Professional Documents

Culture Documents

Practica Numero - 1 PDF

Uploaded by

Alejandro LópezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Practica Numero - 1 PDF

Uploaded by

Alejandro LópezCopyright:

Available Formats

INFORME SEMANAL DEL LABORATORIO

Prctica No. 1

Peso Volumetrico

Da:___Miercoles___ Hora:__2 pm____

Elaborado por:

Alejandro Guadalupe Lpez Espericueta A00810675

Instructor:

Monterrey, N.L., a 22 de Enero del 2014

TECNOLGICO

DE

MONTERREY

DIVISIN DE INGENIERA Y ARQUITECTURA

DEPARTAMENTO DE INGENIERA CIVIL

CURSO DE

LABORATORIO DE MATERIALES

DE CONSTRUCCIN

Cdigo de Honor: Quienes firman hacen constar que

toda la informacin contenida en el presente informe escrito fue

realizada individualmente, que es produccin autntica del firmante

y que no existe ningn tipo de plagio de propiedad intelectual de

otro autor.

Fecha y Sello de Recibido

Almacn de Ingeniera Civil

Ing. Jose Alberto Mendoza

Objetivo:

El objetivo de la practica es sacar el peso volumetrico de dos diferentes materiales:

grava y arena, utilizando los instrumentos proporcionados por el laboratorio, al igual

que distintas operaciones matematicas.

Equipo y Material

!"#$%& (&) *+,-." " /01&%-0) 23-(0( 4031-(0(

5%060 789 !" &:.&;-<-;0("

=%&30 789 !" &:.&;-<-;0("

>?:;,)0 *)&;1%@3-;0 .A09 B

C0%-))0 .,310 (& $0)0 .A09 D

E&;-.-&31& ;"3 6"),#&3 <?;-) (&

(&1&%#-30%9 .A09 D

Procedimiento Peso Volumtrico de la Grava y Arena

1-Lo primero que hicimos fue tomar las medidas del recipiente para poder asi sacar

su volumen.

2-Despues de sacar el volumen del recipiente, lo colocamos en la bscula

electronica, para as registrar su peso inicial.

3-Colocamos grava, hasta aproximadamente 1/3 del volmen total del recipiente.

4-Compactamos con la varilla punta de bala dandole 25 golpes, sin tocar el fondo del

recipiente.

5-Colocamos la segunda capa de grava hasta 2/3 del volumen del recipiente.

6- Repetimos la accion del paso 5, dandole 25 golpes, tratando de no pegarle a la

superficie de la primera capa.

7- A continuacion, colocamos la tercera capa hasta la maxima capacidad del

recipiente.

8- Compactamos, varillando con 25 golpes a la tercera capa, tratando siempre de no

tocar la superficie de la capa inferior.

9-Nivelamos la grava con ayuda de la varilla de punta bala, desplazandola del centro

del area del tope del recipiente hacia la parte superior y de igual manera hacia la

parte inferior.

10- Ya una vez lleno nuestro recipiente, lo colocamos en la bscula electrnica para

registrar su peso final.

11- Con los datos obtenidos en las mediciones y pesajes, dimos paso a calcular el

volumen especfico, lo cual es el objetivo de la prctica.

Este mismo procedimiento fue utilizado para ambos agregados.

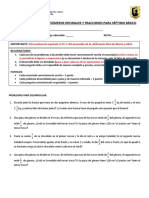

Clculos y resultados

5%060 =%&30

F-?#&1%" E&;-.-&31& "#$% &' "% &'

=)1,%0 E&;-.-&31& (#$) &' "*$+ &'

C"),#&3 E&;-.-&31& #$#,#,(" '( #$#,-,*. '(

G&:" E&;-.-&31& C0;H" -$+ /0 +$+* /0

G&:" E&;-.-&31& I)&3" "#$(, /0 (%$.( /0

Peso volumtrico en kg/m3

PV= (R lleno R vaco) / Volumen del recipiente

Grava

PV=(20.31kg-4.9kg)/0.010132m3

PV= 1520.78 kg/m3

Arena

PV=(36.63kg-9.98kg)/0.014186m3

PV= 1820.8092 kg/m3

Conclusiones

Segn la norma ASTM-C29, el peso volumtrico de la grava ! debe estar dentro del

rango 1300-1950 kg/m3, checando nuestro resultado podemos concluir que

efectivamente es una grava ! . Por otro lado en el caso de la arena no fue as, ya

que segn la norma el peso volumtrico de la arena #5 debe estar en el rango de

1850-2100 kg/m3, viendo el resultado obtenido en la prctico, nos damos cuenta que

no es una arena del #5 ya que no entra en este rango. Por ese motivo me di a la

tarea a investigar cual era realmente el numero de arena segn la norma, pero

desafortunadamente no encontre este dato.

