Professional Documents

Culture Documents

Carbon Steel HT

Uploaded by

LazarasBenny Isprithiyone0 ratings0% found this document useful (0 votes)

69 views6 pagescarbon steel and properties Steels and other iron–carbon alloy phases

Original Title

Carbon Steel Ht

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcarbon steel and properties Steels and other iron–carbon alloy phases

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

69 views6 pagesCarbon Steel HT

Uploaded by

LazarasBenny Isprithiyonecarbon steel and properties Steels and other iron–carbon alloy phases

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Carbon steel

Steels and other ironcarbon alloy phases

Ferrite

Austenite

Cementite

Graphite

Martensite

Microstructures

Spheroidite

Pearlite

Bainite

Ledeburite

Tempered martensite

Widmanstatten structures

Classes

Crucible steel

Carbon steel

Spring steel

Alloy steel

Maraging steel

Stainless steel

Weathering steel

Tool steel

Other iron-based materials

Cast iron

Gray iron

White iron

Ductile iron

Malleable iron

Wrought iron

v

t

e

Carbon steel is steel in which the main interstitial alloying constituent is carbon in the range of

0.122.0%. The American Iron and Steel Institute (AISI) defines carbon steel as the following:

"Steel is considered to be carbon steel when no minimum content is specified or required for

chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium or zirconium, or

any other element to be added to obtain a desired alloying effect; when the specified minimum

for copper does not exceed 0.40 percent; or when the maximum content specified for any of the

following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper

0.60."

[1]

The term "carbon steel" may also be used in reference to steel which is not stainless steel; in this

use carbon steel may include alloy steels.

As the carbon percentage content rises, steel has the ability to become harder and stronger

through heat treating; however it becomes less ductile. Regardless of the heat treatment, a higher

carbon content reduces weldability. In carbon steels, the higher carbon content lowers the

melting point.

[2]

Contents

1 Types

o 1.1 Mild and low-carbon steel

o 1.2 Higher carbon steels

2 Heat treatment

3 Case hardening

4 Forging temperature of steel

5 See also

6 References

7 Bibliography

Types

See also: SAE steel grades

Carbon steel is broken down into four classes based on carbon content:

Mild and low-carbon steel

Mild steel, also known as plain-carbon steel, is the most common form of steel because its price

is relatively low while it provides material properties that are acceptable for many applications,

more so than iron. Low-carbon steel contains approximately 0.050.3% carbon

[1]

making it

malleable and ductile. Mild steel has a relatively low tensile strength, but it is cheap and

malleable; surface hardness can be increased through carburizing.

[3]

It is often used when large quantities of steel are needed, for example as structural steel. The

density of mild steel is approximately 7.85 g/cm

3

(7850 kg/m

3

or 0.284 lb/in

3

)

[4]

and the Young's

modulus is 210 GPa (30,000,000 psi).

[5]

Low-carbon steels suffer from yield-point runout where the material has two yield points. The

first yield point (or upper yield point) is higher than the second and the yield drops dramatically

after the upper yield point. If a low-carbon steel is only stressed to some point between the upper

and lower yield point then the surface may develop Lder bands.

[6]

Low-carbon steels contain

less carbon than other steels and are easier to cold-form, making them easier to handle.

[7]

Higher carbon steels

Carbon steels which can successfully undergo heat-treatment have a carbon content in the range

of 0.301.70% by weight. Trace impurities of various other elements can have a significant

effect on the quality of the resulting steel. Trace amounts of sulfur in particular make the steel

red-short, that is, brittle and crumbly at working temperatures. Low-alloy carbon steel, such as

A36 grade, contains about 0.05% sulfur and melts around 1,4261,538 C (2,5992,800 F).

[8]

Manganese is often added to improve the hardenability of low-carbon steels. These additions

turn the material into a low-alloy steel by some definitions, but AISI's definition of carbon steel

allows up to 1.65% manganese by weight.

Low carbon steel

<0.3% carbon content, see above.

Medium carbon steel

Approximately 0.300.59% carbon content.

[1]

Balances ductility and strength and has good wear

resistance; used for large parts, forging and automotive components.

[9][10]

High-carbon steel

Approximately 0.60.99% carbon content.

[1]

Very strong, used for springs and high-strength

wires.

