Professional Documents

Culture Documents

ITDG-Micro-hydropower in Nepal (Guidelines)

Uploaded by

swasti138Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITDG-Micro-hydropower in Nepal (Guidelines)

Uploaded by

swasti138Copyright:

Available Formats

Contents

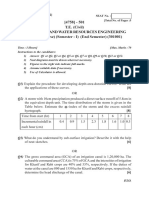

3 DMRSION WORK5 ....

3.1 Overvi ew...

3.2 Generol princi

3.3 Intoke locotio

3.3.1 Charocteristics

3.3.2 Exomple

77

77

77

18

18

20

3.4 Intoke types

vll

1

tf'

t,'

66

vl l l

5.6 Checklist for grovel trop, settling bosin

6.5.4

Quick

method for smoll schemes with crossflow turbines ................ ............. 95

ix

7.

10

11

APPENDICES

Appendix A

Appendix B

Appendix C

LIST OF PHOTOCMPHS

Ph0t0 2.2 0bstructions coused by debris folling from on unstoble slope ......... ..................... 9

Photo 3.2 Side intoke of the Golkot micro-hydro scheme, Boglung, Nepol .........22

Photo 3.3 Where on intoke is lioble to ottroct flooting debris, o troshrock moy be necessory (Sri Lonko) .............22

Ph0t0 3.5 Timber plonks ploced horizontolly in grooves provide o low-cost gote in

q

chonnel (Mhopung) ...........25

Ph0t0 3.11 Gobion wolls ot the heodworks of the 30 kWJhorkot micro-hydro scheme, Mustong, Nepol ................. 35

Ph0t0 4.3 Stone mosonry in cement mortqr heodrqce ccnql of the 50 kW Golkot MHB Gqlkot, Boglung, Nepol ..................... 38

Photo 4.4 Reinforced concrete cover slobs provide protection from folling debris (Bolivio) ................... 38

Photo 4.6 Timber conol with brocing supporting the sides, Thuptenchuling ........ .............. 39

Photo 4.11 Overflow from the foreboy dischorged over o rock cliff, Dhoding micro-hydro, Nepol .......... 50

Photo 4.12 Spillwoy on o crossing where the excess flow is dischorged into

q

gully,

Photo 4.13 HDPE pipes provide

qn

overflow from o timber chonnel (Mhopung) .................... 53

Ph0t0 4.15 Ghqndruk micro-hydro heqdroce crossing, Ghondruk, Nepcl ............ 54

Photo 4.u Flush-outs should be provided

qt

low points in pipelines so the heovy debris cqn be

Photo 4.18 HDPE heodroce pipe olong unstqble olignment, Ghondruk micro-hydro scheme, Nepol ...... 56

Photo 4.19 Bend prepored by cutting ond welding the HDPE heodroce pipe ot Ghqndruk ...................... 56

xl

Photo 4.21

Photo 4.22

Photo 5.1

Photo 5.2

Photo 5.3

Phoro 5.4

Phoro 5.5

Photo 5.6

Photo 5.7

Photo 5.8

Phoro 5.9

Phoro 5.10

Phoro 5.11

Phoro 5.12

Photo 5.11

Phoro 5.14

Photo 5.15

Photo 6.1

Photo 6.2

Phoro 6.3

Photo 6.4

Phoro 6.5

i'iroto 6.6

Phot0 6.7

Phoro 6.8

Photo 6.9

Phot o 6. 10

Photo 6.11

Photo 6.12

Phot o 6. 11

Photo 6.14

Phor 0 6. 15

Photo 7.1

Ph0t0 7.2

Phoro 7.3

Photo 7.4

Photo 7.5

Photo 7.6

Joi ni ng

HDPE pi pes by pushi ng

Col l ors used to

j oi n

HDPE pi pes

thm while hot

57

col kot grovel trop .... ' . . . ' ' , , . . . . . . . . . . . . . ' ' ' ' ' . . . . . . . . 71

Sliding got ot settling bosin entronce, Peru ....___........... ?5

Jhorkot

setti i ng bosi n ....... . . . . . . . . . . . . 76

se( l i ng Dosr n ot

Jhor kor

. . . . . . . . . . . .

1'7

sql l ri Chi oi so setl l i ng bosi n

chondr uksef i l r ng bq) i n . . . . . . . . . . . . . . . . . . . . . 78

81

8l

84

crovel trop. settling bosin ond foreboy ofJhonhe mini'hydro ................

A dry stone mosonry foreboy showi ng the connecti on wi th the penstock .........,..............

A cemnt mosonry chonnl

qnd

foreboy ot the top ofo step sl ope (Dhqdi ngJ .............

82

. . . . . . . . . . . . . 8l

Cleoning con be difiicult with horizontol bors

submerged troshrock, Sol l eri Chi ol so mi ni -hydro scheme............

overfl ow wei r for the settl l ng bosi n

qt

Jhorkot

.................................

An expqnsi 0nj 0i nt shoul d b l ocotedj ust bel ow

qn

onchor bl ock to protect the bl ock

from forces whi ch mqy Il ot be desi gned to resi st (Si kl i s) ..................

chondruk peoki ng reservoi r duri ng constructi on ............. ................. . . . . . . . . . . . . . . . . . . . . . . 85

Ghondruk Deoki D0 reservoi r ofter constructi on .............................

Pnstock

ql i gnment

of the 36 kW

Jhorkot

mi cro-hydm schme, Mustong, Nepol ........................................................ 87

Pen( t oLk. Pur ong. . .

84

85

Penstock olignmert ofthe 50 kW Borpok micro-hydro scheme, Corkho. Nepol

Excovoti on to reduc the cost ofl h

penstock ond reduce the need foronchors

{Si kl i s)

..... .............. ......... ....... ... 88

Penstock i nstol l oti on i s often chol l engi ng ond requi res sofe ond corful work .... ................ 89

Penstock oi i gnment hi gh obove the ground to ol l ow occess for peopl e 0nd cottl eJhonl re mi ni -hydro ................... 89

HDPE-mi l d stel c0upl i ng.

Jhong

mi cro-hydro schme, Mustong, Npol .................. .................................................. 9i

Penstock ot Ghondruk wi th vi l l og i n the bqckground ............

Temporory suppon for site welding work,Jhonl(Ie minihydro, Nepoll08

A strol qht pnsrock wi th four suppons cnd on onchor bl ock before th power house.....

Jhonkre

minihydro onchor block for on upword verticol bend

sl rdl ng expqn5i on

j ornt,

Jhonkre

mrni .hydro

crocki ng 0f the upper surfoce of on unrei nforced oDchor bl ock......

U5e ol dr y st one wol l f or f or m wor k,

JhunLr e

mr n1. hydr 0. . . . . . . . . . . . . . . . . . . . . . . . . . .

droi nqge ond prevel ti ng corri si on betwen the bl ock ond the pi pe (Ki omche) ............................

104

105

106

108

l l l

u1

l l 2

113

I l l

stone mosonry suppoft pi ers,l honkre mi ni ' hydro scheme ...........

The use ofon exl ensi on t0 the concrcte supp0n l i fts the pi pe cl eor 0l on bl ock, ol l owi rl g

Photo7.7 Wooden support pi ers ot Komche mi cro-hydro scheme, Nepol ....................... ........................... I16

Photo 8.2 Powefhouse ond l oi l roce oi the sol l eri Chi ol so mi [i ' hydro scheme . . ... . . ..... .... ..... 130

Phot0 9.1 Unsrobl e sl opes

(re

o throt l 0 schemc. Thi s pol vefhouse wos destroyed by o l ondsl i de ........................................... 119

Photo 9.2 Mosonry steps for entrgy di ssi poti on ond contr0l 0f spi l l wov woter ............ ........................... 140

x I

;

)

)

l

I

t

6

J

0

Ph0t0 9.4 Stone mosonry con provide slope stobilisotion olong the route of the penstock (Barpok) ......... ........ 141

LIST OF FIGURES

Figure 1.2 Heod is the verticol height through which the woter drops ................ 3

Figun 2.1 Viewing the site from o vontoge point gives the opportunity to ossess the options for

Figure 3.7 A temporory weir proposed for the 18 kW Thorong Phedi micro-hydro scheme, Monong, Nepol .............................26

Figure 3.8 Heodworks orrongement of the 500 kWJhonkre mini-hydro scheme, Nepol .............. ........................27

Figure 3.10 A stone mosonry permonent weir proposed for Ghomi micro-hydro scheme, Mustong, Nepol ................................ 29

Figure 3.11 A plum concrete permonent weir proposed for Ghqmi micro-hydro scheme. ............ 30

Figure 3.15 Heodworks orrqngement of the 80 kW Bhujung MHP, under construction in Lomjung, Nepol ................................. 36

Figure 4.3 Buried membrone lining proposed in Design Mqnuols for Irrigction Projects in Nepol ..................... 4l

Figure 4.11 Heqdworks of the 100 kW Siklis micro-hydro scheme (Siklis, Nepol) ........................... 62

Cqnol lining with stone mosonry in cement mortor 66

72

57

81

83

An i deol settl i ng bq\rn

Foll velocity ofquonz spheres in woter

A typi col settl i ng b0si n ond i ts components ..............

Exponsi on 0nd controcti on rol i o i n st0i ng bosi t

Flushing o settling bosin using th verlicol flush pipe method

Vrticol flush pip section in o settiing bosin

Flushing system of

jhqnkr

minihydm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ?4

Foreboy

Fi gure 4.13

Fl gure 5.1

Fi gurc 5.2

Fi gure 5.3

Fi gure 5.4

Fi gure 5.5

Fi gurc 5.6

Figure 5.7

Figurc 5.8

Figure 5.9

Fi gure 6.1

Fi gurc 6.2

Il gure 6.3

FrguIe 6.4

Fi gure 6.5

Figur 6.6

Figur 6.7

Figur 6.8

FiguI 7.1

Figure 7.2

Frgure 7.3

Figure 7.4

Fi gur 7.5

Flgure 7.6

Figure 7.7

Fi gure 7.8

Fjgure 7.9

Fi gurc 8.1

Fi gur 8.2

Flgur 8.3

Figur 8.4

Fl gure 8.5

Fi gun 8.6

Fi gure 9.1

Figure 9.2

Fi gure 9.3

Fi qure 9.4

Fi qure 10.1

ti qure 10.2

Fi gur 10.3

Fi gure 10.4

Tabl e 3.1

Tqbl e 3.2

Wolls ood floon ofwotr retqining structurs

Typicol penstock profile

..... 142

90

9l

93

to2

105

106

107

108

112

112

4

115

119

122

125

127

127

131

133

133

133

135

136

142

142

144

149

lypicol HPDE mild steel pipe

coupling

Surge pressures

Jhonkre

mini-hydro pnstock olignment ot downstrcom end

Tronsition from buried to exposed penstock, jhonkre mini-hydro

Sliding

rype

exponsion

joint

Thermol exporsion ofo pnstock pipe

Setting out rh c$trlin ofth pensto(k 6lignmnt

Anchor block sction.