Bibliografa

Manual del laboratorio de materiales de construccin, Gmez Domnguez Jorge,

Departamento de Ingeniera Civil.

Norma de la Prueba

Norma de la Prueba

Designation: C29/C29M 09

American Association of State

Highway and Transportation Officials Standard

AASHTO No.: T19/T19M

Standard Test Method for

Bulk Density (Unit Weight) and Voids in Aggregate1

This standard is issued under the xed designation C29/C29M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon () indicates an editorial change since the last revision or reapproval.

This stanuaiu has been appioveu foi use by agencies of the Bepaitment of Befense.

--``,,`,`````,,`,,,`,,``,`,`,,`-`-`,,`,,`,`,,`---

3

1

*A Summaiy of Changes section appeais at the enu of this stanuaiu.

Copyright ASTM International

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS

1

Licensee=ITESM/5911350001 Not for Resale, 01/22/2014 14:48:35 MST

S. Teiminology

3.1 BenitionsBenitions are in accordance with Termi-

nology C125 unless otherwise indicated.

3.1.1 bulk uensity, nof aggiegate, the mass of a unit

volume of bulk aggregate material, in which the volume

includes the volume of the individual particles and the volume

of the voids between the particles. Expressed in kg/m3 [lb/ft3].

3.1.2 unit weight, nweight (mass) per unit volume. (Dep-

recated term usedpreferred term bulk uensity.)

3.1.2.1 BiscussionWeight is equal to the mass of the body

multiplied by the acceleration due to gravity. Weight may be

expressed in absolute units (newtons, poundals) or in gravita-

tional units (kgf, lbf), for example: on the surface of the earth,

a body with a mass of 1 kg has a weight of 1 kgf (approxi-

mately 9.81 N), or a body with a mass of 1 lb has a weight of

1 lbf (approximately 4.45 N or 32.2 poundals). Since weight is

equal to mass times the acceleration due to gravity, the weight

of a body will vary with the location where the weight is

determined, while the mass of the body remains constant. On

the surface of the earth, the force of gravity imparts to a body

that is free to fall an acceleration of approximately 9.81

B12Sm/s2 [32.2 ft/s2].

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard, as appropriate for a

specication with which this test method is used. An exception

is with regard to sieve sizes and nominal size of aggregate, in

which the SI values are the standard as stated in Specication

E11. Within the text, inch-pound units are shown in brackets.

The values stated in each system may not be exact equivalents;

therefore, each system shall be used independently of the other.

Combining values from the two systems may result in non-

conformance with the standard.

1.3 This stanuaiu uoes not puipoit to auuiess all of the

safety conceins, if any, associateu with its use. It is the

iesponsibility of the usei of this stanuaiu to establish appio-

piiate safety anu health piactices anu ueteimine the applica-

bility of iegulatoiy limitations piioi to use.

C128 Test Method for Density, Relative Density (Specic

Gravity), and Absorption of Fine Aggregate

C138/C138M Test Method for Density (Unit Weight),

Yield, and Air Content (Gravimetric) of Concrete

C670 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials

C702 Practice for Reducing Samples of Aggregate to Test-

ing Size

D75 Practice for Sampling Aggregates

D123 Terminology Relating to Textiles

E11 Specication for Woven Wire Test Sieve Cloth and Test

Sieves

2.2 AASBT0 Stanuaiu:

T19/T19M Method of Test for Unit Weight and Voids in

Aggregate3

NOTE 1Unit weight is the traditional terminology used to describe the

property determined by this test method, which is weight per unit volume

(more correctly, mass per unit volume or density).

1. Scope*

1.1 This test method covers the determination of bulk

density (unit weight) of aggregate in a compacted or loose

condition, and calculated voids between particles in ne,

coarse, or mixed aggregates based on the same determination.

This test method is applicable to aggregates not exceeding 125

mm [5 in.] in nominal maximum size.

