Professional Documents

Culture Documents

Designing Belgian Ales: Guidelines for Successful Homebrewing

Uploaded by

zpervan10 ratings0% found this document useful (0 votes)

185 views12 pagesThis document provides guidelines for homebrewing three Belgian ale styles: Abbey ales (dubbels and tripels), wit beers, and lambics. It discusses key characteristics and recommended ingredient percentages and processes for each style. For abbey ales, it recommends Pilsner malt as the base with sugar and color malts added. For wit beers, it suggests using wheat as the primary grain along with Pilsner malt and optional spices. Process details like mash temperatures and hopping schedules are also provided.

Original Description:

Belgian Ale

Original Title

Belgian Ale

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides guidelines for homebrewing three Belgian ale styles: Abbey ales (dubbels and tripels), wit beers, and lambics. It discusses key characteristics and recommended ingredient percentages and processes for each style. For abbey ales, it recommends Pilsner malt as the base with sugar and color malts added. For wit beers, it suggests using wheat as the primary grain along with Pilsner malt and optional spices. Process details like mash temperatures and hopping schedules are also provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

185 views12 pagesDesigning Belgian Ales: Guidelines for Successful Homebrewing

Uploaded by

zpervan1This document provides guidelines for homebrewing three Belgian ale styles: Abbey ales (dubbels and tripels), wit beers, and lambics. It discusses key characteristics and recommended ingredient percentages and processes for each style. For abbey ales, it recommends Pilsner malt as the base with sugar and color malts added. For wit beers, it suggests using wheat as the primary grain along with Pilsner malt and optional spices. Process details like mash temperatures and hopping schedules are also provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Page 1 of 12

Designing Belgian Ales

Daniel Morey

November 2001

Belgian ales are an eclectic collection of brews. From light easy drinking session beers to hearty winter

warmers, Belgians have it covered. From yeast to bacteria, Belgians have it covered. Belgian ales offer

the home brewer latitude to experiment, and plenty of opportunity to explore a vast spectrum of flavors,

aromas, and ingredients.

In this paper, I hope to provide you with a set of guidelines for successful Belgian brewing. The

suggestions presented are primarily based upon the common trends found in recipes that have previously

won medals at the National Homebrew Competition. Inf ormation has also been gather from articles in

Zymurgy, the Classic Beer Series, and other texts found on the internet such as the Homebrew Digest.

The styles that will be presented are: Abbey ales (Dubbels and Tripels), Wit beers, and Lambics.

Abbey Ales

In general, abbey ales are top fermented and bottle conditioned. They include the Trappist ales, dubbels,

and tripels. Most exhibit a soft malty profile with a sweet finish. Fruity and phenolic character from the

yeast may be present. Hop character should be subdued. Of course there are exceptions such as Orval

(which is one of my favorites). Most are highly carbonated with levels between 2.0 and 3.5 volumes.

The two main subclasses of abbey ales are dubbels and tripels. Not all brewers label their beers as

dubbels or tripels. Some better known examples are Westvlettern 4 (dubbel) and Chimay Cinq Cents or

Blanche (tripel).

Dubbel

Vital Statistics:

Original Gravity: 1.063 - 1.070*

Final Gravity: 1.012 - 1.018

Alcohol: 6.0 - 7.5% v/v*

IBUs: 20 -35

SRM: 10 - 20

* Guidelines from Belgian Ale by Pierre Rajotte. BJCP guidelines are 1.040 -1.080 and 3.2 - 7.8% v/v.

Pilsner malt (or pale malt extract) should form the backbone of the grain bill. Pilsner malt should comprise

between 80 and 90% of the total grain bill (including copper sugars). Toasted Belgian malts such as

aromatic and biscuit are popular as substitutes for a portion of the base pilsner malt. The combination of

biscuit and aromatic malts should be limited to 10% or less (count these malts towards the base malt

percentage). Sugar is a key ingredient in dubbels. Sugar helps keep the malt balance correct. Without it,

the resulting beer would resemble a dopplebock or barley wine. Sugar comprises between 6 and 9% of

the total grain bill (0.75 - l.0 lb per 5 gallon batch). Dark candi sugar is the sugar of choice. Ordinary table

sugar can be used, but more col or malts wil l be required to get the correct color. Color malts shoul d make

up the remaining 4 - 14%. Special B (~100/L) is an excellent color malt for dubbels. Special B contributes

a plum flavor that is prevalent in dubbels. Other popular color malts are CaraMunich, CaraVienna, crystal

20-60/L, and brown malt. Ive also seen Munich malts used in Dubbel formulations. Dark roasted grains

such as chocolate malt, black patent, and roast barley should be avoided.

Page 2 of 12

Pilsner, Pale malt, or pale extract 80 - 90%

Aromatic or biscuit malt Up to 10%

Sugar (Dark candi sugar or table sugar) 6 - 9%

Color malts 4 - 14%

The mash should be relatively thick (1 to 1.33 quarts per pound of grist). A single temperature infusion

around 151/F for 60 to 90 minutes is sufficient. Mash out at 170/F for five minutes.

A boil time of 90 minutes or longer is recommended. Add sugars during the boil. Stir the wort until the

sugar is dissolved or you may end up with burnt sugar on the bottom of your kettle (worst yet, ruin the

batch)!

An average of 0.29 bittering units per gravity unit is recommended with a range of 0.20 to 0.36 BU:GU.