Composi t onchor bl ock secti on

Arrangement ofweor plote ot a suppon pier

Typicol sction through o support pier

Di ston(es ond ongl s used i n onchor bl ock ond support pi er equoti ons

Proposed onchor bl ock shope

Force diogrom on th

qnchor

block

Suppon pier for smoll schemes with ground height ofless thon 1 m

Suppon pier for smoli schemes with ground height of 1 m to 2 m

Powerhouse floor plon ofthJhonk mini'hydro scheme

Mochine foundotion section

Mochi ne foundoti on pl on......

Resol uti on offors on the mqchi ne foundoti on ...........

Proposed mochin foundotion section for Exomple 8.1

Rinforced concrcte toilroce chonnel

Gobi on retoi ni rg w011..............

Stone mosonry rtoi ni ng wol l ................

Trrocing ond dry stone wolls to retoin slops ....

A gobion check dom 0t the intok ofjhorkot micro-hydro scheme

A Coondo i ntoke scren ..........

Proposd orrongemenr for bursting disc instollotion in micro-hydro s(hmes

Flexible steel suppon pier forJhorkot micro-hydro scheme

Foundoti on for theJhorkot fl exi bl e support pi er...........................

145

'150

LIST OF TABLES

Tobl e 1.t

Tobl e 2.1

Tobi e 2.2

Dillerencs between micro'hydro ond lqrge hydro schemes

Indicotors of slope instobility

Possi bl use 0fsoi l & rock i n mi cro-hydropower .......... 10

t2 Tqbl e 2.3 Cqnol sepdge l osss......

cotgories of Nepolese rivers

Sel ecti on cri teri o tor si de

qnd

bottom i nrcke

19

Toble 4.1 Roughness

Toble 6.1 Advontoges ond disqdvontoges of different penstock moteriol .......... 90

Toble 7.3 Unit weight (y), ongle of friction (Al ond ollowoble beoring pressure for diflerent soil types .......... 121

UST OF WORKED OUT EXAMPLES

UST OF BOXES

Box 3.1 Composite gobion concrte PVC sheet

Box9.1 Use of mosonry grid to stobilise theJhonke mini-hydro powerhouse orec slope ........743

1. Introduction

1.1 Hydropower ond micro-hydropower

Hydropower i s the generoti on ofpower (mechoni col ond/or

el ectri col )usi ng the fol l ofwoter In the cottext ofNpoi , o

hydropower scheme wi th on i nstol l ed copoci ty ofl ess thon 100

kW is clossified os micro hydro. Schemes in the rong 100-1000

kW ore cl ossi {l ed os mi ni hydro, ond shore some ofthe choroc-

teri sti cs 0f mi cro-hydropower schenes. Apqft frorn the power

output ofschemes, some 0fthe moj or di fferences between l orge

ond mi cro hydro cre shown bel ow i n Tobi e Ll .

SOMI DENNITIONS

. Civil engineering is the opplicotion ofscience to the

pr0cti c0l bui l di rg ofsofe ond cost effecti ve structufts.

. A structure i s on ossembl y of motencl s whi ch serves the

pueose for l vhi ch i t i s desi gned (occommodote peopl e,

convy Il ou trofi i c, etc.) ond c0rri es the ossoci oted

l oods. A cr vr l er , gr necr i ng sr r u, r ur e r ' spr r . f i col l y

designed to fulfil o purp0se ond/0r pe orm o function

qt

0n opprop ore quol i ty ond to

qn

occeptobl e ti me scol e

ond cost.

r Civil rvorks are cll octivities necessory for the building of

structures.

. Sforoge schemes moke us ofo dom to stop river flow

bui l di ng up

q

reservoi r 0fwoter behi nd th dom. The

wotrr i s then reLeosed through turbi nes when power i s

neded.

r Run-oiriyer sche mes do not stop the river flow, but

i nsteod di vert p0n ofthe fl ow vi o o heodroce ond

Toblt l.l Differencs btween micro-hydro ond lorge hydro schemes

The desi gn ond constructi on 0fci vi l ngi neeri ng works hove

some important chorocteristics:

They ore depeodent 0n condi ti 0ns ot the si te. No two

sl tes orc the some.

They olwoys involve structures thot ore in contoct with

the ground. Desi gn engi neers moy hcve control overthe

motri ol s used i n corstructi on, but hove l i l ni ted conrr0l

over t he gr ound on whi , h l he \ t r u( l ur e sl 0nds. They

must therefor toke occount ofthe ground condi ti ons,

ond moy hove to consi der ol ternoti ve si tes to ovoi d

stobi l i ty probl eIns

They oi ten i nvol ve o number 0fpeopl e worki ng on

desi gn, supervi si on ond constructi 0n ot the si te. Vori ous

skills ond moteriols ore involved, usuolly over o period

of severoi months. Therefore pl onni ng, communi coti on

ond occount0bility ore very importont.

Foilure ofcivil works con be very dongerous ond very

expensive. Similorly, poor performonce or over-design

ore uneconomi col .

On i mportont poi nt shoul d b recogni sedi compl ete

stondordi soti on 0fci vi l works i s not possi bl due to the

vori 0ti on i n si te condi ti 0ns. Insteod, stondord 0pprooches to

penstock to

q

turbi ne. Mi cro-hydro schemes

qre

ol most

olwoys run'of-th-river.

1.2 Aspects of civil engineering worlc

DESCzuPNON MICRO HYDRO SCHEMES LARCE HYDRO SCHEMES

'IYpe

Pow$ generoti on

Noture oi intoke

funnel s & underground structuri ,s

Penstock oliqnment

surge shoft

Distribution system

Unlined conol

N' l ostl y run-ol :ri ver

El ectri col ond/or rnechoni col

Usuol l y tmporory 0r semi -permonent

Rore

Verti col & Irori zontol bends

Rore, fbreboy octs os surge tqnk

Isol otd (i .e. not coonected to the

nnr i ^ f n1 ol , . f r , . , r v n r i . l r

Cor0rnon

Both run' of' ri vr ond storoge

El ectri col onl y

Pefmonent

CoII]mon

Fewer verti col bends ond usuol l y no h0nzontol

bends

Comrnon

Il ostl y gri d connected

Rqre

I

I

I

design ore used. providing methods ond crireriq thot enoble o

desi gn to b odoptd to condi ti ons ot o si te

Of course, scfe. occurote ond economi c desi gn i s essenti 0l

i n ci vi l engi neeri ng but, becouse ofsi te vori oti ons, o procti col

understondi ng ofdesi gn i s ol so cruci ol . Fqi l ures i n ci vi l engi -

neeri ng do not usucl l y 0ccur through on error i n col cul oti ons

but becouse of o seemi ngl y nri nor vent or cj rcumstonce l vhi ch

drd not sn1 i mponont. A thoi ough understqndi ng i s needed of

whi ch el emenl s ore cri ti cql .

1.3 Components of micro-hydro schemes

Al th0ugh no two mi cro hydro si tes 0re si rl l i Lqr, ol l ofthem

requi re speci fi c common components ofdi fferent di mensi ons to

convey the streom w0ter to the power generoti 0n uni ts ond

bcLk r i l o t : ? sl r eom : he' c i or : : ponent ' oD' shol l n r n Fr gur e

1.1. Thc ci vi l conponents or bri efl y di scussed bel ow:

HEADWORI(s

Structures ot the ston oi the scheme or col l ecti vl y cql l ed the

heodworks. In micro-hydro schemes, the heodriorks ohvoys

include the diversion weir, intoke ond grovel trop. A spillwoy

ond o settling bosin ore

qlso

usuolly ot the hodworks.

DIVERSION WEIR

A diversion weir is o low structure (smqll dqm) ploced ocllss

the river which diverts some ofthe dvr flow into the

hydropower scheme. The weir con be of o permonent, semi-

permonnt 0r temporory n0ture.

INTAJC

This is ot the riverborlk upstreom from the diversion weir

where w0ter i s i ni ti ol l y drown i nto o c0ndui t (conol or o pi pe).

Usuolly 0 flow contrcl structuI! ond o coorse troshr0ck 0rc

i ncorporqted ot th i nroke.

GMVEL TRA"P

Thi s i s 0 bosi n (pond) cl os to the i ntoke wherc grovel 0nd othr

coorse motriols ore tropped ond then removd. In the obsnce

ofthis structur grovel con sttle olong the gentler sction of

the heodroce or in the settling bosin.

SETTUNG BASIN

Thl 5 LS

qLso

o bosi n where sqnd 0nd 0l her Ii ne ' uspended

porti cl .s present i n the ri ver woter ore serti ed ond then

renoved. l f ol l owed t0 enter the pnstock. such porti cl es wordd

obrode l he penstock pi pe ond the turbi ne 0nd hence shonen

thci r opLrqtl ()n0l l i \' fs.

HEADRACE

This is o conql or o pip thot conveys the woter ftom the

heodworks to the foreboy structure. The heodroce olignmenl is

usuol l y on even to gentl y sl opi ng ground; o heqdroce pi p i s

generol l y not subj ect to srqni fi cont hydrcul i c pressure.

