Professional Documents

Culture Documents

Ep 75

Uploaded by

akroma123Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ep 75

Uploaded by

akroma123Copyright:

Available Formats

1

Fan Selection

and Maintenance

J.P. Harner III

Biological and Agricultural Engineering

Kansas State University

J.P. Murphy

Biological and Agricultural Engineering

Kansas State University

M. J. Brouk

Animal Sciences and Industry

Kansas State University

J.F. Smith

Animal Sciences and Industry

Kansas State University

When reducing heat stress in dairy herds, fans are used

to enhance the evaporation of moisture from a cows back. Fan

selection should be based on performance rather than horse-

power and diameter. Certified lab studies of similar size fans

show a 50 percent difference in airflow rate per unit of input en-

ergy. Maintenance is important to ensure desired performance

and to prolong equipment life.

Fan Types

Fans can be axial flow

or centrifugal. Axial flow

fans pass air straight

through the fan parallel to

the fan blade drive shaft.

Centrifugal fans, also

known as squirrel cage

fans, bring air in through

a center inlet. The air then

makes a right angle turn

and is discharged perpen-

dicular to the fan axis.

Axial flow fans are

designed to operate at low

static pressures typically

less than 0.5 inches of

water column and are

commonly used for live-

stock building ventilation.

The initial cost is less, and

performance is influenced

less by dirt buildup on the

fan blades. Axial flow fans

are either propeller, tube

axial or vane-axial fans.

Propeller fans are the

most common. Propeller

fans have propeller-shaped

blades mounted in a circu-

lar ring or orifice plate and

a drive motor. Blade tip

clearance is an important

factor in propeller-fan

performance to achieve

higher static pressure.

A small, uniform clearance

is preferred to prevent air

from flowing back around

the propeller. These fans

move large volumes of air

at low static pressure.

Fan Performance

Airflow rate and static

pressure are closely related

for fans and ventilation

systems. The airflow rate

delivered by a fan is mea-

sured in cubic feet per

minute (cfm) against

a static pressure measured

in inches of water. The

amount of air moved is

inversely rated to the static

pressure. As the resistance

to airflow (static pressure)

increases, the delivered

airflow capacity decreases.

Therefore, a fan delivers

more air against a lower

static pressure than a higher

static pressure. The rela-

tionship between static

pressure and airflow deliv-

ery for a specific fan is

represented by a tabulation

of performance values or

fan performance curve.

Table 1 shows airflow data

of several fans in a table

format.

2

Fan ratings are ob-

tained using laboratory

equipment and standards

established by the Air

Movement and Control

Association (AMCA). If a

fan manufacturer tests fans

following these procedures,

an AMCA label and certifi-

cation can be listed in the

companys literature.

Fan performance data

is used to determine the

airflow rate a fan will

deliver when operating at

a given static pressure.

Ventilation fans are typi-

cally selected based on the

air delivery capacity at

1/10 to 1/8 inch of static

pressure. Generally in dairy

freestall housing, the fans

will be operating at

0 inches of static pressure.

Fans will be operating

against 1/10 to 1/4 inches

static pressure in tie stall or

tunnel ventilated buildings.

Fan performance data

should be reported with all

attachments including

shutters, guards and hoods.

Common measure-

ments used to describe the

characteristics of a fan are

blade diameter, revolutions

per minute (rpm) and motor

horsepower. These are

useful measurements but

without performance

characteristics such as

airflow and static pressure,

they give only general

indicators of fan capacity.

For example, test

results compared the perfor-

mance of 39 commercially

available 36-inch diameter

fans used in the ventilation

of enclosed buildings. The

test showed variability in

fan performance even

though they were similar

size fans. At a static pressure

of 1/10 inch, The air deliv-

ery capacity of these fans

varied from 6,400 to 10,000

cfm. Similar tests of 48-

inch diameter fans showed

that air delivery at 1/10

inch static pressure varied

from 14,100 to 23,000 cfm.

These large variations

in fan capacity for similar

diameter fans significantly

affects the selection process

of fans. This shows the

importance of selecting

fans based on performance

rather than strictly fan

diameter or horsepower.

