Professional Documents

Culture Documents

Warra Et Al 2011

Uploaded by

Pedro Gerardo Trejo FloresOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Warra Et Al 2011

Uploaded by

Pedro Gerardo Trejo FloresCopyright:

Available Formats

Available online at www.scholarsresearchlibrary.

com

Scholars Research Library

Archives of Applied Science Research, 2011, 3 (4):536-541

(http://scholarsresearchlibrary.com/archive.html)

ISSN 0975-508X

CODEN (USA) AASRC9

536

Scholars Research Library

Extraction and Physicochemical Analysis of some selected Northern

Nigerian Industrial oils

Warra, A.A.

*1

, Wawata, I.G

2

. Gunu, S.Y

1

. and Aujara, K.M.

3

1

Dept. of Biochemistry, Kebbi State University of Sci. &Technology, PMB 1144, Aliero, Nigeria

2

Dept. of Pure & Applied Chem., Kebbi State Univ. of Sci. &Tech., PMB 1144, Aliero, Nigeria

3

Department of Science Laboratory Technology, Jigawa State Polytechnic, Dutse, Nigereia

_________________________________________________________________

ABSTRACT

The physicochemical parameters; Saponification value, Iodine value and Acid value of some

selected Northern Nigerian industrial oils were determined. The following values were obtained

for the various parameters measured; For Castor seed oil, Saponification value 123.3 3.428

mgKOH/g, Iodine value 76.93 0.397 g I

2

/100g and Acid value 2.39 0.065 mgKOH/g were

obtained. For Jatropha oil, Saponification value 122.49 2.591 mgKOH/g, Iodine value 73.46

5.00 g I

2

/100g and Acid value 1.20 0.065 mgKOH/g were obtained. For Cotton seed oil,

Saponification value 199.42 0.53 mgKOH/g, Iodine value 119.78 0.81 g I

2

/100g and Acid

value 0.81 0.01 mgKOH/g were obtained. The oil yield for Castor seed oil, Jatropha oil and

Cotton seed oil were 42% , were 48% , were 48% respectively. The objective was to justify their

industrial utilization.

Key words: Seed oils, extraction, oil yield, chemical analysis, industrial uses.

_________________________________________________________________

INTRODUCTION

Seed oils are important sources of nutritional oils, industrial and pharmaceutical importance

[15]. There are numerous vegetable oils derived from various sources. These include the popular

vegetable oils: the foremost oilseed oils - soybean, cottonseed, peanuts and sunflower oils; and

others such as palm oil,palm kernel oil, coconut oil, castor oil, rapeseed oil and others. They also

include the less commonly known oils such as rice bran oil, tiger nut oil, patua oil, kome oil,

niger seed oil, piririma oil and numerous others. Their yields, different compositions and by

extension their physical and chemical properties determine their usefulness in various

Warra, A.A.

et al Arch. Appl. Sci. Res., 2011, 3 (4):536-541

______________________________________________________________________________

537

Scholars Research Library

applications aside edible uses [4]. The characteristics of oils from different sources depend

mainly on their compositions and no oil from a single source can be suitable for all purposes

[13]. This work is aimed at extraction and physicochemical analysis of some selected Northern

Nigerian Industrial oils in order to justify their industrial utilization.

MATERIALS AND METHODS

Source of Research materials

Indigenous Castor and Jatropha seeds were plucked directly from plant during three consecutive

years (2007 - 2009) harvesting seasons. The plants were identified and authenticated by a

Botanist at the Biological Sciences Department, Bayero University, Kano (BUK) Nigeria.

Confirmation of taxonomic identity of the plants was achieved by comparison with voucher

specimens (voucher No. 225 and No. 110) respectively kept at the Herbarium of the Department

of Biological Sciences, Biological Sciences Department, Bayero University, Kano (BUK) and

use of documented literature [11]. Wild variety, which ripens from late October until late

December, was obtained from a test plot in Warra town of Ngaski Local Government Area of

Kebbi State, Nigeria. Good seeds were carefully selected cleaned, de-shelled and well dried.

Seeds were grounded using laboratory plastic pestle and mortar prior to extraction. While the

cotton seeds were collected from Inter-ginnery plant at Gusau in Zamfara state, Nigeria. The

shells were cracked with sharp knife to remove the seed, which were grounded into small sizes

and then sundried for 5days.