2. Refeienceu Bocuments

2.1 ASTN Stanuaius:2

C125 Terminology Relating to Concrete and Concrete Ag-

gregates

C127 Test Method for Density, Relative Density (Specic

Gravity), and Absorption of Coarse Aggregate

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee

C09.20 on Normal Weight Aggregates.

Current edition approved Dec. 1, 2009. Published January 2010. Originally

approved in 1920. Last previous edition approved in 2007 as C29/C29M 07. DOI:

10.1520/C0029_C0029M-09.

2For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTN

Stanuaius volume information, refer to the standards Document Summary page on

the ASTM website.

Available from American Association of State Highway and Transportation

Officials (AASHTO),444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

C29/C29M 09

3.2 Benitions of Teims Specic to This Stanuaiu:

3.2.1 voius, nin unit volume of aggiegate, the space

between particles in an aggregate mass not occupied by solid

mineral matter.

3.2.1.1 Biscussionvoius within particles, either perme-

able or impermeable, are not included in voids as determined

by this test method.

4. Signicance anu 0se

4.1 This test method is often used to determine bulk density

values that are necessary for use for many methods of selecting

proportions for concrete mixtures.

4.2 The bulk density also may be used for determining

mass/volume relationships for conversions in purchase agree-

ments. However, the relationship between degree of compac-

tion of aggregates in a hauling unit or stockpile and that

achieved in this test method is unknown. Further, aggregates in

hauling units and stockpiles usually contain absorbed and

surface moisture (the latter affecting bulking), while this test

method determines the bulk density on a dry basis.

4.3 A procedure is included for computing the percentage of

voids between the aggregate particles based on the bulk density

determined by this test method.

S. Appaiatus

5.1 BalanceA balance or scale accurate within 0.1 % of

the test load at any point within the range of use, graduated to

at least 0.05 kg [0.1 lb]. The range of use shall be considered

to extend from the mass of the measure empty to the mass of

the measure plus its contents at 1920 kg/m3 [120 lb/ft3].

5.2 Tamping RouA round, straight steel rod, 16 mm [58

in.] in diameter and approximately 600 mm [24 in.] in length,

having the tamping end, or both ends, rounded to a hemispheri-

cal tip, the diameter of which is 16 mm [58 in.].

5.3 NeasuieA cylindrical metal measure, preferably pro-

vided with handles. It shall be watertight, with the top and

bottom true and even, and sufficiently rigid to retain its form

under rough usage. The measure shall have a height approxi-

mately equal to the diameter, but in no case shall the height be

less than 80 % nor more than 150 % of the diameter. The

capacity of the measure shall conform to the limits in Table 1

for the aggregate size to be tested. The thickness of metal in the

measure shall be as described in Table 2. The top rim shall be

smooth and plane within 0.25 mm [0.01 in.] and shall be

parallel to the bottom within 0.5 (See Note 2). The interior

wall of the measure shall be a smooth and continuous surface.

TABLE 1 Capacity of Measures

Nominal Maximum

Size of Aggregate

mm

12.5

25.0

37.5

75

100

125

A

TABLE 2 Requirements for Measures

Thickness of Metal, min

Capacity of Measure

Bottom

Less than 11 L

11 to 42 L, incl

over 42 to 80 L, incl

over 80 to 133 L, incl

Less than 0.4 ft3

0.4 ft3 to 1.5 ft3, incl

over 1.5 to 2.8 ft3, incl

over 2.8 to 4.0 ft3, incl

A

Upper 38 mm

or 112 in.

of wallA

2.5 mm

5.0 mm

6.4 mm

7.6 mm

0.10 in.

0.20 in.

0.25 in.

0.30 in.

Remainder of wall

2.5 mm

3.0 mm

3.8 mm

5.0 mm

0.10 in.

0.12 in.

0.15 in.

0.20 in.

5.0 mm

5.0 mm

10.0 mm

13.0 mm

0.20 in.

0.20 in.

0.40 in.

0.50 in.

The added thickness in the upper portion of the wall may be obtained by

placing a reinforcing band around the top of the measure.

NOTE 2The top rim is satisfactorily plane if a 0.25-mm [0.01-in.]

feeler gage cannot be inserted between the rim and a piece of 6-mm

[14-in.] or thicker plate glass laid over the measure. The top and bottom

are satisfactorily parallel if the slope between pieces of plate glass in

contact with the top and bottom does not exceed 0.87 % in any direction.