With this ratio, most dubbels will fall between 18 and 25 IBUs with most example towards the lower end of

the range. Bittering and aroma hops should be used for this style. Preferred varieties and bittering

fractions are li sted below:

Recommended Hops:

Bittering hop additions: Styrian golding, Hallertauer, Tettnager

Aroma hop additions: Saaz and Hallertauer

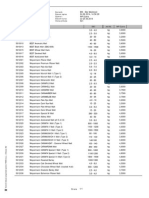

TABLE 1: Dubbel Hop Schedule

Bittering Flavor Aroma Dry

Option % minutes % minutes % minutes oz/gal

1

98 - 99 60 - 80 n/a n/a 1 - 2 1 - 2 n/a

98 70 - - - - - - 2 2 - - -

A good quality Belgian yeast should be used. Fermentation temperature in excess of 75/F should be

avoided. Fermentation temperature between 60 - 70/F are optimum for most of the Wyeast and White

Lab offerings. Wit beer yeasts is not recommended.

Tripel

Vital Statistics:

Original Gravity: 1.070 - 1.095*

Final Gravity: 1.013 - 1.020

Alcohol: 7.0 - 10.0% v/v

IBUs: 20 -35

SRM: 3.5 - 6

* Guidelines from Belgian Ale by Pierre Rajotte. BJCP guidelines are 1.065 -1.095 and 6.3 - 10.0% v/v.

Again, Pilsner malt (or pale malt extract) should form the backbone of the grain bill. Pilsner malt should

comprise about 90% of the total grain bill. Like dubbels, sugar is a key ingredient. Sugar should make up

the remaining grain bill (1.5 to 2.0 lbs per 5 gallon batch). Light candi sugar is the traditional choice, but

ordinary table sugar works just fine. Dark candi sugar can darken the beer beyond the style guidelines.

For this reason dark candi sugar is not recommended.

Pilsner, Pale malt, or pale extract ~90%

Page 3 of 12

Sugar (Light candi sugar or table sugar) ~10%

The mash should be relatively thick (1 to 1.33 quarts per pound of grist). A single temperature infusion

around 151/F for 60 to 90 minutes is adequate. Mash out at 170/F for five minutes.

A boil time of 90 minutes or longer is recommended. Stir the wort while adding the sugar. Continue

stirring until the sugar is dissolved.

An average of 0.38 bittering units per gravity unit is recommended with a range of 0.30 to 0.45 BU:GU.

Wi th thi s rati o, most tripels wil l fall between 27 and 36 IBUs. Unli ke dubbels, tripels have a vari ety of

hopping schedules. Even though option 3 presents aroma additions, this is not typical. Usually tripels will

use bittering and flavori ng additions only. Preferred vari eties and bi tteri ng fractions are li sted below:

Recommended Hops:

Bittering hop additions: N. Brewer, Willemette, Hallertauer, Styrian golding

Flavoring hop additions: Saaz and Willemette

Aroma hop additions: Saaz

TABLE 2: Tripel Hop Schedules

Bittering Flavor Aroma Dry

Option % minutes % minutes % minutes oz/gal

1

88 - 93 60 - 80 7 - 12 10 -15 n/a n/a n/a

92 60 8 13 - - - - - - - - -

2

100 35 - 50 n/a n/a n/a n/a n/a

100 40 - - - - - - - - - - - - - - -

3

98 - 99 60+ n/a n/a 1 - 2 1 - 2 n/a

99 85 - - - - - - 1 1 - - -

The same yeast recommendations from dubbels apply.

Witbier

The first thing you notice about wit beer is its cloudy almost white color. This due to the high portion of

wheat, usually unmalted, used in the grain bill. The specific yeasts that are used also contribute to the

appearance. These yeasts are also responsible for the mild acidity that is present. Spices, malt, and

wheat should dominate the aroma. Hop aroma should be minimal. Beside hops, spice such as coriander

and bitter orange peal are often used to flavor the beer. These beers are lively and have high carbonation

levels (2.0 - 3.0 volumes).

Vital Statistics:

Original Gravity: 1.042 - 1.055

Final Gravity: 1.008 - 1.012

Alcohol: 4.2 - 5.5% v/v

IBUs: 15 - 22

SRM: 2 - 4

Page 4 of 12

Wit beers use a high proportion of wheat in their formulation, but Pilsner or pale still makes up the

backbone. Pilsner or pale malts should make up 50 to 60% of the grain bill. The remaining grain bill is

comprised of mainly wheat, but can include other grains such as oats and rye. Raw or flaked wheat is the

traditional choice. White varieties are preferred over red varieties. Wheat malt, while not traditional, is an

acceptable substitute. If you choose to use oats or rye, the combination should be limited to 10% or less

of the total grain bill (count these grains towards the wheat portion of the grain bill). If making wit beers

from extract, a 50:50 combination of pale and wheat extract should be used. Unlike the abbey beers,

sugar is not commonly included. If you do choose to add sugar, keep it below 5% of the grain bill.

Pilsner or Pale malt 50 - 60%

Flaked wheat, raw wheat, or wheat malt 40 - 50%

Oats and/or rye Up to 10%

Sugar Less than 5%

For all grain f ormulations, a step inf usion or decoction schedule should be followed. A thin mash with

between 1.5 and 2 quarts of water per pound of grist is recommended. Start with a protein rest between

117 and 126/F for about 45 minutes. Raise the mash temperature to saccrification (151 - 153/F). Hold

this temperature for 45 minute to one hour. Mash out at 170/F for five minutes.

A boil time of 90 minutes or longer is recommended.

An average of 0.40 bittering units per gravity unit is recommended with a range of 0.33 to 0.48 BU:GU.