Oil extraction

The extraction of 5.0g of grounded seed kernels of Indigenous Jatropha Curcas.L. and Castor

was conducted in a soxhlet extractor using n-hexane (boiling point of 4060 C) for six hours.

The oils were obtained after the solvent was removed under reduced temperature and pressure

and refluxing at 70 C to remove excess solvent used in the oil.. Extracted seed oil was stored in

freezer at2 C for subsequent physicochemical analysis. While for the cotton seed in addition to

solvent extraction the crude cotton seeds were clarified using 0.5M NaOH.

Oil Yield

Each oil which was recovered by complete distilling of most of the solvent on a heating mantle

was then transferred to measuring cylinder. The measuring cylinder is then placed over water

bath for complete evaporation of solvent for about 2-3 hours in accordance with the method

reported [20] and volume of the oil was recorded and expressed as oil content(%) as follow

Oil weight

Oil content (%) = ____________ 100

Sample weight

Chemical Analysis

The chemical analysis of the oils was carried out using the methods reported [7]., [2], and [8].

Saponification value: 2 g of the oil sample was added to a flask with 30cm

3

of ethanolic KOH

and was then attached to a condenser for 30 minutes to ensure the sample was fully dissolved.

After sample they had cooled, 1cm

3

of phenolphthalein was added and titrated with 0.5M HCl

until a pink endpoint has reached.

Warra, A.A.

et al Arch. Appl. Sci. Res., 2011, 3 (4):536-541

______________________________________________________________________________

538

Scholars Research Library

Saponification value was calculated from the equation

(S-B) x M x 56.1

SV = ____________

Sample weight (g)

Where S = sample titre value

B = blank titre value

M = molarity of the Hcl

56.1 = molecular weight of KOH

Iodine value: 0.4 g of the sample was weighed into a conical flask and 20 cm

3

of carbon tetra

chloride was added to dissolve the oil. Then 25cm

3

of Dams reagent was added to the flask

using a safety pipette in fume chamber. Stopper was then inserted and the content of the flask

was vigorously swirled. The flask was then placed in the dark for 2 hours 30 minutes. At the end

of this period, 20cm

3

of 10% aqueous potassium iodide and 125cm

3

of water were added using a

measuring cylinder. The content was titrated with 0.1M sodium thiosulphate solutions until the

yellow colour almost disappeared.

Few drops of 1% starch indicator was added and the titration continued by adding thiosulphate

drop wise until blue coloration disappeared after vigorous shaking. The same procedure was used

for blank test and other samples [2].

The iodine value (I.V) is given by the expression

12.69C (V

1

-V

2

)

I. V. = _____________

M

Where C = Concentration of sodium

V

1

= Volume of sodium thiosulphate used for blank

V

2

= Volume of sodium thiosulphate used for determination

M = Mass of the sample.

Acid value: 100 ml of neutral ethyl alcohol was heated with 10 g of oil or fat sample in a 250cm

3

beaker until the mixture began to boil. The heat was removed and was titrated with N/10 KOH

solution, using two drops of phenolphthalein as indicator with consistent shaking for which a

permanent pink colour was obtained at the end point.

The Acid value was calculated using the expression; A.V = 0.56 x No. of ml. N/10 KOH used

RESULTS

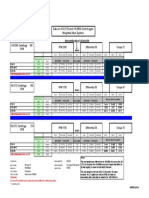

The results obtained are presented in table 1

Warra, A.A.

et al Arch. Appl. Sci. Res., 2011, 3 (4):536-541

______________________________________________________________________________

539

Scholars Research Library

Table 1: Physicochemical characteristics of the selected Nigerian industrial oils*

The values are mean and standard deviation of triplicates determination.*

DISSCUSSION

The physicochemical analysis (Table 1), determined for the soxhlet extracted indigenous

