Professional Documents

Culture Documents

Water Furnace NDW Install Manual

Uploaded by

gerdo1234Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Furnace NDW Install Manual

Uploaded by

gerdo1234Copyright:

Available Formats

IM1007WN 03/10

Installation Information

Water Piping Connections

Electrical Data

Microprocessor Control

Startup Procedures

Preventive Maintenance

N

D

W

I

n

s

t

a

l

l

a

t

i

o

n

M

a

n

u

a

l

NDW 8 to 15 Tons Hydronic Heat Pump

NDW INSTALLATION MANUAL

Table of Contents

Model Nomenclature 4

General Installation Information 5

Dimensional Data 6

Physical Data 7

Field Connected Water Piping 8-9

NDW Typical Application Piping 10

Water Quality 11

Electrical Data 12

Wiring Schematics 13-16

Field Wiring and Control Setup 17-18

Control Features 19-20

Sequence of Operation 21

Inputs and Outputs Configuration 22

Networking Protocol 22

Unit Display and Interface 23-25

Reference Calculations 26

Legend 26

Unit Startup 27

Operating Parameters 28

Pressure Drop 28

Thermistor and Compressor Resistance 29

Heat of Extraction/Rejection Data 29

Heating Cycle Analysis 30

Cooling Cycle Analysis 30

NDW Startup and Troubleshooting Form 31

Troubleshooting 32

Preventive Maintenance 33

Service Parts List 34

4

NDW INSTALLATION MANUAL

NDW 8 to 15 Ton Hydronic Unit

Model Nomenclature

1-3 4-6 7 8 9 10 11 12-13 14

NDW 120 R 1 8 N B SS A

Family

NDW = Envision Series

Hydronic Heat Pump

Capacity

100 MBTUH

120 MBTUH

150 MBTUH

180 MBTUH

Operation

R = Reversible

Voltage

1 = 208-230/60/1 (Residential)

1

0 = 208-230/60/1 (Commercial)

3 = 208-230/60/1

4 = 460/60/3

5 = 575/60/3

NOTES:

1

Vintage code A

2

IntelliStart available only on 208-230/60/1 units

Vintage

A = Residential Voltage Code

B = Commercial Voltage Code

Non-Standard Options

SS = Standard

Water Connections

B = Back mounted connections

T = Top mounted connections

IntelliStart Option

N = None

A = IntelliStart

2

Controls

8 = FX10 without communication,

with User Interface

9 = FX10 w/ Open N2 Com Card,

w/ User Interface

0 = FX10 w/ Lonworks Com Card,

with User Interface

3 = FX10 w/ BacNet Com Card,

w/ User Interface

All Envision Series product is safety listed under UL1995 thru ETL and performance listed with AHRI in

accordance with standard 13256-2. The Envision Series is also Energy Star rated.

5

NDW INSTALLATION MANUAL

Safety Considerations

Installing and servicing air conditioning and heating

equipment can be hazardous due to system pressure and

electrical components. Only trained and qualified service

personnel should install, repair or service heating and air

conditioning equipment. When working on heating and

air conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit and other

safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have

fire extinguisher available for all brazing operations.

NOTE: Before installing, check voltage of unit(s) to ensure

proper voltage.

WARNING: Before performing service or

maintenance operations on the system, turn off

main power switches to the unit. Electrical shock

could cause serious personal injury.

Application

Units are not intended for heating domestic (potable) water

by direct coupling. If used for this type of application, a

secondary heat exchanger must be used.

Moving and Storage

Move units in the normal Up orientation as indicated by

the labels on the unit packaging. When the equipment

is received, all items should be carefully checked against

the bill of lading to ensure that all crates and cartons

have been received in good condition. Examine units for

shipping damage, removing unit packaging if necessary

to properly inspect unit. Units in question should also

be internally inspected. If any damage is observed, the

carrier should make the proper notation on delivery receipt

acknowledging the damage. Units are to be stored in a

location that provides adequate protection from dirt, debris

and moisture.

WARNING: To avoid equipment damage, do not

leave the system filled in a building without heat

during cold weather, unless adequate freeze

protection levels of antifreeze are used. Heat

exchangers do not fully drain and will freeze

unless protected, causing permanent damage.

General Installation Information

Unit Location

Provide sufficient room to make water and electrical

connections. If the unit is located in a confined space,

provisions must be made for unit servicing. Locate the

unit in an indoor area that allows easy removal of the

access panels and has enough space for service personnel

to perform maintenance or repair. These units are not

approved for outdoor installation and, therefore, must be

installed inside the structure being conditioned. Do not

locate units in areas subject to freezing conditions.

WARNING: Do not store or install units in

corrosive environments or in locations subject

to temperature or humidity extremes (e.g. attics,

garages, rooftops, etc.). Corrosive conditions and

high temperature or humidity can significantly

reduce performance, reliability, and service life.

WARNING: To avoid equipment damage and

possible voiding of warranty, be sure that

properly sized strainers are installed upstream

of both brazed plate heat exchangers to protect

them against particles in the fluid.

Mounting Units

Units should be mounted level on a vibration absorbing pad

slightly larger than the base to provide isolation between

the unit and the floor. It is not necessary to anchor the unit

to the floor. Allow access to the front, back, and side access

panels for servicing.

Vibration Pad Mounting

6

NDW INSTALLATION MANUAL

Dimensional Data

LOAD

SOURCE

CONTROL BOX

CONTROL BOX

2' ALTERNATE

SERVICE ACCESS

OPTIONAL LOW VOLTAGE

(7/8" KNOCKOUT)

2' ALTERNATE

SERVICE ACCESS

OPTIONAL LOW

VOLTAGE

(7/8" KNOCKOUT)

OPTIONAL

TOP WATER

CONNECTIONS

LINE VOLTAGE

(1-3/8" KNOCKOUTS)

LOW VOLTAGE

(7/8" KNOCKOUT)

LINE VOLTAGE

(1-3/8" KNOCKOUTS)

LOW VOLTAGE

(7/8" KNOCKOUT)

CONTROL BOX SHIPS

STANDARD OPPOSITE

OF WATERLINES, BUT

HAS FIELD OPTION

TO BE SWITCHED

CONTROL BOX

OPTION

CONTROL BOX

OPTION

CONTROL BOX SHIPS

STANDARD OPPOSITE

OF WATERLINES, BUT

HAS FIELD OPTION

TO BE SWITCHED

17.00

12.11

33.59

25.58

24.01

2.16 21.06 2.16

2.96

10.18

12.11

14.05

12.11

33.60

25.58

24.01

10.18

12.11

14.05

5.28

5.82

2.26 21.07 2.26

LOAD

SOURCE

STANDARD

OPTIONAL

WATERLINES

STANDARD

OPTIONAL

WATERLINES

2'

PRIMARY

SERVICE

ACCESS

2'

PRIMARY

SERVICE

ACCESS

LOAD

SOURCE

CONTROL BOX

CONTROL BOX

2' ALTERNATE

SERVICE ACCESS

OPTIONAL LOW VOLTAGE

(7/8" KNOCKOUT)

2' ALTERNATE

SERVICE ACCESS

OPTIONAL LOW

VOLTAGE

(7/8" KNOCKOUT)