With this ratio, most wits will fall between 17 and 22 IBUs. Preferred varieties and bittering fractions are

l isted below:

Recommended Hops:

Bittering hop additions: Saaz or Goldings

Flavoring hop additions: Saaz or Goldings

Aroma hop additions: Saaz or Goldings

TABLE 3: Witbier Hop Schedules

Bittering Flavor Aroma Dry

Option % minutes % minutes % minutes oz/gal

1

94 - 98 60+ n/a n/a 2 - 6 1 - 5 n/a

96 60 n/a n/a 4 3 - - -

2

65 -75 60+ 25 - 35 10 - 15 n/a n/a n/a

70 60 30 12 - - - - - - - - -

As mentioned, spice are often used to flavor wit beers. The most frequently used spices are coriander

and bitter orange peal. Use bitter orange peal at a rate of 0.04 to 0.07 ounces (1 - 2 grams) per gallon.

Add the bitter orange peal during the last 20 minutes of the boil. Use between 0.15 and 0.20 ounces (4 - 6

grams) of ground coriander per gallon. Coriander should be added in the last 5 minutes of the boil. Other

spices have been used to give each brewer their own unique signature. Examples of other spice that

have found use are: Cumin, cardamom, anise, and black pepper. These extra spices should be used in

limited quantities and should remain far in the background. As with the other spices, they should be

added at knockout or duri ng the last 5 mi nutes. See summary bel ow:

Bitter orange peal 0.20 - 0.35 ounce (5 - 10 g) for final 20 minutes for 5 gal

Page 5 of 12

Coriander 0.65 - 0.80 ounce (20 - 24 g) for final 5 minutes for 5 gal

Others <0.20 ounces (<5 g) at knockout for 5 gal

Belgian wit yeasts are preferred, but German wheat yeast can be used. If using a German wheat yeast

keep temperature toward lower end of the fermentation range to minimize the phenolics (clove) produced.

American wheat yeast will not produce the mild acidity necessary for wits.

Lambics

Lambics are truly unique beers. When comes to making lambic style beers you can forget most of rules

you have learned about home brewing. True lambics come from a ten mile area surrounding Brussels.

By decree they must contain at least 30% unmalted wheat and must be spontaneously fermented. But

you dont have to follow these laws if you want to brew a good lambic style beer.

What makes lambics so different? Three primary differences distinguish lambics from all other beers.

First all are the products of spontaneous fermentation. All have an acetic aroma and sour flavor. Several

microflora are active to produce the eclectic mix of organic acids that create these aromas and flavors.

The diverse microflora at work require a wort rich in carbohydrates which includes unconverted starches

which is the second major difference. The last major difference is the use of old (two to three years) hops.

Oxidation degrades the available alpha and beta acids. Minimal hop character is extracted, but the

preservative qualities are realized.

Lambics are grouped into three groups: Gueuze, Fruit, and Faro. Gueuze is a mixture of old and new

lambics. Gueuze tends to be highly carbonated. The color ranges from golden to honey brown. They

are void of hop bitterness and a rather winey or cidery aroma is predominate. The flavor is acidic.

Vital Statistics:

Original Gravity: 1.044 - 1.056

Final Gravity: 1.006 - 1.012

Alcohol: 4.7 - 5.8% v/v

IBUs: 10 - 15

SRM: 4 - 15

The two classic fruit lambics are: Kriek and framboise. Other fruits are coming into use such as peaches,

strawberries, kiwi, etc... The profile of fruit lambics vary greatly with some sweet and others sour. Color is

largely determined by the fruit used. They are made from the same wort as gueuze.

Page 6 of 12

Vital Statistics:

Original Gravity: 1.044 - 1.056 (plus fruit)

Final Gravity: 1.008 - 1.016

Alcohol: 4.7 - 5.8% v/v

IBUs: 10 - 15

SRM: 4 - 15

Faro is a blend of young lambic with another beer or with sugar. Faro is generally cloudy with moderate

carbonation. The sourness is offset by the blended beer and/or sugar that has been added. Color will

vary. There are no BJCP guidelines for faro.

As with other Belgian beers, Pi lsner or pale mal ts are the backbone. Pil sner or pale mal ts should make

up 50 to 70% of the grain bill. The remaining grain bill is comprised of mainly wheat. Raw or flaked wheat

is the traditional choice. White varieties are preferred over red varieties. Wheat malt, while not traditional,

is an acceptable substitute. In nearly half of the recipes reviewed for this paper, some form of crystal or

carapils malts was used. These malts should compose no more than 5% of the total grain bill. Crystal

40/L should be considered the upper limit for dark crystal malts. A small portion (~15%) of the recipes

used sugar in their formulation. Sugar is probably more applicable to those who wishes to try their hand at

faro.

Pilsner or Pale malt 50 - 70%

Flaked wheat, raw wheat, or wheat malt 30 - 50%

Crystal or carapils Up to 5%

Sugar Up to 5%

Due to the residual starches that are necessary in lambic beers, extract only beers are not recommended.

Mash schedules are unique for lambic brewing. The traditional method is known as turbid mashing. This

old method is similar to decoction, but the portion removed is not returned to the main mash. Additional

infusions of hot water are added to the main mash to dilute the enzymes and increase temperature for

each rest. Those who are interested in turbid mashing should do further reading in the references listed.

A simpler method used by some commercial lambic brewers is a multi-step infusion. The mash programs

detailed in table 4 should produce a thin wort that contains the necessary unconverted starches.

Page 7 of 12

TABLE 4: Mash Programs for Lambi c home brews

Mash Schedule #1 Mash Schedule #2

Step Temperature Time Temperature Time

1 117/F 15 min 95/F 15 min

2 136/F 15 min 113/F 15 min

3 149/F 15 min 131/F 15 min

4 162/F 15 min 149/F 15 min

5 Bring entire mash to boil and hold for

15 minutes.

162/F 15 min

6 Bring entire mash to boil and hold for

15 minutes.

By boiling the entire mash, starches and tannins are extracted. After the mash sparge with 200/F water.

