Professional Documents

Culture Documents

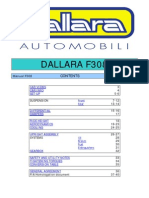

Data Acquisition System For A Formula SAE Race Car

Uploaded by

Rodrigo Bob100%(1)100% found this document useful (1 vote)

1K views43 pagesdata acquisition

Original Title

Data Acquisition System for a Formula SAE Race Car

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdata acquisition

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

1K views43 pagesData Acquisition System For A Formula SAE Race Car

Uploaded by

Rodrigo Bobdata acquisition

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 43

1

UNIVERSITY OF ILLINOIS AT URBANA-CHAMPAIGN

Data Acquisition System for

Formula SAE Race Car

ECE445 Final Report

Project 34

Mohan Sha

Shaik Mohammad Farooq

Raviraj Mahajan

TA: Ryan May

May 1, 2013

2

Table of Contents

1. Introduction

1.1 Statement of Purpose 3

1.2 Objectives 4

2. Design

2.1 Block Diagram 5

2.2 Block Descriptions 6

2.3 Simulations 8

2.4 Design Alterations 10

3. Requirements and Verifications

3.1 Testing Procedures 11

3.2 Quantitative Results 11

4. Cost Analysis

4.1 Labor 16

4.2 Parts 16

5. Conclusion 17

6. Future Work/Alternatives 17

7. Ethical Considerations 18

8. References 20

9. Appendix

A Verification and Requirements Table 22

B Design Schematics 31

C Arduino Code 33

3

1. Introduction

1.1 Statement of Purpose:

Every year the UIUC SAE Formula Electric team builds a car to participate in a racing

competition with other major universities. In order to test and improve performance of the

car it is important to have as much data from the car as possible. Our task is to build a data

acquisition system for the car, collecting and displaying real time data on the dashboard.

This entailed finding the right sensors and a processing unit to convert their outputs to

relevant units and output them to a display placed on the dashboard. The parameters to be

measured were as follows:

Temperature motor, coolant and battery

Speed motor and wheel

Voltage and Current drawn from the battery

Another aspect of the system that we were required to build was the wireless transmission

of this data to a nearby computer and also saving it to an SD card located on the car in case

a computer is not available nearby to receive real time data. This was important as it would

enable the pit stop crew to instruct the driver concerning the optimum usage of the car. It

would also allow the team to know exactly how the car was handling different tracks during

the practice runs which would enable them to make necessary changes to the car before the

final race. The entire system thus created will be modular in nature and could potentially be

implemented in future SAE race cars. The legacy of the project is that after installation of

the DAQ system on to the race car our team will get to assist the Formula SAE team during

the real race in July, 2013.

4

1.2 Objectives

1.2.1 Goals

Provide the driver and team with real time input from all the sensors in the car.

System should be compact and easily transferable to other project cars.

Data should be synchronized.

1.2.2 Functions

Acquire data from various types of sensors temperature, pressure and speed.

Acquire and display the data for the temperatures of the coolant, the batteries and the

motor. Similarly, acquire and display speed of the motor and wheels and pressure of

all the tires.

Ensure that response time of the sensors is optimum by synchronizing all sensors.

Data should be wirelessly transmitted to a computer located at the race pit from where

the rest of the team monitors the race.

1.2.3 Benefits

Service time efficiency due to on-site data analysis and fast feedback.

Service cost efficiency due to time efficient method and higher calibration quality.

Single display with all the required data eliminates the need for manually testing each

part.

Wireless data transmission allows formula SAE team to instruct the driver on how

to boost performance.

1.2.4 Features

Wireless data transmission for over a track of 0.5 mile.

LCD displaying multiple data.

Simultaneous multiple data sensing.

Compact processing system with dimensions of approximately 3 X 3 inches

Wireless transmission.

5

2. Design

2.1 Block Diagrams

Fig 1. Full System Block Diagram

6

2.2. Block Description

The system consists of three main blocks. Firstly, the sensor block consists of several kinds

of sensors that will collect data about the car and an RS232 communication protocol from the

BMS. This signal will then pass through a choke to the microcontroller. The second block is

the processing block consisting of ArduinoUno board containing the ATMEGA328

microcontroller. The microcontroller will translate the digital and analog signals into

readable, useful data. The Ardunio is connected to a Tx Xbee which will wirelessly transmistt

all the data obtained. The third block consists of the three different outputs. Firstly, a LCD

will display speed and temperature data to the driver. Secondly, all the data will be received

at a base station at the pit stop through an Xbee module and a USB Xbee Explorer that allows

the data to be read through a computer. This is the Rx part of the system.

1. Power Supply

The car has a 12VDC power supply separate from its 300 VDC supply for the drivetrain. The

12VDC outlets of the car will be used to power our sensors and processors. A 12V-5V dc-dc

converter powers all the components of the data acquisition system.

Fig 2. Power Module

2. Battery Temperature Sensor

The battery temperature sensors are already integrated in the Elithion Battery Management

System (BMS). The BMS also gives information on the state of charge, voltage and current

of every individual battery cell and of the complete.

The BMS is powered separately via a different 12V power supply from one of the 12 outlets.

7

3. Sensors

a. Motor and Coolant Temperature Sensors

Both the motor and coolant temperature sensor take 5V input form the buck converter.

The coolant temperature will be placed in the out-flow pipe of the coolant.

b. Battery Temperature Sensor

The battery temperature sensors are already integrated in the Elithion Battery

Management System (BMS). The BMS also gives information on the state of charge,

voltage and current of every individual battery cell and of the complete.

a. Motor and Vehicle Speed Sensors:

There are two digital Hall Effect sensors being used to measure the rotation seed of

the motor and the speed of the rotation of the wheels.

4. Arduino Uno

This board is powered by the ATmega 328 microcontroller running at 8 MHz. It has 14

digital I/O pins and 8 analog input pins. It accepts 3-12 VDC as input voltage and hence, we

will use the 5 V obtained from the buck converter as the input voltage.

The code for the microprocessor can be found in the appendix.

5. XBee Module

a. Transmitter:

All the data collected and converted by the Arduino from the sensors is transmitted wirelessly

via the XBee module. We used XBee-PRO S1 wireless RF module. It transmits data at a

frequency of 2.4 GHz. The maximum RF line of sight range is 1.2 km (.8 miles). The Tx unit

is responsible for transmitting the serial data generated by the processor block to the Rx unit

wirelessly at 2.4GHz.

b. Receiver:

The XBEE wireless module employs the Zigbee protocol to communicate to the receiver

module. The Rx will be connected to the computer via XBee Explorer. Rx unit is plugged

into the XBee Explorer, which is attached to a mini USB cable.

8

6. Display

The LCD shows the Vehicle speed and Motor Temperature to the driver. The choice of our

LCD is the Hitachi HD44780. It consists of 4 lines x 20 characters.

