Professional Documents

Culture Documents

ICCMS 2012 - Full Length Paper

Uploaded by

Dipta Ranjan Roy0 ratings0% found this document useful (0 votes)

63 views10 pagesARX Model, Fault Identification, Adaptive System, Recursive Filter, System Identification, Model Based Development

Original Title

ICCMS 2012_Full Length Paper

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentARX Model, Fault Identification, Adaptive System, Recursive Filter, System Identification, Model Based Development

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

63 views10 pagesICCMS 2012 - Full Length Paper

Uploaded by

Dipta Ranjan RoyARX Model, Fault Identification, Adaptive System, Recursive Filter, System Identification, Model Based Development

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

International Congress on Computational Mechanics and Simulation (ICCMS),

IIT Hyderabad, 10-12 December 2012

Page 1 of 10

Auto-Regressive with eXogenous Input (ARX) based Computational

Model for Fault Diagnosis of Spacecraft Systems

Dipta Ranjan Roy, Nibir Chakraborty, D. Roy. Mahapatra

Department of Aerospace Engineering, Indian Institute of Science,

Bangalore, India, 560012

Presenting author: diptaroy2001@yahoo.co.in

ABSTRACT

An effective fault diagnostic method should be supported by a robust damage estimation technique, as well

as, suitable computational techniques for fault identification, isolation etc. The present work is structured

into two components. The first one aims at developing a PID based control system, for a spacecraft nozzle

system mounted on a single axis gimbal, which uses a servo actuator. The second part is aimed at

developing a dynamic diagnostic system, which incorporates a process model based damage detection and

system identification scheme. For computational viability, an AutoRegressive with eXogenous inputARX

model is proposed for feature generation as well as anomaly detection, which uses statistical inference rules.

1. Introduction

Any physical system can be represented by a single degree of freedom, or a combination of several single degree of

freedom, spring-mass-damper system. Whenever a fault is injected into such a system, it brings a change in the

system parameters, and we observe a deviation from its normal behavior. By system parameters, we are commonly

referring to the physical quantities like mass, stiffness and damping. Thus, the first step towards an effective fault

diagnosis of a system is associated with the identification of system parameters, which actually governs its dynamic

behavior. In this work, we have tried to establish and validate a process model based system identification

methodology, based on input-output data. We have used a very fundamental approach, associated with the

construction of the Frequency Response Function (FRF) of a system under investigation and then extracting the

system parameters, i.e., mass, stiffness and damping from the FRF. For physical realization and experimental

validation of the methodology, we have used a servomotor actuated spacecraft thruster nozzle. For simplicity, we

have modeled the spacecraft thruster nozzle as an open-loop PID control system. Then, a recursive filtering or auto-

regressive eXogenous input (ARX) based system identification procedure is used to construct the Bode plot (which

effectively is also equivalent of finding the FRF of the system). After the FRF has been identified, we used simple

mathematical techniques to estimate the system parameters. We used a single degree of freedom spring-mass-

damper system to analytically represent our spacecraft thruster nozzle and performed experimental validations to

implement the ARX based modeling, for estimation of system parameters. The major advantage of the process is that

we can estimate the frequency response of the system, from the experimentally obtained time-domain data. The

experimental results are quite satisfactory and show good coherence with the analytical results. Once the system

parameters are identified using the given technique, it can be used as a reference state, to identify fault induced state

in the system. This accounts for the fault diagnosis part, in context of this work.

