Professional Documents

Culture Documents

P320

Uploaded by

Ivan David Gutierrez SanchezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P320

Uploaded by

Ivan David Gutierrez SanchezCopyright:

Available Formats

WOOD-FRAME

WALL ASSEMBLIES

IECC COMPLIANCE OPTIONS FOR

2

2014 International Code Council, Inc. & APA The Engineered Wood Association

IECC COMPLIANCE OPTIONS

FOR WOOD-FRAME WALL

ASSEMBLIES

Copyright 2014

By

International Code Council Inc.

500 New Jersey Avenue, NW, 6th Floor

Washington, DC 20001

And

APA The Engineered Wood Association

7011 South 19th Street

Tacoma, Washington 98466

Portions of this publication reproduce excerpts from

the 2012 International Energy Conservation Code

,

International Code Council, Inc., Washington, D.C.

Reproduced with permission. All rights reserved.

www.iccsafe.org

ALL RIGHTS RESERVED. IECC Compliance Options for

Wood-Frame Wall Assemblies is a copyrighted work

owned by the International Code Council, Inc. and

APA The Engineered Wood Association (IRC and

other code sections copyrighted solely by ICC). Without

advance written permission from the publishers, no

part of this publication may be reproduced, distributed,

or transmitted in any form or by any means, includ-

ing without limitation, electronic, optical or mechanical

means (this includes, by way of example and not limita-

tion, photocopying or recording by or in an information

storage retrieval system). For information on permission

to copy material exceeding fair use, please contact:

ICC Publications, 4051 West Flossmoor Road,

Country Club Hills, IL 60478;

Phone 1-888-ICC-SAFE (422-7233)

APA, 7011 South 19th Street, Tacoma, WA 98466;

Phone (253) 565-6600

The information contained in this publication is believed

to be accurate; however, it is being provided for infor-

mational purposes only. Publication of this document

by the ICC or APA should not be construed as the ICC

or APA engaging in or rendering engineering, legal or

other professional services. Use of the information con-

tained in this publication should not be considered by

the user as a substitute for the advice of a registered

professional engineer, attorney or other professional. If

such advice is required, it should be sought through the

services of a registered professional engineer, licensed

attorney or other professional.

Trademarks: International Code Council,

the International Code Council logo and the

International Residential Code are trademarks of

the International Code Council, Inc.

Form No. P320/Issued January 2014/0200

2014 International Code Council, Inc. & APA The Engineered Wood Association

3

2014 International Code Council, Inc. & APA The Engineered Wood Association

INTRODUCTION

Energy efficiency in residential construction is a high pri-

ority for builders working to meet more stringent energy

codes and for homeowners who are gaining a better under-

standing of the value of energy-efficient construction. This

guide, published jointly by the International Code Council

(ICC) and APA The Engineered Wood Association, describes

how energy performance is measured in exterior wood

wall assemblies and how builders can improve wall ther-

mal performance to meet code requirements. By following

the design recommendations presented here, builders can

achieve the R20 or R13+5 insulation values (Climate Zones

3-5 and Marine 4 in the 2012 and 2015 International Energy

Conservation Code (IECC) and Climate Zones 5-6 and

Marine 4 in the 2009 IECC) in the IECC Table R402.1.1.

In addition to increasing energy efficiencies, these recom-

mendations demonstrate how builders can reduce material

costs by increasing use of lower cost cavity insulation, opti-

mizing material usage with easy-to-apply advanced framing

techniques, and boosting thermal performance with insu-

lated headers and siding.

All of the assemblies shown in this guide include the use

of continuous minimum 7/16 Performance Category wood

structural panel wall sheathing. In addition to meeting

energy codes, fully sheathing with wood structural panels

i.e., plywood and oriented strand board (OSB) provides

shear strength to a structure and is a simple and cost-effective

solution to meeting the prescriptive bracing requirements

of the International Residential Code (IRC). To learn more

about meeting structural code provisions with wood struc-

tural panels, refer to the additional resources provided by

APA and ICC on page 16.

2014 International Code Council, Inc. & APA The Engineered Wood Association

4

2014 International Code Council, Inc. & APA The Engineered Wood Association

ENERGY EFFICIENCY OF WOOD-FRAME WALLS

In residential construction, exterior walls are comprised of solid wall sections, windows, and doors. The sub-

ject of this publication is conductive heat flow through solid (opaque) wall sections. Conductive heat transfer

through the walls is determined by the heat resistance or R-values of the different components of the wall assem-

bly. Typical components include framing, interior gypsum, exterior wall sheathing, exterior claddings, insulation,

and interior and exterior air films.

Heat transfer occurs through three parallel paths in the wall, as shown in Figure 1:

1. Through areas of the wall containing cavity insulation. This path usually has the greatest amount of

heat resistance because there is no framing material to displace insulation. While wood framing is a

good insulator, heat is transferred through framing components at a higher rate than through insu-

lation between framing.

2. Through areas of the wall containing framing studs and plates, including all of the vertical framing

members, top and bottom wall plates, and full-cavity width blocking.

3. Through areas of the wall containing framing headers that carry structural loads above window and

door openings. Often, the structural headers can accommodate insulation, or the structural portion

of the header can be reduced in thickness to provide space for insulation.

When calculating the overall R-value or U-factor of a solid exterior wall assembly (excluding fenestrations), the

R-values of each component through the entire thickness of the wall in each of the three parallel paths must first

be determined. The R-value for a given path is the sum of the R-values of all of the components within the path.

Each path or section R-value is then converted to a U-factor and multiplied by the percentage of the solid wall

area that the section represents. (Note that U-factors are generally the inverse of R-values and are used to eval-

uate multiple heat flow paths within a single assembly, such as walls.) These values are summed to determine

the overall U-factor for the solid wall.