This higher temperature also extracts the unconverted starches and tannins that the unique microflora will

use.

A boil length of 120 minutes or longer is recommended.

An average of 0.17 bittering units per gravity units is recommended with a range of 0.06 to 0.35 BU:GU.

With this ratio, most lambics will fall between 8 and 10 IBUs. Aged noble hops are preferred. Use the

following values as a rough rule of thumb for calculating alpha acid degradation vs age:

1 year 70%

2 years 50%

3 years 35%

When calculating the weight of hops, adjust the alpha acid percentage by the percentages shown above.

Recommended Hops:

Bittering hop additions: Hallertauer, Fuggle, Saaz, or Tettnager

TABLE 5: Lambic Hop Schedule

Bittering Flavor Aroma Dry

Option % minutes % minutes % minutes oz/gal

1

100 full boil n/a n/a n/a n/a n/a

100 120+ n/a n/a n/a n/a n/a

Lambics require a blend of yeasts and bacteria. The primary organisms besides saccharomyces are

Pediococcus (bacteria) and Brettanomyces (yeast). These can be purchased separately, or as a blend of

yeast with Pediococcus and Brettanomyces. Fermentation can take between 8 months and two years.

For fruit lambics, you will use more fruit than normal for ordinary fruit beers. This is because the flavors

Page 8 of 12

and aroma will degrade with the long aging period required for lambics. The common fruits are: cherries,

raspberries, and peaches. Fruits can be grouped into two categories: mild and assertive. As expected,

mild fruits take more for their character to come through. Mild fruits require about 4 lbs of fruit per gallon

while assertive fruits are usually used at a rate between 1.5 to 3.0 lbs per gallon. Use the whole fruit. Add

the fruit to the fermenter after primary fermentation is complete. Vanilla is often used in fruit lambics. Use

0.2 oz fresh crush vanilla per gallon of finished beer. Add vanilla at the same time the fruit is added.

Mild Fruits (~4lb/gal) Assertive Fruits (1.5 - 3.0 lb/gal)

Peaches Cherries

Strawberries Raspberries

Apricot Blackberries

Mango Passion Fruit

Blueberries

Many people are concerned that equipment used for making a lambic cannot be adequately sanitized and

will contaminate other brews. This is a valid concern for porous items such as airlocks, plastic tubing,

stoppers, racking canes, o-rings, and plastic fermenters. Glass and stainless steel should not pose a

problem when using good cleaning and sanitation practices. If using a corney keg for a fermenter or

dispensing, remember to change to o-rings. Glass bottles can be sanitized with dry heat by placing them

in a oven for 2 hours at 250/F.

Water

The following water profiles have been taken from Dave Drapers web page:

Belgian towns: Ca++ CO3 Cl- Mg++ Na+ SO4

Antwerp 90 76 57 11 37 84

Poperinge 8 528 206 2 380 124

Eeklo 138 255 65 28 115 8

Luik 98 134 142 14 110 14

Brugge 132 326 38 13 20 99

Gent 114 301 38 17 18 84

Willebroek/Rumst 68 143 60 8 33 70

Mechelen 116 330 36 14 16 62

Beerse 41 91 26 8 16 62

Brussels region 100 250 41 11 18 70

Antwerp De Koninck

Popering St. Sixtus, Van Eecke; Belgian hopgrowing region

Eeklo Bios (western Belgium)

Luik (Eastern Belgium)

Willebroek/Rumst Moortgat, makers of Duvel; Palm

Mechelen Het Anker, makers of Gouden Carolus

Beerse Westmalle

All others are from western, northwestern, or central Belgium.

Yeast

The following are commonly available yeast from Wyeast and White Labs. The descriptions and optimum

fermentation ranges are taken from their respective web sites:

Wyeast

Page 9 of 12

1214 Belgian Ale yeast

Abbey-style top-fermenting yeast, suitable for high-gravity beers. Estery. Flocculation medium; apparent

attenuation 72-76%. (58-68

o

F)

1388 Belgian Strong Ale yeast

Robust flavor yeast with moderate to high alcohol tolerance. Fruity nose and palate, dry, tart finish.

Flocculation low; apparent attenuation 73-77%. (65-75

o

F)

1762 Belgian Abbey Yeast II

High gravity yeast with distinct warming character from ethanol production. Slightly fruity with dry finish.

Flocculation medium; apparent attenuation 73-77%. (65-75

o

F)

3463 Forbidden Fruit yeast

From classic Belgian brewery for production of wits to classic grand cru. Phenolic profile with subdued

fruitiness. Seasonal availability. Flocculation low; apparent attenuation 73-77%. (63-76

o

F)

3522 Belgian Ardennes yeast

One of many great beer yeasts to produce classic Belgian ales. Phenolics develop with increased

fermentation temperatures, mild fuitiness and complex spicy character. Flocculation high; apparent

attenuation 72-76%. (65-85

o

F)

3787 Trappist High Gravity

Robust top cropping yeast with phenolic character. Alcohol tolerance to 12%. Ideal for Biere de Garde.

Ferments dry with rich ester profile and malty palate. Flocculation medium; apparent attenuation 75-80%.

(64-78

o

F)

3942 Belgian Wheat yeast

Estery low phenol producing yeast from small Belgian brewery. Apple and plum like nose with dry finish.

Flocculation medium; apparent attenuation 72-76%. (64-74

o

F)

3944 Belgian Witbier yeast

A tart, slightly phenolic character capable of producing distinctive witbiers and grand cru-style ales alike.