OPTIONAL

TOP WATER

CONNECTIONS

LINE VOLTAGE

(1-3/8" KNOCKOUTS)

LOW VOLTAGE

(7/8" KNOCKOUT)

LINE VOLTAGE

(1-3/8" KNOCKOUTS)

LOW VOLTAGE

(7/8" KNOCKOUT)

CONTROL BOX SHIPS

STANDARD OPPOSITE

OF WATERLINES, BUT

HAS FIELD OPTION

TO BE SWITCHED

CONTROL BOX

OPTION

CONTROL BOX

OPTION

CONTROL BOX SHIPS

STANDARD OPPOSITE

OF WATERLINES, BUT

HAS FIELD OPTION

TO BE SWITCHED

17.00

12.11

33.59

25.58

24.01

2.16 21.06 2.16

2.96

10.18

12.11

14.05

12.11

33.60

25.58

24.01

10.18

12.11

14.05

5.28

5.82

2.26 21.07 2.26

LOAD

SOURCE

STANDARD

OPTIONAL

WATERLINES

STANDARD

OPTIONAL

WATERLINES

2'

PRIMARY

SERVICE

ACCESS

2'

PRIMARY

SERVICE

ACCESS

NDW100-180 - Top Waterline Configuration

NDW100-180 - Back Waterline Configuration

7

NDW INSTALLATION MANUAL

Physical Data

Model

NDW

100 120 150 180

Compressor (2 each) Scroll

Factory Charge R410A, oz [kg] 62 [1.76] 62 [1.76] 62 [1.76] 62 [1.76]

Load Water Connection

FPT - in 2 2 2 2

Source Water Connection

FPT - in 2 2 2 2

Weight - Operating, lb [kg] 390 [177] 400 [181] 400 [181] 420 [190]

Weight - Packaged, lb [kg] 385 [175] 395 [179] 395 [179] 415 [188]

3/9/09

8

NDW INSTALLATION MANUAL

General

Each unit is equipped with captive 2 in. [50.8 mm] FPT water

connections to eliminate egg-shaping from use of a backup

wrench. For making the water connections to the unit, a Teflon

tape thread sealant is recommended to minimize internal

fouling of the piping. Do not over tighten connections.

NOTE: Units are factory run-tested using propylene glycol.

Prior to connecting piping to unit, thoroughly flush heat

exchangers.

The piping installation should provide service personnel

with the ability to measure water temperatures and

pressures. The water lines should be routed so as not to

interfere with access to the unit. The use of a short length

of high pressure hose with a swivel type fitting may simplify

the connections and prevent vibration. Optional stainless

steel hose kits are available as an accessory item.

Before final connection to the unit, the supply and return

hose kits must be connected, and the system flushed

to remove dirt, piping chips and other foreign material.

Normally, a combination balancing and close-off (ball) valve

is installed at the return, and a rated gate or ball valve is

installed at the supply. The return valve can be adjusted to

obtain the proper water flow. The valves allow the unit to

be removed for servicing. Both source as well as load fluid

piping must be at least as large as the unit connections on

the heat pump (larger on long runs).

Never use flexible hoses of a smaller inside diameter than

that of the water connection on the unit and limit hose length

to 10 ft. per connection. Check carefully for water leaks.

Load and Source Piping Connections

The NDW Series has two connection options available. Each kit

is intended to connect one piping connection. Therefore, two

kits will be required for each unit. The kits can be mixed for

installer convenience, one on source and the other on load.

CKNDW1 - Strainer Connection Kit includes a 2 copper tee with

integral P/T plug and a 2 Y strainer. Other components to

complete the all copper piping can be sourced locally.

HHK162S - Strainer Hose Kit set includes 2 Hose kit includes a

2 stainless steel braided hose with integral P/T plug and 2 Y

strainer.

Field Connected Water Piping

Water Flow Rate

The proper water flow must be delivered to each unit

whenever the unit heats or cools. To assure proper flow,

the use of pressure/temperature ports is recommended

to determine the flow rate. These ports should be located

adjacent to the supply and return connections on the unit.

The proper flow rate cannot be accurately set without

measuring the water pressure drop through the refrigerant-

to-water heat exchanger (See Pressure Drop Table for water

flow and pressure drop information).

Load Flow Rate

The load flow on all water to water products including the

NDW Series should be 3 gpm per ton (typically the rated

flow and the highest flow shown in the capacity charts).

Refer to the table below. This flow rate is required especially

when heating water to limit the effects of the higher

condensing temperatures of water heating for radiant floor

heating or domestic water use.

Source Flow Rate

The source flow can range between 2.25 and 3 gpm per

ton for earth loops. For open loop well water systems the

minimum flow should be 1.5 gpm per ton. In earth loop

systems where entering water temperatures are expected to

be above 95F, 3 gpm per ton should be used. In well systems

where the water temperature is below 50F, 2 gpm per ton

should be used to avoid nuisance freeze detection trips.

Flushing

Flushing the system of debris is especially important in

brazed plate heat exchanger systems. These systems have

many small parallel flow paths in which debris can clog.

Initial flushing of the system can be accomplished in one of

two ways. First flushing the piping system as shown (pages

6-7) toward the strainer will allow the strainers to capture

all debris prior the heat exchangers and commissioning.

Secondly a temporary bypass can be included in the piping

design so that the heat pump itself can be bypassed during

the initial flushing stage with an external strainer gathering

the debris.

CAUTION: Water piping exposed to outside

temperature may be subject to freezing.

Source Flow Rate

Load

Flow

Rate

Minimum

Open

Loop

Open

Loop

< 50F

Closed Loop Range

(Min - Full Flow)

NDW100 15 20 23 30 30

NDW120 18 24 27 36 36

NDW150 21 28 32 42 42

NDW180 24 32 36 48 48

CKNDW1 HHK162S

9

NDW INSTALLATION MANUAL

Field Connected Water Piping cont.

Closed Loop Tower/Boiler Systems

The water loop is usually maintained between 60F [15.5C]

and 90F [32.2C] for proper heating and cooling operation.

This is accomplished with a cooling tower and a boiler.

To reject excess heat from the condenser water loop, the

use of a closed-circuit evaporative cooler or an open type

cooling tower with a secondary heat exchanger between

the tower and the condenser water loop is recommended.

If an open type cooling tower is used without a secondary

heat exchanger, continuous chemical treatment and filtering

of the water must be performed to ensure the water is free

from damaging materials.

CAUTION: Water piping exposed to outside

temperature may be subject to freezing.

Open Loop Well Water Systems

Installation of an open loop system is not recommended

unless water quality guidelines are met.

Earth Coupled Systems

All supply and return water piping should be insulated to

prevent excess condensation from forming on the water

lines. Ensure pumping system is capable of providing

adequate flow rate at the system pressure drop, 3.0 GPM

per ton [0.054 LPS per kW] (source side) is recommended.

Antifreeze in the loop is strongly recommended.

Heating with High Source Temperatures

Heating water with a water to water unit using high source

temperatures can lead to operating conditions that fall

outside of the system operating range. The condition occurs

when the loop (source) temperature exceeds 70F [21.1C]

with a full flow of 3 GPM per ton [0.054 LPS per kW].