2. Transfer Function approach for System Identification

The most simplistic approach for identifying a single degree of freedom spring-mass-damper system is by identifying

the Transfer Function. This work is based on the verification and validation of system identification using the Transfer

Function approach. For a second order spring-mass-damper system, we will assume that that the forcing function is

also harmonic in nature, which is expressed in the form,

International Congress on Computational Mechanics and Simulation (ICCMS)

IIT Hyderabad, 10-12 December 2012

Page 2 of 10

Substituting the harmonic solutions in the second order differential equation we obtain the equation of motion in the

frequency domain, given by

which is entirely an frequency dependent function. Thus, the Transfer Function of the system is given as,

where,

and

3. Estimation of parameter from analytical models

LMS-AMESim is a commercially available software which is used for vibration simulation [1]. In this work, we used it

to theoretically analyze and study the vibration characteristics of a single degree of freedom spring-mass-damper

system. Secondly, we also used it to generate the Frequency Response Function (FRF) of the system and from the

response characteristics, we estimated the parameters (mass, stiffness and damping) of the system. The process is

very simple and easy to handle and it gives very accurate results. The complete procedure is described in this

section. Later, we used the same procedure to estimate the system parameters for our experimental model.

The parameters used for simulation are,

Physical Mass 2 Kg

Physical Stiffness 6000 kN/m

Physical Damping 5 N/(m/s)

The spring-mass-damper representation in the LMS-AMESim software is shown below,

Fig.1 LMS-AMESim block diagram of the spring mass damper system

International Congress on Computational Mechanics and Simulation (ICCMS),

IIT Hyderabad, 10-12 December 2012

Page 3 of 10

The extreme right block represents the sinusoidal frequency that is imparted to the system. The next block represents

the 2-port mass which in turn is connected to a spring-damper system. On running the simulation the time history for

the mass, as well as, the Frequency Response Function for the system can be obtained. The frequency response

function graph which is used to estimate the physical parameters of the system is shown below.

Fig.2 Frequency Response of the single degree of freedom spring-mass-damper system

a. Stiffness Estimation

The Transfer Function for the one-degree of freedom spring-mass-damper system is given by,

Putting =0 (corner frequency) and substituting the corresponding value of G(0) from the Frequency Response

graph, we can obtain the stiffness of the system as follows,

Here,

G(0)= -75.4481

Thus,

k= 5291.1355 N/m

b. Natural Frequency Estimation

Natural frequency (fn) can be determined from the phase response of the spring-mass-damper system. It is the

frequency where the phase reversal takes place. Thus, from the phase response graph, it can be determined by

extracting the corresponding frequency value where the phase is close to 90 degree.

International Congress on Computational Mechanics and Simulation (ICCMS)

IIT Hyderabad, 10-12 December 2012

Page 4 of 10

Thus,

n = 55.257 Hz

c. Mass Estimation

Mass of the system can be directly estimated using the relation

Thus,

m = 1.9744 Kg

d. Non-dimensional damping co-efficient Estimation

The non-dimensional damping co-efficient can be determined by analyzing the difference in response between the

corner-frequency and the natural-frequency of the system. The relation, to obtain it graphically is given by,

Thus,

=0.0243

e. Damping Estimation

Damping of the system can be directly estimated using the relation

Thus,

c= 5.3229 N/m/s

4. ARX Modeling Approach

The system identification problem is to estimate a model of a system based on observed input-output data. There are

several ways to describe a system to be estimated. The basic single input-single output configuration of a general

system, in the time domain is given as,

where, k=1,2,3..........N

where u(k) is the input signal, y(k) is the output signal, e(k) is the white noise with variance , v(k) is the additional,

immeasurable disturbance (noise) and can be filtered as white noise. Here, z is the shift operator, so that

International Congress on Computational Mechanics and Simulation (ICCMS),

IIT Hyderabad, 10-12 December 2012

Page 5 of 10

Thus, it can be said

where g(i) is the weighting function (or impulse response), G(z-1) is called the transfer function operator or the

transfer function of the linear system.