[11]

Ultra-high-carbon steel

Approximately 1.02.0% carbon content.

[1]

Steels that can be tempered to great hardness. Used

for special purposes like (non-industrial-purpose) knives, axles or punches. Most steels with

more than 1.2% carbon content are made using powder metallurgy. Note that steel with a carbon

content above 2.14% is considered cast iron.

Heat treatment

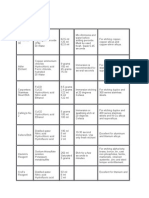

Iron-carbon phase diagram, showing the temperature and carbon ranges for certain types of heat

treatments.

The purpose of heat treating carbon steel is to change the mechanical properties of steel, usually

ductility, hardness, yield strength, or impact resistance. Note that the electrical and thermal

conductivity are only slightly altered. As with most strengthening techniques for steel, Young's

modulus (elasticity) is unaffected. All treatments of steel trade ductility for increased strength

and vice versa. Iron has a higher solubility for carbon in the austenite phase; therefore all heat

treatments, except spheroidizing and process annealing, start by heating the steel to a

temperature at which the austenitic phase can exist. The steel is then quenched (heat drawn out)

at a high rate causing cementite to precipitate and finally the remaining pure iron to solidify. The

rate at which the steel is cooled through the eutectoid temperature affects the rate at which

carbon diffuses out of austenite and forms cementite. Generally speaking, cooling swiftly will

leave iron carbide finely dispersed and produce a fine grained pearlite (until the martensite

critical temperature is reached) and cooling slowly will give a coarser pearlite. Cooling a

hypoeutectoid steel (less than 0.77 wt% C) results in a lamellar-pearlitic structure of iron carbide

layers with -ferrite (pure iron) between. If it is hypereutectoid steel (more than 0.77 wt% C)

then the structure is full pearlite with small grains (larger than the pearlite lamella) of cementite

scattered throughout. The relative amounts of constituents are found using the lever rule. The

following is a list of the types of heat treatments possible:

Spheroidizing: Spheroidite forms when carbon steel is heated to approximately 700 C

for over 30 hours. Spheroidite can form at lower temperatures but the time needed

drastically increases, as this is a diffusion-controlled process. The result is a structure of

rods or spheres of cementite within primary structure (ferrite or pearlite, depending on

which side of the eutectoid you are on). The purpose is to soften higher carbon steels and

allow more formability. This is the softest and most ductile form of steel. The image to

the right shows where spheroidizing usually occurs.

[12]

Full annealing: Carbon steel is heated to approximately 40 C above Ac3 or Ac1 for 1

hour; this ensures all the ferrite transforms into austenite (although cementite might still

exist if the carbon content is greater than the eutectoid). The steel must then be cooled

slowly, in the realm of 20 C (68 F) per hour. Usually it is just furnace cooled, where the

furnace is turned off with the steel still inside. This results in a coarse pearlitic structure,

which means the "bands" of pearlite are thick. Fully annealed steel is soft and ductile,

with no internal stresses, which is often necessary for cost-effective forming. Only

spheroidized steel is softer and more ductile.

[13]

Process annealing: A process used to relieve stress in a cold-worked carbon steel with

less than 0.3 wt% C. The steel is usually heated up to 550650 C for 1 hour, but

sometimes temperatures as high as 700 C. The image rightward shows the area where

process annealing occurs.

Isothermal annealing: It is a process in which hypoeutectoid steel is heated above the

upper critical temperature and this temperature is maintained for a time and then the

temperature is brought down below lower critical temperature and is again maintained.

Then finally it is cooled at room temperature. This method rids any temperature gradient.

Normalizing: Carbon steel is heated to approximately 55 C above Ac3 or Acm for 1

hour; this ensures the steel completely transforms to austenite. The steel is then air-

cooled, which is a cooling rate of approximately 38 C (100 F) per minute. This results

in a fine pearlitic structure, and a more-uniform structure. Normalized steel has a higher

strength than annealed steel; it has a relatively high strength and ductility.