5

2014 International Code Council, Inc. & APA The Engineered Wood Association

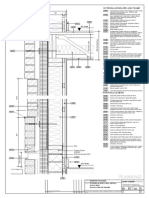

FIGURE 1

TYPICAL WALL ASSEMBLY AND HEAT TRANSFER PATHS

Header

1/2" Drywall

Cavity insulation

Min. 7/16 Performance Category

wood structural panel sheathing

Exterior cladding

Headers thermal path

Cavity insulation thermal path

Studs and plates thermal path

Exterior corner

METHODOLOGIES AND NOTES

The IECC provides four different compliance options for residential buildings. The most easy-to-use option is the pre-

scriptive insulation and fenestration compliance path provided in Section R402.1.1. The assemblies in this publication

are deemed to be equivalent to the frame wall assemblies of the prescriptive insulation requirements specified in

Table R402.1.1 of the 2009, 2012 and 2015 IECC for those climate zones that require R20 or R13+5 insulation. A two-

dimensional assembly U-factor calculation using the parallel path method as outlined in ASHRAE Handbook

Fundamentals (Chapter 27) was used to determine the assemblies that are equivalent to the R20 benchmark wall assem-

blies based on the insulation requirements of IECC Table R402.1.1. This methodology utilizes the U-factors shown in

Table 4 of ESR-2586,

1

issued in accordance with the acceptable criteria for determining wood-frame wall assemblies as

noted in ICC-ES Environmental Criteria EC115

2

and Section R102 of the IECC,

3

to show equivalency to the 2009 and

2012 IECC. To show equivalency to the 2015 IECC, this methodology utilizes Table R402.1.3 in the 2015 code. (Note

for energy raters: During the 2015 IECC code development process, all frame wall U-factors in Table R402.1.3 of the

2012 IECC were revised. The equivalent U-factor for R20 or R13+5 wall assemblies will be 0.060

4,5

in the 2015 code.)

FOOTNOTES

1. ICC Evaluation Service, ESR-2586 (Reissued June 1, 2013)

2. International Code Council Evaluation Service, Environmental Criteria EC115, Environmental Criteria for Determination of

Equivalent Wood Frame Wall Assemblies to the Prescriptive Building Thermal Envelope Requirements of the International Energy

Conservation Code and the International Residential Code (Effective Date: October 1, 2012)

3. International Energy Conservation Code, Section R102 Alternate materials method of construction, design or insulating systems

4. International Code Council, Agenda for the 2013 Public Comment Hearings for the International Energy Conservation Code

Residential, Proposals RE45-13 and RE50-13 (October 2013)

5. International Code Council, 2013 Public Comment Hearing Results for the International Energy Conservation Code Residential

(October 2013)

6

2014 International Code Council, Inc. & APA The Engineered Wood Association

DESIGN CONSIDERATION FOR

ENERGY EFFICIENT WALL ASSEMBLIES

There are a number of key considerations, in addition to the value of the cavity insulation, that affect the U-factor

calculation for wall assemblies. Several of the most common factors are described here; additional energy effi-

ciencies can be realized by varying other aspects of the wall system.

FRAMING FACTORS

The term framing factor is used to express a percentage of the total solid exterior wall area occupied by fram-

ing members, including headers. The remaining balance of the solid exterior wall area is composed of insulation.

According to a study performed for ASHRAE in 2001, there is very little regional variation in wall framing fac-

tors for attached, detached and multi-family dwellings. The report recommended a residential wall framing factor

of 25 percent for inclusion in the ASHRAE Handbook of

Fundamentals.

6

The wood wall U-factors in the IECC are calculated based

on the assumption that the area of a standard residential

wall (solid portions, excluding fenestration) consists of

25 percent framing and 75 percent insulation. This per-

centage of framing includes headers, which are typically 4

percent of the wall area, plus studs, plates and full-cavity

width blocking. Framing that does not bridge the insu-

lation (e.g., exterior or interior strapping, let-in bracing,

rim joist) is excluded.

Framing factors can vary considerably, depending on the type of construction, design and job site framing prac-

tices. An understanding of wall framing factors and insulated wall headers is important in determining the most

cost-effective wall assembly options. By reducing the framing factor, the builder is able to increase the amount

of insulation and achieve greater energy efficiency performance.

ADVANCED FRAMING

The framing factor for a solid wall assembly can be reduced by adopting advanced framing techniques to increase

the energy efficiency. Common advanced framing techniques include the following, which are detailed in APAs

Advanced Framing Construction Guide, Form M400, available from www.apawood.org:

Wall stud spacing. In standard framing, 16-inch on center spacing is typical. Advanced framing

increases stud spacing to as much as 24 inches on center for greater cavity insulation space.

Corner framing. Standard wall corners are often framed in a manner that results in enclosed corner

cavities that are difficult to insulate effectively. Advanced corner framing techniques permit insulation

to extend into corners.

Insulated interior-exterior wall intersections. Advanced framing uses flat-wise horizontal blocking

or other means to provide a means for drywall attachment where interior walls intersect with exterior

walls. This provides room for insulation in the exterior walls at these intersections.

FOOTNOTE

6. Entermodel Engineering Ltd., Characterization of Framing Factors for New Low-Rise Residential Building Envelopes (904-RP)

(August 2001)

STUDS & PLATES HEADERS 21%

INSULATION 75%

4%

Framing Factor

7

2014 International Code Council, Inc. & APA The Engineered Wood Association

Framing support members around openings. Advanced framing eliminates unnecessary cripples,

jack studs, full-cavity width blocking and bridging.

Single top plates. Advanced framing can also incorporate the use of single top plates in the wall,

provided framing members are aligned and other code limitations are satisfied.

As shown in Table 1, the IECC, ASHRAE Handbook Fundamentals, and REScheck are all based on a 25 per-

cent framing factor assumption for standard wall construction. The other referenced documents included in

Table 1 are intended to provide the reader with a basis for determining how advanced framing techniques affect

the framing factor percentage.