2.3 Design and Simulations:

1. Power Supply: Buck converter

12V-5V dc-dc buck converter design schematic:

Fig 3. Buck converter Scehmatic

Voltage ripple: 20mV Tolerance < 20%

Fig 4. Buck converter voltage ripple

9

2. Sensors

a. Motor Temperature Sensor

The sensor gives temperature difference as voltage values between 0-2V. This voltage

can then be converted to temperature in degree Celsius using the following formula:

C = 100 * V-50

The sensor has a 10 mV/C scale factor. It accepts input voltages between 2.7 - 5.5

VDC and hence we will be supplying it with the 5 V obtained from the buck converter

circuit. It has a temperature range of -40 to +125

0

C with an accuracy of 2

0

C. The

motor is not expected to exceed temperatures of 115

0

C which makes this sensor ideal

to use.

b. Coolant Temperature Sensor

The sensor has a known temperature range of -55C to +125C with an accuracy of

0.5C. This sensor gives and output in the form of 9-12 bit digital signals. The

conversion of 12 bit temperature to digital word is at most 0.75s. The code to get the

temperature value from the bit values is included in the Ardunios description.

c. Motor and Vehicle Speed Sensors:

These sensors accept input voltages between 6.5 - 24VDC and hence we will be

powering them with the 5 V output from the buck converter circuit. The sensors have

a frequency range of 0 - 12 KHz and give the frequency as digital output.

Assuming the tire has a radius of 20 cm, i.e. 0.0002 km, the distance covered in one

rotation is 0.0002 * 2 * = 0.001257 km

The highest speed that can be detected for this tire can then be = 1200 rotations per

second * 60 seconds * 60 minutes * distance covered in one rotation = 5428.673 km/h

3. Fuse

A 3A fuse was chosen to protect the circuit, placed between the 12VDC outlet and the buck

converter. The fuse breaks over 3A. Simulation of the fuse:

10

Fig 5. Simulation of 3A Fuse

2.4 Design Alteration:

The Arduino Fio v3 was replaced by the Arduino Uno. This was done to ease the process

of loading code onto the microcontroller. The Arduio Fio can only be programmed

through and FTDI cable or wirelessly through an Xbee. This causes complications as

Microsoft Windows 7 is not able to successfully load the drivers required to recognize the

device. The Arduino Uno is more user-friendly and satisfies all the requirements for our

system. The only drawback is relatively larger size which does not take precedence over

accessibility.

The Elithion Lithiumate Pro BMS system will most probably be replaced soon, therefore

the 19th of June race may very well be its last. Rather than spending excess time

debugging an outdated system, the team has decided to put it on hold.

For the BMS to function correctly, it must know the number of battery cells that it is

monitoring. But since new batteries are introduced, the exact number of cells per bank

and banks per pack are still to be determined. Without this information, the BMS cannot

function correctly.

Due to the above mentioned problem, and many hidden ones as well, the BMS has been

malfunctioning for a long time, giving the wrong voltage reading of 250VDC to

400VDC, while the maximum possible voltage output of the battery pack is only 300V.

And of course, since it is a DC battery pack, the voltage output does not give random

fluctuations either (verified by oscilloscope reading of a sufficiently long period).

11

3. Design Requirements and Verifications

3.1 Testing Procedure:

Refer Appendix A

3.2 Quantitative Results

1 .Buck Converter

We tested the buck converter with the help of an oscilloscope. The following picture shows

that the buck converter outputs 4.8V for an input voltage of 12 V. That is about 4% error

considering that the required voltage is 5V. The error obtained is much below our

requirements. On adjusting the feedback of the buck converter design we were however able

to get an output voltage of 4.99V for the same input voltage of 12V.

Fig 6. Buck converter output test

2. Sensors:

a. Motor and Battery Temperature Sensors:

The following figure shows the expected voltage vs. temperature relation obtained

from the data sheet. We were able to test the sensor by using a controlled heating pad

with known temperatures. The graph in fig 4 shows that the observed voltage ranges

were very close to the expected ranges with an accuracy of 20mV translating to a

accuracy of 2

0

C as expected.

12

Fig 7. Expected Voltage vs. Temperature

Fig 8. Observed Voltage vs. Temperature

Using the slope obtained from the graph we plotted above, we got the following

readings of temperature from the sensor-arduino interface as outlined in the

requirements and verification table.

13

Thermometer

Temp.(C)

Sensor Temp. (C)

25.1 27.7

40.25 44.01

55.42 57.7

75.22 77.91

90.21 93.2

100.02 102.88

Fig 9. Thermometer Temperature vs. Sensor Tempearature

The data collected showed an average error of ~ 5% or 3C.

This was included as an offset of -3 in the formula to calculate the temperature from

the voltage.

b. Coolant Temperature Sensor:

To test the sensor, we used a heating pad with known controlled temperature and

compared it with the temperature read by the sensor. The following table documents

the observations.

Thermometer

Temp.(C)

Sensor Temp. (C)

25.55 23.1

40 37.5

55.5 52.88

75.25 73.15

90.35 87.75

100.25 97.89

14

Fig 10. Thermometer Temperature vs. Sensor Tempearature

This showed an average error of ~ 5 % or 2.45 C.

To compensate for this, we included an offset of +2.45 in the Arduino code when

calculating the temperature.

c. Motor and Vehicle Speed Sensors:

The testing included attaching the speed sensor to a small motor-wheel assembly and

using a stroboscope to measure the RPM. The observations are tabulated below.

Stroboscope

Reading (RPM)

Sensor Reading (RPM)

80 68

110 120

140 155

170 165

200 225

230 212

15

Fig 11. Stroboscope RPM vs. Sensor RPM

The average error in detection was 16 RPM. This large inaccuracy is due to the

fact that the testing was done using 4 targets. More targets will be added to

decrease this error.

3. Arduino Uno

The Arduino was able to fulfill all the requirements included in the requirements and

verification table above.

4. XBee Pro S1

The Xbee Pro S1 was successfully tested at a range of 300m with zero bit error rate.

5. LCD

The LCD was able fulfilled its highest requirement successfully.

16

4. Cost Analysis

4.1 Labor

Name Hourly Rate

($ / hour)

Hours invested over

entire period of

project

Total Cost = Hourly

Rate x 2.5 x Hours

Invested

Mohan Sha 20 120 $2400

Farooq Shaik 20 120 $2400

Raviraj Mahajan 20 120 $2400

Total 60 360 $7200

4.2 Parts

Item Serial Number Quantity Cost per unit

($)

Total

Cost ($)

Digital Temp Sensor DS18B20 2 10 20

LCD (Hitachi) HD44780 1 20 20

Xbee XBP24-AWI-001-ND 1 32 32

Voltage Regulator LM2575IN 4 1.86 7.44

Analog Temperature

Sensor

TMP36 2 1.50 3

Arduino Fio B004G4XVKC 1 34 34

Adafruit Data Logger 243 1 28 28

SD Card (1 GB) 9643151 1 4 4

XBee Explorer USB WRL 08687 ROHS 1 25 25

Speed Sensor SNDH-H3C-G03 2 11.25 22.50

17

Buck Converter 90583 1 7 7

Total 202.94

4.3 Grand Total

Section Total

Labor $7200

Parts $202.94

Total $7402.94

6. Conclusion

The system, as outlined in the introduction, has been completed to Formula SAEe's

requirements with all parts fully functional. The car will now have an LCD in the middle of

its dashboard, displaying the speed of the car, the temperature of the engine and coolant, and

the voltage of the battery packs if the team so requests. All this data is also being wirelessly

transmitted to a nearby computer where it is directly entered into an excel sheet.