Alcohol tolerant. Flocculation medium; apparent attenuation 72-76%. (62-75

o

F)

3278 Belgian Lambic blend

Contains a selection of Saccharomyces cerevisiae which include Belgian style wheat beer yeast, sherry

yeast, two Brettanomyces strains and Lactic Acid Bacteria. While this mixture does not include all possible

cultures found in Belgian Lambics, it is representative of the organisms which are most important for the

desirable flavor components of these beer styles. Individual components available from this blend are

numbered below. Flocculation low to medium; apparent attenuation 65-75%. (63-75/ F)

3112 Brettanomyces bruxellensis

Wild yeast isolated f rom brewery cultures in the Brussels region of Belgium. Produces the classic sweaty

horse hair character indigenous to beers of this region; gueuze, lambics, sour browns. Ferments best in

worts with lower pH after primary fermentation has begun. This strain is generally used in conjunction with

S. Cerevisiae as well as other wild yeast and lactic bacteria. Produces some acidity and may form a

pellicle in bottles or casks. Generally requires 3-6 months aging for flavor to fully develop. Flocculation

medium; apparent attenuation low. (60-75/ F)

3526 Brettanomyces lambicus

Page 10 of 12

Wild yeast isolated f rom Belgian lambic beers. Produces a pie cherry like flavor and sourness along with

distinct brett character. Ferments best in worts with reduced pH after primary fermentation has begun, and

may form a pellicle in bottles or casks. Works best in conjunction with other yeast and lactic bacteria to

produce the classic Belgian character. Generally requires 3-6 months of aging to fully develop flavor

characteristics. Flocculation medium; apparent attenuation low. (60-75/ F)

4335 Lactobacillus delbrueckii

Lactic acid bacteria isolated f rom a Belgian Brewery. This culture produces moderated levels of acidity

and is commonly found in many types of beers including gueuze, lambics, sour brown ales and Berliner

Weisse. Always used in conjunction with S. cerevisiae and often with various wild yeast. (60-95/ F)

4733 Pediococcus cerevisiae

Lactic acid bacteria used in the production of Belgian style beers where additional acidity is desirable.

Often found in gueuze and other Belgian style beer. High acid producer which usually increases overall

acid levels in beer as storage time increases

White Labs

WLP400- Belgian Wit Ale Yeast:

Slightly phenolic and tart, this is the original yeast used to produce Wit in Belgium.

Attenuation: 74-78%

Flocculation: Low to Medium.

Optimum Fermentati on Temperature: 67-74 F.

WLP410- Belgian Wit II Ale Yeast:

Less phenolic than WLP400, and more spicy. Will leave a bit more sweetness, and flocculation is higher

than WLP400. Use to produce Belgian Wit, Spiced Ales, Wheat Ales, and Specialty Beers.

Attenuation: 70-75%

Flocculation: Low to Medium+.

Optimum Fermentati on Temperature: 67-74 F.

WLP500- Trappist Ale Yeast:

From one of the six Trappist breweries remaining in the world, this yeast produces the distinctive fruitiness

and plum characteristics. Excellent yeast for high gravity beers, Belgian ales, dubbels and trippels.

Attenuation: 73-78%

Fl occulation: Medi um to low.

Optimum Fermentation Temperature: 65-70 F. Lower temperatures (under 65 F) will result in less fruity

and more earthy beers. Many authenti c Trappist style beers are brewed at 75 F.

WLP530- Abbey Ale Yeast:

Used to produce Trappist style beers. Similar to WLP500, but is less fruity and more alcohol tolerant (up

to 15% ABV). Excellent yeast for high gravity beers, Belgian ales, dubbels and trippels.

Attenuation: 73-78%

Flocculation: Medium to high.

Page 11 of 12

Optimum Fermentation Temperature: 66-72 F.

WLP550- Belgian Ale Yeast:

Saisons, Belgian Ales, Belgian Reds, Belgian Browns, and White beers are just a few of the classic

Belgian beer styles that can be created with this yeast strain. Phenolic and spicy flavors dominate the

profile, with less fruitiness then WLP500.

Attenuation: 72-78%

Flocculation: Medium.

Optimum Fermentati on Temperature: 68-78 F.

WLP565- Belgian Saison I Yeast:

Classic Saison yeast from Wallonia. It produces earthy, peppery, and spicy notes. Slightly sweet. With

high gravity saisons, brewers may wish to dry the beer with an alternate yeast added after 75%

fermentation.

Attenuation: 65-75%

Flocculation: Medium.

Optimum Fermentati on Temperature: 68-75 F.

WLP570- Belgian Golden Ale Yeast:

From East Flanders, versatile yeast that can produce light Belgian ales to high gravity Belgian beers (12%

ABV). A combination of fruitiness and phenolic characteristics dominate the flavor profile. Some sulfur is

produced during fermentation, which will dissipate following the end of fermentation.

Attenuation: 75-80%

Fl occulation: Low.

Optimum Fermentati on Temperature: 68-75 F.

Page 12 of 12

References

Classic Beer Style Series:

Guinard, Jean-Xavier. Lambic, Classic Beer Style Series, Brewers Publications, 1990

Rajotte, Pierre. Belgian Ale, Classic Beer Style Series, Brewers Publications, 1992

Other Books:

Daniels, Ray. Designing Great Beers - The Ultimate Guide to Brewing Classic Beer Styles, Brewers

Publication , 1996

Zymurgy Magazine:

Winners Circle Zymurgy (Vol. ?, No. ? thru Vol ? No ?)