FOREBAY

Thi s i s o tonk ot th entronce to the penstock pi p. i he foreboy

tonk ollows for fl0w tronsiriorI from open chonnel to pressure

flow ond provides storoge whn there ore flow fluctuotions in

the turbine. It con olso serve os o finol settling bosifl. ln fqct,

someti mes the settl i ng bosi n ond the foreboy structurs om

combi ned.

SPILLWAYS AND ESCAPES

Spi l l woys orc openi ngs i n hodroce conol s thot di vert xcess

fl ows ond 0nl y ol l ow the desi gn fl ow d0l vnstrqm. Note thot

some literoture moy us th{ terms spillweir 0r overflow t0 rfr

to the spillwoy. Escopes ore similor structures but their function

is t0 diven flows from the heqdrqce conols in cose the upstrcom

sectj ons get bl ocked such os i f there ore l 0ndsl i des.

CROSSINGS

Thes ore structurs thot convey the flow over streoms, gullies

or ocross unstoble telloin subject to londslids ond rosion.

Aqueducts. culverls dnd suspxded crossings ore examples of

such structures.

PENSTOCK

This is o pipe thot conveys wotr undr pressur from the

foreboy to the turbine. Th penstock pipe usuqlly storts wher

the grcund profile is steep.

ANCHOR BLOCI(

An onchor block

{thrust

block)is on encosement of o penstock

desi gnd to constroi rl the pi pe m0vemnt i n

ql l di l tcti ors.

Anchor blocks ore ploced ot oll shorp horizonrol orld verticol

bends, since there ore forces ot such bends thqt will tnd to

move the pip 0ut ofolignment. Anchor blocks 0re olso

requi red to resi st oxi ol forces i n l ong strci ght secti ons of

penstock.

SUPPORT PIER

suppon pi ers (ol so col l ed sl i de bl ocks or soddl es) orc structures

thot ore used ol ong stroi ght runs ofexposd perutockpi p

(betwen onchor blocks), to prevent the pipe from sogging ond

becoming overstressed. They need to resist oll verticol forces

such os the wei ght ofthe penstock pi pe ond the wotr. However,

they shoul d ol l ow m0vement porol i ei to the penstock ol i gn-

ment, whi ch occurs duri ng thennol exponsi on und controcti on

Pr0cesses.

POWERHOUSE

Thi s i s o bui l di ng thot oc(omrnodotes ond proteds the el ctr0-

mechoni c0l equl pment such os the turbi ne, generotor ond moy

i ncl ude oqro' pl ocessi ng uni ts. Thc el ectro nechoni col equi p-

ment i n the powerhouse convens the potenti ol 0nd ki nel rc

energy 0Iwoter i nt0 l ectfi col power

TAILMCE

Thrs i s 0 chonnel 0r o pi pe thot conveys rvoter l r0m the turbi ne

(0fter p0wer gneroti 0n) bock i nt0 the streqm; gnerol l y the

s0m str?0m l ronl wi ri ch water wos i ni ti ol l y wi thdrown.

Det0i l ed ds.ri pti ons of thse comp0nents i ncl udi nq

sel ecti on, desi gn

qnd

c0nstructi on l nei hod0l ogy 0rc di scussed i n

subsequent chopt.s.

A

Toi l r oce

l)oul? l.l Components ofo micrc hydro saheme

1.4 The power equotion

'Ilte

powerovoiloble from c hydropower scheme is depndent

on the vol ume l l owi ng i n the system ond i l s drop

j n

hei ghr. The

Rl oti 0nshi p l s exprcssed by l he po!ver equotr0nl

P=0x ox h x

rvhere:

t' i s the power produced i n kw

Q

i s the fl ow i n the penstock pDe i n mr/s

g

j s

the occel erati on due t0 grovi ty

=

9.8 m/s' :

hq,,,, i s the gross heod ovoi l obl e i n m

e is the overoll s!'strn eiliciency

Gross heod, h,,

,.,

i s the di l ference bet!\ren the l voter l evel

ot the f0reb0y ond the turbj ne centrel j ne l evel (or toi l roce woter

suri oce i fo drqft tube i s uscd). Thi s i s shown schemoti col l y i n

Fi gur e 1. 2.

Nel hod, h , i s the pressur heod ot the entronce to the

l urbj ne. Thot i s l he gr0ss head mi rus conveyonce l osses i n l he

penstock. For mi cr0-hydropower schemes the penstock 1s

generol l y desi gned such thoI the net heod i s 90' 95q,r ofthe gross

heod meosured from the Ibrcboy (reier to Secti0n 6.4 for

penstock sj zi ng).

The 0verol l systel n el l i ci ency, e", i s the roti o ofusel ul

po$,er output t0 hydr0ul i c power i nput. It i s the prOduct of

spqrate effl .i enci es for severol components ofthe system. i .e.

e : i r e L e q e , ,

wherc:

er i s the pensto.k effi crerrcy. rypi col i y 0.90 0.95

i h

=h

e)

e, i s the turbi ne efl )ci ency. typi c0l l y 0.65

-

0.80 dependi ng on

rurDl ne ryp

er l s the generot0r efl i cl ency, typi col l y 0.65 0.90 dependi ng

on si ze

pL

i s thr l ronsmi ssi 0n emci ency rncl udi ng trcrnsforners i l

used, typi col l y 0.85 0.90

F0r prel i mi nory pl onni ng of rni cro-hydropower schemes

i n Nepol i t i s comm0n to ossume on overol l system effi ci ency 0f

0.5 to 0.6. However, i t moy be os l ow as 0.3 l or very smol l

i nstol l oti ons ond os hi gh os 0.7 f0r l orger schemes. Therefore ot

detoi l d desi qn stoge i t i s i mponont to recol cul ote the power

output bosed on the octuol desi gn 0nd monufocturcrs' doto for

the proposed equi pment.

Fi g, . r pl l Hc od. r he\ er t ol h. gl . l r hr c u! hwh. , l | , hdr pr dr op.

l rap/

^ / )

a'/'/

z

\{],,

' <\,

l

Anchq

2. Site selection

ond

planning

2.1 0verview

Th sel ecti on 0fon 0ppropri ote sj te i n m0st mi cro-hydropower

schemes i s on i teroti ve process. In the Nepol ese context, usuol l y

some communi ty members rvho hove hod previ ous exp0sure to

mi cro-hydrgpol ver tcahnol ogy oppi ooch fundrn g ogenIi es.

consul tqnts or monufocturers dependi nq upon thei r fl nonci ol

ps0urces

ond the si ze 0fthe scheme. Thf rchni ci ons ofthe

ogency concemed undertoke o si re vi si t to ossess whether the

si te i s feosi bl e f0r a mi cro hydro i rstol l oti on. Bosed on the

feosi bi l i ty report submi tl ed by thse teci rni ci ons, th commu.

ni ty members ond others i nvol ved l n the process decj de

whether t0 pr0ceed f.rfl l i ef wi th I ne di \ /l Jpmpnr of rhe

scheme.

0nceth deci si 0n i s mode to proceed wj th the scheme,

ond i fi t i s i n the uppr ronge 0f Di cro hydro (soy obove 20 kw)

then 0 detoi l ed survey ofthe protect orq i s undcrtoken ond a

detqiled design rcpon is prcpored. Th sor)cti0n oi loons,

subsi dy ond grcnts by fundi ng crgenci es ond bonks ore bosed on

thi s repoft. Thrre ore frequent meti ngs between the concerned

porti es duri ng thi s stoge. F0r the l ower el ]d oi mi cro hydr0 (soy

i ess thon 20 kW). usuol l y the monufocturers undertake both the

desi gn ond i nstoLl oti on.

Apon from soci o econorni c foctors such cs the need 1br

el ectri ci ty, 0l I0rd0bi l i ty, ond suppl y 0nd demond, technj r0l l y

the sel ecti on ofon 0ppropri oi e si te depends on the fol l 0wi ng

two foctors:

. Streom ilolv

. Topogrophy

As menti oned i n Chopter I, the power ovoi l obl e from o

micro'hydroporver scheme is o functjon 0fboth the flow ond

the heod. The heod depends on the topogrophy i\,ficro'hydro

becomes techni c0l l y vi obl e oni y i fthe combi noti on ofhead ond

fl ow ore such thor the demond of the rorgeted conrnruni ty con

be met. Urdsr n0rmol ci rcumstqnces. Ihe l ow scoson fl orv r,i the

I

I

I

nv( r sl r 0ul d be u5ed whi l e( 01, ul l l r ng I hepowpr 0- l pul I l

shoul d be n0ted thot desi gners hove l l l e c0ntrol over the l l ow

ovoi l obl e i n the streonl . Horveve( they h(ve s0me conl r0l over

l ht' topogrophy. They con choose di l l erent ol i gnnents for l he

i ntoke, heodroce ond penst0ck. l hey con ol so modi fy the l ocol

topogrophy through excovoti on, bui l di ng 0fstructures ond by

undertqki ng s0i l stobi l i ty enhoncemenl meosures.

Al though the pl onni ng ofDri cro hydro ci vi l works does

not rBqui re the detoi l ed work ofl orge proj ects, the pri nci pl es orc

tht s0De 0nd core needs to be token to fol l 0w some bosi c rul es.

Proper pl onni ng ond co-0rdi noti 0n i n th i ni ti ol stoge ofthe

projct will keep costs to o mirrimum ond reduce deloys.

Meosurement ofheod ond flow ore beyond the scope of

thpse gui del i nes but ful l desc pti ons 0fthe methods used con be

found i n o number oftexts i ncl udi ng Rei 1.

2.2 Principles of site investigation

Si te rnvesti goti on i s the prel i mi nory work c0rri ed out t0

estobl i sh the sui tqbi l i ty for constructi on ofthe vori 0us opti ons

(or

the most fecsi bl e opti on rI rt i s opporentr tl rrough the

rnvesti goti on of soi l s, sl ope stobj l i ty, fl ood l vl s, surfoce woter

movenent

qnd

subsi dence. Thi s i s di scussed l oter i n thi s

chopter

In most ci vi l ngi neeri ng work, the unexpecred hcppens.

Si t i nvsti goti on oi ms to predi ct whot thi s mi ght be so thot the

engi neer con prepore o desi gn thot wi l l deol wi th i t.