Table 1. Referenced Framing Percentages or Framing Factors

FRAMING FOR WOOD-FRAME WALLS

STUD SIZE 1-1/2" x 3-1/2" (2x4) OR 1-1/2" x 5-1/2" (2x6)

(FRAMING PERCENTAGE INCLUDES 4% HEADERS)

CODE

CONVENTIONAL

FRAMING

ADVANCED

FRAMING

(a)

COMMENTS 16" oc 24" oc 16" oc 24" oc

ASHRAE Handbook Fundamentals 25% 22% IECC-recognized standard

REScheck 25% 22% IECC-recognized software

OTHER REFERENCED SOURCES

RESNET 23% 20% 19% 16% Home Energy Rating System (HERS)

US Energy Star Program 23% 20% 19% 16% References RESNET Table

Canadian Energy Star Program 23% 20% 16% Consistent with US Energy Star

National Building Code

Canada

23% 20% 16%

Advanced framing with

double top plates

(a) See Advanced Framing Construction Guide, APA Form M400, available from www.apawood.org.

From the references in Table 1, the following framing factor reductions can be reasonably estimated:

Increasing stud spacing from 16 to 24 inches on center results in a 3 percent reduction.

Incorporating the additional advanced framing techniques (with the exception of single top plates)

yields an additional reduction of up to 4 percent.

The percentages listed in Table 1 are provided as a reference only. The actual framing factor percentage for each

advanced framing technique incorporated must be determined by the builder or energy designer for a given

project. Builders and designers can estimate their house plan framing factors by dividing the exterior wall area

represented by framing (including headers, plates and framing around all openings) by the exterior solid wall area.

8

2014 International Code Council, Inc. & APA The Engineered Wood Association

HEADER R-VALUES

Wall assemblies can incorporate standard headers or insulated headers. In a standard header, the wall cavity

space over the opening is typically filled by wood framing. When gravity loads do not require large headers, the

amount of space occupied by structural wood members in the header can often be reduced to provide greater

space for cavity insulation. Common types of insulated headers include:

Single-ply headers that use one thickness of lumber or engineered wood to support loads over

openings. The balance of the wall thickness can be filled with cavity insulation. For example: when a

single 2x10 header (1-1/2-inch-thick) is used in a 3-1/2-inch-thick wall, two inches of cavity insulation

can be added to net a total header area R-value of 10 or greater. (See Table 2.)

Double-ply headers with added insulation. While double-ply headers leave less room for insula-

tion, there is still opportunity to increase the thermal performance. For example: when a double 2x10

header (3-inch thick) is used in a 3-1/2-inch wall, 1/2-inch of cavity insulation can be added. If 1/2-inch

EPS rigid board insulation or polyisocyanurate is used to fill the open area, the insulation value of the

header increases from R4.38 to R5.8 and R6.8, respectively. Even greater R-values can be realized in

headers in 2x6 walls due to the additional wall thickness.

Wood structural panel box headers with insulation. Box headers incorporate the exterior wood sheath-

ing and the framing to make a continuous box beam with space inside the header for cavity insulation.

The insulation level of a box beam header can come close to the level of cavity insulation in the surround-

ing wall assembly. Section R602.7.2 of the 2012 IRC provides further details.

9

2014 International Code Council, Inc. & APA The Engineered Wood Association

Table 2 provides example insulation values for frequently used header types. To achieve the tabulated R-values,

a variety of cavity insulation R-values for the headers are indicated in the table.

Table 2. Insulation Values for Frequently Used Header Components

(a)

HEADER TYPE COMPONENT R-VALUES

TOTAL

R-VALUE 2x4 WALL WOOD INSULATION

(b)

Solid engineered wood or lumber header (3-1/2" wood) R4.38 0 R4.38

Wood structural panel box header (3-1/2" insulation) 0 R13 R10.0

(c)

Single-ply header (1-1/2" wood and 2" insulation) R1.9 R8 R9.9

Double-ply header (3" wood and 1/2" insulation) R3.8 R2 R5.8

2x6 WALL

Solid engineered wood or lumber header (5-1/2" wood) R6.88 0 R6.88

Wood structural panel box header (5-1/2" insulation) 0 R18 R14.5

(c)

Single-ply header (1-1/2" wood and 4" insulation) R1.9 R16 R17.9

Double-ply header (3" wood and 2-1/2" insulation) R3.8 R10 R13.8

(a) Common insulation products are shown in the table below. Specific R-values of the insulation products are identified on the

product, the packaging of the product, or in documentation provided by the builder or the installer of the insulation product.

This table is only meant to be used as a guide in selecting a general type of insulation product.

BATT

R-VALUE/

THICKNESS

RIGID BOARD/

SHEETS

R-VALUE/

INCH

LOOSE-FILL/

SPRAY-APPLIED

R-VALUE/

INCH

3-1/2" low density berglass R11 Expanded Polystyrene (EPS) R4 Cellulose R3.6

3-1/2" regular density berglass R13 Extruded Polystyrene (XPS) R5 Glass ber R3.6

3-1/2" high density berglass R15 Polyisocyanurate (faced) R6 Polyurethane low density R3.6

6-1/4" low density berglass

(R19 compressed to 5-1/2")

R18

Rockwool R4 Polyurethane high density R5+

5-1/2" high density berglass R21

(b) The listed R-values are based on the use of R4 rigid board insulation (fiberglass batt insulation for box headers).

(c) The total R-value shown for box headers considers both insulation and framing. 15% of the header area is assumed to be

framing. The actual R-value will vary based on box header design.

10

2014 International Code Council, Inc. & APA The Engineered Wood Association

IECC-COMPLIANT WOOD-FRAME WALL ASSEMBLIES

The wall assemblies provided in this guide comply with the R20 or R13+5 prescriptive requirements of the 2009,

2012 and 2015 IECC. Each example includes continuous minimum 7/16 Performance Category wood struc-

tural panel wall sheathing with either wood or vinyl siding. In each example, the interior and exterior air films

and drywall R-values are held constant. Air film R-values account for the thermal resistances of the interior and

exterior surfaces of the assembly.