Under this scenario, the evaporating temperature can fall

outside of the compressor operating window.

To allow the system to operate correctly, restricting the

source side flow when the evaporating temperature

exceeds 55F [12.7C] is recommended. One way of

accomplishing this is to use a flow-restricting valve on the

source loop circuit that is controlled by the evaporating

temperature. Locate the sensing device on the refrigerant

inlet of the evaporator. In dual circuit systems, the company

recommends monitoring both circuits and controlling off

the sensor that reads the highest temperature.

As an alternative to the evaporating temperature, the

suction line temperature can be monitored with the same

control capability. In this control, temperature should be a

maximum of 65F [18.3C].

A kit is available for this application, contact WaterFurnace

for support.

Open Loop Well Water Systems

NDW

Well Tank

Solenoid

Valve

Ball Valve

Boiler Drain

Y-strainer

PT Ports

Earth Coupled Systems

NDW

Flow

Center

PT Ports

Y-strainer

Closed Loop (Boiler/Tower) Systems

NDW

Ball Valves

Y-strainer

PT Ports

10

NDW INSTALLATION MANUAL

NDW Typical Application Piping

LOAD PUMP

HYDRONIC

LOAD

Source OUT

P/T Ports

Ball Valve

Dielectric

Unions

Dielectric

Unions

WaterFurnace

NDW Series

NOTE: * A 30 PSI pressure relief valve

(Part No: SRV30) should be used in

hydronic applications.

1-1/2

FPT

Expansion

Tank

Air

Vent

Pressure

Gauge

30 PSI

RELIEF VALVE

Air

Separator

Back Flow Preventer /

Pressure Relief Valve

GEO

STORAGE

TANK

3-Way Valves

Y-Strainer

(required to prevent

damage from fouling)

Hose Kit

Pressure

Reduction

Pressure

Reduction

Hose Kit

P/T Ports

Source IN

Y-Strainer

(required to prevent

damage from fouling)

Flow Switch

(optional)

11

NDW INSTALLATION MANUAL

General

NDW systems may be successfully applied in a wide range of

residential, commercial, and industrial applications. It is the

responsibility of the system designer and installing contractor

to ensure that acceptable water quality is present and that all

applicable codes have been met in these installations.

Water Treatment

Do not use untreated or improperly treated water. Equipment

damage may occur. The use of improperly treated or

untreated water in this equipment may result in scaling,

erosion, corrosion, algae or slime. The services of a qualified

water treatment specialist should be engaged to determine

what treatment, if any, is required. The product warranty

specifically excludes liability for corrosion, erosion or

deterioration of equipment.

The heat exchangers in the units are 316 stainless steel plates

with copper brazing. The water piping in the heat exchanger

is steel. There may be other materials in the buildings piping

system that the designer may need to take into consideration

when deciding the parameters of the water quality.

If an antifreeze or water treatment solution is to be used, the

designer should confirm it does not have a detrimental effect

on the materials in the system.

Contaminated Water

In applications where the water quality cannot be held to

prescribed limits, the use of a secondary or intermediate heat

exchanger is recommended to separate the unit from the

contaminated water.

Material Copper 90/10 Cupro-Nickel 316 Stainless Steel

pH Acidity/Alkalinity 7- 9 7 - 9 7 - 9

Scaling Calcium and Magnesium Carbonate (Total Hardness) less than 350 ppm (Total Hardness) less than 350 ppm (Total Hardness) less than 350 ppm

Hydrogen Sulfide

Less than .5 ppm (rotten egg smell

appears at 0.5 PPM)

10 - 50 ppm Less than 1 ppm

Sulfates Less than 125 ppm Less than 125 ppm Less than 200 ppm

Chlorine Less than .5 ppm Less than .5 ppm Less than .5 ppm

Chlorides Less than 20 ppm Less than125 ppm Less than 300 ppm

Carbon Dioxide Less than 50 ppm 10 - 50 ppm 10- 50 ppm

Ammonia Less than 2 ppm Less than 2 ppm Less than 20 ppm

Ammonia Chloride Less than .5 ppm Less than .5 ppm Less than .5 ppm

Ammonia Nitrate Less than .5 ppm Less than .5 ppm Less than .5 ppm

Ammonia Hydroxide Less than .5 ppm Less than .5 ppm Less than .5 ppm

Ammonia Sulfate Less than .5 ppm Less than .5 ppm Less than .5 ppm

Total Dissolved Solids (TDS) Less than 1000 ppm 1000-1500 ppm 1000-1500 ppm

LSI Index

+0.5 to -.05 +0.5 to -.05

Iron, Fe

2

+ (Ferrous)

Bacterial Iron Potential

< .2 ppm < .2 ppm < .2 ppm

Iron Oxide

Less than 1 ppm. Above this level

deposition will occur.

Less than 1 ppm. Above this level

deposition will occur.

Less than 1 ppm. Above this level

deposition will occur.

Suspended Solids

Less than 10 ppm and filtered for max of

600 micron size

Less than 10 ppm and filtered for max of

600 micron size

Less than 10 ppm and filtered for max of

600 micron size

Threshold Velocity (Fresh Water) < 6 ft/sec < 6 ft/sec < 6 ft/sec

Grains = PPM divided by 17 mg/l is equivalent to PPM 2/8/08

Corrosion

Erosion

Iron Fouling

(Biological Growth)

+0.5 to -.05

Water Quality

The following table outlines the water quality guidelines

for unit heat exchangers. If these conditions are exceeded,

a secondary heat exchanger is required. Failure to supply

a secondary heat exchanger where needed will result in a

warranty exclusion for primary heat exchanger corrosion or

failure.

Strainers

These units must have properly sized strainers upstream of

both brazed plate heat exchangers to protect them against

particles in the fluid. Failure to install proper stainers and

perform regular service can result in serious damage to the

unit, and cause degraded performance, reduced operating

life and failed compressors. Improper installation of the unit

(which includes not having proper strainers to protect the

heat exchangers) can also result in voiding the warranty.

Field supplied strainers with 20-40 mesh (530-1060 microns)

are recommended, with 30 mesh (800 microns) being the

optimum choice. The strainers selected should have a mesh

open area of at least 6 square inches (39 square centimeters)

for each unit being serviced by the strainer. Using strainers

with a smaller amount of open area will result in the need for

more frequent cleaning.

Strainers should be selected on the basis of acceptable

pressure drop, and not on pipe diameter. The strainers

selected should have a pressure drop at the nominal flow rate

of the units low enough to be within the pumping capacity of

the pump being used.

WARNING: Must have intermediate heat

exchanger when used in pool applications.