It shoul d b noted thot th meosurement ofheod ond

fl ow serves to estobl i sh the 0pti 0ns ov0i l obl e for devel opment of

the si te f0r mi cro' hydro. The si te i nvesti goti on then

qssesses

the

sui tobi l j ty ofthe si te f0r eoch ol ternoti ve. The si te i nvesri goti on

process hel ps to choose the opti nl unr l oyoul where more thon

on opti 0n oppors to be teosi bl e. Si te condrti ons ore ol s0

recorded duri ng the si te i nvesti gqti on stoge so thot there i s

odequot informotion for the detoiled design phose.

Ther is usuolly o limit t0 th time ond funds ovciloble

for site investigotions. lt is olwoys dimcult to know whn

odequote work hos been comp)eted. Thekeyi stowork

efficielltly ond to think corefully 0bout where mor thorough

i nvesi i gqti on i s requi red. The pri nci pl es

ofsi t i nvesti gotj on 0re:

. Take your time and be thorough. A return visit to collct

informotion missed th first time is costly, ond inod-

equote ci vi l dsi gn evn morc so

. walk oll over the sire. Goin o fulloppreciotion ofthe

opti ons ovoi l qbl e.

. Tolk to local peopla especiol)y those who hove corried

out constructi on work i n the oro. Si nce most ofthe

ri vrs i n th mountoi ns ond th mi ddi e hi l i s ofNpol

hove not been gouged, streom fl ow dqto ore not usuol l y

qvqi l obl e.

Therefore, i t

j s

i mponont to tol k to l 0c0l

peopl e t0 get o l i rl ofth fl o0d l evLs for rore l l ood

everts (soy 20 yeors t0 50 yeors return peri od).

. Overol l , oi m to rqi se the understondi ng ond oworeness

ofchonges i n the si te over ti me.

2.3 Selection of olternotive lovouts

2.3.1 AN OVERVIEW OF THE SITE

This will involve viervlng the site from o physicoLvontoge point

os shown i n Fi gure 2.1, ond toki ng ti m to consi der the procti -

col desi gn

qnd

constructi on ofthe ol ternqti ve l oyouts (i .e.

selected potentiol sites). Eoch possible loyout will require

constructi on work on di fl erent pqrts ofthe potenti ol si te ond

the surveyor should thrcforc note on which pon eoch compo-

neni ofthe scheme wi l l be l occtsd. The overvi ew shoul d note

feoturcs thot moy 0ffect the dsi gn ofth scheme, such os sl ope

stobility, ond lond us ond ownership. A sktch mop ofoch site

pl on shoul d be mode os shown i n Fi gurc 2.2.

23.2 LOCATION OF COMPONENTS

For eoch ofthe ol ternoti ve l oyouts sel ected du ng i he si te vi si t,

l ocoti ons ofeoch component shoul d be i denti fi ed ond thn

i ncl uded i n rhe si te pl orl

os shown i n Fi gure 2.2. Nore thot

generolly the locotion of th intoke is the key cornpolrerlt in

determining the site loyout, sinc thr is usuolly only one most

oppropriote intoke locotion. Therfore the intoke lo(otion moy

determi ne the l ocoti ons

qnd ql i grl ments

ofother components.

lntoke selection is covercd in Chopter 3.

once ol l ol ternoti ves hove been i denti fi ed, the most

sui tnbl e l oyout shou)d b chosn. Ap0rt from the proj ect cost.

the fol l owi rrg ore

(he

nl qLo cri teri o thot shoul d be used to sel ect

the most sui tobl e l oyout:

. The combi noti on ofheod ond fl ow ofeoch ol trnoti ve

should b such thot the required minimum power

output is feosjble.

o Preference should be given to the simplest loyout in

terms ofdesi gn ond constructi on.

. The shoner rhe

ql i gnment

ofthe scheme i s, the l ess the

requi rement for constructi on moteri ol s. Hnce, such

q

scheme con be constructed f0ster ond ot o l owr cost.

. The powerhouse

should be os close os possible

to the

lood centre. It is odvisoble to keep the tronsmissiol line

length less thon 2 kilometrcs.

. Finolly, techDic0l porometers such os overo)l slope

stobi l i ty, fl ood ri sks, ond other si te-speci fi c i ssues shoul d

be consi derd.

Y'r.

{ t l uf t

\ l \ ,

[ ..r

f d 6

dr.-

##

a.-)

\ ,

r)

n k

t 1 /

4

Fl gurc 2.1 Vi ewi ng the si te frotn o vontoge poi nt gl ves the opportuni ty t0 ossess the opti ons for the l oyout ofo scheme

Yi l l qge

o

o

q

req

a

r o

E

a a

Tr qnsmi ssi oa

l j

PoWerlrouse- Qve\

oc,F, Q,l i !n

Ri ve

r tzr

rq.a

spillrrzo

l r r i q q { i o a c - q n q

Tqi

lrq.'

. ! Fore-bqv

Corn f i sl d

Cor n Fi

Sgt t t : " _g

! SS; n

S P i l l wa

l l eqdr c<. e.

C- qnql

G r a v a - l { t

Fi gur 2.2 Atypi col si te pl on

_5lT

E Pt,qN

r l

2.4 Geotechnicol considerotions

2.4.7 GEOLOGY

The geol ogy ofthe si te i s cri ti col to the desi gn, costs ond future

performonce of the civil works of micro-hydro schemes.

Geol ogi col mops ofcertoi n

qreqs

ofNepol ore

qvoi l qbl e qt

the

Deportment of Mining cnd Geology or Tribhuvon University's

geologicol librory. It is worth checking whether such o mop is

ovoiloble for the oreo of interest since this will indicote the

generol geol ogi col condi ti on ofthe si te.

Geol ogi col chorocteri sti cs ofo si te con be grouped i n the

following woy:

c Major weakness zones

-Lorgeoreos

ofgeologicol

instobility in the oreqs where the clvil structures ore to

be l ocqted.

o S/ope stability

-

The degree ofstobility ofthe hillsides of

the site.

. Sorl and rock fypes

-

Foundotion conditions ond liobility

t0 seepoge undermining ond subsidence oround

structures plonned for the site.

2.4.2 MAJOR WEAKNESS ZONES

The moin tectonic zones of the Himcloyos generolly correspond

to the physi ogrophi c di vi si ons ofthe country ond run i n

northeost-southwest direction. Mojor weokness zones such os

thrusts or fqults seporote these zones from eoch other. In

qddition

there ore mony other

"minor" weokness zones which

coul d si gni fi contl y i mpoct the proj ect. If

qvoi l obl e,

o geol ogi col

mop of the oreo where the micro-hydro scheme is proposed

shoul d be consul ted to ovoi d pl or:i ng ci vi l stmctures 0n these

moj or thrusts ond foul ts. If ci rcumstonces di ctote the i nevi tobi l -

i ty ofpl oci ng the scheme i n such zones, expert hel p from o

geol ogi st shoul d be sought.

2.4.3 SLOPE STASILITY

In geol ogi col terms, the hi l l s ond mountoi ns of Nepol ore young

ond unstqble. They could be likened to o pile of sond in thot the

excovotion olong o slope eosily results in the sliding ofthe lond

obove, especiolly when o further triggering mechonism occurs

(porticulorly during the monsoon). Common triggering

mechoni sms ore the fol l owi no:

. Surfqce woter

r Ground woter

r Undercutting ofslope by excovotion

The stobility of slopes will

qffect

the design of oll

components of o micro-hydro scheme

qnd

should therefore be

onolysed thoroughly, porticulorly in the following key oreos:

o Above ond below proposed conoi routes.

o Bel ow the proposed l ocoti on ofo settl i ng bosi n or o

foreboy tonk.

o Along the proposed penstock olignment.

r Above ond below the proposed locotion ofthe power-

house.

Threots in these oreos will either toke the form of

weokening ofthe support oround the foundqtions through lond

sl i ppi ng owqy 0r col l opsi ng, or domoge t0 structures through

folling debris, os shown in Figures 2.3 ond 2.4 ond Photogrophs

2.1 ond 2.2. tndi cqtors ofsl ope i nstobi i i ty ore presented i n

t oDI e z. I .

fi gure 2.3 Threot to structures from bel ow due to l ondsl i p

Fi gure 2.4 Threot t0 structures due to fol l i ng debri s from obove

Photo 2,1 Tension crocks olong oslope Photo 2 2 Obstructions coused by debris follrng from on unstoble slope

tlbk 2.1 Indicotors ofslope instobility

sEcnoN 0F sroPE INDICATOR OF INSTABILITY

LJpper, middle or lower hillslopes Tension crqcks

qlong

slope (Photogroph 2.1), ground shelves shorply, trces leoning downslope

or bending upwords from the bose, woter springs or seepqge

qt

bose ofslope, displocement

of pqths, fence or posts.

Fresh rock foces exposed, presence ofsoft, weotheroble rock, openjoints in rock, tension

crocks, overhongs

qnd

loose rock, woter springs or seepoge ot bqse ofrock foce,

Frcsh dbris ot bose ofslope, tree roots exposed,loose debris which moves underfoot,

profiles steepen towords bose ofslope, debris littered with deod or ovenurned woody plonts

ond oross clumDs.

Bposd foces of londslides

'lle

followilg feotures ofthe slope or rock foc indicot slop

stobilitf

. complete vegetotion cover, including trees stonding

verticolly

. Stroight, even, slope prolile

I Rock surfocs covered with moss, lichen or 0 weotheR

skin

. Hod, impemeobl rock

. Rock with no or fewjoints

. Closed mckjoints

. Wll.pockd dbris, especiolly with fin moteriol

p0cked into voids between coorse moteriol

. Well-estoblished trees ond shrubs

. No octive gullying (olthough o stoble gully system

moy be present)

The incRosed Imowledge ofthe sit goined ftom 0 thorough

investigotion ofthe slopes will influnce the design ofthe

whol scheme, poniculorly the locotion ofprincipol

srruclurEs.