Other wall section components are treated as variable, including:

Assemblies A, B, and C are 2x6 walls that use R19 compressed fiberglass batts (equivalent to R18) as

cavity insulation.

Assembly D is similar to assembly A but has a higher net effective wall R-value and improved U-factor

due to more extensive use of advanced framing techniques.

Assembly E is an alternate prescriptive 2x4 assembly for those instances in which 2x6 walls cannot be

incorporated into a house plan. It includes insulated siding over wood structural panel sheathing as

well as advanced framing techniques and higher performance cavity insulation.

Assembly D is included to illustrate the thermal performance of a wall assembly which incorporates a number of

additional energy-efficient techniques. This example is intended to provide guidance to builders and energy design-

ers who seek greater wall thermal performance in their 2x6 walls, while using wood structural panel wall sheathing.

The wall assemblies in this publication show a variety of insulated corner options. In some cases, drywall clips, or

other means of attaching interior drywall, are not shown for clarity.

The wall assemblies in this publication do not constitute an exhaustive list of wood frame assemblies and options to

achieve equivalent thermal performance to IECC prescriptive requirements. Additional energy efficient materials can

be incorporated into similar assemblies to achieve the same equivalent thermal performance. In addition, the framing

factor percentage for each assembly must be confirmed by the builder or energy designer.

Note that structural code issues, wall bracing, component attachment, and moisture management of the exterior wall

assembly are beyond the scope of this publication.

11

2014 International Code Council, Inc. & APA The Engineered Wood Association

R20 WALL ASSEMBLY A

LOW-DENSITY FIBERGLASS INSULATION / ADVANCED FRAMING TECHNIQUES

In order to offset the performance of lower-cost R19 compressed fiberglass batts (equivalent to R18) as cavity

insulation, this 2x6 wall assembly incorporates advanced framing techniques. The assembly includes conven-

tional headers and double top plates. The framing factor is assumed to be no greater than 20 percent.

(a)

2x6 with R19 Batt Insulation, Advanced Framing

COMPONENTS R-VALUES

Wood/Vinyl Siding 0.59

Min. 7/16 Performance Category Wood Structural Panels 0.62

Cavity Insulation (R19 compressed berglass batts) 18

5-1/2" Framing

16% framing + 4% headers = 20% framing factor

6.88

5-1/2" Headers Conventional 6.88

Air lms and 1/2" Drywall 1.38

Net Effective R-Value of the Total Solid Wall 16.67

Total Wall U-Factor 0.060

(a) 20% framing factor is calculated using studs at 24" o.c. (framing factor = 22%) with a combination of insulated corners,

insulated interior-exterior wall intersections and limited cripple supports at door and window openings (4% maximum reduc-

tion in framing percentage, 2% assumed). See page 7 for additional information. This assembly is subject to verification and

approval by the local authority having jurisdiction.

Engineered wood or lumber header

R19 compressed fiberglass batts

(equivalent to R18)

Min. 7/16 Performance Category

wood structural panel sheathing

2

4

"

o

.

c

.

Insulated corner

12

2014 International Code Council, Inc. & APA The Engineered Wood Association

R20 WALL ASSEMBLY B

LOW-DENSITY FIBERGLASS INSULATION / INSULATED HEADERS

This assembly uses insulated headers and advanced framing techniques to increase thermal values. It uses R19

compressed fiberglass batts (equivalent to R18) as cavity insulation. The assembly includes double top plates.

The framing factor is assumed to be no greater than 22 percent.

(a)

2x6 with R19 Batt Insulation, Insulated Headers, Advanced Framing

COMPONENTS R-VALUES

Wood/Vinyl Siding 0.59

Min. 7/16 Performance Category Wood Structural Panels 0.62

Cavity Insulation (R19 compressed berglass batts) 18

5-1/2" Framing

18% framing + 4% headers = 22% framing factor

6.88

5-1/2" Insulated Headers 9.6

(b)

Air lms and 1/2" Drywall 1.38

Net Effective R-Value of the Total Solid Wall 16.62

Total Wall U-Factor 0.060

(a) 22% framing factor is calculated using studs at 24" o.c. (framing factor = 22%), or studs at 16" o.c. (framing factor = 25%)

with a combination of insulated corners, insulated interior-exterior wall intersections and limited cripple supports at door and

window openings (4% maximum reduction in framing percentage, 3% assumed). See page 7 for additional information. This

assembly is subject to verification and approval by the local authority having jurisdiction.

(b) R9.6 represents a triple-ply wood header consisting of 4.5" of wood and 1" of minimum R4/inch insulation. Any header that

exceeds this R-value (e.g., an R13.8 double-ply header, as shown in Table 2) can be used.

1

6

"

o

r

2

4

"

o

.

c

.

Insulated header

R19 compressed fiberglass batts

(equivalent to R18)

Insulated corner

Min. 7/16 Performance Category

wood structural panel sheathing

13

2014 International Code Council, Inc. & APA The Engineered Wood Association

R20 WALL ASSEMBLY C

LOW-DENSITY FIBERGLASS INSULATION / INSULATED SIDING

This assembly uses only conventional framing techniques with 2x6 studs and increases thermal values with

insulated siding (a minimum insulation value of R2). The assembly includes conventional headers, double top

plates and permits the use of R19 compressed fiberglass batts (equivalent to R18) as cavity insulation. The fram-

ing factor is assumed to be no greater than 25 percent.

(a)

2x6 with R19 Batt Insulation, R2 Insulated Siding Conventional Framing

COMPONENTS R-VALUES

Insulated Siding 2.0

Min. 7/16 Performance Category Wood Structural Panels 0.62

Cavity Insulation (R19 compressed berglass batts) 18

5-1/2" Framing Conventional

21% framing + 4% headers = 25% framing factor

6.88

5-1/2" Headers Conventional 6.88

Air lms and 1/2" Drywall 1.38

Net Effective R-Value of the Total Solid Wall 17.52

Total Wall U-Factor 0.057

(a) 25% framing factor is calculated using studs at 16" o.c. with no advanced framing techniques (no reduction in framing per-

centage). See page 7 for additional information. This assembly is subject to verification and approval by the local authority

having jurisdiction.