Dorsch, Jim. Dubbel Vision, Zymurgy Jan/Feb 2000 (Vol. 23, No. 1), pp. 32-35, 60

Isenhour, John. For the Love of Lambic, Zymurgy Fall 1997 (Vol. 20, No. 3), pp. 19-21, 81-87

Brewing Techniques Magazine:

Lodahl, Martin. Lambic: Belgiums Unique Treasure, Brewing Techniques July/August 1995 (Vol. 3,

No. 4), pp. 35-46

Internet:

http://hbd.org/~ddraper/beer/waterpro.html

http://realbeer.com/spencer/Belgian/

http://www.brewingtechniques.com/library/styles/2_6style.html

http://www.brewingtechniques.com/library/styles/2_4style.html

http://belgianstyle.com/mmguide/

http://www.whitelabs.com

http://www.wyeastlab.com/

http://www.bjcp.org/

Other:

Personal correspondence with Wyeast Laboratories.

You might also like

- BYO - 10 Easiest Beer StylesDocument12 pagesBYO - 10 Easiest Beer StylesduonordesteNo ratings yet

- 2010 SOQ 3 Belgian StrongDocument5 pages2010 SOQ 3 Belgian StrongJoao Carlos MaximianoNo ratings yet

- Designing Great Belgian Dark Strong AlesDocument20 pagesDesigning Great Belgian Dark Strong AlesHermogenes Perezdearc100% (1)

- 15 Classic Belgian Clone Recipes 2Document17 pages15 Classic Belgian Clone Recipes 2JohnRykerNo ratings yet

- Light Beer "Forbidden Fruit"Document2 pagesLight Beer "Forbidden Fruit"Angel CarpioNo ratings yet

- Designing Great DubbelsDocument14 pagesDesigning Great DubbelsBruno RevelloNo ratings yet

- Beer Judge Certification Program: Guide To Beer StylesDocument30 pagesBeer Judge Certification Program: Guide To Beer StylesazbrewerNo ratings yet

- Recipes for Brewing Different Types of Beers and AlesFrom EverandRecipes for Brewing Different Types of Beers and AlesNo ratings yet

- BeerRecipe 37 PDFDocument2 pagesBeerRecipe 37 PDFAngel CarpioNo ratings yet

- Beer Cocktail Recipes: Ultimate Book for Making Refreshing & Delicious Beer Drinks at HomeFrom EverandBeer Cocktail Recipes: Ultimate Book for Making Refreshing & Delicious Beer Drinks at HomeNo ratings yet

- Home Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsFrom EverandHome Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsNo ratings yet

- 101 Old Time Receipts for Beer, Wine, Whiskey, other Spirits and AccoutrementsFrom Everand101 Old Time Receipts for Beer, Wine, Whiskey, other Spirits and AccoutrementsNo ratings yet

- Home Brewing: 70 Top Secrets & Tricks To Beer Brewing Right The First Time: A Guide To Home Brew Any Beer You WantFrom EverandHome Brewing: 70 Top Secrets & Tricks To Beer Brewing Right The First Time: A Guide To Home Brew Any Beer You WantNo ratings yet

- Beer Brewing Recipes: American Lite Lager EditionFrom EverandBeer Brewing Recipes: American Lite Lager EditionRating: 2 out of 5 stars2/5 (1)

- Water Adjustment Key to Unlocking Beer FlavorDocument26 pagesWater Adjustment Key to Unlocking Beer FlavorrarasriwindhuNo ratings yet

- Beer RecipesDocument1 pageBeer Recipes1srafelNo ratings yet

- A Beginner's Guide to Port WineDocument4 pagesA Beginner's Guide to Port WineTeri AlleyneNo ratings yet

- Dry Hopping A Study of Various ParametersDocument5 pagesDry Hopping A Study of Various Parametersfir3f0xNo ratings yet

- Belgian Beer Class 2018Document30 pagesBelgian Beer Class 2018michaelburke47No ratings yet

- 15 American IPAs1Document17 pages15 American IPAs1JohnRykerNo ratings yet

- Beyond Malt HopsDocument46 pagesBeyond Malt Hopsbartolomej7No ratings yet

- Brewing With WheatDocument16 pagesBrewing With WheatGustavo MicheliniNo ratings yet

- The Top Twenty Scotch Whiskies in A Ranking ListDocument4 pagesThe Top Twenty Scotch Whiskies in A Ranking ListminRFNo ratings yet

- Craft: The Brewers Association Guide To AmericanDocument16 pagesCraft: The Brewers Association Guide To AmericanMar KamonNo ratings yet

- Understanding YeastDocument1 pageUnderstanding YeastEmbdenNo ratings yet

- Malt & The Malting Process: Kelly J. Kuehl - National Sales Director The Country Malt GroupDocument33 pagesMalt & The Malting Process: Kelly J. Kuehl - National Sales Director The Country Malt GroupOleg Burlac100% (1)

- BJCPExamForDummies2018 Rev2Document67 pagesBJCPExamForDummies2018 Rev2ronsup67% (3)

- Late Hop & Hop OilsDocument3 pagesLate Hop & Hop OilsBill LimaNo ratings yet

- Belgian Beer Experiences tcm24-7788 PDFDocument64 pagesBelgian Beer Experiences tcm24-7788 PDFAlejandro HercenbergNo ratings yet

- Zymurgy Introduction To HomebrewingDocument44 pagesZymurgy Introduction To HomebrewingCoup CreeNo ratings yet

- Belgian BeerDocument52 pagesBelgian BeerGary DonostiNo ratings yet

- Mangrove Jacks Craft SeriesDocument18 pagesMangrove Jacks Craft Seriesalvaromviegas_191514100% (1)

- Bavarian Weizen All GrainDocument7 pagesBavarian Weizen All GrainDavide NicolisNo ratings yet

- BESTMALZ Malzbroschuere Malt Catalog ENDocument56 pagesBESTMALZ Malzbroschuere Malt Catalog ENPhilip Walker100% (1)

- Castle Malting Weyermann Malts Equivalents Oct 20131Document2 pagesCastle Malting Weyermann Malts Equivalents Oct 20131turbonatics0% (1)