The recommend0ti 0ns frOm thp rnvesl i goti on ofsl 0pe

stobrl i ty 5houl d i ol l o!\, rwo bcrsi c rul es:

. Never construct on fi l l , thot i s, l ond \,vhi ch hos beerl

bui l r up or fi l l ed usi ng excovotd moteri ol .

. Avoi d the l ocol i 0D of structLrrcs cl ose t0 l ondsl i de zones

2.4.4 SOIL AND ROCK TYPES

The surveyor shoul d i nvesti gote whot l ocol a0nstrLrcti on

moteri qLs such os soi l ond rock ore ov0i l obl e ot si te. Possi bl e

uses 0fsuch moteri ol s 0re preserted i n Tobl e 2.2.

The type of soi l or ro(k ol so ofl ecl s thf l ourdoti on oi

\ r f l r t ur e. 0ndl l - pLun0l t y pe. f or

px onr pl ,

. . f he. oi ) t 1pe, .

sondy l oom, o l orger tbundoti 0n depth i s .equi red. 0n the

othr hond, structures moy be bui l t di rectl y on hord rock

wi th0ut ony excovol i 0r). Si mi l orl y, l i ni ng nl 0v not be requj red

for heodroce ccnol i f rhe soi l type i s cl oy HDw{rvr, l i ni ng wi l l

be requi red i fthe oLgnmcnt rs through sondy soi l .

Subsi dence i s coused by the l ocoti on 0fqci d substoncs

i n the l ocol groundwoter octi ng on sol ubl rocks such cs

l i mest0ne. by the presence of rocks whi ch ore l i obl e t0 spl i l ti ng

ond l 0l i oti oi r, oi bV undcrEround cdverns \rhi ch cre prone to

coLl opsc. The presence of thi ck l oyers of l oo!c sqndy soi l

(Ioy

ol so Leod to subsi dence.

These chorocteristics

qre

identilled by coreful observo-

ti 0n 0fthe si te. Li mesi one 0utcrops, si nkh0l es (hol es of 2-10 nr

i n di omter whi ch l orrrl when the i i mstorl e beneoth di ss0l VeJ,

cousi ng the s0i l obove t0 col l opse), the oppeqronce ol streoms

or other seepoge from depressi ons or crocks i n the ground

surfoce ore excmpl es 0l choroctri i sti cs ro l ook for.

Undermi ni ng refers 10 the octj 0n of surfuce woter on the

tbundqti ons 0fsrrucrures. The i Dtoke ofthe scheme ond the

penstock ore porti cul orl y prone to undcrmi nl ng where surl oce

woter threqtens the structures, but the hodroce conol i s ol so

vul nerqbl e.

Toble 2.2 Possible use ofsoil

qnd

rock in micro.hydropower

2.5 Hydrology ond wster ovoilqbility

2.5.1 PRf,DICTION METHODOLOGIES

Hydrol ogy di ctotes the si ze ofvori oLrs mi cro-hydr0 conponents

l i ke the turbi ne, chonnel ond the penstock.l t ol so hos gfeot

i nfl uence on the schene bei ng desi gned over or under copoci ty.

The gncrol pro(ti ce

j n

Nepol tor ml cro-hydro schms i s t0 vi si t

th sj te dufLng dry secson ond meosure the fl o!v. The scheme i s

then desi gned bosed 0n thj s fl ow Thi s moy l eod to si tuoti ons

wherc the l l ows ore l ess thon the desi gn fl ow ond consequentl y

turbi nes orp pr0duci ng l ess porver thon expecl ed The foct thot

nr o ny nl cr o hyd r o . hr nr ?5 . r L Nepol r epon gr nr r or l on woy

bel ow the i ostol l ed copoci ty i s strong evi dence of thi s. It i s

i mperoti ve t0 understond whether the fl ow wos meosured i n o

dri er thon ri yeroge yeor or i n on overoqe yeor, becouse ofthe

i nfl uence th0t thi s hos on sel ecti ng the desi gn fl orv. To be obl e to

produce o desi gn fl ow os occurql el y os possi bl e. o predi cti on

study must be undertoken.

Most potenti ol mi cro hydropower si tes orc l ocoted on

ungouged cotchments where si te speci fi c hydrol ogi c doto i s

l o.ki ng. To esti m0te yi el d from ung0uged corchmerts, two

techni qLl es

qre

currentl y ovoi l qbl e to predi ct fl 0ws. These ore

known os th WECS/DHM ond l he MIP methods, and

qre

presentd i n the subsequent di scussi ons to predi ct fl ows i n

ungouged cotchments i n Nepol .

fi owvr, o( o rcgi 0noi troi ni ng workshop on l ow fl ow

meosurment ond onol ysl s orgqni sed by ICl l r{OD i n Apri l 1999

i n I(othmondu, Nepol , i t wos reported thot both the WECS/DHM

ond MIP methods for esti motrng yi el d from ungouged cotch-

ments hod moj or drowbocks, ond use ofthese methods hod to

be exrci sed wi th extro ccutl on- It was recommended thot rhe

WECSi DHM sl udi es be revi el ved, ond esti moti on ofthe porom-

eters be updoted from time t0 time. In this regord, DHN'I is n0w

colloboroting with WECS Io rsview the prvious studies, ond

i mprove 0nd updot the por0nl eters by usi ng more stoti ons

wi th Longer records ofdcto. [t wos stressed rhot wi th Nepo]

focing blg problems in estimoting the dsign low flows for o

N' IE OF SOIL

OR ROCK

POSSIBLE USE IN

Ii'IICRO.HYDRO CIVIL WORKS

TRIATMENT BI]FOR-L USE

Sond Concrcte

Ag!reg0te i n concrete

Bed moteri ol i n droi ns

Cdbi ons ond masonrv

Conol l i ni ng

Musr be selected or thoroughly woshed to be free from orgonic motter, fine

poni cl es, cl oy l umps 0Dd excessi ve mi co.

Musl be coreful l y soned ond woshed.

Must b woshd.

N{usl be selected for c0rrct type of rock, density ond size.

Testi ng ofcl oy content requi red to ensur thot i t wi l l serve os on

i mpermeobl e l oyer

crovel

Rocks

Cl ov

10

v0riety of opplicotions including micro-hydropower, o Ielioble

method wos urgentl y requi red. In thi s c0ntext, the l nsti tute of

Hydr0logy, U.K. is undertoking 0 project titled

'Regi0nol

Flow

Regimes Estimotion f0r Smoll-scole Hydropower Assessment

(REFRESIiA)" in coilcboroti0n with ICIIUoD ond DHII from 1999,

whi ch oi ms to provrde o rel i obl e method for esti moti ng the

hydrol ogi coi regi me ot ung0uged si tes i n the Hrmol oyon rgi On

0fthe country RIFRISHA is scheduled to b rtody in obout fivo

ye0rs trme.

WhcslDepotr|Jfjent of Hydrotogy and

Meteorolry pHMl

method

The woter

qnd

Energ-v conl nri ssi 0n Sccretori ot (wECs) cud DHN{

(Rel 4) method l s b0sed 0n 0 seri es of regressi on equ0ti ons thot

orc deri ved from onol vses ofol l the hvdrol ogi [ol records i r0m

Nepol . The fi ndi ngs ofthi s l "gfessi on onol ysi s hov ben used to

produce quotions for predicting different hydrologic poronr-

eters such os the l0!v flols, flood flows

qnd

floiv durotion

rurves.l t

j s

beyond the scope ofthi s boQk to expl oi n i n det0i l

the WICS/DHIVI meth0d. Reodel s ore odvi sed to consul t the

Rfercnce. detoi l s 0f \\ hr.\ ore provrded i n Chop' er I L Appen-

dix Adescribes this method with

qn

exomple.

lledium lrrigation Project method (MIPI

l h MIP method pre5nts o techni que i br sl i mcti ng the

distributloi, 0f nont hly ilows throuqhout 0

yeor'for

ung0uged

l 0t0ti ons. Th l vl l P mthod0l Ogy uses o dut0hqse consi sti ng of

DHM spot meosurenenrs. The 0ccosi onol wddj ng gougi ngs

conducted by DHM include only 1ow llows ond these flows d0

not rPpresent the noturol c0ndjtions since they ore residuol

llows amoining ofter obsrroction ior different purposes like

i ri q0ti on. MIP prsents non-di mensi onol hydrogrophs of meqn

rnonthly fl0ws for seven difierent physiogr0phic regi0ns. These

hydrogrophs present nonrhly fl0ws os o rotio ofthe flow in

April (0ssumed IOwest onnuol flow). For opplicotion to

ungougd sites, it is necessory r0 obtoin o I0w flow dischorge

e5tim0te by gouging ot a pofticulor site. Th mosurcd flow is

then used with ih rgionoL non dimensionol hydrogroph t0

synl hesi se on 0nnu0l hydr0gr0ph for the si te. Appendi x A

describes this method rvjth on exomple.

Comryisons of the WECSIDHM s,,d the MIP opprooches

IIDCSIDHM: Dliootion 01 droinoge bosins

qnd

elevati0n

(ontours

oR oftn distcfird on rhe cv0rlobl mops: olso

ngmsions wen derived 0n lhe bosis ofobserved 0ows for

c0tdlments ronging in size fr0m 4 up t0 54,100 kTn'. Therefore,

fol llows in smoller cotchments the results would prov to be

unnlioble.

MIP: The MIP method opprooch bosed on wodrng meosure.

ments takn 0n on intrmittent b0sis connot be expected to

gi ve 0 good esti moti on oftot0l fl ow i n the monsoon months, i t

con, however, give o reosonoble opproximotion ofthe divertoble

fl ows i n these months. In the rvet seoson months, Nl l P woul d be

expecred to underesti mol e WECS tl qures, whi ch shoul d more

0ccurotel y represent totol fl ow In the dry seosor l i l l P ond

!VECS shoul d both provi de rotol fl ow esti motes. The MIP

prOcedure, whi ch xpl i ci tl y odvocots the use 0fl oc0l doto to

odjust the regionol hydrogroph, should give rosonobly

occurote esti motes through rhe dry seoson months thot ore

cri ti col i n ossessi ng mi cr0 hydro proj ects.

Not drot nei ther the WECS/DHM nor i he MIP nthOds

rvere derived from doto for high oltitude snow'fed cotchments.