1

6

"

o

.

c

.

m

in

.

Engineered wood or lumber header

R19 compressed fiberglass batts

(equivalent to R18)

Min. 7/16 Performance Category

wood structural panel sheathing

Any code-compliant corner

Insulated siding (R2 minimum)

14

2014 International Code Council, Inc. & APA The Engineered Wood Association

BETTER THAN R20 WALL ASSEMBLY D

AGGRESSIVE ADVANCED FRAMING AND INSULATION LEVELS

This assembly combines several enhancements to achieve a lower U-factor or higher R-value. It features 2x6 framing

and a framing factor of no greater than 18 percent through the use of advanced framing techniques. The assembly

includes R21 cavity insulation, insulated headers and double top plates. This assembly exemplifies how the per-

formance of a typical 2x6 wall can be improved with the addition of aggressive advanced framing techniques.

(a)

2x6 with R21 Batt Insulation, Insulated Headers, Advanced Framing

COMPONENTS R-VALUES

Wood/Vinyl Siding 0.59

Min. 7/16 Performance Category Wood Structural Panels 0.62

Cavity Insulation (R21 high density berglass batts, or equivalent) 21

5-1/2" Framing

14% framing + 4% headers = 18% framing factor

6.88

5-1/2" Insulated Headers 13.8

(b)

Air lms and 1/2" Drywall 1.38

Net Effective R-Value of the Total Solid Wall 19.24

Total Wall U-Factor 0.052

(a) 18% framing factor is calculated using studs at 24" o.c. (framing factor = 22%) with a combination of insulated corners, insulated inte-

rior-exterior wall intersections and limited cripple supports at door and window openings (4% reduction in framing percentage). See

page 7 for additional information. This assembly is subject to verification and approval by the local authority having jurisdiction.

(b) R13.8 represents a double-ply header consisting of 3" of wood and 2-1/2" of minimum R4/inch insulation, as shown in Table 2.

Insulated header

R21 Cavity insulation

Insulated corner

2

4

"

o

.

c

.

Min. 7/16 Performance Category

wood structural panel sheathing

15

2014 International Code Council, Inc. & APA The Engineered Wood Association

R20 WALL ASSEMBLY E

2x4 WALL

This assembly combines 2x4 framing with some advanced framing techniques. It includes insulated siding,

insulated headers, R15 cavity insulation and double top plates. The framing factor is assumed to be no greater

than 22 percent.

(a)

2x4 with R15 Batt Insulation, Insulated Headers, Insulated Siding,

Advanced Framing

COMPONENTS R-VALUES

Insulated Siding 3.0

Min. 7/16 Performance Category Wood Structural Panels 0.62

Cavity Insulation (R15 high density berglass batts, or equivalent) 15

3-1/2" Framing

18% framing + 4% headers = 22% framing factor

4.38

3-1/2" Insulated Headers 13.9

(b)

Air lms and 1/2" Drywall 1.38

Net Effective R-Value of the Total Solid Wall 16.59

Total Wall U-Factor 0.060

(a) 22% framing factor is calculated using studs at 16" o.c. (framing factor = 25%) with a combination of insulated corners, insu-

lated interior-exterior wall intersections and limited cripple supports at door and window openings (4% maximum reduction

in framing percentage, 3% assumed). See page 7 for additional information. This assembly is subject to verification and

approval by the local authority having jurisdiction.

(b) R13.9 represents a single-ply wood header consisting of 1.5" of wood and 2" of minimum R6/inch insulation.

1

6

"

o

.

c

.

Insulated siding (R3 minimum)

Insulated header

R15 Cavity insulation

Insulated corner

Min. 7/16 Performance Category

wood structural panel sheathing

16

2014 International Code Council, Inc. & APA The Engineered Wood Association

ADDITIONAL RESOURCES

RESOURCES FROM APA

APA The Engineered Wood Association offers a comprehensive set of services and tools for builders, designers,

energy raters, building officials, and other industry professionals. If youre looking for detailed product informa-

tion, training materials or technical assistance, APA can help. Resources available from APA include:

APA Website www.apawood.org is your link to in-depth design and building support, including a library of

more than 500 publications available for free instant PDF download.

CAD Details www.apacad.org features more than 250 free CAD details for wood-frame construction, including

advanced framing details.

Performance Walls www.performancewalls.org provides resources that support the design and construc-

tion of safe, durable walls that are code-compliant and energy efficient. Featured topics include wall bracing and

advanced framing. Related APA publications available for free download from this website include:

Advanced Framing Construction Guide, Form M400

Brace Walls with Wood, Form G440

Performance Walls: Simplified Bracing Method Streamlines Design, Form P310

APA System Report: APA Simplified Wall Bracing Method, Form SR-102

Build Energy Efficient Walls, Form J440

The IRC Wall Bracing Calculator is also featured at www.performancewalls.org. This online tool provides assistance

with the design of residential wall bracing for compliance with the 2009 and 2012 International Residential Code.

To learn more about the International Residential Code prescriptive bracing provisions, refer to A Guide to the

2012 IRC

Wood Wall Bracing Provisions, co-authored by APA and the International Code Council. The book,

along with information about related residential wall bracing seminars, is available at www.iccsafe.org/apa2012.

Build a Better Home www.buildabetterhome.org features construction details, tips, videos and other resources

that support the protection of homes against damaging moisture infiltration. Related APA publications available

for free download from this website include:

Build A Better Home: Walls, Form A530

Build A Better Home: Roofs, Form A535

Build A Better Home: Foundations, Form A520

Build A Better Home: Mold and Mildew, Form A525

APA Product Support Help Desk Staffed by engineered wood product specialists, the APA Help Desk answers

your questions about the specification and application of APA products. Contact (253) 620-7400 or help@apawood.org.