It has been confirmed that one of our team members, Mohan will go to the race with the

team to help resolve any unforeseen errors that may occur in the system.

This is the first year where the FSAE Electric car team will have a car fully functional and

ready to race, we are very glad that our fully functioning data acquisition system will enter

the race and be put on the race track with the car.

7. Future work

The system has been tested independent of the car. As soon as the car is available, we will

18

attach the system onto the car and perform further testing. The data lines and power lines to

the sensor will be wrapped together with the other cables of the car, and tied to the chassis

once the car is assembled. Only the mount for the speed sensor targets, which may require

welding to the chassis, is a small concern.

The team has suggested a few features that can be added on to the car:

Steering wheel potentiometer to measure the steering angle.

Automatic lap time recorder. This is difficult because in order to do this, usually, as

target is put on the ground, once the car passes the target, the lap time is logged. But

as per FSAE rules, individual teams are not allowed to place any object on the race

track.

Independently powered data acquisition system. Currently, there are several

maneuvers that will cut the power from the batteries, such as, violently braking,

braking while accelerating, accelerator potentiometer malfunction. This is done in

accordance with the FSAE rules. Once the power is cut, there will be no power to the

microcontroller. With an independent power supply of its own, the microcontroller

and the sensors will remain functional even if the car is turned off. Thus, the pit crew

will be able to read when and where did the illegal maneuver occur that cause the car

to shut down; rather than abruptly loosing data collection.

8. Ethical Considerations:

IEEE Code of Ethics Considerations

1. To accept responsibility in making

decisions consistent with the safety,

health and welfare of the public, and

to disclose promptly factors that

might endanger the public or the

environment.

Since the driver will be using the data from our

sensors and we must make sure it is absolutely

accurate. A false speed can mislead the driver. We

must also make sure that there is no chance of electric

shock from our components in the system as the SAE

team will be required to replace the sensors when

damaged.

19

2. To avoid real or perceived conflicts

of interest whenever possible, and to

disclose them to affected parties when

they do exist.

Throughout this course, our team will ensure that we

manage our time wisely, coordinate work among the

team members and make sure we utilize all available

resources. Therefore we will try our best to balance

our work and achieve the goals.

3. To be honest and realistic in stating

claims or estimates based on available

data.

Our system will be advertised accurately in its

reliability and how long it lasts (battery).

4. To maintain and improve our

technical competence and to

undertake technological tasks for

others only if qualified by training or

experience, or after full disclosure of

pertinent limitations.

Since we are not very experienced in this field of

building a product from scratch we will try our best to

learn the necessary skills to complete the project.

5. To seek, accept, and offer honest

criticism of technical work, to

acknowledge and correct errors, and

to credit properly the contributions of

others.

Throughout the course we will critique each other

work to make sure that we create the best product

possible.

20

7. REFERENCES

[1] "Arduino - SD." Arduino - SD. Scott Fitzgerald, 11 Nov. 2011. Web. 01 Oct. 2012.

<http://arduino.cc/en/Reference/SD>.

[2]"Analog Filter Design Demystified." - Tutorial. N.p., n.d. Web. 02 Oct. 2012.

<http://www.maximintegrated.com/app-notes/index.mvp/id/1795>.

[3]"IEEE Code of Ethics," [Online].

http://www.ieee.org/about/corporate/governance/p7- (accessed February 15, 2013)

[4]"2013 Formula SAE Rules." Formula SAE.

students.sae.org/competitions/formulaseries/rules/2013fsaerules.pdf (accessed March

13, 2013).

[5]Amin, Archit , Zachary Beran, and Ben Kimey. "Alternative Energy Monitoring System."

ECE 445 Course Website.

courses.engr.illinois.edu/ece445/projects/fall2011/project7_final_paper.pdf (accessed

December 7, 2011).

[6]Assem, Pourya, and Paul Lupas. "On-Site Hotbox Calibration System." ECE 445 Course

Page. courses.engr.illinois.edu/ece445/projects/fall2012/project2_final_paper.pdf

(accessed December 12, 2012).

[7]Dallas Semiconducto. "DS18B20 Programmable Resolution 1-Wire Digital

Thermometer." Dallas Semiconducto.

dlnmh9ip6v2uc.cloudfront.net/datasheets/Sensors/Temp/DS18B20.pdf (accessed

February 13, 2013).

[8]Adafruit . "Data-Logger Shield for Arduino - User manual." limor.

http://www.ladyada.net/make/logshield/use.html (accessed March 9, 2013).

[9]"GEARTOOTH SPEED SENSOR GS101205 Series." Cherry Corporation.

21

www.cherrycorp.com/english/sensors/pdf/CHE-214006_GS101205_DtSh_E.pdf

(accessed March 8, 2013).

[10] Analog Devices. "Low Voltage Temperature Sensors." TMP36 Data Sheet.

dlnmh9ip6v2uc.cloudfront.net/datasheets/Sensors/Temp/TMP35_36_37.pdf

(accessed February 5, 2013).

22

8. Appendix

A. Verification and Requirements

1. Power Supply

Requirements Verification Success

12 V, 7.2 Ah low voltage power

supply

1. The battery should be able to

supply a

voltage of 12VDC (1V) and 3A.

2. Different sensors have different

voltage requirements as follows.

One Buck Converter should be

able supply 50.2V at 2A input

voltage. The following

components connected in parallel

will draw current from the 5V

supply:

Motor temp. sensor: 2.7 to 5.5 VDC

Coolant temp sensor: 3.0 to 5.5 VDC

Hall effect sensors: 5 to 24 VDC

LCD input: 3 to 5.5 VDC

Arduino Uno v3 3.3 to 5.5VDC

1. A multimeter will be used to measure

the voltage across the battery. A 100

ohm resistor will be connected from

power to ground for the 12 V power

supply. The voltage should not drop

below 11V.

2. Use a multimeter to test all the

outputs. Check the power input to

each of the components using a

multimeter. The sensors, LCD,

Arduino, and the data logger should

receive an input of

50.2V from the buck converter and

draw a maximum current as follows:

Motor Temp Sensor: 50uA

Coolant Temp Sensor: 4 mA

LCD: 2mA

Arduino: 100mA

Hall Effect Sensor: 50mA

3. We can test the voltage supply for

Yes

Yes

Yes

23

3. The Arduino must supply a

voltage input stable at 3.30.1V

to XBee Tx

XBee using multimeter. If

microcontroller functions well, the

3.3V port should output a stable

voltage. If the XBee does not have

power, we should put checking the

functionality of Microprocessor into

consideration.

2. Buck Converter

Requirements Verifications Success

1. The buck converter will

decrease the voltage from

the 121 V power supply to

the required 50.2 volts for

the motor.

2. The duty cycle should be

about 0.416.

3. Buck converter efficiency

should be about 90%

1. The output voltage of the

buck converter will be tested

by Digital Multimeter. The

converter should maintain a set

voltage level with ripple of

about 4%.

2. Calculate the duty cycle

based output the input and

output voltages.

3. Calculate the current

flowing through each

component using the Digital

Multimeter. Using P = I

2

R, and

the given resistances of the

components calculate the total

power dissipated.