- Hops ManualDocument37 pagesHops Manualtylerdurdenmademe100% (1)

- Cask CleaningDocument4 pagesCask Cleaningde_klusNo ratings yet

- First Look: Beer For All SeasonsDocument15 pagesFirst Look: Beer For All SeasonsStorey PublishingNo ratings yet

- Zymurgy - Intro To Homebrewing - 2009Document36 pagesZymurgy - Intro To Homebrewing - 2009pixtaccioNo ratings yet

- BYO 1995 Vol 01-03 September PDFDocument76 pagesBYO 1995 Vol 01-03 September PDFpixtaccioNo ratings yet

- BYO 1995 Vol 01-02 August PDFDocument76 pagesBYO 1995 Vol 01-02 August PDFpixtaccioNo ratings yet

- Topped With Hops Double IPADocument2 pagesTopped With Hops Double IPABautista John DexterNo ratings yet

- Yeast SubstitutionsDocument2 pagesYeast SubstitutionsBruno VintilaNo ratings yet

- Weyermann Product Information PDFDocument46 pagesWeyermann Product Information PDFEliseu DrummondNo ratings yet

- Zymurgy 1991 Vol 14-02 SummerDocument78 pagesZymurgy 1991 Vol 14-02 Summerlordmaul100% (1)

- Mangrove Jacks CatalogoDocument13 pagesMangrove Jacks CatalogolhcorreaNo ratings yet

- Brew Like A MonkDocument3 pagesBrew Like A MonkSonia Cireaşă0% (1)

- Yakima Chief Hops VarietiesDocument147 pagesYakima Chief Hops VarietiesStephenNo ratings yet

- Old British Beers PDFDocument31 pagesOld British Beers PDFjavijavier100% (1)

- City of BeerDocument60 pagesCity of BeernaokiyokoNo ratings yet

- REVIVAL OF DRY HOPPING TECHNIQUESDocument3 pagesREVIVAL OF DRY HOPPING TECHNIQUESAlison AbreuNo ratings yet

- Sustainable Brewing Concept Desalination ChemicalsDocument5 pagesSustainable Brewing Concept Desalination ChemicalsAndalusia Martha Novaline SiboroNo ratings yet

- Mastering The BJCP ExamDocument23 pagesMastering The BJCP Examwbruder1No ratings yet

- Beer Magazine 2008-11-12Document100 pagesBeer Magazine 2008-11-12faviomezzanoNo ratings yet

- Brewing ProcessDocument34 pagesBrewing ProcessDiana Mdm100% (1)

- Journal of Human Resources in Hospitality & TourismDocument18 pagesJournal of Human Resources in Hospitality & Tourismzpervan1No ratings yet

- Programme STW 26-30 Nov 2018 ProvDocument1 pageProgramme STW 26-30 Nov 2018 Provzpervan1No ratings yet

- Table 410: Drug TestingDocument6 pagesTable 410: Drug Testingzpervan1No ratings yet

- The Funbook of Creative Writing PDFDocument34 pagesThe Funbook of Creative Writing PDFJuan Cartes Font100% (2)

- Pavao NujicDocument5 pagesPavao Nujiczpervan1No ratings yet

- Ocial Cience: To Test or Not To Test: Do Workplace Drug Testing Programs Discourage Employee Drug Use?Document19 pagesOcial Cience: To Test or Not To Test: Do Workplace Drug Testing Programs Discourage Employee Drug Use?zpervan1No ratings yet

- Mijat Stojanović's autobiography publishedDocument2 pagesMijat Stojanović's autobiography publishedzpervan1No ratings yet

- (Perry) Frege On Demonstratives PDFDocument25 pages(Perry) Frege On Demonstratives PDFzpervan1No ratings yet

- 12 13 KapetanovicDocument17 pages12 13 Kapetanoviczpervan1No ratings yet

- This and That Revisited: A Social and Multimodal Approach To Spatial DemonstrativesDocument4 pagesThis and That Revisited: A Social and Multimodal Approach To Spatial Demonstrativeszpervan1No ratings yet

- Demonstratives As Individual ConceptsDocument72 pagesDemonstratives As Individual Conceptszpervan1No ratings yet

- Words and Their Metaphors A Corpus-Based PDFDocument43 pagesWords and Their Metaphors A Corpus-Based PDFzpervan1100% (1)

- The Linguistic Landscape of The Human BodyDocument107 pagesThe Linguistic Landscape of The Human BodyAna B. Adams100% (1)

- Gestural Demonstratives in English: An Experiment: Tóth EnikőDocument11 pagesGestural Demonstratives in English: An Experiment: Tóth Enikőzpervan1No ratings yet

- Schmidt, G., & Omazić, M. (2009) - Time Metaphors in English and Croatian. A Corpus-Based Case StudyDocument12 pagesSchmidt, G., & Omazić, M. (2009) - Time Metaphors in English and Croatian. A Corpus-Based Case StudyJ JNo ratings yet

- 19938Document15 pages19938zpervan1No ratings yet

- Representation of Categories MetaphoricaDocument9 pagesRepresentation of Categories Metaphoricazpervan1No ratings yet

- English SubjunctiveDocument1 pageEnglish Subjunctivezpervan1No ratings yet

- 8 Article Khare PDFDocument5 pages8 Article Khare PDFLionny Candra DewiNo ratings yet

- SCIENCE IN THE FRENCH REVOLUTIONDocument8 pagesSCIENCE IN THE FRENCH REVOLUTIONzpervan1No ratings yet

- "Ideologically-Correct" Science: The French RevolutionDocument26 pages"Ideologically-Correct" Science: The French Revolutionzpervan1No ratings yet