5.3.1 If the measure is to also be used for testing for bulk

density of freshly-mixed concrete according to Test Method

C138/C138M, the measure shall be made of steel or other

suitable metal not readily subject to attack by cement paste.

Reactive materials, such as aluminum alloys are permitted,

where as a consequence of an initial reaction, a surface lm is

formed which protects the metal against further corrosion.

5.3.2 Measures larger than nominal 28 L [1 ft3] capacity

shall be made of steel for rigidity, or the minimum thicknesses

of metal listed in Table 2 shall be suitably increased.

5.4 Shovel oi ScoopA shovel or scoop of convenient size

for lling the measure with aggregate.

5.5 Calibiation Equipment:

5.5.1 Plate ulassA piece of plate glass, at least 6 mm [14

in.] thick and at least 25 mm [1 in.] larger than the diameter of

the measure to be calibrated.

5.5.2 uieaseA supply of water-pump, chassis, or similar

grease.

5.5.3 TheimometeiA thermometer having a range of at

least 10 to 32 C [50 to 90 F] and that is readable to at least

0.5 C [1 F].

5.5.4 BalanceA balance as described in 5.1.

6. Sampling

6.1 Obtain the sample in accordance with Practice D75, and

reduce to test sample size in accordance with Practice C702.

7. Test Sample

7.1 The size of the sample shall be approximately 125 to

200 % of the quantity required to ll the measure, and shall be

handled in a manner to avoid segregation. Dry the aggregate

sample to essentially constant mass, preferably in an oven at

110 6 5 C [230 6 9 F].

8. Calibiation of Neasuie

8.1 Measures shall be recalibrated at least once a year or

whenever there is reason to question the accuracy of the

calibration.

8.2 Determine the mass of the plate glass and measure the

nearest 0.05 kg [0.1 lb].

2

Licensee=ITESM/5911350001

Not for Resale, 01/22/2014 14:48:35 MST

Capacity of MeasureA

m3[L]

0.0028[2.8]

0.0093 [9.3]

0.014 [14]

0.028 [28]

0.070 [70]

0.100 [100]

ft3

1 2

1

212

312

1 10

13

in.

12

1

112

3

4

5

The indicated size of measure shall be used to test aggregates of a nominal

maximum size equal to or smaller than that listed. The actual volume of the

measure shall be at least 95 % of the nominal volume listed.

--``,,`,`````,,`,,,`,,``,`,`,,`-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS

C29/C29M 09

8.3 Place a thin layer of grease on the rim of the measure to

prevent leakage of water from the measure.

8.4 Fill the measure with water that is at room temperature

and cover with the plate glass in such a way as to eliminate

bubbles and excess water. Remove any water that may have

overowed onto the measure or plate glass.

8.5 Determine the mass of the water, plate glass, and

measure to the nearest 0.05 kg [0.1 lb].

8.6 Measure the temperature of the water to the nearest

0.5 C [1 F] and determine its density from Table 3,

interpolating if necessary.

8.7 Calculate the volume, v, of the measure. Alternatively,

calculate the factor, F, for the measure.

NOTE 3For the calculation of bulk density, the volume of the measure

in SI units should be expressed in cubic metres, or the factor as 1/m3.

However, for convenience the size of the measure may be expressed in

litres.

10.3 Determine the mass of the measure plus its contents,

and the mass of the measure alone, and record the values to the

nearest 0.05 kg [0.1 lb].

11. }igging Pioceuuie

11.1 Fill the measure in three approximately equal layers as

described in 10.1, compacting each layer by placing the

measure on a rm base, such as a cement-concrete oor,

raising the opposite sides alternately about 50 mm [2 in.], and

allowing the measure to drop in such a manner as to hit with a

sharp, slapping blow. The aggregate particles, by this proce-

dure, will arrange themselves in a densely compacted condi-

tion. Compact each layer by dropping the measure 50 times in

the manner described, 25 times on each side. Level the surface

of the aggregate with the ngers or a straightedge in such a way

that any slight projections of the larger pieces of the coarse

aggregate approximately balance the larger voids in the surface

below the top of the measure.

11.2 Determine the mass of the measure plus its contents,

and the mass of the measure alone, and record the values to the

nearest 0.05 kg [0.1 lb].

