Professional Documents

Culture Documents

SPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High Pressure

Uploaded by

Aris KancilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High Pressure

Uploaded by

Aris KancilCopyright:

Available Formats

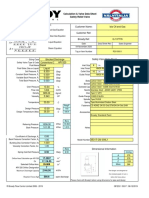

1 BB

2 2500#

3 2500#RF

4

5

6 1.00

7 375.00 barg

8 38.0C

9 20.000 ksi

10 1.40 mm 12.5%

11 0.4

12 0.272

13 t

pressure

= (P x D) / [2 x {(S.E) + (P.Y)}]

14 (Valid for t<D/6)

15 Where, (As per para. 304.1.2 of of ASME B31.3 2002 Edition)

16 D =Outside diameter of pipe in inch and also derived in mm; Refer ASME B36.10M-1996.

17 P =Internal design gage pressure in psi and also derived in bar;

18 t

min

= Minimum required thickness, including mechanical, corrosion and erosion allowances;

19 t

pressure

= Pressure design thickness, as calculated in accordance with para. 304.1.2, for internal pressure;

20 S =Allowable stress value from Table A-1 of ASME B31.3;

21 E =Quality factor from Table A-1A or A-1B of ASME B31.3;

22 Y =Coefficient from Table 304.1.1 of ASME B31.3, valid for t<D/6;

23 T = The minimum wall thickness for the pipe selected or purchased, considering manufacturer's minus

24 tolerance shall be NOT less than t min. For t min, refer Column " A" and for T, refer Column " B" .

25 (All nomenclatures, definitions and parameters are generally in accordance with ASME B31.3 2002 Edition.)

26 Selected

27 Pipe NPS Pipe OD t

pressure

t

min

Sch / Nominal Min. Thk. Max.Allow. Ratio Check

28 inch (mm) D (mm) (mm) (mm) Thk. (inch) Thk. (mm) T (mm) P (barg) (D/t) (T>t

min

)

29 Column " A" T

nom

Column " B" Check (>6)

30 " (15) 21.34 2.62 4.02 Sch.160 4.78 4.18 400.9 7.7 Passed.

31 " (20) 26.67 3.27 4.67 Sch.160 5.56 4.87 400.2 7.7 Passed.

32 1" (25) 33.40 4.10 5.50 Sch.160 6.35 5.56 381.1 8.0 Passed.

33 1" (32) 42.16 5.17 6.57 0.3125" 7.94 6.95 405.4 7.6 Passed.

34 1" (40) 48.26 5.92 7.32 0.3750" 9.53 8.33 447.7 7.0 Passed.

35 2" (50) 60.33 7.40 8.80 0.4375" 11.11 9.72 427.7 7.2 Passed.

36 2" (65) 73.03 8.96 10.36 0.5000" 12.70 11.11 410.5 7.5 Passed.

37 3" (80) 88.90 10.90 12.30 0.5625" 14.29 12.50 382.6 8.0 Passed.

51 Notes: 1. The user shall arrive at the worst case P-T condition, based on maximum (P/SE) ratio.

52 2. The user shall be responsible to check the allowable stress value for the material & temp.

53 3. The user shall be responsible to check the applicable Y Coefficient value for the material & temp.

PIPE

CLASS

REV. CALC. BY DATE CHKD. BY DATE

CLIENT: 3

PROJECT: 2

LOCATION: 1

SUBJECT: 0 SH 1 OF 1

=5438.92 psig

HIGH PRESSURE LINE

Y Coefficient @ 38C =

Seamless Pipe or Tube Pipe Manufacturing Type =

=137.90 MPa

Corrosion Allowance =

= (5,438.9 x D) / [2 x {(20,000.0 x 1.00) + (5,438.9 x 0.4)}]

= 0.1226330626 x D inch

Ratio of (P/SE) =

JOB NUMBER

PTC & Branch Calc_ASME B31.3_Upto NPS 24

Version: 1.11

Please check from Table A-1 of ASME B31.3 Latest Edition.

Please check from ASME B31.3 Table 304.1.1.

=0.06 inch

Internal Pressure Thk. Calc. Sheet

Please input temperature value in C.

Valid for t<D/6

CALCULATION NUMBER

Please input

Check Passed.