[14]

Quenching: Carbon steel with at least 0.4 wt% C is heated to normalizing temperatures

and then rapidly cooled (quenched) in water, brine, or oil to the critical temperature. The

critical temperature is dependent on the carbon content, but as a general rule is lower as

the carbon content increases. This results in a martensitic structure; a form of steel that

possesses a super-saturated carbon content in a deformed body-centered cubic (BCC)

crystalline structure, properly termed body-centered tetragonal (BCT), with much internal

stress. Thus quenched steel is extremely hard but brittle, usually too brittle for practical

purposes. These internal stresses cause stress cracks on the surface. Quenched steel is

approximately three to four (with more carbon) fold harder than normalized steel.

[15]

Martempering (Marquenching): Martempering is not actually a tempering procedure,

hence the term "marquenching". It is a form of isothermal heat treatment applied after an

initial quench of typically in a molten salt bath at a temperature right above the

"martensite start temperature". At this temperature, residual stresses within the material

are relieved and some bainite may be formed from the retained austenite which did not

have time to transform into anything else. In industry, this is a process used to control the

ductility and hardness of a material. With longer marquenching, the ductility increases

with a minimal loss in strength; the steel is held in this solution until the inner and outer

temperatures equalize. Then the steel is cooled at a moderate speed to keep the

temperature gradient minimal. Not only does this process reduce internal stresses and

stress cracks, but it also increases the impact resistance.

[16]

Quench and tempering: This is the most common heat treatment encountered, because

the final properties can be precisely determined by the temperature and time of the

tempering. Tempering involves reheating quenched steel to a temperature below the

eutectoid temperature then cooling. The elevated temperature allows very small amounts

of spheroidite to form, which restores ductility, but reduces hardness. Actual

temperatures and times are carefully chosen for each composition

Austempering: The austempering process is the same as martempering, except the steel

is held in the molten salt bath through the bainite transformation temperatures, and then

moderately cooled. The resulting bainite steel has a greater ductility, higher impact

resistance, and less distortion. The disadvantage of austempering is it can only be used on

a few steels, and it requires a special salt bath.

Case hardening

Case hardening processes harden only the exterior of the steel part, creating a hard, wear

resistant skin (the "case") but preserving a tough and ductile interior. Carbon steels are not very

hardenable; therefore wide pieces cannot be through-hardened. Alloy steels have a better

hardenability, so they can through-harden and do not require case hardening. This property of

carbon steel can be beneficial, because it gives the surface good wear characteristics but leaves

the core tough.

Forging temperature of steel

Steel Type

Maximum forging temperature

(F / C)

Burning temperature (F /

C)

1.5% carbon 1920 / 1049 2080 / 1138

1.1% carbon 1980 / 1082 2140 / 1171

0.9% carbon 2050 / 1121 2230 / 1221

0.5% carbon 2280 / 1249 2460 / 1349

0.2% carbon 2410 / 1321 2680 / 1471

3.0% nickel steel 2280 / 1249 2500 / 1371

3.0% nickelchromium steel 2280 / 1249 2500 / 1371

5.0% nickel (case-hardening)

steel

2320 / 1271 2640 / 1449

Chromiumvanadium steel 2280 / 1249 2460 / 1349

High-speed steel 2370 / 1299 2520 / 1382

Stainless steel 2340 / 1282 2520 / 1382

Austenitic chromiumnickel

steel

2370 / 1299 2590 / 1421

Silico-manganese spring steel 2280 / 1249 2460 / 1349

You might also like

- Portrait Name Constituency CM Tenure Elections Appointed by Political Party 1Document2 pagesPortrait Name Constituency CM Tenure Elections Appointed by Political Party 1LazarasBenny IsprithiyoneNo ratings yet

- Dupont Design GuideDocument136 pagesDupont Design Guidemarcelo_atomoNo ratings yet

- Fmea Process TemplateDocument20 pagesFmea Process TemplateLazarasBenny IsprithiyoneNo ratings yet

- Din 78 Thread Ends and LengthsDocument5 pagesDin 78 Thread Ends and LengthsLazarasBenny Isprithiyone100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chemistry Paper 2 November 2009Document14 pagesChemistry Paper 2 November 2009deanNo ratings yet

- Chem 305 Lab 2Document7 pagesChem 305 Lab 2Gobe JamNo ratings yet

- Formulae, Stoichiometry and The Mole ConceptDocument12 pagesFormulae, Stoichiometry and The Mole ConceptElvis NyambokNo ratings yet