Energy Efficiencies

Another characteristic

that is becoming important

when selecting fans for an

animal ventilation system is

energy efficiency. This is

expressed as airflow per

unit of input energy, or cfm

per watt. The higher cfm

per watt rating will indicate

a more efficient fan. Tests

at the University of Illinois

Agricultural Engineering

Department on 36-inch

diameter blade fans indi-

cated a wide variation in

both fan performance

(6,400 to 13,000 cfm) and

energy efficiencies (8.3 to

18.6 cfm per watt) at

1/10 inch static pressure.

Table 2 shows some effi-

ciencies ratings listed in

manufacturers literature

for several 36-inch fans.

Even fans with similar

airflow ratings can have

a significantly different

energy efficiencies. In the

study at University of

Illinois, six 36-inch fans

had airflow ratings between

9,000 and 9,900 cfm at

1/10 inch static pressure.

However, the energy

efficiencies, as measured in

cfm per watt, for these six

fans varied 8.4 to 18.6 cfm

per watt. The electrical

energy cost of these two

fans based on an airflow

rating at 1/10 inch static

Table 1. Example of airflow rates (cfm) for different fans operating at different static pressure based on data

taken from manufacturers literature.

Fan Characteristics Static Pressure (inch of water)

Diameter Horsepower Rpms 0.00 0.05 0.10 0.15

24 1/3 1100 5,300 5,000 4,700 4,400

36 1/2 845 10,800 10,300 9,700 9,000

48 1 845 19,200 18,200 17,800 16,800

3

pressure with an electrical

rate $0.10 per kilowatt hour

and 120 days (24 hrs per

day) of operation for a

warm-weather fan, shows a

cost savings of nearly $190

per year ($340 compared to

$150) by using the more

energy efficient fan. A more

energy efficient fan will

cost an additional $150 to

$250. Remember in

freestalls, one 36-inch fan

is used per six stalls, so the

net savings is around

$30 per stall after the initial

cost is recovered.

Guards typically

reduce airflow and effi-

ciency by less than five

percent. Guards are essen-

tial for the safe operation of

the fan. Guards also protect

the fan from being damaged

by large objects that can

strike the blades. Some fan

manufacturers rate fans

both with and without

shutters or guards.

If fan efficiency

ratings are not available,

the following guidelines

may be helpful.

For a given airflow and

static pressure, a large

diameter fan is more energy

efficient than a small

diameter fan.

For a given ventilating

rate, one large diameter fan

is more efficient than

several small diameter fans.

When two fans have the

same diameter and rpm, the

fan with the lower motor

current input rating is

usually more efficient.

If two fans deliver the

same airflow at the same

static pressure, the fan with

the slower speed is usually

quieter and more efficient.

If there are no methods

for comparison, a reason-

able goal for a 36-inch fan

is 11,000 cfm at zero inches

static pressure. The goal for

a 48-inch fan would be

20,000 cfm.

Maintenance

Poor maintenance can

reduce fan efficiency by

40 percent or more. Follow

manufacturers recommen-

dations for cleaning and

lubricating fans. Livestock

buildings should be wired

according the National

Electric Codes. Visual

observation at dairies reveal

dust accumulation on fans,

fan orientation adjustments

and fan damage by skid-

steers as some of the areas

where routine maintenance

may be improved.

Fan blades that are

damaged or misaligned can

be repaired. Wind and

vibration loosen the mount-

ing brackets often causing

them to become misaligned.

Correct fan orientation is

obtained by tightening the

fan and mounting brackets.

Careless operation of

equipment used to scrape

alleys, level freestalls and

bed freestalls may damage

fan guards. The whole fan

may have to be replaced

due to blade damage.

Always turn off the

electricity at the circuit

breaker or fuse box before

servicing or adjusting fans.

If pressure washers are used

for cleaning, it is a a good

idea to turn the power off

for the entire building. The

water stream may come in

Table 2. Fan performance and efficiency for different types of 36 inch -

1

/

2

hp fans based on

manufacturers literature and state performance.

Fan Diameter Airflow (cfm) at 0 Fan Efficiency

(inches) static pressure (cfm/watt)

36 11,100 17.0

36 10,400 19.0

36 11,500 19.6

36 10,810 20.0

36 10,500 24.5

36 13,200 24.8

36 11,000 15.4

*

36 11,700 16.4

*

*Watts calculated based on amps and 115 V rather than measured as with other fans.