DENPASAR BALI

SPBG PALEMBANG

2500#

DIRJEN MIGAS

Design Temperature =

Mill Tolerance =

Low Temperature Process

Allow. Stress @ 38C =

Only RED font cells are meant for Input.

Select / Input Special Requirements, if any =

=100.4F

Natural Gas

PMS Line Class ID =

ASME Flange Rating =

Fluid / Service =

Material Specification =

Optional Comments: Non-Lethal Low Temperature Process Hydrcarbons

A106 Gr B

Please input pressure value in barg.

Material Type: Carbon steels, C <=0.3%

Quality Factor, E =

Design Pressure =

You might also like

- Attachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)Document4 pagesAttachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)ISRAEL PORTILLONo ratings yet

- Insulation Calculation For 36 inDocument18 pagesInsulation Calculation For 36 inSaepul RochmanNo ratings yet

- API 610 Check CaesarDocument22 pagesAPI 610 Check CaesarSeptian FirdausNo ratings yet

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- The Feasibility of Transporting Hydrogen in Existing PipelinesDocument9 pagesThe Feasibility of Transporting Hydrogen in Existing PipelinesomiitgNo ratings yet

- Test Report Long-Term Ring Bending Strain (SB)Document4 pagesTest Report Long-Term Ring Bending Strain (SB)Diana QuinteroNo ratings yet

- Amipox GRE Cal Manual Ws HiddDocument20 pagesAmipox GRE Cal Manual Ws HiddrahulNo ratings yet

- Mechanical Engineering: Merger Turns To Collaboration - COADE Remains IndependentDocument24 pagesMechanical Engineering: Merger Turns To Collaboration - COADE Remains IndependentfileseekerNo ratings yet

- Wall Thickness CalDocument6 pagesWall Thickness CalNorazlan Shah MahadiNo ratings yet

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDocument5 pagesPetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetNo ratings yet

- Engineered Spring SupportsDocument43 pagesEngineered Spring SupportsNestor Barranco RadaNo ratings yet

- Ips G Pi 280Document23 pagesIps G Pi 280MahdiNo ratings yet

- Pipe Stress Analysis Complete Course From PassDocument2 pagesPipe Stress Analysis Complete Course From Passsleiman shokrNo ratings yet

- Curriculum Vitae: Sridhar VijayanDocument5 pagesCurriculum Vitae: Sridhar VijayanSridhar VijayanNo ratings yet

- Gas RegulationsDocument168 pagesGas RegulationsJijo GeorgeNo ratings yet

- Load Cases For Typical Piping System Using CAESAR IIDocument4 pagesLoad Cases For Typical Piping System Using CAESAR IIsj22No ratings yet

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDocument5 pagesPetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetNo ratings yet

- Upheaval & Lateral Buckling Calculations For Buried Pipelines - TR Engineering Consultancy LLCDocument2 pagesUpheaval & Lateral Buckling Calculations For Buried Pipelines - TR Engineering Consultancy LLCRaakze MoviNo ratings yet

- 9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesDocument12 pages9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesAnjani Prabhakar100% (1)

- Caesar Newsletter Timehistory AnalysisDocument16 pagesCaesar Newsletter Timehistory AnalysisNixonNo ratings yet

- 매설배관 건전성평가 PDFDocument169 pages매설배관 건전성평가 PDF이선엽No ratings yet

- TN10 Critical Line List SampleDocument2 pagesTN10 Critical Line List Sampleyulianus_srNo ratings yet

- HDPE Flange AdaptorDocument1 pageHDPE Flange Adaptorcld72No ratings yet

- Mss sp-71 1997 PDFDocument10 pagesMss sp-71 1997 PDFChotiwan RattanasatienNo ratings yet

- Quality Requirements For Line Pipe: JanuaryDocument14 pagesQuality Requirements For Line Pipe: JanuaryJose Anisio Silva100% (1)

- Crossing Calculation API Rp1102 TemplateDocument1 pageCrossing Calculation API Rp1102 TemplateBudi SantonyNo ratings yet

- Mathcad - Natural Bend Radius Cal Rev. 0Document3 pagesMathcad - Natural Bend Radius Cal Rev. 0hamid sobirin100% (2)