BUILDING CODES REFERENCED IN THIS GUIDE

Published by the International Code Council. For more information, visit www.iccsafe.org.

2009, 2012 and 2015 International Building Code

2009, 2012 and 2015 International Energy Conservation Code

2012 and 2015 International Residential Code

17

2014 International Code Council, Inc. & APA The Engineered Wood Association

ADDITIONAL REFERENCES

ASHRAE: www.ashrae.org

Building Energy Codes Program REScheck: www.energycodes.gov/rescheck

Building Science Corporation: www.buildingscience.com

Coalition for Advanced Wood Structures: www.fpl.fs.fed.us/partners/caws/index.shtml

ENERGY STAR:

www.energystar.gov

ENERGY STAR

in Canada: www.oee.nrcan.gc.ca/residential/10759

National Association of Home Builders, ICC 700 National Green Building Standard:

www.nahbgreen.org/NGBS

ICC Evaluation Service, ICC-ES Environmental Criteria: www.icc-es.org/ep/er-ec.shtml

National Research Council Canada, National Model Construction Codes and Guides:

www.nrc-cnrc.gc.ca/eng/publications/codes_centre/codes_guides.html

National Institute of Building Sciences: www.nibs.org

Residential Energy Services Network (RESNET): www.resnet.us

U.S. Department of Energy, Building Energy Codes Program: www.energycodes.gov

U.S. Department of Energy, Building Technologies Office: www.eere.energy.gov/buildings

ABOUT THE INTERNATIONAL CODE COUNCIL

The International Code Council is a member-focused association. It is dedicated to developing model codes and

standards used in the design, build and compliance process to construct safe, sustainable, affordable and resil-

ient structures. Most U.S. communities and many global markets choose the International Codes. ICC Evaluation

Service (ICC-ES) is the industry leader in performing technical evaluations for code compliance fostering safe

and sustainable design and construction.

Headquarters: 500 New Jersey Avenue, NW, 6th Floor, Washington, DC 20001-2070

District Offices: Birmingham, AL; Chicago, IL; Los Angeles, CA | 1-888-422-7233 | www.iccsafe.org

ABOUT APA

APA The Engineered Wood Association is a nonprofit trade association of and for structural wood panel, glulam

timber, wood I-joist, structural composite lumber, and other engineered wood product manufacturers. Based in

Tacoma, Washington, APA represents approximately 150 mills throughout North America, ranging from small,

independently owned and operated companies to large integrated corporations.

APA is a leader in wood-design testing and research. APAs 42,000-square-foot Research Center is staffed with

an experienced corps of engineers, wood scientists, and wood-product technicians. Their expertise plays an

important role in producing panel and engineered wood systems that meet the industrys highest performance

standards and braced-wall designs that promote the structural safety of building construction.

7011 So. 19th St., Tacoma, Washington 98466 | Headquarters: 253-565-6600

Product Support Help Desk: 253-620-7400 / help@apawood.org | www.apawood.org

ICC-ES

is the nations leader in performing technical evaluations of

building products and materials for code compliance.

ICC-ES is dedicated to providing evaluation reports of the highest quality

and technical excellence.

ICC-ES is a subsidiary of ICC

, the publisher of the IBC

, IRC

, IPC

and

other I-Codes

, and has unique expertise in building codes and standards.

We do thorough research. You approve with confdence.

Look for the ICC-ES marks of conformity before

approving for installation

www.icc-es.org | 800-423-6587

Subsidiary of ICC

CONFI DENCE

APPROVE WITH

13-07615

2014 International Code Council, Inc. & APA The Engineered Wood Association

Simple Solutions for

Code-Compliant Wall Construction

nderstanding the IRC wall bracing requirements can be a challenge, but following them is of critical importance

to a homes structural integrity. Thats why APA provides free resources and support to help building professionals

design and build safe, durable walls that are code-compliant and energy efcient. Visit PerformanceWalls.org for

instant free access to APAs extensive library of publications, CAD details, and other wall-construction resources.

SIMPLIFIED BRACING

The new APA Simplied Wall Bracing

Method using continuous plywood

or OSB sheathing delivers a more

exible, streamlined approach to

wall bracing.

ADVANCED FRAMING

Energy-efcient advanced framing

techniques are a cost-effective

solution for builders trying to balance

energy and structural building code

requirements.

SUPPORT & TRAINING

The APA Help Desk answers your

questions about wall bracing systems

and products. Our Engineered Wood

Specialists also provide webinars,

training and consultations upon request.

Visit PerformanceWalls.org to learn the bracing basics from APA

2014 International Code Council, Inc. & APA The Engineered Wood Association

IECC COMPLIANCE OPTIONS

FOR WOOD-FRAME WALL

ASSEMBLIES

Energy efficiency in residential construction is a high

priority for builders working to meet more stringent

energy codes and for homeowners who are gaining a

better understanding of the value of energy-efficient

construction. IECC Compliance Options for Wood-Frame

Wall Assemblies, published jointly by the International

Code Council and APA The Engineered Wood

Association, describes how energy performance is

measured in exterior wood wall assemblies and how

builders can improve wall thermal performance to

meet code requirements. This guide includes several

examples of wood-frame wall assemblies that comply

with the R20 and R13+5 prescriptive requirements

of the 2009, 2012 and 2015 International Energy

Conservation Code.

In addition to increasing energy efficiencies, the

recommendations in this guide demonstrate how

builders can reduce material costs by increasing use

of lower cost cavity insulation, optimizing material

usage with easy-to-apply advanced framing tech-

niques, and boosting thermal performance with

insulated headers and siding.