- Cjenik: Korisnik Datum Ispisa Cijena 1 Datum Kursa Vrsta ArtikalaDocument1 pageCjenik: Korisnik Datum Ispisa Cijena 1 Datum Kursa Vrsta Artikalazpervan1No ratings yet

- Evolutionary Biology Ideology Then and NowDocument20 pagesEvolutionary Biology Ideology Then and Nowzpervan1No ratings yet

- (William DeJong-Lambert) The Cold War Politics ofDocument204 pages(William DeJong-Lambert) The Cold War Politics ofzpervan1No ratings yet

- Humor and Translation An InterdisciplineDocument24 pagesHumor and Translation An Interdisciplinezpervan1No ratings yet

- "Race: A Social Destruction of A Biological Concept" by Neven Sesardić PDFDocument20 pages"Race: A Social Destruction of A Biological Concept" by Neven Sesardić PDFjameshertzNo ratings yet

- Budak 161 167Document7 pagesBudak 161 167zpervan1No ratings yet

- Cjenik Old Bridz HMELJDocument1 pageCjenik Old Bridz HMELJzpervan1No ratings yet

- ATN Vol 5 No 2 PavlovicDocument20 pagesATN Vol 5 No 2 Pavloviczpervan1No ratings yet

- Quiz 3Document4 pagesQuiz 3dEEP THE hELPERNo ratings yet

- Appendix B DAX ReferenceDocument174 pagesAppendix B DAX ReferenceTomislav Mališ100% (1)

- Skripsi #2 Tanpa HyperlinkDocument19 pagesSkripsi #2 Tanpa HyperlinkindahNo ratings yet

- Test Automation Design PrinciplesDocument15 pagesTest Automation Design PrinciplesSujay KumarNo ratings yet

- Delphi Temp SensorDocument2 pagesDelphi Temp SensorAlways Super Gaming vatsal GehlotNo ratings yet

- 93C66 Microwire EepromDocument13 pages93C66 Microwire EepromadrianramonNo ratings yet

- Boeing 757-767 Study Guide SummaryDocument134 pagesBoeing 757-767 Study Guide SummaryEldonP100% (2)

- Serial Number AutoCAD 2014Document5 pagesSerial Number AutoCAD 2014Punith Ky67% (9)

- Prescurtari PDFDocument67 pagesPrescurtari PDFהוד אנדרוNo ratings yet

- Percentage Conversion Worksheet PDFDocument2 pagesPercentage Conversion Worksheet PDFJamie LeeNo ratings yet

- 325F Diagrama Electrico CHASIS PDFDocument8 pages325F Diagrama Electrico CHASIS PDFRICHARDNo ratings yet

- A Steganography Intrusion Detection SystemDocument21 pagesA Steganography Intrusion Detection SystemjamessomNo ratings yet

- Darktrace Csensor Release NotesDocument10 pagesDarktrace Csensor Release NotesNelson JuniorNo ratings yet

- Understanding the Strength and Limitations of DES EncryptionDocument32 pagesUnderstanding the Strength and Limitations of DES EncryptionArya KumariNo ratings yet

- Mos PDFDocument194 pagesMos PDFChoon Ewe LimNo ratings yet

- Transient Step Response Specification of Z-Source DC-DC ConverterDocument5 pagesTransient Step Response Specification of Z-Source DC-DC ConverterijsretNo ratings yet

- ZF AVS Automatic Gearbox Manual PDFDocument67 pagesZF AVS Automatic Gearbox Manual PDFDardan HusiNo ratings yet

- DEPP Programmer's Reference ManualDocument5 pagesDEPP Programmer's Reference ManualRaul Gil BayardoNo ratings yet

- Multistage Amplifier Frequency ResponseDocument29 pagesMultistage Amplifier Frequency ResponseMuhammad HafizNo ratings yet

- PFR Lime Kiln Process With Blast Furnace Gas and OxygenDocument4 pagesPFR Lime Kiln Process With Blast Furnace Gas and OxygenVitor Godoy100% (1)

- Problem Set 3 NonparaDocument3 pagesProblem Set 3 NonparaRhia Mae TeporaNo ratings yet

- FragAnal RC QDocument26 pagesFragAnal RC QhjmaranhaoNo ratings yet

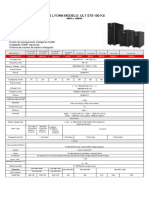

- Ups Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVADocument1 pageUps Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVASebastian Matias CruzNo ratings yet

- Vodafone Bid HBS Case - ExhibitsDocument13 pagesVodafone Bid HBS Case - ExhibitsNaman PorwalNo ratings yet

- Fluid Mechanics Chapter on Mechanical Energy and EfficiencyDocument43 pagesFluid Mechanics Chapter on Mechanical Energy and EfficiencyShazrel IzlanNo ratings yet

- B483B483M 13e1Document10 pagesB483B483M 13e1Mohamad ZandiNo ratings yet

- A B C D Supply I1 1 2 3 4 Deman D I1Document7 pagesA B C D Supply I1 1 2 3 4 Deman D I1Shaurya DewanNo ratings yet

- Hydraulic Filter ReportDocument6 pagesHydraulic Filter ReportSandrock_01sr2No ratings yet

- IGCSE Chemistry TEST YOUR SELF CHAPTER 4Document12 pagesIGCSE Chemistry TEST YOUR SELF CHAPTER 4Nguyễn Việt Huy RoyNo ratings yet

- Elasticity and Its Applications: For Use With Mankiw and Taylor, Economics 4 Edition 9781473725331 © CENGAGE EMEA 2017Document39 pagesElasticity and Its Applications: For Use With Mankiw and Taylor, Economics 4 Edition 9781473725331 © CENGAGE EMEA 2017Joana AgraNo ratings yet