Jatropha seed oil includes; Saponification value of 122.49 2.591 mgKOH/g the value

obtained was lower than that of Dennettia tripatala fruit oil(Pepper fruit)159.331-20 suitable

for soap making [14] but higher than that of beeswax (93 mgKOH/g), which are commonly used

in soap making [12]. This indicates that the oil could be used in soap making since its

saponification value falls within the range of these oils. Higher saponification justifies the usage

of fat or oil for soap production. Iodine value of 50.50 8.023 I

2

/100g (less than 100) was

obtained, which shows that the oil belongs to the class of Non-drying oils, which are useful in

the manufacture of soaps [11]. An Acid value of 14.77 0.065mgKOH/g was obtained which is

lower than that of olive oil 17 mgKOH/g [9] higher than the 10.49 3mgKOH/g reported [19]

suitable for soap production. The results of the physicochemical analysis (Table 1), determined

for the soxhlet extracted indigenous castor seed oil includes; Saponification value of 123.3

3.428 mgKOH/g the value obtained was lower than that of Terminalia catappa seed oil 207

0.13 suggested for use in the production of liquid soap, shampoos and lather shaving creams [16]

but higher than that of beeswax (93 mgKOH/g), which are commonly used in soap making [12].

This indicates that the oil could be used in soap making since its saponification value falls within

the range of these oils. Higher saponification justifies the usage of fat or oil for soap production.

Iodine value of 76. 93 0.397 I2/100g (less than 100) was obtained, which shows that the oil

belongs to the class of Non-drying oils, which are useful in the manufacture of soaps [11]. Castor

oil has only one double bond in each fatty acid chain and so is classified as nondrying oil. An

Acid value of 2.39 0.065 mgKOH/g was obtained which is lower than that of Demettia

tripetala fruit oil( Pepper fruit) 5.34 0.04 mgKOH/g [14] and Shea butter 10.3mgKOH/g [23],

higher than that of Palm kernel seed oil 0.834 0.004mgKOH/g reported [1] suitable for soap

production.

The results of the physicochemical analysis of Nigerian cotton seed oil (Table 1) showed that it

has Saponification value of 199.42 0.53 mgKOH/g which is lower than 213mgKOH/g in

neem seed oil [3] and 253.2mgKOH/g in coconut oil [18] higher than that of Dennettia tripatala

fruit oil(Pepper fruit)159.331-20 [14] and African pear oil 143.76 mgKOH/g which could be

good for soap making [10]. This indicates that the oil could be used in soap making since its

saponification value falls within the range of these oils. Higher saponification justify the usage of

fat or oil for soap production.

Iodine value of 119.78 0.81g I

2

/100g was obtained which is higher than 104.3g I

2

/100g for

sesame seed oil [21] and 84.8 g I

2

/100g for ground nut oil [22] useful in the manufacture of

Selected Industrial oils Castor seed oil Jatropha curcas L. seed oil Cotton seed oil

Saponification value mgKOH/g

Iodine value gI

2

/100g

Acid value mgKOH/g

Oil yield (%)

123.3 3.428

76.93 0.397

2.39 0.065

42

122.49 2.591

73.46 5.00

1.20 0.065

48

199.42 0.53

119.78 0.81

0.81 0.01

48

Warra, A.A.

et al Arch. Appl. Sci. Res., 2011, 3 (4):536-541

______________________________________________________________________________

540

Scholars Research Library

soaps and lower than the Iodine value of C. lanatus 119.8 g I

2

/100g [5] which is within a range

of semi-drying oils consisting predominately polyunsaturated fatty acids mainly oleic and

lenoliec fatty acids. This class of oils whose iodine value is between 100 150 possesses the

property of absorbing oxygen on exposure to the atmosphere; though do not do so sufficiently to

qualify them as drying oils. They become thicken and remain sticky but do not form a hard dry

film. They are used in the production of margarine and soap [17]; [6].

An Acid value of 0.81 0.01 was obtained which is lower than that of olive oil 17 mgKOH/g

[9] and shea nut fat 10.49mgKOH/g reported [19] and 10.3mgKOH/g for shea nut butter

reported [23] suitable for soap making.

REFERENCES

[1] Afolabi,I.S.. Biokemistri. 2008; 20: 71-75

[2] Akpan, U. G., Jimoh, A. and Mohammed, A. D.. Leonardo J. Sci. 2006; 8: 43-52.

