

4% 1,5.S allowable = 172,7 MPa 37% compression stress induced by pressure an

Diametral Plate Diametral Plate loads, shall not exceed the following limits:

S

m 0,0 MPa (5)=(2) S

T 166,0 MPa (12)=(7)+(9) or (10) (I) for plate section of rectangular cross sec

0% 1,5.S allowable = 172,7 MPa 96% times the allowable design stress SE;

(4)

N/A

13-4(b) "The joint efficiency factor E shall also be applied to

the allowable design stress for evaluation of the calculated

bending stress Sb at the location of the joint only. See 13-

l(d), 13-5 footnote 1, and 13-8(b)."

primary membrane +bending stress allowable

Use consistant units (mm, N/mm =MPa) or (in., psi.) with help of parameter b.

(c) for the case of unequal pressures in the compartiments, stresses are

as follows, where P is the maximum value of P1 or P2.

USE GREEN RESULTS

enter 1 for inch or 25,4 for mm

primary membrane +bending stress allowable

(b) for the case of equal pressures

with b =1,0 in. (25,4mm) for vessel without

reinforcements and for vessels with stay plates

etc note 2 p. 393

See UW-9 Design of welded joints, (f) Welded Joints Subject to Bending Stresses :

corner joints with fillet welds shall not be used unless the plates forming the corner are

properly supported independently of such welds. See UW-18 FILLET WELDS

See Section 2 for fatigue considerations.

Is this check mandatory?

If yes, is correct to check against

SE and not 1,5.SE?

14/11/200709:58 tigny - Eng-Tips ENG-TIPS de Vessel circular section single diametral staying member rev 000c.xls13-13

You might also like

- Wind Pressure Calculation As per SP-1275Document7 pagesWind Pressure Calculation As per SP-1275Siva baalanNo ratings yet

- API 650 Tank Nozzle Stand OutDocument5 pagesAPI 650 Tank Nozzle Stand Outtry&tryNo ratings yet

- Bab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselDocument36 pagesBab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselTri AgungNo ratings yet

- Tailing LugDocument3 pagesTailing LugSajad AbdulNo ratings yet

- PVElite RefDocument6 pagesPVElite RefakhilNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- Design of lifting lug on spreader beamDocument2 pagesDesign of lifting lug on spreader beamSabrang LorNo ratings yet

- Project Floodable LengthDocument5 pagesProject Floodable Lengthluckman231No ratings yet

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- Analysis of a rectangular pressure vesselDocument7 pagesAnalysis of a rectangular pressure vesselPressure VesselNo ratings yet

- Cone To Shell ReinforcementDocument4 pagesCone To Shell ReinforcementSajal KulshresthaNo ratings yet

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Loadings and Sign Convention SummaryDocument9 pagesLoadings and Sign Convention SummaryGovindan KrishnamoorthybashyamNo ratings yet

- Seismic LoadDocument1 pageSeismic LoadJae Kyoung LimNo ratings yet

- TQ-0305-R00 - Calculo Estrutura PDFDocument4 pagesTQ-0305-R00 - Calculo Estrutura PDFPeterson MagroNo ratings yet

- Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsDocument9 pagesPressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsJoemarie MartinezNo ratings yet

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNo ratings yet

- 6700 Series BearingsDocument2 pages6700 Series Bearingsmanju2designNo ratings yet

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag0% (1)

- Beams On Elastic FoundationsDocument3 pagesBeams On Elastic FoundationsIgnatius SamrajNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Shell BC-10 - FPSO Hogging and Sagging Enforced Displacements On Topsides Roel SoelemanDocument6 pagesShell BC-10 - FPSO Hogging and Sagging Enforced Displacements On Topsides Roel SoelemanRoel SoelemanNo ratings yet

- Stillwell Pipe ArrangementDocument1 pageStillwell Pipe ArrangementVishalDhiman100% (1)

- E4.5.1 6 PTB 4 2015 PDFDocument50 pagesE4.5.1 6 PTB 4 2015 PDFKingston RivingtonNo ratings yet

- ASCE 7-05 Table 15-4-2Document1 pageASCE 7-05 Table 15-4-2barouniamineNo ratings yet

- Oriental Engineering Works PVTDocument20 pagesOriental Engineering Works PVTDarshan DhimanNo ratings yet