Efficiency formula is given in

the bock description of buck

converter.

Yes

Yes

Yes

24

a. Micro-controller (Arduino Uno)

Initially we planned to use Arduino Fio. We were unable to upload the program onto the Fio

and hence could not even test it. We decided to work on Arduino Uno and successfully

completed all the actions on Uno. The requirements of Arduino Fio and Arduino Uno are

similar. Hence below is table representing the requirements and verifications using Arduino

Uno.

Requirements Verification Success

1. The microcontroller must be able

to run the code as expected. Also,

the serial output should be

working properly as we will be

using it to debug the circuit at

different levels.

2. Microcontroller should be able to

withhold the code loaded onto it.

3. Check if the analog inputs are

working.

1. Write a simple program to

display Hello World as output

ten times. Run the program

after loading it onto the

microcontroller and use the

Serial output to read the output

on the computer. Another test

would be to make the LEDs on

the Arduino board to blink.

2. Disconnect the microcontroller

from the computer after loading

the code onto it. The above

LED test should be performed

again and the output confirmed.

3. The formulae to convert the

analog signals from the various

sensors to digital will be

programmed into the code.

Using signal generator, generate

a 5V DC supply and connect it

to the analog inputs. Using

serial interface with a computer

through USB we can read the

Yes

Yes

Yes

25

4. Check if the digital pins are

working.

output from the microcontroller

on the computer. Change the

input voltage and check

whether the resulting output is

in accordance with the input

voltage. Perform the test with

multiple inputs to test that the

microcontroller can handle

multiple inputs simultaneously.

4. This can be done by using the

pin as an output. Then connect

it to an LED and make it blink.

pinMode(pin, OUTPUT);// set

pin to input

digitalWrite(pin, HIGH);//

turn on pullup resistors

Yes

b. XBee Module

Requirements Verification Success

1. The Xbees must

communicate with 0 bit

error rate with an effective

range of 1 km as required

for the race.

1. Connect RS232 serial cable to XBEE units on

two separate computers and use the terminal

port to send and receive specific test vectors.

Ensure the connections from Tx

microprocessor to Tx XBEE are correct. Tx

of the microprocessor goes to the Rx of the

XBEE and the Rx of the microprocessor goes

to the Tx of XBEE. The test can be performed

with two laptop computers in an open field

(Bardeen quad). Check for accuracy of data

received ideally 0 bit error rate is expected.

Yes

26

2. Transmittiing Xbee should

be connected to the correct

output (most significant bit

is on pin D12, and least

significant bit in on pin

D11)

3. Transmitter should

communicate to receiver.

4. Transmitting Xbee should

send signal two signals

from two different pins.

5. Receiver should receive

the most significant bit,

followed by the least

significant bit

6. Receiver should receive

Note that baud rate on both Xbees should be

set to the same value.

2. Check if the output of microcontroller is

connected to the correct digital input pin.

3. Try sending random data, and see if the red

light on both Xbees are blinking (if they are

blinking, they are communicating to one

another).

4. Connect transmitter to PC, and use the

terminal tab from X-CTU to try sending data

to receiver.

If sending sample data succussful, try to

execute UART API command line to send

data from D12, and execute another one to

send data from D11.

5 Create a debugging code to print out the

command line received from transmitter.

Open serial monitor from arduino program to

check the received command line. Check if there

are two different command lines printed in the

serial monitor.

6. Add a printing line to the receiver Xbee code,

Yes

Yes

Yes

Yes

Yes

27

the exact same signal sent

by transmitter.

The received data should

be assigned to

corresponding variable.

7. Module has 99.9%

accuracy of transmitting

data. a. Transmission from

IPC to MCU is 99.9%

successful.

8. Transmission Rate: Make

sure more than 10000

signals can be transmitted

every second.

to print out the value of both variables. Check if

the value for each variable matches the one sent

from transmitter.

Check if the Arduino code contains function

that extract the value from the command lines

received (assigning parts of the command lines to

variables).

Print the value of both variables, and see if they

match the value in the command lines.

2. A standard XBee can send 250 kilobits

every second. We are sending signals in

rate of 8 bits a time. Technically, we can

send 31250 samples every second. Since

we only need to send tens signals each

second, we can send multiple times to

guarantee the transmission accuracy. We

will send each data 5 times. The

component receiving it will compare the 5

results. If one of them is different with the

other four, we still consider it as a

success. If two or more results are

different, we consider it as a failure and

output a failure signal.

3. Send signals in both directions 10000

times each second. Check the accuracy

and the number of signals we received.

Print out the result on the screen if

necessary.

Yes

Yes

a. Sensors

i. Temperature sensors

28

Requirements Verification Success

Motor Temperature

Sensor

1. Sensor should be

properly calibrated.

2. Sensor accuracy should

be 2C as specified in

the data sheet. Minimum

error of 3C is tolerable.

Coolant Temperature

Sensor

1. Sensor accuracy should

be 2C.

2. Sensor should be

waterproof.

1. Connect the terminals of the sensor to a voltmeter.

Place the sensor on a surface with known temperature

or measure the temperature with a thermometer. For

room temperature 27 degree (Celsius) the sensor

should give an output of 0.77V.

Several intermediate temperatures will be taken. The

readings can then be plotted on a graph Temp vs

Volts. All the points on the graph should

approximately lie on the line:

C = 100*V 50.

2. Use a heating pad found is the ME 340 lab as a

controlled heating object. Place sensor on it and note

the output temperature. Take 15 readings from 25C

to 120C which is the maximum expected temperature

for the motor. Compare the readings with actual

temperatures of the heating pad to check for accuracy.

1. Perform above step and using arduino to read the

output with the code attached in appendix.

2. Dip the sensor into a glass of water. Measure the

temperature of the water with a thermometer and

compare with the sensor output. Heat the water to

~50C and repeat the test.

Yes

Yes

Yes

Yes

29

ii. Motor/Wheel Speed Sensors

Requirements Verification Success

1. The sensors should

be able to detect the

magnet.

2. The sensor should

be calibrated correctly.

Max. speed of the car: 80

mph.

18in wheels = 1.44m per

rotation.

89,408 rotations per hour.

Frequency: 24.84Hz.

Well within the ratings. (0-

10kHz)

The error of speed read

must be <3%.

3. The sensor should

detect speeds of at least

180 km/h.

1. Check if the magnet is within 1.5mm of

the sensor head. Move the sensor over the

magnet several times while checking the

output to verify that the sensor is detecting

the magnet.

2. A tachometer will be used to record the

speed of a rotating steel object. Then use

the sensors to find out the speed of the

object. These two readings must be within

3% of each other. (Rotating motors found

in the ECE 486 lab are perfect for the

testing)

Equations:

Frequency**diameter(in)=speed

To convert this speed into mph,

multiply it by 2.24.

3. Using the test motor in the lab, rotate the

motor at 2400 rpm. This is equal to 180

km/h for a radius of 20 cm. The sensor

should be able to detect the magnet and give

an output of approximately 40 Hz which is

well within the range of the sensor.

Yes

Yes

No

We were not able to

get the higher speeds

accurately as we

were using just 1

sensor on the wheel.

We need to add

more sensors to get

accurate data of

higher speeds.