- APT001-S-DS-PI-004 Insulation - Gasket - Data - Sheet - Rev0+Document10 pagesAPT001-S-DS-PI-004 Insulation - Gasket - Data - Sheet - Rev0+Roy RahadianNo ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- Free Span Design According To The DNV-RP-F105 For Free Spanning PipelinesDocument24 pagesFree Span Design According To The DNV-RP-F105 For Free Spanning PipelinesconanbhNo ratings yet

- Cast - Basket Strainers - 2nd EditionDocument27 pagesCast - Basket Strainers - 2nd EditionmartinnovelNo ratings yet

- How Do You Carry Out Estimation? Ans: 1. Input From BidDocument21 pagesHow Do You Carry Out Estimation? Ans: 1. Input From BidSunil ShaNo ratings yet

- Petrofac International LTD.: Document TransmittalDocument2 pagesPetrofac International LTD.: Document TransmittalbelhaskaNo ratings yet

- Commercial Gas Pipe Sizing PART 2 - Using The Pressure Drop Calculator (PDC)Document12 pagesCommercial Gas Pipe Sizing PART 2 - Using The Pressure Drop Calculator (PDC)Catalin StrugariuNo ratings yet

- P&id SeminarDocument30 pagesP&id SeminaryasirvazhikkadavuNo ratings yet

- Orifice Plate BrochureDocument39 pagesOrifice Plate Brochureronzies100% (1)

- HDPE-MaterialData 78281Document2 pagesHDPE-MaterialData 78281tayyabmubarik2417No ratings yet

- Calculation of PipeReinforcement ASMEB31 1Document4 pagesCalculation of PipeReinforcement ASMEB31 1threedlabsNo ratings yet

- Sample Hot Tap Construction Schedule PDFDocument1 pageSample Hot Tap Construction Schedule PDFrajkamal eshwarNo ratings yet

- 4.1 Rerating Piping and Pressure Vessels: Major Piping Inspection CodesDocument23 pages4.1 Rerating Piping and Pressure Vessels: Major Piping Inspection CodesMahmoud samahaNo ratings yet

- Lesson Learnt From SNC On Stress AnalysisDocument3 pagesLesson Learnt From SNC On Stress AnalysiszahoorNo ratings yet

- Woc Hse Manual Standards: Woc LP EP DepartmentDocument12 pagesWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadNo ratings yet

- Rock Shield Material Data SheetDocument1 pageRock Shield Material Data SheetR.S.No ratings yet

- Input:: Note de Calcul Calculation NoteDocument4 pagesInput:: Note de Calcul Calculation NotekardujorgeNo ratings yet

- Piping Support Ofon NG 018 XX PNL 405102 00Document136 pagesPiping Support Ofon NG 018 XX PNL 405102 00CHUKUDINo ratings yet

- SLR Strainer Data Sheet PDFDocument7 pagesSLR Strainer Data Sheet PDFKailas NimbalkarNo ratings yet

- Offshore Pipeline Hydraulic and Mechanical AnalysesDocument25 pagesOffshore Pipeline Hydraulic and Mechanical AnalysesEslam RedaNo ratings yet

- 02 Samss 006Document17 pages02 Samss 006inatt101No ratings yet

- Easyflex Flexible Hose DatasheetDocument2 pagesEasyflex Flexible Hose DatasheetzassssNo ratings yet

- 6-76-0002 Bolt Tension For FlangesDocument33 pages6-76-0002 Bolt Tension For Flangesrovergamma100% (1)

- Few Important Points For Stress Analysis Based On ASME B 31Document4 pagesFew Important Points For Stress Analysis Based On ASME B 31Nilesh GohelNo ratings yet

- Static Calculation of Pipeline Free SpansDocument1 pageStatic Calculation of Pipeline Free SpansMannattil Krishna KumarNo ratings yet

- 347 Stainless Steel Class 2500 Piping SpecificationDocument3 pages347 Stainless Steel Class 2500 Piping SpecificationTrevor KanodeNo ratings yet

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 pagesPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNo ratings yet

- Branch Reinforcement Pad Requirement Calculation PDFDocument1 pageBranch Reinforcement Pad Requirement Calculation PDFdeua2004No ratings yet

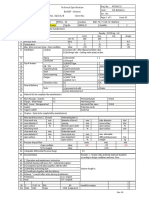

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- ASME B31.3.4.8 Wall Thickness CalculatorDocument26 pagesASME B31.3.4.8 Wall Thickness Calculatoreko123100% (1)