- Unit-5 Design of Belt DrivesDocument39 pagesUnit-5 Design of Belt DrivesCHANDRASEKARANNo ratings yet

- Fiberglass Tank Saddle Support DetailsDocument1 pageFiberglass Tank Saddle Support Detailsxaaabbb_550464353No ratings yet

- Comp 2Document9 pagesComp 2YYo YudiNo ratings yet

- Screeing Method Fea FatigueDocument34 pagesScreeing Method Fea FatigueGokul Amarnath0% (1)

- Spreaer Beam&Lifting Line Beam p5Document2 pagesSpreaer Beam&Lifting Line Beam p5Sabrang LorNo ratings yet

- Vessel Data Sheet DetailsDocument1 pageVessel Data Sheet DetailsunitedmanticoreNo ratings yet

- Calculation For Gauge Pole SupportsDocument7 pagesCalculation For Gauge Pole SupportsrichardchiamNo ratings yet

- Piping Wind LoadsDocument2 pagesPiping Wind LoadsAbhishek GorkarNo ratings yet

- 2 A Davit CalculationDocument30 pages2 A Davit CalculationKarina RoquelNo ratings yet

- External Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitDocument1 pageExternal Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitSachinNo ratings yet

- Welding Neck Flanges 1Document3 pagesWelding Neck Flanges 1bikkelbobNo ratings yet

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul AdliNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- Large Horizontal Vessel Supported by Two Saddles Stress AnalysisDocument7 pagesLarge Horizontal Vessel Supported by Two Saddles Stress AnalysisSiva baalanNo ratings yet

- NozzleDocument11 pagesNozzleharyfadlyNo ratings yet

- Project JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552Document1 pageProject JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552Darshan PanchalNo ratings yet

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- Saddle Calc PD5500Document4 pagesSaddle Calc PD5500rsubramaniNo ratings yet

- Davit With ElbowDocument2 pagesDavit With Elbownitin400No ratings yet

- WRC Check List CriteriaDocument1 pageWRC Check List CriteriaAlvin Smith100% (1)

- Lifting Davit Spreadsheet Structure (Robin)Document2 pagesLifting Davit Spreadsheet Structure (Robin)TsukomaruNo ratings yet

- API 650 Storage Tank HRD - SubDocument7 pagesAPI 650 Storage Tank HRD - SubBimal DeyNo ratings yet

- Beam Spreadsheet: Ignore Lateral Torsional BucklingDocument5 pagesBeam Spreadsheet: Ignore Lateral Torsional BucklingPurnima ArkalgudNo ratings yet

- BREVIA DE CALCUL PENTRU SEPARATORUL ORIZONTAL TRIFAZIC 80MCDocument223 pagesBREVIA DE CALCUL PENTRU SEPARATORUL ORIZONTAL TRIFAZIC 80MCakın ersözNo ratings yet

- Pin StressesDocument5 pagesPin Stressesprajakt_pieNo ratings yet

- 4 - PFC To Hanging Plate ConnDocument13 pages4 - PFC To Hanging Plate Connabdul khaderNo ratings yet

- 吊耳计算Document4 pages吊耳计算huangjlNo ratings yet

- Design of Corriguteed Sheet PDFDocument41 pagesDesign of Corriguteed Sheet PDFflorinelvvNo ratings yet

- Calculation of Davit ArmDocument1 pageCalculation of Davit ArmpiziyuNo ratings yet

- Clearance CalculationDocument12 pagesClearance CalculationshazanNo ratings yet

- API 650 Tank Nozzle Stand OutDocument5 pagesAPI 650 Tank Nozzle Stand OutJunaid MateenNo ratings yet

- VT Program Rotary Screw Compressors 40-75HPDocument6 pagesVT Program Rotary Screw Compressors 40-75HPQco MyNo ratings yet

- Worked Example (Not in Notes) : Reinforced Concrete Beam: Z F A Z F M BD F A F D Z F B F A X E F D XDocument5 pagesWorked Example (Not in Notes) : Reinforced Concrete Beam: Z F A Z F M BD F A F D Z F B F A X E F D XJakir Hussain SyedNo ratings yet

- Handy 2010 Case StudyDocument6 pagesHandy 2010 Case Studycancer6No ratings yet

- Data Sheet: High-Speed DiodesDocument7 pagesData Sheet: High-Speed DiodesZoltán ÁgostonNo ratings yet