Water Quality Guidelines

12

NDW INSTALLATION MANUAL

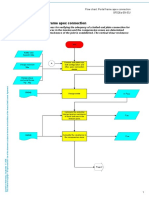

Figure 1 - Control Box

208 or 230

Volt Switch

(If applicable)

Power Supply

(Field line voltage

connection)

Compressor

Contactor (CC-A)

Compressor

Contactor (CC-B)

Field Low Voltage

Connections

FX10 Control Board

FX10 Expansion Board

Run Capacitor

(Single Phase Only)

Transformer

Compressor

Current Sensors

Optional IntelliStart

TM

(Single Phase Only) Pump Contactor

(CC-P)

Electrical Data

Model

Supply

Circuit

Rated

Voltage

Voltage

Min/Max

Compressor* Load

Pump

FLA

Source

Pump

FLA

Total

Unit

FLA

Min

Circ

Amp

Max

Fuse/

HACR

MCC RLA LRA LRA**

100

L1/L2 208-230/60/1 187/253 41.2 26.4 134.0 47.0 - - 26.4 33.0 50

L3/L4 208-230/60/1 187/253 41.2 26.4 134.0 47.0 4.2 4.2 34.8 41.4 60

Single 208-230/60/3 187/253 24.9 16.0 110.0 - - - 32.0 36.0 50

Single 460/60/3 414/506 12.1 7.8 52.0 - - - 15.6 17.6 25

Single 575/60/3 517/633 8.9 5.7 38.9 - - - 11.4 12.8 15

120

L1/L2 208-230/60/1 187/253 47.0 30.1 145.0 51.0 - - 30.1 37.6 60

L3/L4 208-230/60/1 187/253 47.0 30.1 145.0 51.0 4.2 4.2 38.5 46.0 70

Single 208-230/60/3 187/253 28.0 17.3 120.0 - - - 34.6 38.9 50

Single 460/60/3 414/506 15.0 9.6 70.0 - - - 19.2 21.6 30

Single 575/60/3 517/633 12.5 8.0 53.0 - - - 16.0 18.0 25

150

L1/L2 208-230/60/1 187/253 42.0 26.9 145.0 51.0 - - 26.9 33.6 60

L3/L4 208-230/60/1 187/253 42.0 26.9 145.0 51.0 4.2 4.2 35.3 42.0 60

Single 208-230/60/3 187/253 35.0 22.4 190.0 - - - 44.8 50.4 70

Single 460/60/3 414/506 19.0 12.2 87.0 - - - 24.4 27.5 30

Single 575/60/3 517/633 15.0 9.6 62.0 - - - 19.2 21.6 30

180

L1/L2 208-230/60/1 187/253 50.0 32.1 185.0 65.0 - - 32.1 40.1 70

L3/L4 208-230/60/1 187/253 50.0 32.1 185.0 65.0 4.2 4.2 40.5 48.5 80

Single 208-230/60/3 187/253 39.0 26.0 190.0 - - - 52.0 58.5 80

Single 460/60/3 414/506 19.0 13.0 100.0 - - - 26.0 29.3 40

Single 575/60/3 517/633 14.5 9.3 72.0 - - - 18.6 20.9 30

7/22/09

HACR circuit breaker in USA only

* Ratings per each compressor - unit supplied with two

** With optional IntelliStart (single phase only)

13

NDW INSTALLATION MANUAL

Wiring Schematics

208-230/60/1

2 4 V

T r a n s f o r m e r

S

F

S

L

F

S

E

S

J

o

h

n

s

o

n

F

X

-

1

0

5

V

D

C

A

I3

3

5

3

6

3

7

3

8

+ -A

I5

-+A

I4

-+A

I6

A

I2

A

I1

5

V

D

C

5

V

D

C

L

E

D

--- +++

24VAC

24VACCom

GROUND

3

9

4

0

4

1

P

W

M

2

P

W

M

2

C

o

m

P

W

M

1

4

2

4

34

4

4

54

6

4

7

4

8

2

4

V

A

C

C

o

m

D

I1

2

D

I1

1

D

I1

0

D

I9

D

I8

D

I7

4

9

5

0

5

1

5

2

5

3

5

4

5

5

5

6

D

I 3

/4

/5

/6

/ C

o

m

D

I6

D

I5

D

I4

D

I3

D

I2

D

I1

9

V

D

C

2

0

1

9

1

8

1

7

1

61

5

1

4

1

3

1

21

1

1

0987654321

D

0

9

D

0

8

D

0

7

D

06

D

0

5

D

0

4

D

0

3

D

0

2

D

0

1

J

8

J

2

J

1

0

J

9

J

7

N

O

T

E

7

A21 A12

A25 A22

A32

A31 A35

A23

A13

A11

A15

A14

A24

A34

A33

3

4

L

P

-A

L

P

-B

3 1

3 0

2 9

2 8

2 7

2 6

2 5

2 4

2 3

2 2

2 1

2 0

A I 4 E X P

5 V d c C o m

J 2

5 V d c

5 V d c C o m

A I 3 E X P

5 V d c

5 V d c C o m

A I 2 E X P

5 V d c

5 V d c C o m

A I 1 E X P

5 V d c

1 7

1 6

1 5

1 4

1 3

1 2

1 1

1 0

D O 3

2 4 V a c

D O 4

D O 5

D O 6

2 4 V a c

2 4 V a c C o m

J 3

2 4 V a c

J 1

M a i n B o a r d

C o n n e c t i o n

A 4 1

A 3 1

A 2 3

A 1 3

A

4

3

A

4

2

A

3

2

A

3

3

A

2

1

A

2

2

A

1

2

A

1

1

4

3

2

1

D 0 2

D 0 1

6

D 0 75

8

D 0 87

J

o

h

n

s

o

n

F

X

1

0

E

x

p

a

n

s

io

n

B

o

a

r

d

P

B

1

23 1

(

C

ir

c

u

it B

)

C

u

rre

n

t S

w

itc

h

C

S

B

B

la

c

k

B

la

c

k

C

o

m

p

r

e

s

s

o

r

B

la

c

k

(F

1

)

B

la

c

k

(F

2

)

B

la

c

k

(F

3

)

B

la

c

k

(F

4

)

B

la

c

k

(F

5

)

B

la

c

k

(F

6

)

B

la

c

k

(F

7

)

B

la

c

k

(F

8

)

B

la

c

k

(F

9

)

B

la

c

k

(F

1

0

)

B

la

c

k

(F

1

1

)

B

la

c

k

(F

1

2

)

B

la

c

k

(F

1

3

)

B

la

c

k

(F

1

4

)

B

la

c

k

(F

1

5

)

B

la

c

k

(F

1

6

)

B

la

c

k

(F

1

7

)

B

la

c

k

(F

1

8

)

B

la

c

k

(F

1

9

)

B

la

c

k

(F

2

0

)

1 2 3 4 5 7 8 9 1

06 1

1

1

2

1

3

1

6

1

5

1

4

1

7

2

0

1

9

1

8 A

3

3

3

2

3

1

3

0

2

9

2

8

2

7

2

6

2

5

2

4

2

3

162734951

0 8

W

h

ite/R

e

d

(8

0

)

W

h

ite/R

e

d

(8

1

)

W

h

ite/B

lu

e

(3

3

)

W

h

ite/B

lu

e

(3

4

)

Y

e

llo

w

/R

e

d

(3

5

)

Y

e

llo

w

/R

e

d

(3

6

)

Y

e

llo

w

/B

lu

e

(3

7

)

Y

e

llo

w

/B

lu

e

(3

8

)