4

contact with other electrical

circuits such as outlets or

lights. It is also important to

use lock-out procedures

when washing fans. Lock-

out procedures allow the

individual performing

maintenance on the system

to place a lock on the

service entrance panel, or

circuit breaker box, to

prevent it from being

opened. The individual

performing the work keeps

the lock key and is the only

one authorized to open the

box. This prevents another

person from turning on the

electrical circuit during

maintenance.

Ventilation systems

require routine mainte-

nance. This involves clean-

ing and adjusting fans and

thermostats. A dust build up

of an eighth of an inch on

fan blades can reduce fan

performance. Dust accumu-

lations on fan guards and

shutters can reduce fan

performance up to

40 percent. Fans should be

cleaned with a vacuum

cleaner and stiff-bristled

nylon brush to loosen dirt

before washing with a

sprayer. Care must be taken

when using a brush or high-

pressure washer to avoid

damaging the blades.

A bent or scratched blade

will cause an imbalance

between the blades, reduc-

ing fan life and perfor-

mance. A pressure washer

can be used to clean the

fan, housing and hood.

Recommended fans for

livestock buildings should

use the TE (totally en-

closed) label and ball

bearings. The fan motor

must be totally enclosed to

prevent water and dirt from

damaging motor windings.

If the motor is not totally

enclosed, then it must be

removed and cleaned

separately before cleaning

the housing with water.

Motors should be

lubricated based on

manufacturers recommen-

dations. Most ventilation

fans have sealed bearings

and do not require lubrica-

tion. Manufacturers recom-

mendations on oil type and

amount should be followed.

Oil should be used spar-

ingly on fans and motors

since it attracts dust and

soaks into the motor wind-

ings.

Thermostats should be

checked and recalibrated

monthly. Dust and dirt

accumulate on the sensors

acting as an insulator. As

a result, the sensor does not

measure temperatures

accurately or rapidly.

It is also a good idea to

schedule routine mainte-

nance on the electrical

circuit. Fuses should fit

tightly and be free of

corrosion. Periodically

examine the wire and other

electrical system compo-

nents for signs of predator

damage. Poor connections

or corrosion result in

greater electrical resistance

that can lead to overheating

and increase the chance of

fire. Plastic, water-tight

boxes and conduit are

recommended for frequent

cleaning in livestock build-

ings.

Examine fan housings,

frames and hoods for dirt

build up and corrosion. After

cleaning, they can be re-

painted with a rust and

corrosion-resistant paint to

prolong their life. When

ordering new fans, consider

fans constructed of fiber-

glass, stainless steel, plastic

or epoxy-coated housings.

Ventilation equipment

needs routine maintenance

to ensure efficient opera-

tion. Establish a service

schedule for all components

and maintain written

records of activities.

Table 3 provides a routine

maintenance schedule.

Summary

Many factors influence

the efficiency of a fan.

These include motor ability,

blade speed, housing

design, clearances and

blade shape. However, even

the most efficient fan will

not perform satisfactorily if

it is not kept clean and

properly serviced. Remem-

ber to keep fan blades clean

and motors clean and

lubricated.

5

Table 3. Listing and recommended schedule of maintenance activities.

Maintenance Activity Maintenance Schedule

Daily Monthly 6 Months Annual

Fan guards attached X

Sprinkler nozzles working X

Leaks in sprinkler water lines X

Clean/calibrate thermostat X

Fans fastened tightly to post X

Check fan orientation X

Clean fan guards X

Clean motor and controls X

Calibrate curtain controller X

Lubricate fans X

Repaint corroded metal X

Check total electrical circuit X

11

J.P. Harner, Grain and Livestock Systems, Biological & Ag Engineering, J.P. Murphy, Extension State

Leader, Biological & Ag. Engineering, M. J. Brouk, Dairy, Animal Sciences & Industry, J. F. Smith, Extension State

Leader, Dairy, Animal Sciences & Industry. Kansas State University. Manhattan, Kansas.