12. Shoveling Pioceuuie

12.1 Fill the measure to overowing by means of a shovel

or scoop, discharging the aggregate from a height not to exceed

50 mm [2 in.] above the top of the measure. Exercise care to

prevent, so far as possible, segregation of the particle sizes of

which the sample is composed. Level the surface of the

aggregate with the ngers or a straightedge in such a way that

any slight projections of the larger pieces of the coarse

aggregate approximately balance the larger voids in the surface

below the top of the measure.

12.2 Determine the mass of the measure plus its contents,

and the mass of the measure alone, and record the values to the

nearest 0.05 kg [0.1 lb].

1S. Calculation

13.1 Bulk BensityCalculate the bulk density for the rod-

ding, jigging, or shoveling procedure as follows:

N S ~u 2 T!/V (1)

9. Selection of Pioceuuie

9.1 The shoveling procedure for loose bulk density shall be

used only when specically stipulated. Otherwise, the compact

bulk density shall be determined by the rodding procedure for

aggregates having a nominal maximum size of 37.5 mm

[112 in.] or less, or by the jigging procedure for aggregates

having a nominal maximum size greater than 37.5 mm [112 in.]

and not exceeding 125 mm [5 in.].

1u. Rouuing Pioceuuie

10.1 Fill the measure one-third full and level the surface

with the ngers. Rod the layer of aggregate with 25 strokes of

the tamping rod evenly distributed over the surface. Fill the

measure two-thirds full and again level and rod as above.

Finally, ll the measure to overowing and rod again in the

manner previously mentioned. Level the surface of the aggre-

gate with the ngers or a straightedge in such a way that any

slight projections of the larger pieces of the coarse aggregate

approximately balance the larger voids in the surface below the

top of the measure.

10.2 In rodding the rst layer, do not allow the rod to strike

the bottom of the measure forcibly. In rodding the second and

third layers, use vigorous effort, but not more force than to

cause the tamping rod to penetrate to the previous layer of

aggregate.

NOTE 4In rodding the larger sizes of coarse aggregate, it may not be

possible to penetrate the layer being consolidated, especially with angular

aggregates. The intent of the procedure will be accomplished if vigorous

effort is used.

or

N S ~u 2 T! S F (2)

TABLE 3 Density of Water

Temperature

C

15.6

18.3

21.1

23.0

23.9

26.7

29.4

F

60

65

70

73.4

75

80

85

999.01

998.54

997.97

997.54

997.32

996.59

995.83

62.366

62.336

62.301

62.274

62.261

62.216

62.166

kg/m3 lb/ft3

where:

N = bulk density of the aggregate, kg/m3 [lb/ft3],

u = mass of the aggregate plus the measure, kg [lb],

T = mass of the measure, kg [lb],

v = volume of the measure, m3 [ft3], and

F = factor for measure, m!3 [ft!3].

13.1.1 The bulk density determined by this test method is

for aggregate in an oven-dry condition. If the bulk density in

terms of saturated-surface-dry (SSD) condition is desired, use

the exact procedure in this test method, and then calculate the

SSD bulk density using the following formula:

Nssu S N|1 1 ~A1uu!# (3)

where:

NSSB = bulk density in SSD condition, kg/m3 [lb/ft3], and

3

Licensee=ITESM/5911350001

Not for Resale, 01/22/2014 14:48:35 MST

Copyright ASTM International

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS

--``,,`,`````,,`,,,`,,``,`,`,,`-`-`,,`,,`,`,,`---

Laboratorio de Materiales de Construccin

Departamento de Ingeniera Civil ITESM, Campus Monterrey

C29/C29M 09

= % absorption, determined in accordance with Test

Method C127 or Test Method C128.

13.2 voiu ContentCalculate the void content in the aggre-

gate using the bulk density determined by either the rodding,

jigging, or shoveling procedure, as follows:

% voius S 100[~S S W! 2 Nj~S S W! (4)

A

where:

N = bulk density of the aggregate, kg/m3 [lb/ft3],

S = bulk specic gravity (dry basis) as determined in

accordance with Test Method C127 or Test Method

C128, and

W = density of water, 998 kg/m3 [62.3 lb/ft3].

13.3 volume of NeasuieCalculate the volume of a mea-

sure as follows:

v S ~W 2 N!/D

F S B~W 2 N!