T

a

n

/B

la

c

k

(8

4

)

T

a

n

/B

la

c

k

(8

5

)

W

h

ite/R

e

d

(8

0

)

W

h

ite/R

e

d

(8

1

)

TTT T

W

h

ite/B

lu

e

(3

3

)

W

h

ite/B

lu

e

(3

4

)

Y

e

llo

w

/R

e

d

(3

5

)

Y

e

llo

w

/R

e

d

(3

6

)

T

Y

e

llo

w

/B

lu

e

(3

7

)

Y

e

llo

w

/B

lu

e

(3

8

)

T

a

n

/B

la

c

k

(8

4

)

T

a

n

/B

la

c

k

(8

5

)

S

-W

C

T

C

irc

u

it A

L

-W

C

T

C

irc

u

it A

S

-W

C

T

C

irc

u

it B

L

-W

C

T

C

irc

u

it B

L

L

T

B

la

c

k

R

e

d

2

0

8

V

B

lu

e

2

3

0

V

B

la

c

k/W

h

ite

Y

e

llo

w

Y

e

llo

w

Y

e

llo

w

Y

e

llo

w

Y

e

llo

w

(2

4

)

B

la

c

k

(9

5

)

G

re

e

n/Y

e

llo

w

(2

3

)

Y

e

llo

w

(2

1

)

B

la

c

k/W

h

ite

(2

2

)

Y

1

C

O

M

P

1

L

C

1

C

o

m

p

A

A

la

rm

R

S

D

O

-9

X

2

D

O

-7

R

2

4

V

A

C

S

S

D

O

-8

L

C

2

C

o

m

p

B

A

la

rm

X

1

A

c

c

C

2

4

V

A

C

C

O

M

T

O

N

O

T

U

S

E

D

S

C

N

O

T

U

S

E

D

A

IC

N

O

T

U

S

E

D

L

N

O

T

U

S

E

D

O

/B

R

E

V

V

A

L

V

E

G

N

O

T

U

S

E

D

Y

2

C

O

M

P

2

1

6

1

2 8 2 9 4 1

07 5 3 1

1

1

461

3

1

5 1

T

B

B

la

c

k

(S

S

)

B

la

c

k

(C

)

B

la

c

k

(R

S

)

B

la

c

k

(R

)

B

la

c

k

(X

2

)

B

la

c

k

(L

C

2

)

B

la

c

k

(L

C

1

)

B

la

c

k

(X

1

)

B

la

c

k

(Y

1

)

B

la

c

k

(Y

2

)

B

la

c

k

(O

/B

)

B

la

c

k

(G

)

B

la

c

k

(A

IC

)

B

la

c

k

(S

C

)

B

la

c

k

(L

)

B

la

c

k

(T

O

)

B

7

/

2

8

/

0

9

B

la

c

k/W

h

ite

(2

6

)

B

la

c

k

(3

0

)

B

la

c

k

(3

0

)

B

la

c

k

(2

9

)

B

la

c

k

(2

9

)

Y

e

llo

w

(2

5

)

Y

e

llo

w

(2

5

)

B

la

c

k

(2

8

)

B

la

c

k

(2

8

)

B

ro

w

n

(5

3

)

B

ro

w

n

(5

3

)

B

ro

w

n

(5

2

)

B

ro

w

n

(5

2

)

B

lu

e

(5

1

)

B

lu

e

(5

1

)

B

la

c

k

(7

5

A

)

B

la

c

k/O

rg

(7

5

B

)

C

C

-B

C

C

-A

B

la

c

k

(6

4

A

)

V

io

le

t (6

7

)

V

io

le

t (6

6

)

B

la

c

k/W

h

ite

(2

7

)

B

la

c

k/W

h

ite

(2

7

)

23 1

P

B

2

B

la

c

k

(5

4

)

R

e

d

(5

5

)

G

ra

y

(5

6

)

P

in

k

(5

8

)

B

ro

w

n

(5

7

)

G

ra

y

(5

9

)

61

571

6981

7

1

45 1

8

1

3413 1

2

1

0

1

12

T

E

S

T

B

rn

/W

h

t (8

6

)

B

rn

/W

h

t (8

7

)

T

L

S

T

B

rn/B

lk

(4

1

)

B

rn/B

lk

(4

2

)

B l a c k

B l a c k

C

S

-A

C

irc

u

it A

B l a c k

B l a c k

C

S

-B

C

irc

u

it B

B

lu

e

(4

5

)

B

lu

e

(4

5

)

B

lu

e

(4

6

)

B

lu

e

(4

6

)

B

lu

e

(4

5

)

B

lu

e

(4

6

)

O

ra

n

g

e

(4

7

)

O

ra

n

g

e

(4

7

)

O

ra

n

g

e

(4

7

)

G

ra

y

(4

8

)

C

o

n

n

e

c

t to

R

o

n

P

B1

-1

W

h

ite

(6

7

)

W

h

ite

(6

7

)

W

h

ite

(6

7

)

W

h

ite

(6

6

)

W

h

ite

(6

6

)

W

h

ite

(6

6

)

B

lu

e

(5

0

)

O

ra

n

g

e

(6

0

)

O

ra

n

g

e

(6

0

)

O

ra

n

g

e

(6

0

)

T

a

n

/W

h

ite

(8

2

)

T

a

n

/W

h

ite

(8

3

)

B l a c k ( A )

B l a c k ( A )

W h i t e ( B )

W h i t e ( B )

O

ra

n

g

e

(6

1

A

)

O

ra

n

g

e

(6

1

A

)

O

ra

n

g

e

(6

1

B

)

R

V

1

R

V

2

O

ra

n

g

e

(6

0

A

)

O

ra

n

g

e

(6

1

A

)

O

ra

n

g

e/W

h

t (6

0

B

)

O

ra

n

g

e/W

h

t (6

1

B

)

T

E

L

T

T

a

n

/W

h

ite

(8

2

)

T

a

n

/W

h

ite

(8

3

)

T

a

n

/W

h

ite

(8

2

)

T

a

n

/W

h

ite

(8

3

)

B

la

c

k

(4

9

)

B

lu

e

(7

6

A

)

B

lu

e

(7

6

A

)

B

lu

e

(7

6

B

)

B

lu

e

(7

6

B

)

B

lu

e

(4

9

A

)

B

lu

e

(7

6

A

)

B

lu

e

/W

h

t (4

9

B

)

B

lu

e

/W

h

t (7

6

B

)

B

L

A

C

K

W

IR

E

H

A

R

N

E

S

S

B

la

c

k

(7

0

A

)

B

la

c

k/O

rg

(7

0

B

)

N

O

T

E

2

N

O

T

E

3

N

o

t

e

s

3

-

D

is

c

o

n

n

e

c

t fo

r 1

5

d

e

g

re

e

F

lo

a

d

s

id

e

fre

e

z

e

d

e

te

c

tio

n

4

-

A

c

c

o

u

tp

u

t is

c

y

c

le

d

w

ith

th

e

le

a

d

c

o

m

p

re

s

s

o

r

.