F0r such cotchments, more wei ght shoul d be gi ven to the resul ts

of si te meosuremnts.

It must be mphosi 5ed that one con get o fel for 0nnuol

i l oods by meosuri ng f)ood l evl s ot sj te. Si l t ond debns depos-

i ted ol ong the ri ver bonks or l vel j ust bel ow th vegercti on

growl h 0re i rdi coti 0ns ol l l ood depths. By meosuri ng fl ood

deprh, wi dth ond overoge gr0di ent ofthe ri ver ot the i ntoke

orco, i t i s possi bl e to cal cul ote the fl ood fl ow usi ng I' l onni ng' s

equoti on, descri bed i n 4.3.2. Il i s beyond the scope ofthi s book

to dcscri be the di fferent methods ofri ver gougi ng: pl eos se

Re[. I or Rel . 2 fbr gui donce.

2.5.2 PROCEDURX TO ESTABLTSH fiE DESIGN FLOW

l . C0ndLr( | 0 fl ow n.eosurement ol srl e duri ng the dry

Jeo\on

rNov(

mber \1oyJ. Pr| .fcrobl y rn February l or

snow-fed rivers ond li{orchiApril for 0ther rivrrs. Note if

the yeor i s dri er thon overog, overoge or wettcr l hon

overoge Thi s con be estobl i shed by tol ki og to rhe l ocol s.

Consi der i fthere orE sj gni fi cont obstrocti ons by 0ther

wqter users, such os

j fi goti 0n

ond dri nki ng woter

schemes upstreom ol the p0i nt where th gougi ng wos

conducted.

2. Col cul ote :

. Averoge nl onthl y fl ows by usi ng WECS/MIP methods.

. Flow durotion curve using WECs.

. lnstontoneous flood 0ows ofdifferent return periods

usi ng WECS.

L compore the dry seqson rneon monthl y fl ows obtoi ned

by IVECS ond N{l P method. l fthe tl ow meosurd ot si te i s

0bout overoge occordj ng to the l ocol peopl e, romp0re

the dry seoson meon moDthl y fl ow obtoi ned by the

WICS method with thot obtoined by the lr'llP method,

ond use the l ower vol ue. Ifthe fl 0w wos meosured ot

11

si t du ng el ther o wetter thon

qverqgr

yeqr or o dri er

thon overoge yeor, then use the volue obtoined by th

WECS mel hod.

Use the llow durorion curve (FDc) to estoblish the

probobi l i ty of exceedonc ofthe vol ue fron step 3. The

FDC i s useful becouse the power qui vol ent ofthe fl ow

con be superi mposed onto i t, so thot i t i s p0ssj bl e l o reod

ofl the omount ofti rne eoch ye0r thot certoi n power

l evel s con be obtoi red. Thi s i s o useful pl onni ng tool ,

oJl owi ng o choi ce ofsi ze ofturbi ne t0 be mod, together

v,/i th 0n i ndi c0ti 0n 0frcqui red vori obl e fl ol v perform-

once ofturbi ne 0nd on i ndj c0ti on ofthe pl onl f0ctor

constroi nts whi ch wi l l resul t from ony portj cul or choi ce

oftu.bi ne si z. Se Rf. l fordetai l s.

Deci de on whct percntoge

ofthe l l ow es(qbl i shed i n

stp 3 cqn be di vfted for power generoti on. l fusi ng a

temporory wei r ossum thot 50% ofrhe 1l 0w corl be

divened. lfthe rive! preselts farmidoble dimculties,

ossume less thon 500/0. If using o permqnent wir

founded on bedrock ossume 954/0 ood for weir bosed on

ol l uvi um foundoti on, ol l ow for seepqge l osses ond

ossume thot 90olo of the flow c0n be drvened.

Toble 2.3 cqnql seepoge losses

N PE OF SOIL SEEPACE LOSS, (lh/1000 n'

OF WETTED AREA)

Rock

Impervi ous cl oy l oom

Medium cloy loom

cloy loom or silty soil

crovel l y cl oy l oom or sondy

cl oy or grovel cennted wi th cl oy

Sondy l oom

Sondy soi l

Sondy soi l wi th grovel

Pervious grove)ly soil

Grcyel wrth some eorth

<0. 5

0.8

-

1.2

1. 2

-

t . 7

1. 7

, 2. 7

2. 7

, 3. 5

3.5 5.2

5.2 6.4

6.4 8.6

8.6

-

10.4

10.4 20.8

5.

6. c0l cul ote seepoge l osses f0r the w0ter conveyonce

structures. Thse iosses must be deducted fr0m the flow

estobl i shed

j n

step 5. Ssepoge col cul oti on i s covered

j n

Secti on 2.5.3.

7. Consi der i ftherc are other rvoter users such os

j rdgotj on

ond drinking water dowlstreom ofth diversion works.

Estobiish th omount of flow that hos to be rleased

downstrrom ond deduct this omount lr0m the 0ow

ifom stp 6. This is the design IIow.

A desi gn exoti pl e i s i nci uded i n Appendi x A.

2.5.3 SEEPAGE

It i . i mperol i ve ro exomi ne l he soi l ol ong the r0ute o[the

proposed conol ond esti mote the omount ofseepoge thot o

cqnol mqy suffer, on imponont issue thot is often overlo0ked by

Dicro-hydro designers. Thls is especiolly trut for micro-

hydropower schemes wi th l ong unl i ned conol s. Tobl e 2.3 gi ves

conol seepoge losses for djffer0nt soil tvpes. By colculoting th

wetted oreo for o gi ven cross secti on ofthe conol , seepoge con

be col cul ofed usi ng doto from the tobl e. [x0mpi e 2.1 i l ]ustrotes

thi s method.

2.6 Otherconsiderotions

2.5.I FLOOD RISK

In si te i nvesti g0l i 0n, the concern i s for the sel ecti on ofthe bst

opti on for the desj gn ofthe scheme. Therefore know)edge of

fl ood l evel s i s i mponont ot the two extremes ofthe mi cro' hydro

scheme, the i ntoke ond the powerhouse, 0r ot other pons ofthe

A 500 metre lorlg unlined heodroce conol is to be con-

structed in sondy cloy to convey o design flow ofO.l m?/s.

A stondord tropezoidol sction is pmposed with o depth

of0.2 m, o bonom width of0.6 m ond side slopes of1:2

(V:H). Colculote the seepoge loss in rhe conol.

Solution:

The wetted perimetr (P) ofth ccnol con be colculoted

using the following equotion:

p =

s + 2 x H x

{ifM(see

chopter4)

=o. o+zxo. 2xVi i TZT

=

1.49m

The wetted dro

: Px L

=

1..19 x 500

=

747 ml

From Tobi 2.1, seepage loss ir sqody clcy is 3.5 lA/1000

m'z ofwetted oreo. Th seepog loss is givn by:

q.,!

=

3.5 x wettd oroi 1000

=

3.5 x 747

/1000

=

2.6

Vs

Which is 2.6% of the designed flow of the conol.

12

scheme thot moy be lulneroble to flood domoge from the river.

Flood lvels moy be prdicted by hydrologicol colculotion

from ovoiloble doto to give the 20 yeor or 50 yeor 0ood level, 0r

by ronsulting locol people. ldeolly, both methods should be used

t0 give 0 relioble estimote. Alwoys cllow o morgin oferror so

thot o rore llood event is ollowed for, ond think rorefully obout

how the floods will olTect eoch ofthe prcposed loyouts for the

proJect. The locotion ofthe poweftouse higher oD o slope will

rcduce the ovnilobie heod ond therfore hcve on importqnt

unpoc on the.opoory ond the economrcs ofthe prqect.

2.5.2 CROSS DMINAGE

Someti mes, because 0fthe n0tur ofthe topogrophy, the

he0dmc conol ond/or the pgnstock olignments will ned to

cr0ss gullies ond smoll streoms. Note thot dry slopes ole more

stobl thqn soturoted slopes. Surfoce woter con be diverted by

conslructing v0rious t)?es of cross droinoge works. For

exomple, cotch droins con be constructed uphill from the

rnicro-hydro olignment to divert th surfoce runoff. Cotch

droins ore smoll chonnels thot divert surfqce runoff(thus cotch

it)qnd diveft it int0 neorby gullies or noturol drqinqge.

Another exomple ofcross drqinoge works is the use ofo

superpossoge. This is o covered heodroc conol orrongement

sudr thot the surfoce runoffllows over it whereos the design

flow is sofely conveyed in the conol.

2.6J WATER RIGHTS

Sometirnes there con be woter use conflicts betwen the

pmposed micro-hydro schme ond other prior uses oFthe source

stnon. For xomple, ifthep is on irrigotion scheme down-

stn0m 0fthe proposed micro-hydro intoke thot moy rceive less

wotI

{once

the micro-hydro plqnt

js

commissioned), thelt will

be conflicts. Such w0rer righrs issues should be rcsolvd beforc

inplementing the micro'hydrc schme.

It sh0uld b notd thqt irrigqtion ord micro-hydro ccn be

c$ordjnoted ifon cgrcment with oll concrned porties is

Rodred in the initiol stoge. This is bcqus inigqtiorL woter is

not ltquind throughout the yeor orld thercfore woter cqn b

usd for power production ot other times. This moy resuit in

less or even no power ovoiloble during peok irrigotion period.

fiowver, ifthe elertdcity users or olso owners ofthe irrigotd

lond, they con prioritise their needs, such os by irrigoting in the

oftemoons ond nights ond producing power duriDg mornings

ond evenings.

2J.{ tiND OWNEnSHIP AND LqND USE

T1I surveyor should note down the issues conceming lond use

ond ownership. Ifthe olignment trqverss thrcugh o formr's

poddy neld, the lond moy hove to be boughr by the prcjct.

Another xomple is thot on open chonnl heodroce moy be

technicolly feqsible but the designer m0y hove to choose o

buried pipe ifthe heodroce olignment is r.rlong cultivoted lond.