(5)

(6)

where:

v = volume of the measure, m3 [ft3]

W = mass of the water, plate glass, and measure, kg [lb]

N = mass of the plate glass and measure, kg [lb]

B = density of the water for the measured temperature,

kg/m3 [lb/ft3], and

F = factor for the measure, 1/m3 [1/ft3]

14. Repoit

14.1 Report the results for the bulk density to the nearest 10

kg/m3 [1 lb/ft3] as follows:

14.1.1 Bulk density by rodding, or

14.1.2 Bulk density by jigging, or

14.1.3 Loose bulk density.

14.2 Report the results for the void content to the nearest

1 % as follows:

14.2.1 Voids in aggregate compacted by rodding, %, or

14.2.2 Voids in aggregate compacted by jigging, %, or

14.2.3 Voids in loose aggregate, %.

1S. Piecision anu Bias

15.1 The following estimates of precision for this test

method are based on results from the AASHTO Materials

Reference Laboratory (AMRL) Prociency Sample Program,

with testing conducted using this test method and AASHTO

Method T 19/T19M. There are no signicant differences be-

tween the two test methods. The data are based on the analyses

of more than 100 paired test results from 40 to 100 laborato-

ries.

15.2 Coaise Aggiegate (bulk uensity):

15.2.1 Single-0peiatoi PiecisionThe single-operator

standard deviation has been found to be 14 kg/m3 [0.88 lb/ft3]

(1s). Therefore, results of two properly conducted tests by the

same operator on similar material should not differ by more

than 40 kg/m3 [2.5 lb/ft3] (d2s).

15.2.2 Nultilaboiatoiy PiecisionThe multilaboratory

standard deviation has been found to be 30 kg/m3 [1.87 lb/ft3]

(1s). Therefore, results of two properly conducted tests from

two different laboratories on similar material should not differ

by more than 85 kg/m3 [5.3 lb/ft3] (d2s).

15.2.3 These numbers represent, respectively, the (1s) and

(d2s) limits as described in Practice C670. The precision

estimates were obtained from the analysis of AMRL pro-

ciency sample data for bulk density by rodding of normal

weight aggregates having a nominal maximum aggregate size

of 25.0 mm [1 in.], and using a 14-L [12-ft3] measure.

15.3 Fine Aggiegate (bulk uensity):

15.3.1 Single-0peiatoi PiecisionThe single-operator

standard deviation has been found to be 14 kg/m3 [0.88 lb/ft3]

(1s). Therefore, results of two properly conducted tests by the

same operator on similar material should not differ by more

than 40 kg/m3 [2.5 lb/ft3] (d2s).

15.3.2 Nultilaboiatoiy PiecisionThe multilaboratory

standard deviation has been found to be 44 kg/m3 [2.76 lb/ft3]

(1s). Therefore, results of two properly conducted tests from

two different laboratories on similar material should not differ

by more than 125 kg/m3 [7.8 lb/ft3] (d2s).

15.3.3 These numbers represent, respectively, the (1s) and

(d2s) limits as described in Practice C670. The precision

estimates were obtained from the analysis of AMRL pro-

ciency sample data for loose bulk density from laboratories

using a 2.8-L [110-ft3] measure.

15.4 No precision data on void content are available.

However, as the void content in aggregate is calculated from

bulk density and bulk specic gravity, the precision of the

voids content reects the precision of these measured param-

eters given in 15.2 and 15.3 of this test method and in Test

Methods C127 and C128.

15.5 BiasThe procedure in this test method for measuring

bulk density and void content has no bias because the values

for bulk density and void content can be dened only in terms

of a test method.

16. Keywoius

16.1 aggregates; bulk density; coarse aggregate; density;

ne aggregate; unit weight; voids in aggregates

Laboratorio de Materiales de Construccin

Departamento de Ingeniera Civil ITESM, Campus Monterrey

Fotos

You might also like

- Audifoam 2019Document4 pagesAudifoam 2019Alejandro LópezNo ratings yet

- Lección 6 Con GraficosDocument4 pagesLección 6 Con GraficosAlejandro LópezNo ratings yet

- Hebreos 6 PDFDocument2 pagesHebreos 6 PDFAlejandro LópezNo ratings yet

- Carta de Intención (Ejemplo) TranspaisDocument1 pageCarta de Intención (Ejemplo) TranspaisAlejandro LópezNo ratings yet

- Permiso de Poda y DerriboDocument1 pagePermiso de Poda y DerriboAlejandro LópezNo ratings yet