[3] Akpan, U.G In: (Ed) Eyo, A.A. Aluko, P.O, Garba, S.A, Ali, U.D, Lamai, S.L and

Olufeagba, S.O.2000. Proceedings of the 12

th

Annual Conference of the Biotechnology Society

of Nigeria, 1999; PP.63-66.

[4] Aluyor, E.O. and Ori-Jesu, M. African J. Biotechnol, 2008; 7 (25): 4836-4842

[5] Anhwange, B. A., Ikyenge, B.A, Nyiatagher, D.T.and Ageh, J.T. J. Appl. Sci. Res. 2010;

6(3): 265-268

[6] Anyasor, G.N., K.O. Ogunwenmo, O.A. Oyelana, D. Ajayi and J. Dangana, Pakistan J.

Nutrition., 2009; 8(3): 269-272

[7] AOAC. Official Methods of analysis of the Association of Official Analytical Chemists,16

th

Edition, 1998; Gaithersburg, USA.

[8] Bassir, O.(1978). Handbook of Practical Biochemistry, Ibadan University Press, 1978;

Ibadan, Nigeria.

[9] Davine, J and Williams,P.N. The chemistry and technology of edible oils and fats. 1

st

Edetion, Pergamon press. 1961. London .

[10] Ikhuoria,E.U. and Maliki, M. African J. Biotechnol. 2007; 6(7): 950-952

[11] Kochhar,S.L(1998).Economic Botany in the Tropics. 2

nd

edition. 1998; Macmillan India

Ltd.

[12] Mabrouk, S.T. J. Chem. Educ. 2005; 82(10):1534-1537

[13] Mohammed, R.F. and Jorf-Thomas, M. Phytochem. Anal., 2003; 14: 366-370.

[14] Nwinuka, N. M.and Nwiloh, B. I. Nigerian J. Biochem. Mol. Biol.. 2009; 24 (1): 42 - 46.

[15] Nzikou, J.M., Mvoula-Tsiri, M., Pambou-Tobi, N.P.G., Ndangui, C.B., Kimbonguila, A.,

Silou, T. Linder, M., Scher,J., and. Desobry,S. Australian J. Basic Appl. Sci.2010; 4(7): 2039-

2047.

[16] Nzikou, J.M., Matos, .L., Bouanga-Kalou,.G., Ndangui,.C.B., Pambou-Tobi, N. P. G.

Kimbonguila, A. Silou, T., Linder, M and Desobry,S. Advance J. Food Sci. Technol. 2009;

1(1): 6-11

[17] Odoemelam, S.A. Pakistan J. Nutrition. 2005; 4(6): 382-383.

[18] Oshinowo, T. J. Nigerian Soc. of Chem. Engineers. 1987; 6(1):36-41.

[19] Oyedele, A.O. Nigerian J. Nat. Prod. Med. 2002; 66: 26-29

[20] Pant,K.S., Koshla,V.,Kumar,D.and Gairola,G. Lyonia. 2006; 11(2):31-34

[21] Warra, A.A., Suraj, L.G .and Jega, S.A. Bayero J. Pure Appl. Sci. 2011; 4(1):180-183

Warra, A.A.

et al Arch. Appl. Sci. Res., 2011, 3 (4):536-541

______________________________________________________________________________

541

Scholars Research Library

[22] Warra, A.A., Hassan, L.G.

Gunu, S.Y and Jega, S.A. Nigerian J. Basic Appl. Sci.2010;

18: 315-321

[23] Warra, A.A. ,Gunu,S.Y, Jega,S.A and Aisha, J.A.(2009). Int. J. Nat. Appl. Sci., 2009; 5(4):

410-412

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Tap Yourself FreeDocument134 pagesTap Yourself Freenguyenhavn100% (2)

- 500 Important Spoken Tamil Situations Into Spoken English Sentences SampleDocument7 pages500 Important Spoken Tamil Situations Into Spoken English Sentences SamplerameshdurairajNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Configuration & Options List: 30Xw0452 1752 Water Cooled Liquid ChillerDocument22 pagesConfiguration & Options List: 30Xw0452 1752 Water Cooled Liquid ChillerOctavio Farid Rossi YumhaNo ratings yet

- Citric Acid Passivation of Stainless SteelDocument41 pagesCitric Acid Passivation of Stainless Steelnqh2009100% (2)