To be able to estimate the functions G and H they typically, have to be parameterized, most often as rational

functions in the delay operator z-inverse. Let the parameters be the numerator and denominator co-efficient. Thus we

give a general parametric model structure:

where A,B,C,D,F are polynomials in the delay operator z-inverse. The polynomials in the delay operators are given by

the form,

The structure variables na, nb, nc, nd and nf are called the orders of the respective polynomials. The number nk is

the number of delays from input to output. More on the ARX based modeling is dispersed elsewhere in the literature

[2], [3], [4], [5] and can be used for further usage. The model based FDI method uses a mathematical model of the

plant under investigation and computes the redundancy between the measured values and the analytical value of the

plant variable. The resultant difference, also known as the residuals, gives a proper indication of the fault that has

incurred in the system [6]. An online identification scheme is also possible using the ARX based model. The online

identification of the ARX model uses recursive least-squares (RLS) algorithm based on a Kalman filter approach. The

ARX model, in this case, can be expressed as

where, y[k] is the discrete output signal and u[k] is the discrete input signal; measured at a discrete time k. The

structure of a recursive algorithm based system identification scheme is given below,

International Congress on Computational Mechanics and Simulation (ICCMS)

IIT Hyderabad, 10-12 December 2012

Page 6 of 10

Fig 3. Recursive System Identification Scheme.

The error of the system output is defined as

where the adaptive model generates a one-step ahead predicted response ) n ( y 1 +

)

based on the u(n+1) after

adjusting the parametric vector ) n ( w

)

based on the error e(n). The goal of the adaptive algorithm is to minimize the

cost function J(n) described as

5. Experimental setup for system characterization

An instrumented testbed is designed and assembled to achieve the desired objectives, as discussed in the previous

sections. The designed model consists of an accelerometer mounted on the thruster nozzle. The thruster nozzle is in

turn fitted to a shaft, where the rotation of the shaft is controlled by a servomotor. The accelerometer gives the

magnitude of vibration that occurs due to the torque produced by the servomotor. In this experimental setup, the

servomotor acts as the actuator, this produces the necessary angular displacements.

S

e

r

v

o

m

o

t

o

r

p

o

c

k

e

t

S

h

a

f

t

B

e

a

r

i

n

g

Base Plate

Adjustable Screw Holes

Countersunk Screw Holes

Vertical Side Stand

S

e

r

v

o

m

o

t

o

r

p

o

c

k

e

t

S

h

a

f

t

B

e

a

r

i

n

g

Base Plate

Adjustable Screw Holes

Countersunk Screw Holes

Vertical Side Stand

Fig 4. Schematic of the model Fig 5. Schematic of the base plate

To keep our experimental model simple, we decided to go with an open-loop loop control. Even though the thruster

nozzle is excited by the servomotor torque, we are not using the accelerometer reading to counterbalance the torque

produced by the servomotor. That is why we are referring to the system as an open loop control problem. However,

there is full scope of using the same system as a closed loop PID control system, where the accelerometer reading

International Congress on Computational Mechanics and Simulation (ICCMS),

IIT Hyderabad, 10-12 December 2012

Page 7 of 10

can be used as a feedback to stabilize the trajectory of the thruster nozzle. Since we tried to estimate the system

parameters using frequency response analysis (Bode plot estimation), another objective was to use a nominal

thruster nozzle configuration. The advantage is that the whole system can be represented as a single degree of

freedom spring-mass-damper system, which makes it easy to compare the analytical calculations and the

experimental results. Thus, we decided to go with the open-loop system configuration, where we used the

servomotor as the actuation source, to analyze the vibration characteristics of the thruster nozzle. Hence, the overall

objective reduces to a simple System Identification problem, where the plant matrix can be obtained from the input-

output values. Once the co-efficient for the system matrix are determined we can easily introduce faults in it to predict

and determine its behavior.

6. Model independent System Identification

This section deals with the experimental approach to characterize the system, using auto-regressive and adapting

filtering based technique (ARX Model), from input-output data. This accounts for the Model-independent approach in

our work. For the input configuration, the measurements were taken without the cantilever beam. In order to achieve

this, the accelerometer was mounted on the top of the thruster nozzle. In the next step, i.e. for the output

configuration, the cantilever beam was attached to the thruster nozzle body and the accelerometer was mounted on

the top of the cantilever beam. The purpose of doing this it that, when the accelerometer is mounted on the tip of the

cantilever beam, we can ,mathematically model the whole system as a single degree of freedom, spring-mass-

damper system with a tip mass. Once the input and output measurements were properly captured, we used the

System Identification toolbox available in MATLAB, to determine the Frequency Response function of the system.