- Catalogo Pilas Torre Iii CuajimalpaDocument5 pagesCatalogo Pilas Torre Iii CuajimalpaAlejandro LópezNo ratings yet

- Líder nacional en soluciones y productos para la construcciónDocument16 pagesLíder nacional en soluciones y productos para la construcciónAlejandro LópezNo ratings yet

- Oscar PDF 2Document1 pageOscar PDF 2Alejandro LópezNo ratings yet

- Lev - Top. Cancha 05102019Document1 pageLev - Top. Cancha 05102019Alejandro LópezNo ratings yet

- T01. - Certificado de Uso de SueloDocument2 pagesT01. - Certificado de Uso de SueloAlejandro LópezNo ratings yet

- Tarjeta PascualDocument1 pageTarjeta PascualAlejandro LópezNo ratings yet

- Curriculum de Desarrollo Constructivo López SanchezDocument7 pagesCurriculum de Desarrollo Constructivo López SanchezAlejandro LópezNo ratings yet

- Capital de TrabajoDocument1 pageCapital de TrabajoAlejandro LópezNo ratings yet

- Costos fase 1 urbanización PAFADocument11 pagesCostos fase 1 urbanización PAFAAlejandro LópezNo ratings yet

- Examen AutoCADDocument1 pageExamen AutoCADAlejandro LópezNo ratings yet

- SA PCB 02 T30 Revisión Autorización PlanosDocument1 pageSA PCB 02 T30 Revisión Autorización PlanosAlejandro LópezNo ratings yet

- Licencia de Construcción para Local Comercial.Document1 pageLicencia de Construcción para Local Comercial.Alejandro LópezNo ratings yet

- Catalogo Acero Proy 28081Document1 pageCatalogo Acero Proy 28081Alejandro LópezNo ratings yet

- Duma-Lcf-13-T47 Certificado de AlineamientoDocument2 pagesDuma-Lcf-13-T47 Certificado de AlineamientoAlejandro LópezNo ratings yet

- Manual de Construccion de FraccionamientosDocument7 pagesManual de Construccion de FraccionamientosAlejandro LópezNo ratings yet

- Dumat Otiu 05 T - Lic. Funcionamiento.Document2 pagesDumat Otiu 05 T - Lic. Funcionamiento.Alejandro LópezNo ratings yet

- PREVIO CON Base en Las Disposiciones Legales Aplicables y El Plan o Programa VigenteDocument2 pagesPREVIO CON Base en Las Disposiciones Legales Aplicables y El Plan o Programa VigenteAlejandro LópezNo ratings yet

- Recolección de BasuraDocument1 pageRecolección de BasuraAlejandro LópezNo ratings yet

- Daf Di 04 T17 Certificado de No Adeudo de Impuesto PredialDocument1 pageDaf Di 04 T17 Certificado de No Adeudo de Impuesto PredialAlejandro LópezNo ratings yet

- Duma-Otiu-04-T Proyecto de VentasDocument2 pagesDuma-Otiu-04-T Proyecto de VentasAlejandro LópezNo ratings yet

- 06.-Formato de Tramites LINEAMIENTOS URBANISTICOSDocument1 page06.-Formato de Tramites LINEAMIENTOS URBANISTICOSAlejandro LópezNo ratings yet

- Duma-Lcf-12-T46 Certificado de MedidasDocument2 pagesDuma-Lcf-12-T46 Certificado de MedidasAlejandro LópezNo ratings yet

- Duma-Lcf-09-T43 Terminación de ObraDocument1 pageDuma-Lcf-09-T43 Terminación de ObraAlejandro LópezNo ratings yet

- MANIFIESTODocument2 pagesMANIFIESTOAlejandro LópezNo ratings yet

- Daf-Dc-05-T07-Fusion, Subdivisiones, Relotificacion y Fracciones de TerrenosDocument2 pagesDaf-Dc-05-T07-Fusion, Subdivisiones, Relotificacion y Fracciones de TerrenosAlejandro LópezNo ratings yet

- Bombas EspanolasDocument21 pagesBombas EspanolasDreamk990No ratings yet

- Anexo 3 Formato Tarea 3 Estudiante 1 ResueltosDocument6 pagesAnexo 3 Formato Tarea 3 Estudiante 1 ResueltosYeisson Salabarria MolinaNo ratings yet