30

b. LCD

Requirements Verification Success

1. The display functions with

an input voltage of 5V.

2. It should display numbers,

letters,

symbols and musical notes in

color without any lag,

flickering or disruption.

3. Check the refresh rate is at

least 0.25seconds.

9. Using a digital multimeter, supply 5V to the

VCC pin on the LCD module through a

banana wire with a 4mm male

output socket. 1. The LCD should light up

when attached to the power source.

10. Run a simple program that displays numbers,

letters, symbols and musical notes. The

program is to be written and run in the

arduino. This is similar to a Hello World test.

11. Write a program on arduino to send output

every 0.5 seconds. If this is seen on the LCD

we know refresh rate is below 0.5 seconds.

Then, write another program to send output

every 0.25 seconds and check if LCD shows

this output and so on.

Yes

Yes

Yes

31

Appendix B. Design Schematic

Fig 8. Design Schematic involving Tx Module

32

Fig 9. Design Schematic involving Rx module

33

Appendix C. Arduino Code

//downloaded library

#include <OneWire.h>

#include <SPI.h>

#include <LiquidCrystal.h>

//for Xbee use

#include <SoftwareSerial.h>

SoftwareSerial mySerial(8,9); // RX, TX

//Digital temp sensor Signal pin on digital 13

int DS18S20_Pin = 13;

//Wheel Speed Hall effect sensor constants on pin 2

volatile byte rpmcount;

unsigned int rpm;

unsigned long timeold;

//Motor Speed Hall effect sensor constants on pin 3

volatile byte rpmcount2;

unsigned int rpm2;

unsigned long timeold2;

//Declaring digital Temperature sensor on digital pin 13

OneWire ds(DS18S20_Pin);

//set the speed variable as zero so when the interrupt for the

//speed sensor is not in effect speed is detected as zero

34

volatile int speed1 = 0;

volatile int speed2 = 0;

/*The circuit:

* LCD RS pin to digital pin 12

* LCD Enable pin to digital pin 11

* LCD D4 pin to digital pin 7

* LCD D5 pin to digital pin 6

* LCD D6 pin to digital pin 5

* LCD D7 pin to digital pin 4

* LCD R/W pin to ground

* 10K resistor:

* ends to +5V and ground

* wiper to LCD VO pin (pin 3)*/

// initialize the library with the numbers of the interface pins

LiquidCrystal lcd(12, 11, 7, 6, 5, 4);

void setup() {

// initialize serial communication at 9600 bits per second:

Serial.begin(9600);

// set the data rate for the SoftwareSerial port

mySerial.begin(9600);

// set up the LCD's number of columns and rows:

lcd.begin(20, 4);

//message to check lcd function

lcd.print("Initialising LCD");

lcd.clear();

35

//hall effect sensor constants and set interrupt to whenever magnet is detected

//attachInterrupt 0 means pin 2

attachInterrupt(0, rpm_fun, RISING);

rpmcount = 0;

rpm = 0;

timeold = 0;

//attachInterrupt 1 means pin 3

attachInterrupt(1, rpm_fun2, RISING);

rpmcount2 = 0;

rpm2 = 0;

timeold2 = 0;

//Serial.println("#S|HEADER|[Units:,Celsius,Celsius,Celsius,Kmph,,Kmph,]#");

//Serial.println("#S|HEADER|[Date Time,Motor Temperature,Battery Temperature,Coolant

Temperature,Wheel Speed,Wheel RPM,Motor Speed,Motor RPM]#");

mySerial.println("Xbee Connection Established");

mySerial.println("#S|HEADER|[Units:,Celsius,Celsius,Celsius,Kmph,,Kmph,]#");

mySerial.println("#S|HEADER|[Date Time,Motor Temperature,Battery

Temperature,Coolant Temperature,Wheel Speed,Wheel RPM,Motor Speed,Motor RPM]#");

}//end of setup

// the loop routine runs over and over again forever:

void loop() {

// read the input on analog pin 0:

int temp1Value = analogRead(A0);

//delay(20);

int temp2Value = analogRead(A1);

36

//delay(20);

int digitalTemp = getTemp();

digitalTemp = digitalTemp + 3;

// delay(20);

// Convert the analog reading (which goes from 0 - 1023) to a voltage (0 - 5V):

float voltage1 = temp1Value * (5.0 / 1023.0);

float voltage2 = temp2Value * (5.0 / 1023.0);

//Convert voltage reading to temperature in celcius

int actTemp1 = (voltage1*100-55)-4;

int actTemp2 = (voltage2*100-55)-4;

//change to float to display on lcd

float temp1 = actTemp1;

//print out the value you read:

Serial.print("Analog Temp 1: ");

Serial.println(actTemp1);

//delay(5);

Serial.print("Analog Temp 2: ");

Serial.println(actTemp2);

//delay(5);

Serial.print("Digital Temp: ");

Serial.println(digitalTemp);

//delay(5);

Serial.print("\n");

lcd.setCursor(0, 0);

37

lcd.print("Motor Temp:");

lcd.print(temp1, 2);

lcd.setCursor(0, 2);

lcd.print("Speed (kmph):");

//Hall effect 1 - wheel speed

if (rpmcount >= 20) {

//Update RPM every 20 counts, increase this for better RPM resolution,

//decrease for faster update

rpm = 30*1000/(millis() - timeold)*rpmcount;

timeold = millis();

rpmcount = 0;

//Calculating speed based on wheel radius = 2*pi*radius*60*rpm

//this value is for 17.7cm wide tires. divide by 4 for 4 magnets

speed1 = 0.00111715034*rpm*60/4;

Serial.println("Wheel RPM: ");

Serial.println(rpm,DEC);

Serial.println("Wheel Speed KMPH: ");

Serial.println(speed1,DEC);

mySerial.println("Wheel RPM: ");

mySerial.println(rpm,DEC);

mySerial.println("Wheel Speed KMPH: ");

mySerial.println(speed1,DEC);

}

//Hall effect 2 - motor speed

if (rpmcount2 >= 4) {

//Update RPM every 20 counts, increase this for better RPM resolution,

38

//decrease for faster update

rpm2 = 30*1000/(millis() - timeold2)*rpmcount2;

timeold2 = millis();

rpmcount2 = 0;

//Calculating speed based on wheel radius = 2*pi*radius*60*rpm

//this value is for 20cm wide tires

speed2 = 0.00047877872*rpm*60;

Serial.println("Motor RPM: ");

Serial.println(rpm2,DEC);

Serial.println("Motor Speed KMPH: ");

Serial.println(speed2,DEC);

mySerial.println("Motor RPM: ");

mySerial.println(rpm2,DEC);

mySerial.println("Motor Speed KMPH: ");

mySerial.println(speed2,DEC);

}

//print speed to lcd

float speedInt = speed1;

lcd.print(speedInt, 2);

excelDataXbee(actTemp1, actTemp2, digitalTemp, rpm, speed1, rpm2, speed2);

//excelDataSerial(actTemp1, actTemp2, digitalTemp, rpm, speed1, rpm2, speed2);

//delay(750);