- 316L-SS-annealed Bar and Cold DrawnDocument2 pages316L-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- Lesson 2 Covalent BondDocument34 pagesLesson 2 Covalent Bondnevaeh tancioNo ratings yet

- Croda NF-TDocument3 pagesCroda NF-Tnirai101259No ratings yet

- EDEXCEL IGCSE Chemistry Practice Unit Test 1Document7 pagesEDEXCEL IGCSE Chemistry Practice Unit Test 1KasunDilshan100% (1)

- Aquacheck Instruction SheetDocument56 pagesAquacheck Instruction SheetAdem YildirimNo ratings yet

- Half-Life and Mean LifeDocument10 pagesHalf-Life and Mean LifeIsaac KandaNo ratings yet

- CLC 18-9L: General Purpose 18Cr-9Ni Austenitic Stainless Steel (304L Grade)Document4 pagesCLC 18-9L: General Purpose 18Cr-9Ni Austenitic Stainless Steel (304L Grade)MichaelNo ratings yet

- Impact Test ASME IXDocument13 pagesImpact Test ASME IXbounatiro Hatem0% (1)

- Fundamentals of General Organic and Biological Chemistry 8th Edition by McMurry Ballantine Hoeger Peterson ISBN Test BankDocument30 pagesFundamentals of General Organic and Biological Chemistry 8th Edition by McMurry Ballantine Hoeger Peterson ISBN Test Bankmichelle100% (25)

- Chemical Properties of SoilDocument100 pagesChemical Properties of SoilrjbgavilenoNo ratings yet

- Corby AndersonDocument127 pagesCorby AndersonDouglas Vásquez SandovalNo ratings yet

- 8 Sci LM U3 M3Document15 pages8 Sci LM U3 M3ravenNo ratings yet

- IS4736.1986 - Galvanizing On Tubes PDFDocument15 pagesIS4736.1986 - Galvanizing On Tubes PDFdombipin100% (1)

- Waste Disposal SOP PDFDocument29 pagesWaste Disposal SOP PDFFerijanto Wahjudi0% (1)

- HW#5Document9 pagesHW#5AbdullahNo ratings yet

- New Simplified Chemistry Class 9 ICSE Solutions Atomic StructureDocument20 pagesNew Simplified Chemistry Class 9 ICSE Solutions Atomic StructureAalana MachadoNo ratings yet

- Asme Sec - Ii D (Sa 193 GR.B7)Document3 pagesAsme Sec - Ii D (Sa 193 GR.B7)AARTICKNo ratings yet

- AP-Physical Science Sample Paper - Class 10 Question PaperDocument5 pagesAP-Physical Science Sample Paper - Class 10 Question PaperFirdosh KhanNo ratings yet

- Sefako Makgatho Health Sciences University: (Chemistry 1A)Document6 pagesSefako Makgatho Health Sciences University: (Chemistry 1A)MotseilekgoaNo ratings yet

- Niobium: Niobium, Also Known As Columbium, Is A Chemical Element With TheDocument15 pagesNiobium: Niobium, Also Known As Columbium, Is A Chemical Element With TheVysakh VasudevanNo ratings yet

- IGCSE Chemistry: 10.5.1 Patterns of ReactivityDocument50 pagesIGCSE Chemistry: 10.5.1 Patterns of ReactivityAmirtha Krish100% (1)

- Lecture 25 Principles of DegassingDocument5 pagesLecture 25 Principles of DegassingAdam McNo ratings yet

- List of Etchant For MetallographyDocument3 pagesList of Etchant For Metallographyniraj_hwbNo ratings yet

- 2017-5-22 - Rare EarthDocument8 pages2017-5-22 - Rare EarthTJEKEYKURFKRYRKNo ratings yet

- Stellite Alloys - Chemical Composition, Mechanical Properties and Common ApplicationsDocument3 pagesStellite Alloys - Chemical Composition, Mechanical Properties and Common ApplicationsASHIL PRABHAKARNo ratings yet

- 344 11 - Inorganic Chemistry-I - MSC - (CRC) PDFDocument320 pages344 11 - Inorganic Chemistry-I - MSC - (CRC) PDFromaliaNo ratings yet

- Nuclide Guide and International Chart of NuclidesDocument4 pagesNuclide Guide and International Chart of Nuclideselena lopez albaNo ratings yet