- Boletin 3ºDocument192 pagesBoletin 3ºSebastian QuintanillaNo ratings yet

- Guia de Ejercitacion 21 de MarzoDocument4 pagesGuia de Ejercitacion 21 de MarzoDavid ReandaNo ratings yet

- Ec Nte 0785 1985Document14 pagesEc Nte 0785 1985GENESIS KARISMA LIZARRAGA DIAZNo ratings yet

- 6° Materia GuíaDocument4 pages6° Materia Guíaandrea rey rizoNo ratings yet

- Problemas de Fenomenos de Transporte I II III UnidadDocument13 pagesProblemas de Fenomenos de Transporte I II III UnidadOscar Javier Pasten BravoNo ratings yet

- 259308417203/virtualeducation/190/anuncios/177/CESAP SUPERVISOR PARA TRABAJOS DE IZAJEDocument153 pages259308417203/virtualeducation/190/anuncios/177/CESAP SUPERVISOR PARA TRABAJOS DE IZAJEmartin lizzetti rosalesNo ratings yet

- Metrologia y TransductoresDocument10 pagesMetrologia y TransductoresEduardo DíazNo ratings yet

- QuesoDocument136 pagesQuesoMiguel Angel GranadosNo ratings yet

- Sistema Internacional de Unidades (Abr-Jul 2020)Document27 pagesSistema Internacional de Unidades (Abr-Jul 2020)Alejandro RequenaNo ratings yet

- Ejercicio 1Document7 pagesEjercicio 1lizethpaNo ratings yet

- Razona. Matematico PDFDocument48 pagesRazona. Matematico PDFJosue ChumanNo ratings yet

- Taller Sistema de Unidades VALENDocument5 pagesTaller Sistema de Unidades VALENJuan Jose Reyes CanizalesNo ratings yet

- Unidades FundamentalesDocument7 pagesUnidades FundamentalesDiego Parra DuarteNo ratings yet

- Guía de Operatoria de Números Decimales y Fracciones para Séptimo BásicoDocument2 pagesGuía de Operatoria de Números Decimales y Fracciones para Séptimo BásicoCynthiaNo ratings yet

- Norma - Rivera - IDA702 - Entregable 1Document21 pagesNorma - Rivera - IDA702 - Entregable 1Regina Vazquez RiveraNo ratings yet

- Diseño Industrial - Introducción a normas de unidades y lenguaje gráficoDocument7 pagesDiseño Industrial - Introducción a normas de unidades y lenguaje gráficojesusogarciaNo ratings yet

- Pre-184-01 Procedimiento para Realizar Pruebas de PozosDocument20 pagesPre-184-01 Procedimiento para Realizar Pruebas de PozosjulianNo ratings yet

- Programacion Lineal Problemas02Document6 pagesProgramacion Lineal Problemas02GabyNo ratings yet

- Densidad de Tintura de YodoDocument11 pagesDensidad de Tintura de YodoNilser Fustamante VasquezNo ratings yet

- Historia de La MetrologiaDocument2 pagesHistoria de La Metrologiaabelrguez05No ratings yet

- Byrsa 2016 2017.moreno ArevaloDocument40 pagesByrsa 2016 2017.moreno ArevaloElena Moreno PulidoNo ratings yet

- U.D.9 - Muestreo de PlaguicidasDocument77 pagesU.D.9 - Muestreo de Plaguicidasvmircas065No ratings yet

- Cuadernillo 6°Document16 pagesCuadernillo 6°trabajo internetNo ratings yet

- Revisión de Conceptos Físicos y Procedimientos MatemáticosDocument123 pagesRevisión de Conceptos Físicos y Procedimientos Matemáticoslucia luzNo ratings yet

- SENA Gestión Logística Metrología ConversiónDocument60 pagesSENA Gestión Logística Metrología Conversiónbetucho75No ratings yet

- Problemario de Termodinamica Aplicada BAJO Azcapotzalco PDFDocument227 pagesProblemario de Termodinamica Aplicada BAJO Azcapotzalco PDFJacinto Canek0% (1)

- Sistema Internacional de Unidades en La Tecnologia Del ConcretoDocument10 pagesSistema Internacional de Unidades en La Tecnologia Del ConcretoAparicio MejiaNo ratings yet

- Reconoces El Lenguaje Técnico Básico de La FísicaDocument9 pagesReconoces El Lenguaje Técnico Básico de La FísicaJosè Juan Roca RamìrezNo ratings yet