Similorly, sediment flushing ond spillwoy flows need to be

sofely diverted owoy from cultivoted lond. It is importont to

note down londowners whose lorld will be used for structures,

so thot ogreements such os leose orrongements cqn be negoti'

oted. These foctors will offect the design ofth schene.

2.5,5 HIGH AITITUDE SITES

These guidlines ore gnrolly opplicoble to micro-hydropower

in Nepol, but some porticulor mosurcs ned to be tokn for

high oltitude sits to ovoid ill'efffects fmm freziDg tempero-

turs.

To 0void frost dom0ge to concrele ond mosonry, th

following meosurcs ore necessory:

. Keep the woter to cement rotio os low os possible,

prferobly not mole thon 0.50.

. Avoid oggregot with o lorye moximum size, or o lorge

proportion of fl ot porticles.

. Use o woter reducirg oir entrqining ogent (plosticiser).

. Ensure good compoction.

. Do not build while night temperutufts ole below

freezing. Surfoces must be prevented from drying out

for ot leost three weel6 ifthe ombient temperoture is on

qverog

5oC or less.

To ovoid ice domoge to conols ond structurcs, the woter

foce of wolls should b smooth concrete or plostred mosonry

oDd i ncl i ned ot 0pproxrDotel y l :1. The expondi ng i ce con then

ise between the wolls, instod ofpushing the wolls aport.

Heodrqce c0nols should be designed for o minimum

velocity 0f0.6 m/s. Evn though the surfoce mcy frceze, woter

will flow under the ice.

The rop ofrroshrqcks should be below ony expcted ice

lev1, to ovoid ice forming oround the troshrock bors. Timbr

trsshrock bors moy b less lioble to icing thqn steel bors.

Th foundotion lvel of structures should be below the

deprh of ground freezing. This is )ikely to be obout one metr

depth.

2.7 Plonning

Th plqnning ofcivil engjnering works lor lorg projects is 0

complex process ond the skills Iequired ore considered to be o

seporote disciplin within the fild ofcivil enginee ng. The

reqson thot plonning is given so much importonce ir th0t the

project construction cost con be significontly brought dowr by

13

emcient co-ordinqtion of lobou! quipment ond motriols. This

eruurs thot the Esources orc used ot their moximum prcduc-

tlury

As mentioned eorlir. the plonning ofmicro'hydro civil

work does not rcquire the detoiled work oflorge prcjects-

However, the principles orc the sqme ond corc needs to be tqken

to follow some bqsic rules. The pmcess ofconstructing micro-

hydro civil works hos three ports:

. Unde$tandingwhot hos to be built

. Estoblishingthemethod, quipment ond the pople

required

. Corr!'ng outthework sofly, economicolly ond to the

quolity rquircd to sotisry th clint.

"Ihe

undentondingpqrt ofthe prccss sounds stroightfor-

word, but it should not be overlookd. civen the likely number

ofpeople involved, effective commumcotion ord cleor demqrco-

tion of responsibilities ore essentiql in plonning. Everyone

needs to lanow whot they ore occountoble for ond to whom.

There orc a number offoctors offecting hoq when ond in

whot order the work con be corried out. A checklist of these

foctors is os follows:

. Performonce ofstoff, quipment ond moteriols.

. Avoilobility of stoff, equipment ond moteriols.

. Holidoys ond festivols.

. Access to the site.

. Weother, seosons.

r Avoilobility oftunds.

. Sit geology

qnd

topogrcphy.

. Existing use ofthe site

qnd

its boundories.

. Public relotions.

PRporing o

"Project Implementotion Chort" in the

initiol stog is olwoys helpfr.[ since it will indicote whot

octivities ore in th criticol poth ond ollow for plonning

qheod.

Undoubtedly, such o chort wiU undergo frequent revision

du ring the construction phose- However, it is stil helpful to

formulote o chort ord moke chonges os necessqry since it con

be used to monitor the progress of work ond plon for futurc

octivities such os proculmellt ofconstruction moteriols ond

lobour orlqngements. A typico] implementotion chort is

showninFigure 2.5.

Activity Durqtion in months

1 2 3 4 5 6 7 8 9 10

Public relotionsi oworeness roisino

il

D

Site survey including lowflow

meosurement & dotq processing

I

Detoileddesign s

Finoncing

Tendering ond oword of

construction contrqct @6weeks

A n

Fobricotion & supply ofsteel ports

(penstock, troshrocks, flush pipes etc.)

construction of heqdroce cqnql o N

Construction of settlino bosin & forebov N

Construction of mosomy wol & gully crossing s F T

Insto.llotion ofpnstock & construction of

onchorblocks & support pie$

o E

Fobricotion & supply oftuftine. beh drive

ond otierelectrGmechonicol eouiDment

s

Instollotiol of tronsmission Iine N T A

Powerhouse construction T I

Electrcmechonicol instollotion

qt

powerhouse

Testing & commissioning A

Projct hondover to the client L

Figure 2 5 A rwicol Prolect lJnplemcnlohon Chon

74

2.E Checklist for site selection

IAND OWNERSHIE LAND USE A,I!D WATER RIGIITS

H0ve 0ll issues concrning lond use ond owlership been duly

recorded during the srte visit? Does the olignment troverse

through o former's poddy field or is

jt

olong bqmn lqnd? Hove

woter rights issues such os irrigotion use ben odequotly

oddressed?

INTAXE

Moke sure woter con be diverted

qwqy

from tie river ond

towqrds the heodroce. Does the river course oppeor stoble or

does it look like it will meonder? Think obout floods ond flood

levels. Does lhe rivr corry l0rge boulders? Ifso, think obout

temporory diversion works r0ther thon o permonent wir.

GRAVU, TRAP

Does the river c0rry o sigflificont omount ofgrovel during the

monsoon? If so provid 0 grovl trop os close to the heodworks

0s possible. Con rhe grovel be eosily flushed into the stlom or 0

neorby gully from the grovel trqp?

SETruNG BASIN

'this

stucture should be locoted

qs

close to the intoke

qs

possible. The e0rlier the sediment is removed the less rhe

mohtenonc in the heodrqce. Ifthe source river is not for owqy

tle sedimenr c0n be dischorged bock into ir.

IIEADRAG

Il generoJ the heodroce olignment should be on level to slightly

doping ground. Ifthe olignmnt is step, corsider using o

hodroce pipe insteod ofo conol. Try to get the olignment owoy

ftomtbe river os eorly os possible to minimis llood domog.

Pmvide escopes upstreom oforeos where the conol might be

blocked by lorddides. tfseepoge fiom the heodroce cqnol con

triggr londdides, think obout hning the conol or using pipes.

FONBAY

Allowonce shonld be mode for finol settling ofsediments.

Gnerolly. this structurc should be locqted

just

uphill ofthe

tr0nsition 0reo whete the ground profile chonges from Ievel to

step, ts thIe o possibility to sqfely dischorge the nt[e flow

ftom o spillwoy in cose ofsystem m0lfunctiol?

PE{STffX

Tle pNtock olignmenr should stort where the ground profil

gets steeper. An ideol ground slope would be between 1:1 ond

'l:2

lV:H).

The Ilqtter the ground slope, the less economrc is rhe

ptrsto&.lt is dimcult to mqnuolly loy penstock, construct

support piers ond onchor blocks ifthe slope is greqter thon 1:1.

Also try to minimise bends since thse will require odditionol

onchor block.

POWERIIOUSE

Moke sule thot ther is enough spoce for o powerhouse with the

requiftd dimensions (to fit the electro-mechonicol equipmnt)

ot the loc0tion selcted. Excqvotion con be minimised by

locoting the powerhouse on lvl grcund. Think obout wher

the toilwoter con be dischorgd (i.. tolhoce olignment).ls the

powerhouse high enough obove the river to be sofe from floods?

IAII,RACE

Moke sur thot th t0ilroce is protected fiom the streom into

which woter emerging from the turbine is dischorged. The

toihoce should be oriented downstreom to prevent floodwqter,

debris, ond bed lood from being funnelled into it toword the

powerhouse.

TR,qNSIItrSSION UNES

ls the vlllqge situoted owoy from the powerhouse site? lfso,

tronsmission lines 0re requipd. The cost oftronsmission lines

Photo: 2 3 A Stroight pnstock run keeps costs to o mininum

15

qdds

significondy to the overcli cost ofo scheme. Consult Ri I

for dioiis.

AVAII.IIBIIIIY OF COI{STRUCTION

MATERIALS AND IIAOUR

Constructiorl mdtriols for micro-hydro schemes thot m0y be

fould at site ore sond, cagregote ond stons. Arc thes mcte

-

ols eosily avoilobl 0t site or brought fronl outside? AIe skilled

lobourers such os mosons cnd carpenters ond ulskilled

lobourcrs ovoilabl at site?

The unit rotes for such construction moteriols ond lobour

should be obtoined while ot site for esrimoting quonritjes ond

cost ofthe scheme duing the design phose. It is more Ielevont

to use prcvai l i ng rotes rother thon di strj ct rotes, whi ch ore

norrnol ]y l ower thon the prev0i l i ng r0tes.

STAB!UTY

Apon from the obove criterio, it is very impofiont for the entire

scheme to be 0n stobl e ground. Ifonl y o smc)l l ength ofthe

0l i gnment i s unstobi e i t m0y be possi bl e to stobi hse i r. Refer to

S0ct r on 2. 4 0nd Chopr er 9 r o 0sseqs l hi s

j ssue.

3. Diversion works

3.1 0verview

The divfiion works for o micro-hydropower schme control

the flow 0fr{oter frcm the source river into the heqdroce.

ThE c0mp* o di versi on wei r (usuol l y). on i ntoke, ond

s0metunes nver troiDing works. The diversion works ore pqrt

oftheheodworks,

qnd

serve the foLlowing functions:

. m0intoin the design 0ow with nominol heod losses

during both monsoon ond dry seosoDs;

.

!rcvnt,

or 0t leost minimise, th bed lood ond other

flo0ting moteriols (ice, timber, leqves etc.) entering th

conol;

. sofely cont0in pe0k flows ir the iver ond owoy from

th micro-hydro systm so thot domoge is not coused

to th structures.