- Ford 1982 3.8L V6Document22 pagesFord 1982 3.8L V6sc100% (1)

- Philippine Mango Seed Oil: An Untapped ResourceDocument8 pagesPhilippine Mango Seed Oil: An Untapped ResourceFrancis Peñaflor0% (1)

- NitrocelluloseDocument7 pagesNitrocellulosejumpupdnbdjNo ratings yet

- Celiac DiseaseDocument14 pagesCeliac Diseaseapi-355698448100% (1)

- High Risk Medications in AyurvedaDocument3 pagesHigh Risk Medications in AyurvedaRaviraj Pishe100% (1)

- Jessyresearch PDFDocument8 pagesJessyresearch PDFGisse May Concepción ZamoraNo ratings yet

- Quassia Undulata Seed OilDocument4 pagesQuassia Undulata Seed OilPedro Gerardo Trejo FloresNo ratings yet

- Sensory Characteristics of Ice Cream Produced in The U.S.A. and ItalyDocument19 pagesSensory Characteristics of Ice Cream Produced in The U.S.A. and ItalyPedro Gerardo Trejo FloresNo ratings yet

- Articulo de HeladosDocument11 pagesArticulo de HeladosPedro Gerardo Trejo FloresNo ratings yet

- Khaya SenegalensisDocument3 pagesKhaya SenegalensisPedro Gerardo Trejo Flores100% (1)

- 17 .Unifem Oil Extraction Food Cycle Technology Source Book No 1 1987Document48 pages17 .Unifem Oil Extraction Food Cycle Technology Source Book No 1 1987Pedro Gerardo Trejo FloresNo ratings yet

- HemiDocument28 pagesHemiPedro Gerardo Trejo FloresNo ratings yet

- Colorimetric Method Determination Sugars and Related SubstancesDocument7 pagesColorimetric Method Determination Sugars and Related SubstancesPedro Gerardo Trejo FloresNo ratings yet

- Aqueous Enzymatic Extraction ofDocument92 pagesAqueous Enzymatic Extraction ofPedro Gerardo Trejo FloresNo ratings yet

- Papaya Seeds PDFDocument6 pagesPapaya Seeds PDFPedro Gerardo Trejo FloresNo ratings yet

- Arbuscular in TibetDocument7 pagesArbuscular in TibetPedro Gerardo Trejo FloresNo ratings yet

- Albizia Seed Oil PDFDocument5 pagesAlbizia Seed Oil PDFPedro Gerardo Trejo FloresNo ratings yet

- Effect of Antioxidants On The Oxidative StabilityDocument15 pagesEffect of Antioxidants On The Oxidative StabilityPedro Gerardo Trejo FloresNo ratings yet

- Amylases and Their ApplicationsDocument5 pagesAmylases and Their Applicationsmy krishnaNo ratings yet

- nấmDocument18 pagesnấmthaibinh90No ratings yet

- Plant CellDocument8 pagesPlant CellPedro Gerardo Trejo FloresNo ratings yet

- Effect of Pectinolytic and Amylolytic Enzymes OnDocument16 pagesEffect of Pectinolytic and Amylolytic Enzymes OnPedro Gerardo Trejo FloresNo ratings yet

- Effect of Pectinolytic and Amylolytic Enzymes OnDocument16 pagesEffect of Pectinolytic and Amylolytic Enzymes OnPedro Gerardo Trejo FloresNo ratings yet

- Aqueous Enzymatic Extraction ofDocument92 pagesAqueous Enzymatic Extraction ofPedro Gerardo Trejo FloresNo ratings yet

- Anti NutritiveDocument11 pagesAnti NutritivePedro Gerardo Trejo FloresNo ratings yet

- AMF in ChinaDocument11 pagesAMF in ChinaPedro Gerardo Trejo FloresNo ratings yet

- Leachate For SorghumDocument7 pagesLeachate For SorghumPedro Gerardo Trejo FloresNo ratings yet

- Comparación de Las Características Químicas, Físicas y Perfil de ÁcidosDocument11 pagesComparación de Las Características Químicas, Físicas y Perfil de ÁcidosJalcamNo ratings yet