6

Kansas State University Agricultural Experiment Station and Cooperative Extension Service

EP 75 March 2001

It is the policy of Kansas State University Agricultural Experiment Station and Cooperative Extension Service that all persons shall have equal

opportunity and access to its educational programs, services, activities, and materials without regard to race, color, religion, national origin,

sex, age or disability. Kansas State University is an equal opportunity organization. Issued in furtherance of Cooperative Extension Work, Acts

of May 8 and June 30, 1914, as amended. Kansas State University, County Extension Councils, Extension Districts, and United States

Department of Agriculture Cooperating, Marc A. Johnson, Director.

Brand names appearing in this publication are for identification purposes only. No endorsement is intended,

nor is criticism implied of others not mentioned.

Publications from Kansas State University are available on the World Wide Web at: http://www.oznet.ksu.edu

Contents of this publication may be freely reproduced for educational purposes. All other rights reserved. In each case, credit Smith et al.,

Fan Selection and Maintenance. Manhattan, KS, Kansas State University, December 2000.

References

Arnold, G.J. and M.A. Veenhuizen. 1994. Livestock Housing Ventilation Fan Performance and

Management. Cooperative Extension Service. Ohio State University. Fact Sheet AEX-111-94.

Bodman, G.R., L.E. Stetson and J.L. Schinstock. 1993. Electrical Systems for Agricultural Build-

ings. Cooperative Extension Service. University of Nebraska-Lincoln. Neb Guide G87-846- A (revised

June 1993.)

Bodman, G.R. and D.P. Shelton. 1995. Ventilation Fans: performance. Cooperative Extension

Service. University of Nebraska-Lincoln. Neb Guide G95-1242-A.

Ford, S.E., L.L. Christianson, G.L. Riskowski, T.L. Funk, and J.B. Priest. 1992. Agricultural Venti-

lation Fans - Performance and Efficiencies. Report of Bioenvironmental and Structural Systems Labora-

tory. Department of Agricultural Engineering. University of Illinois.

Jacobson, L.D. and J.P. Chastain. 1994. Fan Performance and Efficiency for Animal Ventilation Systems.

Cooperative Extension Service. University of Minnesota. Publication No. FO-0956-GO.

MWPS. 1990. Mechanical Ventilating Systems for Livestock Housing. Midwest Plan Service. Iowa

State University. Ames. IA.

Shelton, D.P. and G.R. Bodman. 1995. Ventilation Fans: efficiency and maintenance. Cooperative

Extension Service. University of Nebraska-Lincoln. Neb Guide G95-1244-A.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Effect of Self Weight On A Cantilever BeamDocument5 pagesEffect of Self Weight On A Cantilever Beamakroma123No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- ANSYS Truss - Variable GeometryDocument2 pagesANSYS Truss - Variable Geometryakroma123No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Tut10 Modal Analysis of A Cantilever Beam Using AnsysDocument9 pagesTut10 Modal Analysis of A Cantilever Beam Using AnsysMaher KattanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Harmonic Analysis of a Cantilever Beam ResponseDocument12 pagesHarmonic Analysis of a Cantilever Beam Responseakroma123No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

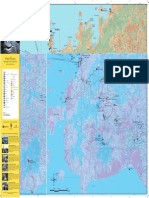

- Map of West Flores MainlandDocument1 pageMap of West Flores Mainlandakroma123No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Application of Distributed LoadsDocument7 pagesApplication of Distributed Loadsakroma123No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Design OptimizationDocument15 pagesDesign Optimizationakroma123No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Effect of Self Weight On A Cantilever BeamDocument5 pagesEffect of Self Weight On A Cantilever Beamakroma123No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Contact Element ExampleDocument3 pagesContact Element Exampleakroma123No ratings yet

- Reel Pflueger "Trion Gx-7": Metal BodyDocument2 pagesReel Pflueger "Trion Gx-7": Metal Bodyakroma123No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 463687CentFans Iom 1Document12 pages463687CentFans Iom 1akroma123No ratings yet

- Training Conveyor Belts to Run StraightDocument4 pagesTraining Conveyor Belts to Run StraightAk AbdulwahabNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- TelescopicDocument1 pageTelescopicakroma123No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- ATNEST SampleQuestionsDocument13 pagesATNEST SampleQuestionsakroma123No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Ala Institutions May2011Document1 pageAla Institutions May2011akroma123No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Interpol As IDocument6 pagesInterpol As Iakroma123No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Siart, Et. Al (2018) Digital GeoarchaeologyDocument272 pagesSiart, Et. Al (2018) Digital GeoarchaeologyPepe100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Kavanaugh On Philosophical EnterpriseDocument9 pagesKavanaugh On Philosophical EnterprisePauline Zoi RabagoNo ratings yet