2014 International Code Council, Inc. & APA The Engineered Wood Association

You might also like

- Carpentry Notes On Basic Roof & Ceiling FramingDocument85 pagesCarpentry Notes On Basic Roof & Ceiling FramingBenessa Rose Quiambao100% (16)

- What is Post-Frame ConstructionDocument20 pagesWhat is Post-Frame ConstructionDoug Johns100% (5)

- Setting Up ShopDocument242 pagesSetting Up ShopFredy Alvarez Lucas100% (15)

- Everything you need to know about skillion roofsDocument2 pagesEverything you need to know about skillion roofsTeodoro Miguel Carlos IsraelNo ratings yet

- Canadian Technical Guide 20.3 SpreadsDocument48 pagesCanadian Technical Guide 20.3 SpreadsVlad Novokhatko100% (1)

- Floor Truss GuideDocument4 pagesFloor Truss GuideSamia H. BhuiyanNo ratings yet

- AWC STD355 2018WFCMWorkbook 181206 PDFDocument74 pagesAWC STD355 2018WFCMWorkbook 181206 PDFSuno AliNo ratings yet

- Five Story Wood Frame Structure Over Podium Slab 2017Document80 pagesFive Story Wood Frame Structure Over Podium Slab 2017philiSCDNo ratings yet

- Slabs TYpes of SLABS...Document15 pagesSlabs TYpes of SLABS...xhero71No ratings yet

- Post Frame Building Design ManualDocument129 pagesPost Frame Building Design Manualdiego2190No ratings yet

- Unit 3 - Sizing Beams, Joist and Lintels-ExamDocument63 pagesUnit 3 - Sizing Beams, Joist and Lintels-ExamSparki100% (1)

- Tall Walls-E PDFDocument66 pagesTall Walls-E PDFDylanLiNo ratings yet

- Truss ManualDocument10 pagesTruss ManualRiyaz SiddiqueNo ratings yet

- MinimumStandards - (Ext Wall Framing)Document14 pagesMinimumStandards - (Ext Wall Framing)Samia H. BhuiyanNo ratings yet

- Roof Sheathing FasteningDocument4 pagesRoof Sheathing Fasteningnumber_25No ratings yet

- Draining Low-Sloped Roof StructuresDocument100 pagesDraining Low-Sloped Roof StructuresAnonymous pD2ymRUguNo ratings yet

- Wood Structural SystemsDocument54 pagesWood Structural SystemsRene BermudezNo ratings yet

- 5 Roof Structure Types ExplainedDocument5 pages5 Roof Structure Types ExplainedFathi RashidNo ratings yet

- Condensation and Indoor Air Quality ProblemsDocument12 pagesCondensation and Indoor Air Quality Problemsadrian77777No ratings yet

- Air Leakage Control Materials and TechniquesDocument15 pagesAir Leakage Control Materials and TechniquesAbubakkar Siddiq100% (1)

- Apa - A535Document24 pagesApa - A535Patrice AudetNo ratings yet

- Leed ChecklistDocument96 pagesLeed ChecklistIsabela AlvesNo ratings yet

- Roof Design Principles: GenerallyDocument55 pagesRoof Design Principles: Generallyrcxy98No ratings yet

- Advanced Building Envelope Components: Comparative ExperimentsFrom EverandAdvanced Building Envelope Components: Comparative ExperimentsNo ratings yet

- Wall Framing Power PointDocument18 pagesWall Framing Power Pointapi-347440938No ratings yet

- APA - Engineered Wood Construction GuideDocument20 pagesAPA - Engineered Wood Construction GuidePatrice AudetNo ratings yet

- CGA s-1 2 1980Document24 pagesCGA s-1 2 1980Ravi GurugeNo ratings yet

- MITEK Roof ConstructionDocument20 pagesMITEK Roof ConstructionNik Btt100% (3)

- FlooringDocument27 pagesFlooringSwezen DesuzaNo ratings yet

- Design of Stacked Multistorey Wood Shearwalls Using A Mechanics Based ApproachDocument19 pagesDesign of Stacked Multistorey Wood Shearwalls Using A Mechanics Based ApproachPatrice AudetNo ratings yet

- Fireline Ceilings DetailsDocument14 pagesFireline Ceilings DetailsconorNo ratings yet

- EnerSIP Construction ManualDocument53 pagesEnerSIP Construction ManualIvan Klyuchka100% (2)

- APA Diaphragms and Shear WallsDocument32 pagesAPA Diaphragms and Shear WallsagustinussetNo ratings yet

- CS Hafele EbookDocument40 pagesCS Hafele EbookAjrod RodNo ratings yet

- SmartJoist Design Guide 2011Document40 pagesSmartJoist Design Guide 2011Suciul E ViuNo ratings yet

- 2018 NBC Book PreviewDocument70 pages2018 NBC Book PreviewRonald KahoraNo ratings yet

- Guidelines For Residential Construction 2012 International Residential CodeDocument133 pagesGuidelines For Residential Construction 2012 International Residential CodeMinh ThienNo ratings yet

- Accredited Construction Details Quinn Building ProductsDocument5 pagesAccredited Construction Details Quinn Building ProductsShofi SyarifahNo ratings yet

- 04AC - OBC Concepts and Code Analysis - Part 2Document158 pages04AC - OBC Concepts and Code Analysis - Part 2anas jbain100% (1)

- CSR Roofing ArchManual S1-S8Document127 pagesCSR Roofing ArchManual S1-S8k2v1n5100% (1)

- E2356.9080 Asbestos PDFDocument53 pagesE2356.9080 Asbestos PDFAshraf MohamedNo ratings yet

- Householders Guide To Flat RoofingDocument24 pagesHouseholders Guide To Flat RoofingBudi SudrajatNo ratings yet

- Detail Praxis - Timber ConstructionDocument55 pagesDetail Praxis - Timber Constructionaajz88% (16)

- Organizing Construction DocumentsDocument2 pagesOrganizing Construction DocumentskrisNo ratings yet