5

-

If n

o

flo

w

p

ro

v

in

g

s

w

itc

h

is

b

e

in

g

u

s

e

d

o

n

th

e

lo

a

d

s

id

e

, th

e

in

p

u

t m

u

s

t b

e

ju

m

p

e

re

d

to

P

B

2

-3

fo

r th

e

u

n

it to

o

p

e

ra

te

.

2

-

D

is

c

o

n

n

e

c

t fo

r 1

5

d

e

g

re

e

F

s

o

u

rc

e

s

id

e

fre

e

z

e

d

e

te

c

tio

n

7

-

J

u

m

p

e

rs

m

u

s

t b

e

s

e

t a

s

s

h

o

w

n

fo

r c

o

rre

c

t c

o

n

tro

l o

p

e

ra

tio

n

. If a

c

o

m

m

u

n

ic

a

tio

n

c

a

rd

is

p

re

s

e

n

t, it m

u

s

t b

e

re

m

o

v

e

d

to

c

h

e

c

k

th

e

ju

m

p

e

rs

.

6

-

If n

o

flo

w

s

w

itc

h

is

b

e

in

g

u

s

e

d

o

n

th

e

s

o

u

rc

e

s

id

e

, th

e

in

p

u

t m

u

s

t b

e

ju

m

p

e

re

d

to

R

o

n

P

B

1

-1

fo

r th

e

u

n

it to

o

p

e

ra

te

.

1

-

S

w

a

p

R

e

d

a

n

d

B

lu

e

T

ra

n

s

fo

rm

e

r w

ire

s

fo

r

2

0

8

V

o

p

e

ra

tio

n

.

8

-

R

e

v

e

rs

in

g

V

a

lv

e

w

ill b

e

e

n

e

rg

iz

e

d

fo

r c

o

o

lin

g

m

o

d

e

.

9

-

U

s

e

d

fo

r E

m

e

rg

e

n

c

y

S

h

u

td

o

w

n

in

c

o

n

ju

n

c

tio

n

w

ith

a

n

o

rm

a

lly

o

p

e

n

re

la

y N

O

T

E

4

N

O

T

E

5

N

O

T

E

6

N

O

T

E

8

N

O

T

E

8

N

O

T

E

9

N

O

T

E

1

G

ro

u

n

d

L

e

g

e

n

d

C

C

C

o

m

p

re

s

s

o

r C

o

n

ta

c

to

r

C

S

C

u

rre

n

t S

w

itc

h

E

L

T

E

n

te

rin

g

L

o

a

d

T

e

m

p

E

S

E

m

e

rg

e

n

c

y

S

h

u

td

o

w

n

E

S

T

E

n

te

rin

g

S

o

u

rc

e

T

e

m

p

H

P

H

ig

h

P

re

s

s

u

re

L

F

S

L

o

a

d

F

lo

w

S

w

itc

h

L

L

T

L

e

a

v

in

g

L

o

a

d

T

e

m

p

L

P

L

o

w

P

re

s

s

u

re

L

S

T

L

e

a

v

in

g

S

o

u

rc

e

T

e

m

p

L

-W

C

T

L

o

a

d

W

a

te

r C

o

il T

e

m

p

P

B

P

o

w

e

r B

lo

c

k

R

V

R

e

v

e

rs

in

g

V

a

lv

e

S

F

S

S

o

u

rc

e

F

lo

w

S

w

itc

h

S

-W

C

T

S

o

u

rc

e

W

a

te

r C

o

il T

e

m

p

T

B

T

e

rm

in

a

l B

o

a

rd

F

a

c

to

ry

lo

w

v

o

lta

g

e

w

irin

g

F

a

c

to

ry

lin

e

v

o

lta

g

e

w

irin

g

F

ie

ld

lo

w

v

o

lta

g

e

w

irin

g

F

ie

ld

lin

e

v

o

lta

g

e

w

irin

g

O

p

tio

n

a

l b

lo

c

k

F

ie

ld

S

u

p

p

lie

d

O

p

tio

n

T

h

e

rm

is

to

r

R

e

la

y

c

o

il

T

O

p

e

n

J

u

m

p

e

r

C

lo

s

e

d

J

u

m

p

e

r

Q

u

ic

k

C

o

n

n

e

c

to

r

H

P

-A

H

P

-B

B

la

c

k

/O

ra

n

g

e

(7

4

B

)

B

la

c

k/O

ra

n

g

e

(7

3

B

)

B

la

c

k

(7

4

A

)

B

la

c

k

(7

3

A

)

B

la

c

k

(6

5

A

)

B

la

c

k/O

ra

n

g

e

(6

4

B

)

B

la

c

k/O

ra

n

g

e

(6

5

B

)

B

la

c

k

(7

0

A

)

B

la

c

k/O

rg

(7

0

B

)

B

la

c

k

(7

5

A

)

B

la

c

k/O

rg

(7

5

B

)

B

la

c

k

(7

0

A

)

B

la

c

k/O

rg

(7

0

B

)

B

la

c

k

(7

5

A

)

B

la

c

k/O

rg

(7

5

B

)

(

C

ir

c

u

it A

)

C

o

m

p

r

e

s

s

o

r

C

u

rre

n

t S

w

itc

h

C

S

A

B

la

c

k

B

la

c

k

G

re

e

n/Y

e

llo

w

(1

6

)

E

X

1

E

X

2

O

ra

n

g

e

(6

1

A

)

C

R

S

C

R

S

U

n

it P

o

w

e

r S

u

p

p

ly

#

2

2

0

8

-2

3

0

/6

0

/1

G

L

1

L

2

U

n

it P

o

w

e

r S

u

p

p

ly

#

1

2

0

8

-2

3

0

/6

0

/1

G

L

1

L

2

C

C

A

L

1

L

2

T

1

T

2

B

la

c

k

T

a

n

(5

2

A

)

B

lu

e

R

e

d

C

C

B

L

1

L

2

T

1

T

2

R

e

d

B

la

c

k

C

C

P

L

1

L

2

T

1

T

2

B

la

c

k/W

h

ite

(2

6

)

B

la

c

k/W

h

ite

(6

2

)

B

lu

e

(5

0

)

T

a

n

(5

2

B

)

B

la

c

k

B

lu

e

2

3

0

V

W

h

ite

(8

)

B

la

c

k

(7

)

G

L

o

a

d

P

u

m

p

G

E

x

te

r

n

a

l

S

o

u

rc

e

P

u

m

p

N

O

T

E

1

0

1

0

-

E

x

te

rn

a

l lo

a

d

a

n

d

s

o

u

rc

e

p

u

m

p

s

m

u

s

t b

e

e

x

te

rn

a

lly

fu

s

e

d

.

C

C

-P

B

lu

e

1

2

A

W

B

1

2

A

W

B

14

NDW INSTALLATION MANUAL

Wiring Schematics cont.