'Ihe

principol mointenonce t0sk ossocioted with cjvil

works is oftenthe removql ofsediment orld debris conjed by

$e incoming woter, which con couse domoge to the turbines

should itbe pemifted t0 enter rhe penslock. It is therefore

tlsgltiol th0t the odapted intoke design prevents sqnd, bed

lood ond debris irom entering the intoke os much os possible.

one ofthe p nci pol couses ofprobl ems i n the operoti on

ofhydroporver schemes i s o poorl y desi gned i ntake whi ch moy

permi t oper0ti on ofth schem i n the shon' term but beyond

thot. cous seri ous domoge to the system. The desi gn ofon

oppropriote intok structure for micm-hydrc in Nepol requires

on odequoi understonding of Himoloyon riven since they

h ' v , < ^ m, , , n i . ' , , f , n r ' , r , c

3.2 Generol principles for

selecting intqke locqtion

The mojor considerqtions requird to select 0ppropridte intok

locotiols ore disaussed in this section. It is imponqnt for the

design enginer to rolis thst much con b lomed from

observing the irrigotion intoke sites selected by locol formers.

The forDers ore fomili0r with the rivem ond hove the odded

odvontoge thot they hove observed them over c long period of

ti ne. In foct, some of the former monoged i rri goti 0n schemes

in Nepol or more thon 100 yeors old ond the intokes ofsuch

17

sites hove foced most problens brought

qbout

by Himoloyon

rivers.

The following princrples should be considered whiie

selecting oppropriote intoke locotLons:

Minimol disturbs,ncc to the nstursl stste ofthe iver

Constructi on ofhi gh ond permonent wei rs

1l o!gr

thqn 1' 2 m)

ocross the totol width ofthe dver is gnerolly ufldesiroble,

becouse domming hos the eflect 0fropid sedimnt deposition

ond chonge ofpresent ri ver course,l eovl ng the l ntoke dry ond

useless. The design ond construction of weirs requires coreful

considerotion to

qvoid

preserltinq on obstocle to flood flow in

the roiny seoson. F0r diversion from o noturol pool, no weir is

required ond woter con be conveyed through HDPE pipes 0r o

covered mosonry flume t0 o heodroce conol.

For this reoson, ottempts should be made to locote

intokes such thot the noturol woter level ot low flow in the

strcom is suitoble for the intoke level ofthe con01. This will

ollow the conol intok structure to be built ot stream level ond

the onJy meosures necssory within the streom or river bed

itselfore meosures for th stobilisoti0n ofthe

present stote of

the streom.

Locotion in on srea which offers nsturol prctection

When withdrowing wotr from o streom whose level moy

increose morkedly dudng roiny periods, it is desiroble to locote

the intoke behind or under lorge, permonently plocd boulders

or rcck, these limit the woter thot con enter the intoke, ond

deflect flood flows ond river borne debris owoy. Advontoge con

olso be roken ofstoble bonl<s 0nd rock outcrops.

Lnation on the oubide ofo bcnd

Therc is o noturol tendency ofthe ver to deposit sediment on

the inside ofbends olong th ive. At bends, the direction 0lrh

flqw closst to the river bed chonges compored wjth the sudoce

flow. A spircl flow forms, which tronsports the bed 10od to the

inner side ofthe river bend. On oll streoDs ond rivers it c0n be

observd thot grovelond sand bonks form ot the inside bend,

i.e. the bed loqd is dive(ed from the deflecting bonk. As o rcsult

ofthis when the river flow dcreoses, the river width decrcoss

from the inside ofthe bend. Therefore cn intoke should not be

si ted on the i nsi de ofo bend. To mi ni mi se sedi ment l oqd ond to

ensure flow

(tvoilqbility

during the dry season, on intqke should

be si ted on the outsi de ofo bend. The best l ocati on i s about 2i 3

t0 3/4 ofthe di stonce oround the bend or l he outsi de

qs

shown

in Figur 3.1. Shorper bends orc more effective in preventing

i he entry of sedi ment, and the omount 0fbed l ood tronsported

into the conol decreoses os the diverted proponio[ ofthe totol

flow ln the dver decroses.

FLgure l-1 Locoting intoke oround o bnd

other considerations

In stroight sections of0 iver, the water flows poro)lel to the

bonks

qnd

the bed lood is transported olong the bottom.

Thefelore iIl stroight sectians the locqtion of the intoke is

governed by foctors such os bcnk stability and heodroc

ol l gnment.

Ih locqtion ofqn iltcke structure must be so chosen

thot th lorgest p0ssible ponion afrhe bed load remoins in the

river ond is not dive(ed into the hecdrcce. Howvec even c

good intoke lvill not exciude oll sediment; lhe grovel trqp cnd

sel tl i ng bosi n [unher ol ong the conql

(ompl te

thi s.

3.3 tntoke locqtion in relotion

to river chqrocteristics

3J.1 CHARACTERISTICS OF HIMAJ.AYAN RIVERS

In Nepol, most micrc'hydropower schemes ore locoted in the

foothills ofthe Himolqyon Ronge. This includes the High

Mountoins, Middle Mountoins ond the Siwqliks os shown in

Fi gure 3.2. It i s essenti ol to hqve

q

cl eor understondi ng ofthe

chorocteristics of these Himolqyon rivers beforr opprooching

tbe design ond construction ospects ofdiversion works. These

ri vers fl ow i n geol ogi col l y young mountoi n structuEs ond con

be choroctedsed os follows:

steep river grodient ond steep slopes olong both river

bonks;

Hi gh degrce ofconti nui ng ercsi on 0nd sedi ment

rr0nsporT;

Sm0l l r streqms of steep ond unstobl e noture wi th o

boul dery ol )uvi ol bed;

Ii 0bl e to tronsport consi derobl e quonti ti es ofsedi rnent

r ncl udi ng boul der s dur i ng l he monso0n; .

A significont flow ond sdjment incrcose in the rivers

du ng the monsoon.

Due to these u!ique choroctristics, development of

hydropower from the Himoloyon rive$ prsents grcot chol

Figur 3.2 Feosible locotions of mrcro-hydro schemes in Nepol

lenges. Design ond c0nstruction ofoppropriqte structures to

cope with movement 0f lorge boulders

qnd

high sediment

loods ore two ofthese chollenges. River intokes used elsewhere

in nlotively flot ond stoble rivers including the Teroi ore

inoppropriote in the cose of mountqin rivers of Nepol.

Ioble 3.1 Cotegories of Nepolese rivers

Rivers in Nepol con be categorised occording to the woy

in which they ore influenced by vorious chorocteristics. The

types of river thot sre mostly utilised in micro-hydro ore shown

in Tqble 3.1.

TYPE GMDIENT

(MArN LOCATToN)

VALLEY SHAPE BED MATERTAT CHANNEL PATTERN SEDIMENT MOVEMENT

(N: NORMAL, F: FLOOD)

1A very steep

(Mountqins)

Norrow volley no

flood ploins

Rocks, very lorge

boulders

Si ngl e N

-

Sond in suspension

F

-

ravel. cobbles

qnd

boulders

IB Steep (Mountoins

ond hill regions)

Norrow volley,

irregulor norrow

fiood pioins

Rocks ond bouiders,

grovel ond cobbles

in shools

One moin plus flood

byposs chonnel

N

-

Sond ond grovel

F

-

Includes cobbles

qnd

smqll

boulders.

ic Steep (Mountoins

ond hill regions)

Norrow volley,

irregulor norrow

flood ploins

Rocks ond boulders,

grovel ond cobbles

in shools

Severol octive chqnnels

os well os floodwoys.

N

-

Sqnd ond grovel

F

-

Includes cobbles ond smqll

boulders.

A

,$

{

ry

Intermediote

(Hill regions)

Outwosh river,

confined by

volley sides

Some boulders,

moinly grovel

qnd

cobbles

Single plus limited

floodwoys

N

-

Sand ond fine to medium

grovel

F

-

Includes coorse grovel,

cobbles, perhops smqll boulders.

28. Intermediote

(Hillregions)

Ditto but less

confined volley

Some boulders,

moinly grovel

ond cobbles

24 octive chonnels

with floodwoys

N

-

Sand

qnd

fine to medium

grovel

F

-

Includes coorse grovel,

cobbles, perhops smoll boulders.

2C. Intermediate

(Hill regions)

Ditto but wider

volley

Some boulders,

moinly grovel

ond cobbles

Broided, severol octive

floodwoys.

N

-

Sond ond fine to medium

grovel

F

-

Includes coorse grovel,

cobbles, perhops smoll boulders.

Soune: Ref.5

19

33.2 EXAMPLE INTAXf,S

'typicol

intoke locotions for some ofthse rivers ore shown in

Figures 3.3 ord 3.4. It should be noted thot these ligures

illustrote only possibl locotions for iltoks, not the prefened

rype ofintoke.

fijver type 1A

Mountoin rivers of Type 1A prcvide fovouroble conditions for

intokes in trms ofpermonence

qnd

lqck ofinterference from

sdiment irl normol conditions.

Iigure 3 3 Slung ofinlokes rn mountoin rive6 ofType lA

(Soufte: ReL 5)

Nver

We

1B

Int0kes on Type 1B rivers con olso be locoted similor to 1A.

However. these riv6 provide o greoter choice ofintoke site, ond

prmit more permonnt irtok structurcs, either ftom the side

ofthe chqnnel or os

qn

ongld or frontol inroke built inro the

chonnel It is often possible to protect the intoke behind o rock

0utcr0p.

fjver

We

lC

Intoke selection in these rivn differs from 1A ond 18 oDly in

rcqui ng contrcl of one or more of the chonnels in order to

ensur thqt sumcient flow reochs the intoke. A possible

orrongment is shown in Figurc 3.4.

Figure 3-4 Siting ofintoke in mouDtoin or step hill rivers ofType lC.

(Soufte: Ret. 5)

crsvel bed rtvers

These or cotegory 2 rivers (2A, 28 & 2C) which hqve less steep

chonnels compord to cotegory 1 types. The riverbeds ore

moinly ofcobbles ond grovel, togther with some boulders.

Intoke siting follows the some generol principles os in cotegory

]. However, these vers provide more flexibiliry For exomple, it