}

//function to print data in CSV format which is excel compatible

void excelDataXbee(int actTemp1, int actTemp2, int digitalTemp, int rpm, int speed1,int

rpm2, int speed2){

39

mySerial.print("#S|ADDDATA|[,");

char buffer1[5];

mySerial.print(itoa((actTemp1),buffer1,10));

mySerial.print(",");

char buffer2[5];

mySerial.print(itoa((actTemp2),buffer2,10));

mySerial.print(",");

char buffer3[5];

mySerial.print(itoa((digitalTemp),buffer3,10));

mySerial.print(",");

char buffer4[5];

mySerial.print(itoa((rpm),buffer4,10));

mySerial.print(",");

char buffer5[5];

mySerial.print(itoa((speed1),buffer5,10));

mySerial.print(",");

char buffer6[5];

mySerial.print(itoa((rpm2),buffer6,10));

mySerial.print(",");

char buffer7[5];

mySerial.print(itoa((speed2),buffer7,10));

mySerial.println("]#");

40

//non-excel format data

mySerial.print("Analog Temp 1: ");

mySerial.println(actTemp1);

//delay(5);

mySerial.print("Analog Temp 2: ");

mySerial.println(actTemp2);

//delay(5);

mySerial.print("Digital Temp: ");

mySerial.println(digitalTemp);

//delay(5);

mySerial.print("\n");

//delay(200);

}

void excelDataSerial(int actTemp1, int actTemp2, int digitalTemp, int rpm, int speed1,int

rpm2, int speed2){

Serial.print("#S|ADDDATA|[,");

char buffer1[5];

Serial.print(itoa((actTemp1),buffer1,10));

Serial.print(",");

char buffer2[5];

Serial.print(itoa((actTemp2),buffer2,10));

Serial.print(",");

char buffer3[5];

Serial.print(itoa((digitalTemp),buffer3,10));

41

Serial.print(",");

char buffer4[5];

Serial.print(itoa((rpm),buffer4,10));

Serial.print(",");

char buffer5[5];

Serial.print(itoa((speed1),buffer5,10));

Serial.print(",");

char buffer6[5];

Serial.print(itoa((rpm2),buffer6,10));

Serial.print(",");

char buffer7[5];

Serial.print(itoa((speed2),buffer7,10));

Serial.println("]#");

}

//function that returns the temperature from digital sensor in DEG Celsius

float getTemp(){

byte data[12];

byte addr[8];

if ( !ds.search(addr)) {

//no more sensors on chain, reset search

ds.reset_search();

return -1000;

}

42

if ( OneWire::crc8( addr, 7) != addr[7]) {

Serial.println("CRC is not valid!");

return -1000;

}

if ( addr[0] != 0x10 && addr[0] != 0x28) {

Serial.print("Device is not recognized");

return -1000;

}

ds.reset();

ds.select(addr);

ds.write(0x44,1); // start conversion, with parasite power on at the end

byte present = ds.reset();

ds.select(addr);

ds.write(0xBE); // Read Scratchpad

for (int i = 0; i < 9; i++) { // we need 9 bytes

data[i] = ds.read();

}

ds.reset_search();

byte MSB = data[1];

byte LSB = data[0];

float tempRead = ((MSB << 8) | LSB); //using two's compliment

43

float TemperatureSum = tempRead / 16;

return TemperatureSum;

}

//Hall effect : Each rotation, this interrupt function is run twice

void rpm_fun()

{

rpmcount++;

}

void rpm_fun2()

{

rpmcount2++;

}

You might also like

- V8 Supercar Case StudyDocument5 pagesV8 Supercar Case Studytushar girotraNo ratings yet

- AC Worksheet v016Document82 pagesAC Worksheet v016Игорь БелецкийNo ratings yet

- Damper Curves 2Document6 pagesDamper Curves 2Piyush DubeNo ratings yet

- FSAE Data Analysis Day 2 To PrintDocument55 pagesFSAE Data Analysis Day 2 To PrintJorge CorderoNo ratings yet

- Tire-Road Friction CoefficientDocument11 pagesTire-Road Friction CoefficientAnonymous Hy5Ir9QXNo ratings yet

- Analysis of 2014 Formula One Hybrid Powertrain - Ver1 PDFDocument27 pagesAnalysis of 2014 Formula One Hybrid Powertrain - Ver1 PDFFabiola Esmeralda Covarrubias EspejoNo ratings yet

- Chapter Four - Kinematic Steering - 2015 - Essentials of Vehicle DynamicsDocument11 pagesChapter Four - Kinematic Steering - 2015 - Essentials of Vehicle DynamicsJulián AvellaNo ratings yet

- Development and Experimental Verification of A Parametric Model of An Automotive DamperDocument126 pagesDevelopment and Experimental Verification of A Parametric Model of An Automotive DamperMrudula Amar WardeNo ratings yet

- Dynamic Weight Transfer CalcDocument3 pagesDynamic Weight Transfer CalcRob50% (2)

- Springs&Dampers Tech Tip 1Document4 pagesSprings&Dampers Tech Tip 1Sankhadeep BhattacharyyaNo ratings yet

- Suspension Analyzer ManualDocument156 pagesSuspension Analyzer ManualSankalp SharmaNo ratings yet

- Racing Simulation of A Formula 1 Vehicle With Kinetic Energy Recovery SystemDocument15 pagesRacing Simulation of A Formula 1 Vehicle With Kinetic Energy Recovery SystemRodrigo Bob100% (1)

- Combined Effect of Ground Presence and Heaving Motion On A Race Car WingDocument86 pagesCombined Effect of Ground Presence and Heaving Motion On A Race Car WingMatteo de'Giovanetti100% (3)

- OptimumLap Getting StartedDocument17 pagesOptimumLap Getting StartedAyushNo ratings yet

- F308manual v03Document40 pagesF308manual v03John McGillNo ratings yet

- Dual Clutch TransmissionDocument11 pagesDual Clutch TransmissionKunalLuthraNo ratings yet

- 253 Suspension Calc ExplainedDocument1 page253 Suspension Calc ExplainedholaqNo ratings yet

- The Basic Nature of Vehicle Understeer-OversteerDocument36 pagesThe Basic Nature of Vehicle Understeer-OversteerRTCNNo ratings yet

- Vehicle Suspension Modeling NotesDocument25 pagesVehicle Suspension Modeling Notesahmetlutfu100% (2)

- Automotive Differentials, ReleaseDocument30 pagesAutomotive Differentials, Releasestefanovicana1No ratings yet

- Vehicul HybridDocument89 pagesVehicul Hybridmihai_1957No ratings yet

- Chapter 6Document66 pagesChapter 6Arkew Bogale50% (2)

- Aerodynamic Optimization of The Opel Calibra ITC Racing Car Using Experiments and Computational Fluid DynamicsDocument12 pagesAerodynamic Optimization of The Opel Calibra ITC Racing Car Using Experiments and Computational Fluid DynamicsVyssionNo ratings yet

- Dallara P217 LMP2: User ManualDocument25 pagesDallara P217 LMP2: User ManualarthurvalinhoNo ratings yet

- FSAE PowerTrain Phase 4 NNDocument80 pagesFSAE PowerTrain Phase 4 NNAnonymous NK2QBE9oNo ratings yet

- Ackermann Steering For Performance Race Cars PDFDocument22 pagesAckermann Steering For Performance Race Cars PDFr2d23No ratings yet