208-230/60/1 with IntelliStart Option

2 4 V

T r a n s f o r m e r

S

F

S

L

F

S

E

S

J

o

h

n

s

o

n

F

X

-

1

0

5

V

D

C

A

I3

3

5

3

6

3

7

3

8

+ -A

I5

-+A

I4

-+A

I6

A

I2

A

I1

5

V

D

C

5

V

D

C

L

E

D

--- +++

24VAC

24VACCom

GROUND

3

9

4

0

4

1

P

W

M

2

P

W

M

2

C

o

m

P

W

M

1

4

2

4

34

4

4

54

6

4

7

4

8

2

4

V

A

C

C

o

m

D

I1

2

D

I1

1

D

I1

0

D

I9

D

I8

D

I7

4

9

5

0

5

1

5

2

5

3

5

4

5

5

5

6

D

I 3

/4

/5

/6

/ C

o

m

D

I6

D

I5

D

I4

D

I3

D

I2

D

I1

9

V

D

C

2

0

1

9

1

8

1

7

1

61

5

1

4

1

3

1

21

1

1

0987654321

D

0

9

D

0

8

D

0

7

D

06

D

0

5

D

0

4

D

0

3

D

0

2

D

0

1

J

8

J

2

J

1

0

J

9

J

7

N

O

T

E

7

A21 A12

A25 A22

A32

A31 A35

A23

A13

A11

A15

A14

A24

A34

A33

3

4

L

P

-A

L

P

-B

3 1

3 0

2 9

2 8

2 7

2 6

2 5

2 4

2 3

2 2

2 1

2 0

A I 4 E X P

5 V d c C o m

J 2

5 V d c

5 V d c C o m

A I 3 E X P

5 V d c

5 V d c C o m

A I 2 E X P

5 V d c

5 V d c C o m

A I 1 E X P

5 V d c

1 7

1 6

1 5

1 4

1 3

1 2

1 1

1 0

D O 3

2 4 V a c

D O 4

D O 5

D O 6

2 4 V a c

2 4 V a c C o m

J 3

2 4 V a c

J 1

M a i n B o a r d

C o n n e c t i o n

A 4 1

A 3 1

A 2 3

A 1 3

A

4

3

A

4

2

A

3

2

A

3

3

A

2

1

A

2

2

A

1

2

A

1

1

4

3

2

1

D 0 2

D 0 1

6

D 0 75

8

D 0 87

J

o

h

n

s

o

n

F

X

1

0

E

x

p

a

n

s

io

n

B

o

a

r

d

P

B

1

23 1

(

C

ir

c

u

it B

)

C

u

rre

n

t S

w

itc

h

C

S

B

B

la

c

k

B

la

c

k

C

o

m

p

r

e

s

s

o

r

B

la

c

k

(F

1

)

B

la

c

k

(F

2

)

B

la

c

k

(F

3

)

B

la

c

k

(F

4

)

B

la

c

k

(F

5

)

B

la

c

k

(F

6

)

B

la

c

k

(F

7

)

B

la

c

k

(F

8

)

B

la

c

k

(F

9

)

B

la

c

k

(F

1

0

)

B

la

c

k

(F

1

1

)

B

la

c

k

(F

1

2

)

B

la

c

k

(F

1

3

)

B

la

c

k

(F

1

4

)

B

la

c

k

(F

1

5

)

B

la

c

k

(F

1

6

)

B

la

c

k

(F

1

7

)

B

la

c

k

(F

1

8

)

B

la

c

k

(F

1

9

)

B

la

c

k

(F

2

0

)

1 2 3 4 5 7 8 9 1

06 1

1

1

2

1

3

1

6

1

5

1

4

1

7

2

0

1

9

1

8 A

3

3

3

2

3

1

3

0

2

9

2

8

2

7

2

6

2

5

2

4

2

3

162734951

0 8

W

h

ite/R

e

d

(8

0

)

W

h

ite/R

e

d

(8

1

)

W

h

ite/B

lu

e

(3

3

)

W

h

ite/B

lu

e

(3

4

)

Y

e

llo

w

/R

e

d

(3

5

)

Y

e

llo

w

/R

e

d

(3

6

)

Y

e

llo

w

/B

lu

e

(3

7

)

Y

e

llo

w

/B

lu

e

(3

8

)

T

a

n

/B

la

c

k

(8

4

)

T

a

n

/B

la

c

k

(8

5

)

W

h

ite/R

e

d

(8

0

)

W

h

ite/R

e

d

(8

1

)

TTT T

W

h

ite/B

lu

e

(3

3

)

W

h

ite/B

lu

e

(3

4

)

Y

e

llo

w

/R

e

d

(3

5

)

Y

e

llo

w

/R

e

d

(3

6

)

T

Y

e

llo

w

/B

lu

e

(3

7

)

Y

e

llo

w

/B

lu

e

(3

8

)

T

a

n

/B

la

c

k

(8

4

)

T

a

n

/B

la

c

k

(8

5

)

S

-W

C

T

C

irc

u

it A

L

-W

C

T

C

irc

u

it A

S

-W

C

T

C

irc

u

it B

L

-W

C

T

C

irc

u

it B

L

L

T

B

la

c

k

R

e

d

2

0

8

V

B

lu

e

2

3

0

V

B

la

c

k/W

h

ite

Y

e

llo

w

Y

e

llo

w

Y

e

llo

w

Y

e

llo

w

Y

e

llo

w

(2

4

)

B

la

c

k

(9

5

)

G

re

e

n/Y

e

llo

w

(2

3

)

Y

e

llo

w

(2

1

)

B

la

c

k/W

h

ite

(2

2

)

Y

1

C

O

M

P

1

L

C

1

C

o

m

p

A

A

la

rm

R

S

D

O

-9

X

2

D

O

-7

R

2

4

V

A

C

S

S

D

O

-8

L

C

2

C

o

m

p

B

A

la

rm

X

1

A

c

c

C

2

4

V

A

C

C

O

M

T

O

N

O

T

U

S

E

D

S

C

N

O

T

U

S

E

D

A

IC

N

O

T

U

S

E

D

L

N

O

T

U

S

E

D

O

/B

R

E

V

V

A

L

V

E

G

N

O

T

U

S

E

D

Y

2

C

O

M

P

2

1

6

1

2 8 2 9 4 1

07 5 3 1

1

1

461

3

1

5 1

T

B

B

la

c

k

(S

S

)

B

la

c

k

(C

)

B

la

c

k

(R

S

)

B

la

c

k

(R

)

B

la

c

k

(X

2

)

B

la

c

k

(L

C

2

)

B

la

c

k

(L

C

1

)

B

la

c

k

(X

1

)

B

la

c

k

(Y

1

)

B

la

c

k

(Y

2

)

B

la

c

k

(O

/B

)

B

la

c

k

(G

)

B

la

c

k

(A

IC

)

B

la

c

k

(S

C

)

B

la

c

k

(L

)

B

la

c

k

(T

O

)

B

7

/

2

8

/

0

9

B

la

c

k/W

h

ite

(2

6

)

B

la

c

k

(3

0

)

B

la

c

k

(3

0

)

B

la

c

k

(2

9

)

B

la

c

k

(2

9

)

Y

e

llo

w

(2

5

)

Y

e

llo

w

(2

5

)

B

la

c

k

(2

8

)

B

la

c

k

(2

8

)

B

ro

w

n

(5

3

)

B

ro

w

n

(5

3

)

B

ro

w

n

(5

2

)

B

ro

w

n

(5

2

)

B

lu

e

(5

1

)