- The 2018 International Existing Building Code®: A Compilation of Wind Resistant ProvisionsDocument16 pagesThe 2018 International Existing Building Code®: A Compilation of Wind Resistant ProvisionsTommyCasillas-GerenaNo ratings yet

- TBA 09 Detailing of Clay MasonryDocument42 pagesTBA 09 Detailing of Clay MasonryHenderson CheungNo ratings yet

- Roof Tile: Insulated Panel SystemDocument48 pagesRoof Tile: Insulated Panel SystemCormac DooleyNo ratings yet

- Architects and Specification Writers: Part 1: Photo © BigstockphotoDocument11 pagesArchitects and Specification Writers: Part 1: Photo © Bigstockphotogreg gabrielNo ratings yet

- Heat Trace Fundamentals: Types, Monitoring, and Control OptionsDocument9 pagesHeat Trace Fundamentals: Types, Monitoring, and Control OptionsGanesh GanyNo ratings yet

- Space For Electrical and Machanical Services in BuildingsDocument31 pagesSpace For Electrical and Machanical Services in BuildingsAkshat Dev Singh100% (1)

- CSSBI 59 05 IntroductionDocument8 pagesCSSBI 59 05 IntroductionrigaschNo ratings yet

- Acoustical Glass: Specs & TechDocument12 pagesAcoustical Glass: Specs & TechChen Yaohui VictorNo ratings yet

- FireResistiveDocument25 pagesFireResistiveAdil KhanNo ratings yet

- Building TechnologyDocument4 pagesBuilding TechnologyDanica LuarezNo ratings yet

- Joist Design GuideDocument98 pagesJoist Design GuidemtNo ratings yet

- 08AC The Building Code Act and The OBCDocument24 pages08AC The Building Code Act and The OBCAromoc RanojNo ratings yet

- Seismic Technical Guide Seismic Expansion Joints en SC2496Document15 pagesSeismic Technical Guide Seismic Expansion Joints en SC2496carrimonn11No ratings yet

- WoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 1 PDFDocument4 pagesWoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 1 PDFtdegrobertNo ratings yet

- Roofing ShinglesDocument10 pagesRoofing Shinglescertainteed 98No ratings yet

- Disadvantages of WPC BoardDocument32 pagesDisadvantages of WPC BoardvidhiNo ratings yet

- CIB 271 - Towards Sustainable RoofingDocument33 pagesCIB 271 - Towards Sustainable RoofingAndon Setyo WibowoNo ratings yet

- WoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 2 PDFDocument4 pagesWoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 2 PDFtdegrobertNo ratings yet

- SEA Product Selector v8Document128 pagesSEA Product Selector v8Krishnakant RaneNo ratings yet

- Facade SystemDocument2 pagesFacade SystemJassimar SinghNo ratings yet

- Precast Concrete - Sandwich Panel ConstructionDocument16 pagesPrecast Concrete - Sandwich Panel Constructionalberto5791No ratings yet

- Michel Sleiman PortfolioDocument30 pagesMichel Sleiman PortfolioAnonymous 95jQpyJghVNo ratings yet

- Building Components RequirementsDocument3 pagesBuilding Components Requirementsoladipo GraceNo ratings yet

- HONOMOBO Canada Email Package 2016-June-1 PG 1 / 7Document9 pagesHONOMOBO Canada Email Package 2016-June-1 PG 1 / 7Daniel StaveNo ratings yet

- Cross-Laminated Timber Construction - An Introduction: Engineering BulletinDocument8 pagesCross-Laminated Timber Construction - An Introduction: Engineering BulletinKNo ratings yet

- BOI Guidelines For Factory Building PDFDocument16 pagesBOI Guidelines For Factory Building PDFRuwan PiyarathnaNo ratings yet

- Spancrete - CarbonCast - HP Insulated Wall PanelsDocument8 pagesSpancrete - CarbonCast - HP Insulated Wall PanelsMattSearsNo ratings yet

- Silicon Valley Power Residential Rebate Application: QualificationsDocument4 pagesSilicon Valley Power Residential Rebate Application: QualificationssandyolkowskiNo ratings yet

- Technical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesDocument117 pagesTechnical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesJankoNo ratings yet

- Architect Uses Ancient Techniques To Cool Modern Building in India - TreeHuggerDocument6 pagesArchitect Uses Ancient Techniques To Cool Modern Building in India - TreeHuggerShashank JainNo ratings yet

- Recess in Brick DetailDocument1 pageRecess in Brick DetailMartinNo ratings yet

- Nov 11Th: Next IssueDocument40 pagesNov 11Th: Next IssuemwmccarthyNo ratings yet

- GLACIER LAr Tank Design (Deliverable 2.2)Document76 pagesGLACIER LAr Tank Design (Deliverable 2.2)atiqulaNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intertherm - 3350 - Eng - A4 - 20150818Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intertherm - 3350 - Eng - A4 - 20150818vtnhoemNo ratings yet

- Promethean Insulation Technology v. Energy Efficient SolutionsDocument22 pagesPromethean Insulation Technology v. Energy Efficient SolutionsPriorSmartNo ratings yet

- Mongolia Housing Feasibility StudyDocument34 pagesMongolia Housing Feasibility Studymunir HussainNo ratings yet

- Literature ReviewDocument1 pageLiterature ReviewShammas MohamedNo ratings yet

- Sanctum Technologies LTD - Company ProfileDocument15 pagesSanctum Technologies LTD - Company ProfileKumarNo ratings yet

- Energy Consumption and Efficiency in Green BuildingsDocument5 pagesEnergy Consumption and Efficiency in Green BuildingsM Raihan SaputraNo ratings yet

- Lossna-Board: Heat-Resistant Material SeriesDocument14 pagesLossna-Board: Heat-Resistant Material SeriesLord VarioNo ratings yet

- Data Sheet Pit Carburizing Furnace - 1656052217Document4 pagesData Sheet Pit Carburizing Furnace - 1656052217Kestrel MgNo ratings yet