- IDBU-CW-LSPDS-000029 Rev G - Upstream Piping Comp. SelectDocument115 pagesIDBU-CW-LSPDS-000029 Rev G - Upstream Piping Comp. Selectjoey garciaNo ratings yet

- Claude Frederic BastiatDocument3 pagesClaude Frederic Bastiatapi-26172897No ratings yet

- Segmen Mjpahit Jatingaleh MjpahitDocument1 pageSegmen Mjpahit Jatingaleh MjpahitAris KancilNo ratings yet

- Electrical GroupingDocument1 pageElectrical GroupingAris KancilNo ratings yet

- 01 DS Ball Valve CSDocument4 pages01 DS Ball Valve CSAris KancilNo ratings yet

- Segmen Jatingaleh Bawen-3of3Document1 pageSegmen Jatingaleh Bawen-3of3Aris KancilNo ratings yet

- Energi Indonesia 2012Document29 pagesEnergi Indonesia 2012Aris KancilNo ratings yet

- PipeP PE2406 CharacteristicDocument3 pagesPipeP PE2406 CharacteristicAris KancilNo ratings yet

- Flow Based On KatoDocument3 pagesFlow Based On KatoAris KancilNo ratings yet

- Flow Sheet Sago Rev Feb 2014 Flow ChartDocument1 pageFlow Sheet Sago Rev Feb 2014 Flow ChartAris KancilNo ratings yet

- Flow Sheet Layout3Document1 pageFlow Sheet Layout3Aris KancilNo ratings yet

- Blok Diagram Ekstrasi Sagu Rev 1 April 2013Document4 pagesBlok Diagram Ekstrasi Sagu Rev 1 April 2013Aris KancilNo ratings yet

- SImulasi Mass Balance - 18april2013 - As (Version 1)Document7 pagesSImulasi Mass Balance - 18april2013 - As (Version 1)Aris KancilNo ratings yet

- Water Flow Diagram Ver Feb 27022013Document1 pageWater Flow Diagram Ver Feb 27022013Aris KancilNo ratings yet

- Gas Line Sizing - SPBG PalembangDocument24 pagesGas Line Sizing - SPBG PalembangAris KancilNo ratings yet

- 01 DS Ball Valve CSDocument4 pages01 DS Ball Valve CSAris KancilNo ratings yet

- Cng-000-El-011 Voltage Drop Calculation (MS) r1Document6 pagesCng-000-El-011 Voltage Drop Calculation (MS) r1Aris KancilNo ratings yet

- 10.Cnb-dwg-p-006 Layout SPBG Jalan Ki MeroganDocument1 page10.Cnb-dwg-p-006 Layout SPBG Jalan Ki MeroganAris KancilNo ratings yet

- Risk ManajemenDocument4 pagesRisk ManajemenAris KancilNo ratings yet

- Instrument and Control Design BasisDocument3 pagesInstrument and Control Design BasisAris KancilNo ratings yet

- Burlian Plot Plan Burlian - Okt 2012 2007 ModelDocument1 pageBurlian Plot Plan Burlian - Okt 2012 2007 ModelAris KancilNo ratings yet

- Risk Assestment Gas Terminal N PipelineDocument14 pagesRisk Assestment Gas Terminal N PipelineAris KancilNo ratings yet

- Spek PipaDocument7 pagesSpek PipaAris KancilNo ratings yet

- Gas Transmision CodeDocument59 pagesGas Transmision CodeAris KancilNo ratings yet

- Valve SheetDocument23 pagesValve SheetAris KancilNo ratings yet

- Spesifikasi Truc HyundayDocument32 pagesSpesifikasi Truc HyundayAris Kancil50% (4)

- Biogas GuideDocument63 pagesBiogas GuideAris KancilNo ratings yet

- Kalkulasi Studikasus KSDocument6 pagesKalkulasi Studikasus KSAris KancilNo ratings yet

- Fire and Gas Detection SpecificationDocument4 pagesFire and Gas Detection SpecificationAris KancilNo ratings yet

- Gas Technology Institute PresentationDocument14 pagesGas Technology Institute PresentationAris KancilNo ratings yet

- BWG - Birmingham Wire GaugeDocument8 pagesBWG - Birmingham Wire GaugepurnawanNo ratings yet

- Setting Time of ConcreteDocument1 pageSetting Time of ConcretemiyaeunchaeNo ratings yet