B

lu

e

(5

1

)

B

la

c

k

(7

5

A

)

B

la

c

k/O

rg

(7

5

B

)

C

C

-B

C

C

-A

B

la

c

k

(6

4

A

)

V

io

le

t (6

7

)

V

io

le

t (6

6

)

B

la

c

k/W

h

ite

(2

7

)

B

la

c

k/W

h

ite

(2

7

)

23 1

P

B

2

B

la

c

k

(5

4

)

R

e

d

(5

5

)

G

ra

y

(5

6

)

P

in

k

(5

8

)

B

ro

w

n

(5

7

)

G

ra

y

(5

9

)

61

571

6981

7

1

45 1

8

1

3413 1

2

1

0

1

12

T

E

S

T

B

rn

/W

h

t (8

6

)

B

rn

/W

h

t (8

7

)

T

L

S

T

B

rn/B

lk

(4

1

)

B

rn/B

lk

(4

2

)

B l a c k

B l a c k

C

S

-A

C

irc

u

it A

B l a c k

B l a c k

C

S

-B

C

irc

u

it B

B

lu

e

(4

5

)

B

lu

e

(4

5

)

B

lu

e

(4

6

)

B

lu

e

(4

6

)

B

lu

e

(4

5

)

B

lu

e

(4

6

)

O

ra

n

g

e

(4

7

)

O

ra

n

g

e

(4

7

)

O

ra

n

g

e

(4

7

)

G

ra

y

(4

8

)

C

o

n

n

e

c

t to

R

o

n

P

B1

-1

W

h

ite

(6

7

)

W

h

ite

(6

7

)

W

h

ite

(6

7

)

W

h

ite

(6

6

)

W

h

ite

(6

6

)

W

h

ite

(6

6

)

B

lu

e

(5

0

)

O

ra

n

g

e

(6

0

)

O

ra

n

g

e

(6

0

)

O

ra

n

g

e

(6

0

)

T

a

n

/W

h

ite

(8

2

)

T

a

n

/W

h

ite

(8

3

)

B l a c k ( A )

B l a c k ( A )

W h i t e ( B )

W h i t e ( B )

O

ra

n

g

e

(6

1

A

)

O

ra

n

g

e

(6

1

A

)

O

ra

n

g

e

(6

1

B

)

R

V

1

R

V

2

O

ra

n

g

e

(6

0

A

)

O

ra

n

g

e

(6

1

A

)

O

ra

n

g

e/W

h

t (6

0

B

)

O

ra

n

g

e/W

h

t (6

1

B

)

T

E

L

T

T

a

n

/W

h

ite

(8

2

)

T

a

n

/W

h

ite

(8

3

)

T

a

n

/W

h

ite

(8

2

)

T

a

n

/W

h

ite

(8

3

)

B

la

c

k

(4

9

)

B

lu

e

(7

6

A

)

B

lu

e

(7

6

A

)

B

lu

e

(7

6

B

)

B

lu

e

(7

6

B

)

B

lu

e

(4

9

A

)

B

lu

e

(7

6

A

)

B

lu

e

/W

h

t (4

9

B

)

B

lu

e

/W

h

t (7

6

B

)

B

L

A

C

K

W

IR

E

H

A

R

N

E

S

S

B

la

c

k

(7

0

A

)

B

la

c

k/O

rg

(7

0

B

)

N

O

T

E

2

N

O

T

E

3

N

o

t

e

s

3

-

D

is

c

o

n

n

e

c

t fo

r 1

5

d

e

g

re

e

F

lo

a

d

s

id

e

fre

e

z

e

d

e

te

c

tio

n

4

-

A

c

c

o

u

tp

u

t is

c

y

c

le

d

w

ith

th

e

le

a

d

c

o

m

p

re

s

s

o

r

.

5

-

If n

o

flo

w

p

ro

v

in

g

s

w

itc

h

is

b

e

in

g

u

s

e

d

o

n

th

e

lo

a

d

s

id

e

, th

e

in

p

u

t m

u

s

t b

e

ju

m

p

e

re

d

to

P

B

2

-3

fo

r th

e

u

n

it to

o

p

e

ra

te

.

2

-

D

is

c

o

n

n

e

c

t fo

r 1

5

d

e

g

re

e

F

s

o

u

rc

e

s

id

e

fre

e

z

e

d

e

te

c

tio

n

7

-

J

u

m

p

e

rs

m

u

s

t b

e

s

e

t a

s

s

h

o

w

n

fo

r c

o

rre

c

t c

o

n

tro

l o

p

e

ra

tio

n

. If a

c

o

m

m

u

n

ic

a

tio

n

c

a

rd

is

p

re

s

e

n

t, it m

u

s

t b

e

re

m

o

v

e

d

to

c

h

e

c

k

th

e

ju

m

p

e

rs

.

6

-

If n

o

flo

w

s

w

itc

h

is

b

e

in

g

u

s

e

d

o

n

th

e

s

o

u

rc

e

s

id

e

, th

e

in

p

u

t m

u

s

t b

e

ju

m

p

e

re

d

to

R

o

n

P

B

1

-1

fo

r th

e

u

n

it to

o

p

e

ra

te

.

1

-

S

w

a

p

R

e

d

a

n

d

B

lu

e

T

ra

n

s

fo

rm

e

r w

ire

s

fo

r

2

0

8

V

o

p

e

ra

tio

n

.

8

-

R

e

v

e

rs

in

g

V

a

lv

e

w

ill b

e

e

n

e

rg

iz

e

d

fo

r c

o

o

lin

g

m

o

d

e

.

9

-

U

s

e

d

fo

r E

m

e

rg

e

n

c

y

S

h

u

td

o

w

n

in

c

o

n

ju

n

c

tio

n

w

ith

a

n

o

rm

a

lly

o

p

e

n

re

la

y N

O

T

E

4

N

O

T

E

5

N

O

T

E

6

N

O

T

E

8

N

O

T

E

8

N

O

T

E

9

N

O

T

E

1

G

ro

u

n

d

L

e

g

e

n

d

C

C

C

o

m

p

re

s

s

o

r C

o

n

ta

c

to

r

C

S

C

u

rre

n

t S

w

itc

h

E

L

T

E

n

te

rin

g

L

o

a

d

T

e

m

p

E

S

E

m

e

rg

e

n

c

y

S

h

u

td

o

w

n

E

S

T

E

n

te

rin

g

S

o

u

rc

e

T

e

m

p

H

P

H

ig

h

P

re

s

s

u

re

L

F

S

L

o

a

d

F

lo

w

S

w

itc

h

L

L

T

L

e

a

v

in

g

L

o

a

d

T

e

m

p

L

P

L

o

w

P

re

s

s

u

re

L

S

T

L

e

a

v

in

g

S

o

u

rc

e

T

e

m

p

L

-W

C

T

L

o

a

d

W

a

te

r C

o

il T

e

m

p

P

B

P

o

w

e

r B

lo

c

k

R

V

R

e

v

e

rs

in

g

V

a

lv

e

S

F

S

S

o

u

rc

e

F

lo

w

S

w

itc

h

S

-W

C

T

S

o

u

rc

e

W