- J-Dampers in Formula OneDocument3 pagesJ-Dampers in Formula Onertech01No ratings yet

- Advances in The Modelling of Motorcycle Dynamics: Multibody System Dynamics October 2004Document34 pagesAdvances in The Modelling of Motorcycle Dynamics: Multibody System Dynamics October 2004Tyrone BerryNo ratings yet

- ChassisSim F3 Case StudyDocument6 pagesChassisSim F3 Case Studytushar girotraNo ratings yet

- A Study of Kinetic Energy Recovery SystemsDocument57 pagesA Study of Kinetic Energy Recovery SystemsMohammad Usman0% (1)

- Virtualizing The TCU of BMW's 8 Speed TransmissionDocument7 pagesVirtualizing The TCU of BMW's 8 Speed TransmissionSergiu EneNo ratings yet

- Developments of A Method For Lap Time SimulationDocument7 pagesDevelopments of A Method For Lap Time SimulationRodrigo Bob100% (1)

- A Tool For Lap Time Simulation PDFDocument5 pagesA Tool For Lap Time Simulation PDFRodrigo BobNo ratings yet

- Understanding The Limitations of Different Vehicle Models For Roll Dynamics StudiesDocument27 pagesUnderstanding The Limitations of Different Vehicle Models For Roll Dynamics StudiesAntonio Navarrete0% (1)

- Development of Aerodynamics For A Solar Race CarDocument7 pagesDevelopment of Aerodynamics For A Solar Race CarAmr MagdyNo ratings yet

- Optimumt Product Description: Key FeaturesDocument6 pagesOptimumt Product Description: Key FeaturesPierre LalsingNo ratings yet

- OptimunG Springs&Dampers Tech Tip 3Document4 pagesOptimunG Springs&Dampers Tech Tip 3Thomas Moura100% (1)

- Simulation and Experiments On An Isolated Racecar Wheel Rotating in Ground ContactDocument15 pagesSimulation and Experiments On An Isolated Racecar Wheel Rotating in Ground ContactVyssionNo ratings yet

- Suspension CalculatorDocument89 pagesSuspension CalculatorMichael Serra100% (1)

- CFD of Clubman Roll CagesDocument18 pagesCFD of Clubman Roll CagesJoel ForbesNo ratings yet

- 09 Suspension ConceptsDocument33 pages09 Suspension Conceptskaka1211402No ratings yet

- RoehrigDocument40 pagesRoehrigGuille GarofaloNo ratings yet

- 03 - Aerodynamics and Race CarsDocument13 pages03 - Aerodynamics and Race CarsFabio BosioNo ratings yet

- DamperDocument52 pagesDampergnaniofs3960No ratings yet

- CG Height Calculator - Automotive Brake System Calculator - BRAKE POWERDocument2 pagesCG Height Calculator - Automotive Brake System Calculator - BRAKE POWERAnonymous QiMB2lBCJLNo ratings yet

- Cosworth Data Bytes Live - Pi Toolbox v0 8Document41 pagesCosworth Data Bytes Live - Pi Toolbox v0 8Guilherme PfeilstickerNo ratings yet

- Force Based Roll CentersDocument6 pagesForce Based Roll Centersnick944100% (1)

- 6.dynomite Dynamometer Accessories Catalog PDFDocument52 pages6.dynomite Dynamometer Accessories Catalog PDFLanggeng PrasetyoNo ratings yet

- Kinematics and Compliance of Sports Utility VehicleDocument7 pagesKinematics and Compliance of Sports Utility VehicleInternational Research Journal in Engineering and Emerging Technology100% (1)

- MPC Based Yaw and Lateral Stabilisation Via Active Front Steering and Braking PDFDocument19 pagesMPC Based Yaw and Lateral Stabilisation Via Active Front Steering and Braking PDFKiran KoneNo ratings yet

- Modeling and Control of Quarter-Vehicle Suspension With A Semiactive Actuator, Stamat Stamatov - DissertationDocument335 pagesModeling and Control of Quarter-Vehicle Suspension With A Semiactive Actuator, Stamat Stamatov - DissertationsstamatovNo ratings yet

- Renault 32454 1 5Document11 pagesRenault 32454 1 5AxisOfOversteerNo ratings yet

- At2402 NotesDocument7 pagesAt2402 NotesAnonymous ETBwIduGiNo ratings yet

- Real Time Simulation and Parametric Optimization Applied To Racing Cars The BMW Team Brasil Case PDFDocument47 pagesReal Time Simulation and Parametric Optimization Applied To Racing Cars The BMW Team Brasil Case PDFDebra JacksonNo ratings yet

- BLDC Sinusoidal ControlDocument6 pagesBLDC Sinusoidal ControlOctavian MîrţiNo ratings yet

- Speedometer-Cum-odometer For MotorbikeDocument6 pagesSpeedometer-Cum-odometer For MotorbikeAnonymous 8pCXXs100% (2)

- Digital Dash Board AutomissionDocument72 pagesDigital Dash Board AutomissionVinayaga ProjectinstituteNo ratings yet

- Telemetry System PDFDocument30 pagesTelemetry System PDFizwan909No ratings yet

- Intelligent Breaking SystemDocument21 pagesIntelligent Breaking SystemMurugan MNo ratings yet

- Microprocessor Based Digital PID Controller For Speed Control of D.C. MotorDocument6 pagesMicroprocessor Based Digital PID Controller For Speed Control of D.C. MotorSwapnica GarreNo ratings yet

- Aerodynamics of Gurney Flaps On A Single-Element High-Lift Wing PDFDocument7 pagesAerodynamics of Gurney Flaps On A Single-Element High-Lift Wing PDFRodrigo Bob100% (1)

- Mountain Darryl R.. Disrupting Conventional Law0AFirm Business Models Using0ADocument AssemblyDocument22 pagesMountain Darryl R.. Disrupting Conventional Law0AFirm Business Models Using0ADocument AssemblyRodrigo BobNo ratings yet

- Basic ConceptsDocument5 pagesBasic ConceptsRodrigo BobNo ratings yet

- Iracing 2022 Season 2 CalendarDocument117 pagesIracing 2022 Season 2 CalendarRodrigo BobNo ratings yet

- Assignment 1Document5 pagesAssignment 1Rodrigo BobNo ratings yet

- UCEM Accumulator Final ReportDocument40 pagesUCEM Accumulator Final ReportRodrigo BobNo ratings yet

- A Tool For Lap Time Simulation PDFDocument5 pagesA Tool For Lap Time Simulation PDFRodrigo BobNo ratings yet

- University of Southampton Undergraduate Prospectus 2016 PDFDocument99 pagesUniversity of Southampton Undergraduate Prospectus 2016 PDFRodrigo BobNo ratings yet

- Manual Powerbank PB-6KDocument2 pagesManual Powerbank PB-6KRodrigo BobNo ratings yet

- Developments of A Method For Lap Time SimulationDocument7 pagesDevelopments of A Method For Lap Time SimulationRodrigo Bob100% (1)

- Advanced Dynamics - TU Delft OnlineDocument1 pageAdvanced Dynamics - TU Delft OnlineRodrigo BobNo ratings yet