- Service Details Man BW PDFDocument7 pagesService Details Man BW PDFTapas ChaudhuriNo ratings yet

- 20222608332322tangazo Kazi TPDCDocument18 pages20222608332322tangazo Kazi TPDCJontelli SimonNo ratings yet

- Spec Sheet - American StandardDocument2 pagesSpec Sheet - American StandardJohn Enrick ManuelNo ratings yet

- BPC 600k Hwo Snubbing UnitDocument6 pagesBPC 600k Hwo Snubbing UnitYiDey87No ratings yet

- Secondary Composite ExampleDocument12 pagesSecondary Composite Examplef2662961No ratings yet

- Countryman Manual (Eng) (13204)Document30 pagesCountryman Manual (Eng) (13204)Moz NazNo ratings yet

- 547315-En 1.0.0Document160 pages547315-En 1.0.0Jose MustienesNo ratings yet

- Automatic Sprinklers: Hanger Spacing For Nonmetallic Pipe: Learning ObjectiveDocument1 pageAutomatic Sprinklers: Hanger Spacing For Nonmetallic Pipe: Learning ObjectiveReymart Jaynar ReyesNo ratings yet

- 14.gi Conduit BecDocument4 pages14.gi Conduit BeckailasamvvNo ratings yet

- Bridge Types: CIL (COWI India Pvt. Limited) - Bridge DepartmentDocument29 pagesBridge Types: CIL (COWI India Pvt. Limited) - Bridge DepartmentvikramannNo ratings yet

- Standard and Specifications Based On NSCP 2010 DeadloadsDocument7 pagesStandard and Specifications Based On NSCP 2010 DeadloadsIan Dave AdvinculaNo ratings yet

- Curriculum Vitae: Personal Information Sallam Q. ShurrabDocument3 pagesCurriculum Vitae: Personal Information Sallam Q. ShurrabSallam Q. ShurrabNo ratings yet

- SATIP-S-030-01, Rev 8 Storm Water Drainage System G FinalDocument3 pagesSATIP-S-030-01, Rev 8 Storm Water Drainage System G Finalmomin0% (1)

- TRM 150Document3 pagesTRM 150Jefferson fernandesNo ratings yet

- Fosroc Bitucell: Constructive SolutionsDocument2 pagesFosroc Bitucell: Constructive SolutionsIna RoseNo ratings yet

- ONE Lake Club IIDocument15 pagesONE Lake Club IIErvin92No ratings yet

- Foundation Design For A High Bay Warehouse With A Steel Fibre Reinforced Concrete SlabDocument13 pagesFoundation Design For A High Bay Warehouse With A Steel Fibre Reinforced Concrete SlabEstetika chinta PertiwiNo ratings yet

- E2121-13 Standard Practice For Installing RadonDocument13 pagesE2121-13 Standard Practice For Installing RadonRony YudaNo ratings yet

- Kitz Stainless Steel Catalog New PDFDocument58 pagesKitz Stainless Steel Catalog New PDFel_apache10No ratings yet

- DIN Low Pressure Fittings and AccessoriesDocument184 pagesDIN Low Pressure Fittings and AccessoriesImtiaz NusratNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationrustamriyadi100% (2)

- STAIRCASE DESIGN: Dog Legged StaircaseDocument2 pagesSTAIRCASE DESIGN: Dog Legged StaircasePraYush RajbhandariNo ratings yet

- D392002424 MKT 001 PDFDocument2 pagesD392002424 MKT 001 PDFfajarulmNo ratings yet

- Why The BS 8500 Durability Tables Are The Way They Are-Concrete June2016Document4 pagesWhy The BS 8500 Durability Tables Are The Way They Are-Concrete June2016Vipin Kumar ParasharNo ratings yet

- Material Consumption Norms For Various Civil Works - Civil4MDocument1 pageMaterial Consumption Norms For Various Civil Works - Civil4MAnubhav NautiyalNo ratings yet

- CaseStudy-Philippine Procurement Process Loophole InvestigationDocument7 pagesCaseStudy-Philippine Procurement Process Loophole InvestigationCrestine Lily DongosaNo ratings yet

- Meca Report 2015 11 r270 C Barka PrestressDocument91 pagesMeca Report 2015 11 r270 C Barka Prestressajay katrojNo ratings yet