- Diaz Et Al 2008Document7 pagesDiaz Et Al 2008Pedro Gerardo Trejo FloresNo ratings yet

- Continuous Biodiesel Production via Transesterification of Vegetable Oils in Supercritical MethanolDocument6 pagesContinuous Biodiesel Production via Transesterification of Vegetable Oils in Supercritical MethanolPedro Gerardo Trejo FloresNo ratings yet

- Bondioli., Et Al (2003)Document7 pagesBondioli., Et Al (2003)Pedro Gerardo Trejo FloresNo ratings yet

- Sarín Et Al., 2010Document5 pagesSarín Et Al., 2010Pedro Gerardo Trejo FloresNo ratings yet

- Bunyakiat 2006Document8 pagesBunyakiat 2006Pedro Gerardo Trejo FloresNo ratings yet

- HemiDocument28 pagesHemiPedro Gerardo Trejo FloresNo ratings yet

- Overlord - Volume 01 - The Undead KingDocument223 pagesOverlord - Volume 01 - The Undead KingPaulo FordheinzNo ratings yet

- Print Date:: Container No NO Size Seal No Seal Party Supplier Status Movement TypeDocument3 pagesPrint Date:: Container No NO Size Seal No Seal Party Supplier Status Movement TypeYudha PermanaNo ratings yet

- Principle Harmony RhythmDocument16 pagesPrinciple Harmony RhythmRosalinda PanopioNo ratings yet

- HS-2172 Vs HS-5500 Test ComparisonDocument1 pageHS-2172 Vs HS-5500 Test ComparisonRicardo VillarNo ratings yet

- Manual Del GVMapper v3 3 PDFDocument102 pagesManual Del GVMapper v3 3 PDFguanatosNo ratings yet

- Speech for pecha kuchaDocument6 pagesSpeech for pecha kuchaaira mikaela ruazolNo ratings yet

- Advanced Composite Materials Design EngineeringDocument19 pagesAdvanced Composite Materials Design EngineeringpanyamnrNo ratings yet

- GSM Modernization Poster2Document1 pageGSM Modernization Poster2leonardomarinNo ratings yet

- Contact GRRSB Team for InquiriesDocument2 pagesContact GRRSB Team for Inquiriesmsis81No ratings yet

- Project Data Collection & Risk ReportingDocument2 pagesProject Data Collection & Risk Reportinggambler yeagerNo ratings yet

- Datta Das FET ExplanationDocument2 pagesDatta Das FET ExplanationJulie HaydenNo ratings yet

- Tyfo SDocument2 pagesTyfo SAndi AsNo ratings yet

- Datasheet Optris XI 410Document2 pagesDatasheet Optris XI 410davidaldamaNo ratings yet

- News Writing April 2019Document39 pagesNews Writing April 2019Primrose EmeryNo ratings yet

- GPS and The Quest For Pizza: National Aeronautics and Space AdministrationDocument1 pageGPS and The Quest For Pizza: National Aeronautics and Space Administrationvijay maddiNo ratings yet

- 18 Butterfly Valves A Disc BrayDocument10 pages18 Butterfly Valves A Disc BrayAli FananiNo ratings yet

- White Paper Without Track ChangesDocument7 pagesWhite Paper Without Track Changesapi-609064761No ratings yet

- 1999 - Seismic Soil Structure Interaction in Buildings - I Analytical Aspects PDFDocument13 pages1999 - Seismic Soil Structure Interaction in Buildings - I Analytical Aspects PDFCesar PugsioNo ratings yet

- Hexagon MI GLOBAL S DataSheet Letter EN NAFTA Rel5Document22 pagesHexagon MI GLOBAL S DataSheet Letter EN NAFTA Rel5dudecastro1542No ratings yet

- A Feature Selection Based On The Farmland Fertility Algorithm For Improved Intrusion Detection SystemsDocument27 pagesA Feature Selection Based On The Farmland Fertility Algorithm For Improved Intrusion Detection SystemsRashed ShakirNo ratings yet

- IMRAD - G1 PepperDocument13 pagesIMRAD - G1 PepperRomero, Ken Angelo B.No ratings yet

- Causes of DyspneaDocument9 pagesCauses of DyspneaHanis Afiqah Violet MeowNo ratings yet