Once the FRF of the system was determined, we used it to estimate the system parameters (mass, stiffness and

damping) using the methodology described in the previous section. The corresponding input-output response and the

sampled data which is used for identification of the system is shown below.

Fig.6 Schematic to capture the input response of the system

Fig 7 Schematic to capture the input response of the system

International Congress on Computational Mechanics and Simulation (ICCMS)

IIT Hyderabad, 10-12 December 2012

Page 8 of 10

The corresponding real-time response of the system which is acquired by the usage of LABView data acquisition tool

and NI-PCX DAQ card. The data is then transferred to MATLAB and the corresponding plots are shown below.

Fig.8 Trapezoidal pulse as Servomotor input (generated using AUDRINO)

Fig.9 Input Response of the Thruster Nozzle (without the cantilever beam)

Fig.10 Output Response of the Thruster Nozzle (without the cantilever beam)

International Congress on Computational Mechanics and Simulation (ICCMS),

IIT Hyderabad, 10-12 December 2012

Page 9 of 10

Fig. 11 System identification Toolbox in MATLAB

Fig.12 Frequency Response Function of the Experimental Model

The estimated values of the parameters from the Experimental Model are described in the table below.

PARAMETRS ESTIMATED VALUES

Corner Frequency 1.0003 [Hz]

Natural Frequency 4.805456 [Hz]

1

st

Peak value (Corner Frequency) 0.01191 [dB]

International Congress on Computational Mechanics and Simulation (ICCMS)

IIT Hyderabad, 10-12 December 2012

Page 10 of 10

2

nd

Peak value (Natural Frequency) 0.0009389 [dB]

Non-dimension damping constant () 0.5100

Physical Mass 0.04329 [Kg]

Physical Stiffness 0.9999 [N/m]

Physical Damping 0.2122 [N/m/s]

7. References

[1] http://nupet.daelt.ct.utfpr.edu.br/_ontomos/paginas/AMESim4.2.0/doc/pdf/manuals/amesim.pdf

[2] http://alexandria.tue.nl/extra1/erap/publichtml/8835148.pdf

[3] System Identification Toolbox, MATLAB

[4] Karel J. Keesman, System Identification-An Introduction, Springer-Verlag London Limited 2011, ISBN 978-0-

85729-521-7, DOI 10.1007/978-0-85729-522-4

[5] Rolf Isermann, Marco Munchhof, Identification of Dynamic Systems-An Introduction with Applications, Springer-

Verlag London Limited 2011, ISBN 978-3-540-78878-2, DOI 10.1007/978-3-540-78879-9

[6] Rolf Isermann, Fault-Diagnosis Applications, Model-Based Condition Monitoring: Actuators, Drives, Machinery,

Plants, Sensors, and Fault-tolerant Systems, Springer-Verlag London Limited 2011, ISBN 978-3-642-12766-3, DOI

10.1007/978-3-642-12767-0

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Electrical Engineering Hand BookDocument22 pagesElectrical Engineering Hand Bookjicksonjohn100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Foxboro™ SCADA SCD6000 Controller - 41s2m17Document25 pagesFoxboro™ SCADA SCD6000 Controller - 41s2m17Muhd Nu'man H100% (1)

- 194 Construction, Laying and Installation Techniques For Extruded and Self-Contained Fluid Filled Cable Systems PDFDocument147 pages194 Construction, Laying and Installation Techniques For Extruded and Self-Contained Fluid Filled Cable Systems PDFAkhil Anumandla100% (1)

- Application Notes: Application Notes P14X/En Ap/B54 Micom P141, P142, P143Document178 pagesApplication Notes: Application Notes P14X/En Ap/B54 Micom P141, P142, P143Dũng Đinh TiếnNo ratings yet

- Service Manual: LCD TVDocument73 pagesService Manual: LCD TVJose Luis Medina CastañedaNo ratings yet