- Enabling Keycloak Metrics - KeycloakDocument3 pagesEnabling Keycloak Metrics - Keycloakhisyam darwisNo ratings yet

- ABS Approved Foundries May 12 2014Document64 pagesABS Approved Foundries May 12 2014Joe ClarkeNo ratings yet

- A Study To Assess The Effectiveness of PDocument9 pagesA Study To Assess The Effectiveness of PKamal JindalNo ratings yet

- Tes P 119 10 R0 PDFDocument43 pagesTes P 119 10 R0 PDFAbin Meetu100% (4)

- PLTW: Digital Electronics Syllabus For Mrs. Yusufi: Unit 1: Fundamentals of Analog and DigitalDocument5 pagesPLTW: Digital Electronics Syllabus For Mrs. Yusufi: Unit 1: Fundamentals of Analog and DigitalTriston DurbinNo ratings yet

- An Introduction To Muscle Response Testing MRTDocument14 pagesAn Introduction To Muscle Response Testing MRTJuan Aguilar HernándezNo ratings yet

- Acer Veriton S480G Service ManualDocument90 pagesAcer Veriton S480G Service ManualAndreea Georgiana ChirilaNo ratings yet

- Project Planning HandbookDocument21 pagesProject Planning HandbookPhilip JonesNo ratings yet

- Toaz - Info Interchange 2 Quiz Units 5 Ampamp 6 Revision Del Intento PRDocument5 pagesToaz - Info Interchange 2 Quiz Units 5 Ampamp 6 Revision Del Intento PRMarco Antonio Gonzalez CastilloNo ratings yet

- Zeal Institute of Manangement and Computer ApplicationDocument4 pagesZeal Institute of Manangement and Computer ApplicationSONAL UTTARKARNo ratings yet

- CBL Training ReportDocument12 pagesCBL Training ReportSwapnil Modak100% (1)

- NCP 1014Document24 pagesNCP 1014rodricaldasNo ratings yet

- BOQ Sample of Electrical DesignDocument2 pagesBOQ Sample of Electrical DesignAshik Rahman RifatNo ratings yet

- Nature vs Nurture DebateDocument3 pagesNature vs Nurture DebateSam GoldbergNo ratings yet

- Training Needs Analysis (Managing Training & Development)Document78 pagesTraining Needs Analysis (Managing Training & Development)Henrico Impola100% (1)

- Active-Passive VoiceDocument18 pagesActive-Passive VoiceDivya JainNo ratings yet

- Marginal Field Development Concepts (Compatibility Mode)Document17 pagesMarginal Field Development Concepts (Compatibility Mode)nallay1705100% (1)

- Formulating and Solving LPs Using Excel SolverDocument8 pagesFormulating and Solving LPs Using Excel SolverAaron MartinNo ratings yet

- Automation & Control Esst en 200804Document356 pagesAutomation & Control Esst en 200804Sveinn Rúnar JúlíussonNo ratings yet

- ManupptDocument65 pagesManupptKrishanarju VenkatesanNo ratings yet

- CDM 856 WheelloaderweichaiengineDocument1 pageCDM 856 WheelloaderweichaiengineRusmiyanto YantoNo ratings yet

- Toolbox Meeting Or, TBT (Toolbox TalkDocument10 pagesToolbox Meeting Or, TBT (Toolbox TalkHarold PonceNo ratings yet

- Ayurveda Signs of LifeDocument15 pagesAyurveda Signs of LifeSanjeethNo ratings yet

- Journal of Travel & Tourism MarketingDocument19 pagesJournal of Travel & Tourism MarketingSilky GaurNo ratings yet

- List of SDAsDocument4 pagesList of SDAsAthouba SagolsemNo ratings yet

- EN6VC IIIa 6.2 - 2023 2024Document2 pagesEN6VC IIIa 6.2 - 2023 2024Ma. Feliza SaliganNo ratings yet

- Be Circular Fibre Reinforced ConcreteDocument4 pagesBe Circular Fibre Reinforced ConcreteLim Kang HaiNo ratings yet

- Arduino - Decision Making StatementsDocument20 pagesArduino - Decision Making StatementsJohn Clifford Ambaic JayomaNo ratings yet