- Vibration Based Monitoring Applied To The Identification of DefectsDocument10 pagesVibration Based Monitoring Applied To The Identification of DefectsRodrigo BobNo ratings yet

- ADAMS Tutorial - Session 1 - DOFsDocument21 pagesADAMS Tutorial - Session 1 - DOFsRodrigo BobNo ratings yet

- CL Vs AlphaDocument22 pagesCL Vs Alpharahultri333No ratings yet

- NAS120 WS14 Parasolid ModelingDocument34 pagesNAS120 WS14 Parasolid ModelingPieter Van AschNo ratings yet

- Racing Simulation of A Formula 1 Vehicle With Kinetic Energy Recovery SystemDocument15 pagesRacing Simulation of A Formula 1 Vehicle With Kinetic Energy Recovery SystemRodrigo Bob100% (1)

- Eita GiovannaDocument40 pagesEita GiovannaRodrigo Bob100% (1)

- 1 ChassisDocument61 pages1 ChassisRodrigo Bob100% (2)

- Stress Analysis of Piping SystemsDocument108 pagesStress Analysis of Piping SystemsShijumon KpNo ratings yet

- A Tool For Lap Time SimulationDocument5 pagesA Tool For Lap Time SimulationRodrigo BobNo ratings yet

- Application of Computers To Automobile AerodynamicsDocument10 pagesApplication of Computers To Automobile AerodynamicsRodrigo BobNo ratings yet

- Patran 2010 Reference Manual Part 1: Basic FunctionsDocument798 pagesPatran 2010 Reference Manual Part 1: Basic FunctionsDon100% (1)

- Vehicle DynamicsDocument24 pagesVehicle Dynamicssviggnesh_hpNo ratings yet

- Politecnica - Di - Torino - Specific Qualification PDFDocument3 pagesPolitecnica - Di - Torino - Specific Qualification PDFRodrigo BobNo ratings yet

- Projeto de Pontes de Macarrão PDFDocument8 pagesProjeto de Pontes de Macarrão PDFRodrigo BobNo ratings yet

- Using Modelica Models For Driver-In-The-loop SimulatorsDocument8 pagesUsing Modelica Models For Driver-In-The-loop SimulatorsRodrigo BobNo ratings yet

- Response Surface Methodology (RSM) and Design of Experiments (Doe) Applied To Racecar Vehicle Dynamics Simulation and DevelopmentDocument20 pagesResponse Surface Methodology (RSM) and Design of Experiments (Doe) Applied To Racecar Vehicle Dynamics Simulation and DevelopmentRodrigo BobNo ratings yet

- 1-CC-Link IE TSN Na EngDocument71 pages1-CC-Link IE TSN Na EngThanh Kieu Nguyen ThiNo ratings yet

- 35312aa Command Station PC Spec SheetDocument2 pages35312aa Command Station PC Spec SheetProduccion TAMNo ratings yet

- S W A N 1 0 0 0: Installation InstructionsDocument2 pagesS W A N 1 0 0 0: Installation InstructionsLuisAlbertoSaldañaRmzNo ratings yet

- Hardware Notes - Creo 1.0 Parametric, Direct and Simulate: Table of ContentDocument7 pagesHardware Notes - Creo 1.0 Parametric, Direct and Simulate: Table of ContentMohankumarNo ratings yet

- Catalog AP Merit Installer V4Document264 pagesCatalog AP Merit Installer V4BillNo ratings yet

- Introduction To Database Management (Tp4)Document16 pagesIntroduction To Database Management (Tp4)Kalicia RodriquesNo ratings yet

- Unit 2: Introduction To The Engineering Profession: Engr. Roman M. Richard, MengDocument13 pagesUnit 2: Introduction To The Engineering Profession: Engr. Roman M. Richard, MengRoman MarcosNo ratings yet

- WT R13 Lab Manual PDFDocument119 pagesWT R13 Lab Manual PDFsiddarth rpNo ratings yet

- Risk Assessment - ElectricalDocument6 pagesRisk Assessment - ElectricalFawaaz KhurwolahNo ratings yet

- Total Productive Maintenance and Reliability Notes 2Document4 pagesTotal Productive Maintenance and Reliability Notes 2carr carrNo ratings yet

- 12 TriesDocument10 pages12 TriesNikhil 20528No ratings yet

- LAB3.2 - Connecting Windows Host Over iSCSI With MPIODocument13 pagesLAB3.2 - Connecting Windows Host Over iSCSI With MPIOwendy yohanesNo ratings yet

- LP Fujitsu 1din2014Document11 pagesLP Fujitsu 1din2014Anonymous 4MLEo9TVQNo ratings yet

- Society of International Gas Tanker & Terminal Operators (Sigtto)Document8 pagesSociety of International Gas Tanker & Terminal Operators (Sigtto)Mohamed MekkyNo ratings yet

- Project Report On BhelDocument101 pagesProject Report On BhelP.satya vinay tejaNo ratings yet

- JTM-30C Configuration & User Manual Rev-I PDFDocument12 pagesJTM-30C Configuration & User Manual Rev-I PDFVladimirs ArzeninovsNo ratings yet

- JSA New Revision Grader and Vibro and Dozer 8 5 18Document7 pagesJSA New Revision Grader and Vibro and Dozer 8 5 18risky indra antariNo ratings yet

- Map Reading Fluency Fact SheetDocument2 pagesMap Reading Fluency Fact Sheetapi-424731280No ratings yet

- An Intelligent Algorithm For The Protection of Smart Power SystemsDocument8 pagesAn Intelligent Algorithm For The Protection of Smart Power SystemsAhmed WestministerNo ratings yet

- Elon Musk and Twitter - TBADocument11 pagesElon Musk and Twitter - TBASibghatullah SiyalNo ratings yet

- Yahaya Current CVDocument2 pagesYahaya Current CVJennifer PetersNo ratings yet

- MasterFormat - Wikipedia, The Free EncyclopediaDocument3 pagesMasterFormat - Wikipedia, The Free EncyclopediaMartin SabahNo ratings yet

- Ethics in Ict An Australian Perspective PDFDocument2 pagesEthics in Ict An Australian Perspective PDFAndrew0% (1)

- Aluminium ProfileDocument23 pagesAluminium ProfileRobert CedeñoNo ratings yet

- 574 Danthanh Asm2 Gbd18485Document29 pages574 Danthanh Asm2 Gbd18485Huynh Ngoc Hai Dang (FGW DN)No ratings yet

- Safety and Security: by Walusimbi KennethDocument55 pagesSafety and Security: by Walusimbi KennethSolángé MirembeNo ratings yet

- Big Data Analytics in Supply Chain Management Between 2010 and 2016Document12 pagesBig Data Analytics in Supply Chain Management Between 2010 and 2016Kuldeep LambaNo ratings yet

- Pro 5632Document9 pagesPro 5632Phat HoangNo ratings yet

- CLO 1 Scope and Role of SCM in An OrganizationDocument28 pagesCLO 1 Scope and Role of SCM in An OrganizationMelvinNo ratings yet

- Datasheet of DS-KIS204 Video Door Phone V1.1.0 20180502 PDFDocument3 pagesDatasheet of DS-KIS204 Video Door Phone V1.1.0 20180502 PDFNareshNo ratings yet