- Circuit Theory: DR Paul S SpencerDocument13 pagesCircuit Theory: DR Paul S SpencerMathew ClewlowNo ratings yet

- Monitoring and Controling of Remote Industrial PlantDocument15 pagesMonitoring and Controling of Remote Industrial PlantraghuNo ratings yet

- Hand-Out For CO LessonPlan Fabricate Ethernet CablesDocument4 pagesHand-Out For CO LessonPlan Fabricate Ethernet CablesFearNova QuasarNo ratings yet

- ADC Eco Dry ES-50 COIN SpecificationsDocument2 pagesADC Eco Dry ES-50 COIN Specificationsmairimsp2003No ratings yet

- Ledmall Optonica Nees Paralaves 1 1 23Document42 pagesLedmall Optonica Nees Paralaves 1 1 23dridarthNo ratings yet

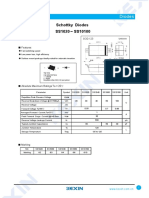

- SMD Type Diodes: Schottky Diodes SS1020 SS10100Document2 pagesSMD Type Diodes: Schottky Diodes SS1020 SS10100Momo MendozaNo ratings yet

- View APGENCO AE Exam Pattern For ExamDocument3 pagesView APGENCO AE Exam Pattern For ExamViswanath NtNo ratings yet

- Dual, Simultaneous Sampling, 16-Bit/14-Bit, 4 Msps Sar Adcs, Differential InputsDocument32 pagesDual, Simultaneous Sampling, 16-Bit/14-Bit, 4 Msps Sar Adcs, Differential InputsDaniel DiazNo ratings yet

- Power Electronics: Chapter 4: Switch-Mode Dc-Ac InvertersDocument71 pagesPower Electronics: Chapter 4: Switch-Mode Dc-Ac InvertersAjay KumarNo ratings yet

- Datasheet 25 50KTL V3Document2 pagesDatasheet 25 50KTL V3Houssem KhelilNo ratings yet

- Power Quality: Case StudyDocument6 pagesPower Quality: Case StudymarinflorentinaoanaNo ratings yet

- Marantz PM-14s1 AUSDocument2 pagesMarantz PM-14s1 AUSDra CavisNo ratings yet

- 1406 2s1312 50hz Split Commercial Ac Series PDFDocument57 pages1406 2s1312 50hz Split Commercial Ac Series PDFRizwanNo ratings yet

- GCC 28 enDocument6 pagesGCC 28 enEduardo VicoNo ratings yet

- Loadbreak ElbowsDocument8 pagesLoadbreak ElbowsGustavo PérezNo ratings yet

- lm00614 Onboard DC Grid Brochure - June2014 - 1 PDFDocument8 pageslm00614 Onboard DC Grid Brochure - June2014 - 1 PDFStefanitaNo ratings yet

- Module 3Document29 pagesModule 3Zaid AliNo ratings yet

- Abb Type CoordinationDocument98 pagesAbb Type CoordinationGaurav SinghNo ratings yet

- BJT and MOSFET REVIEWDocument43 pagesBJT and MOSFET REVIEWJamesNo ratings yet

- Power Supply and Ground Circuit Power Supply and Ground Circuit Wiring DiagramDocument9 pagesPower Supply and Ground Circuit Power Supply and Ground Circuit Wiring DiagramDavid QuispeNo ratings yet

- EB CGAK XX Draft - EN Cambio de PLCDocument10 pagesEB CGAK XX Draft - EN Cambio de PLCOmar PiñaNo ratings yet

- Application of The Wavelet TransformDocument23 pagesApplication of The Wavelet TransformSumit SinghNo ratings yet

- Tia 569-ADocument13 pagesTia 569-AEduardo CudiaNo ratings yet

- FURQANDocument39 pagesFURQANsamsNo ratings yet

- Control Lab Report Experiment No. 04Document2 pagesControl Lab Report Experiment No. 04Nahin AminNo ratings yet