- Excel Data AnalysisDocument30 pagesExcel Data AnalysisРоман УдовичкоNo ratings yet

- EtomDocument1 pageEtomarthryxNo ratings yet

- Demand Performa For Annual DemandDocument10 pagesDemand Performa For Annual DemandpushpNo ratings yet

- Laser Module 5Document25 pagesLaser Module 5Luis Enrique B GNo ratings yet

- Sewer CadDocument10 pagesSewer CadAlvaro Jesus Añazco YllpaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HWXX 6516DS1 VTM PDFDocument1 pageHWXX 6516DS1 VTM PDFDmitriiSpiridonovNo ratings yet

- Superficial ConclusionDocument49 pagesSuperficial ConclusionIngrid ParissNo ratings yet

- Events of National Importance 2016Document345 pagesEvents of National Importance 2016TapasKumarDashNo ratings yet

- Amber ToolsDocument309 pagesAmber ToolshkmydreamsNo ratings yet

- Design of Hydraulic Structures Seepage TheoryDocument13 pagesDesign of Hydraulic Structures Seepage TheorySuleman FaisalNo ratings yet

- 31 Legacy of Ancient Greece (Contributions)Document10 pages31 Legacy of Ancient Greece (Contributions)LyreNo ratings yet

- Detect Plant Diseases Using Image ProcessingDocument11 pagesDetect Plant Diseases Using Image Processingvinayak100% (1)

- 1993 - Kelvin-Helmholtz Stability Criteria For Stratfied Flow - Viscous Versus Non-Viscous (Inviscid) Approaches PDFDocument11 pages1993 - Kelvin-Helmholtz Stability Criteria For Stratfied Flow - Viscous Versus Non-Viscous (Inviscid) Approaches PDFBonnie JamesNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Internal Controls and Risk Management: Learning ObjectivesDocument24 pagesInternal Controls and Risk Management: Learning ObjectivesRamil SagubanNo ratings yet

- REFLEKSI KASUS PLASENTADocument48 pagesREFLEKSI KASUS PLASENTAImelda AritonangNo ratings yet

- Hackathon Statements V1Document10 pagesHackathon Statements V1AayushNo ratings yet

- Scan & Pay Jio BillDocument22 pagesScan & Pay Jio BillsumeetNo ratings yet

- Materials Technical Specification.: Stainless SteelDocument6 pagesMaterials Technical Specification.: Stainless SteelMario TirabassiNo ratings yet

- VLSI Physical Design: From Graph Partitioning To Timing ClosureDocument30 pagesVLSI Physical Design: From Graph Partitioning To Timing Closurenagabhairu anushaNo ratings yet

- Understanding Logistics and Supply Chain Management ConceptsDocument12 pagesUnderstanding Logistics and Supply Chain Management Conceptsarfat kabraNo ratings yet

- TM500 Design Overview (Complete ArchitectureDocument3 pagesTM500 Design Overview (Complete ArchitectureppghoshinNo ratings yet

- Shop SupervisionDocument38 pagesShop SupervisionSakura Yuno Gozai80% (5)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mock PPT 2023 TietDocument22 pagesMock PPT 2023 Tiettsai42zigNo ratings yet

- U-PJT WASHER-MD SimpleUX WEB SSEC-01 EU EnglishDocument76 pagesU-PJT WASHER-MD SimpleUX WEB SSEC-01 EU EnglishszerenguettiNo ratings yet

- WORK ORDER TITLEDocument2 pagesWORK ORDER TITLEDesign V-Tork ControlsNo ratings yet

- Board of Intermediate & Secondary Education, Lahore: Tahir Hussain JafriDocument2 pagesBoard of Intermediate & Secondary Education, Lahore: Tahir Hussain Jafridr_azharhayatNo ratings yet

- MAPEH 6- WEEK 1 ActivitiesDocument4 pagesMAPEH 6- WEEK 1 ActivitiesCatherine Renante100% (2)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)