Professional Documents

Culture Documents

Material Alloy KHR35CL

Uploaded by

Iebe Seventynine50%(2)50% found this document useful (2 votes)

1K views2 pagesDetail Material Composition

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDetail Material Composition

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

50%(2)50% found this document useful (2 votes)

1K views2 pagesMaterial Alloy KHR35CL

Uploaded by

Iebe SeventynineDetail Material Composition

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

25 Commerce Road, Orillia, Ontario, Canada L3V 6L6

Phone (705) 325-2781 Fax (705) 325-5887

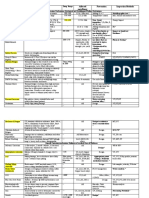

ALLOY DATA SHEET HEAT RESISTANT ALLOY

KHR35CL REVISION: 06/99

DESCRIPTION

KHR 35CL is a low carbon modification of KHR 35C. This alloy is particularly suited for service in conditions

where resistance to thermal fatigue and thermal shock is required. While somewhat comparable to the low

carbon KHR 32C alloy, the higher chromium and nickel levels provide greater resistance to oxidation and

carburization.

COMPOSITION

C Mn Si Cr Ni P S Nb

Min % 0.18 - 0.5 24 36.5 - - -

Max % 0.23 1.5 1.2 26 38.5 <.03 <.03 1.5

APPLICATIONS

Ethylene pyrolysis coils and fittings, heat treatment furnace rolls, trays and fixtures.

PRODUCT FORMS

Horizontal and vertical centrifugal castings, static castings, formed fittings and sweeps.

PHYSICAL PROPERTIES

CARBURIZATION

Density (lbs/in

3)

0.291 RESISTANCE

Melting Solidus 2310 F (Pack-cyclic tests @ 1560-2100 F,

Thermal Conductivity 18.1 @ 1922 F weight percent gain in 5 mm.)

(Btu ft / ft

2

hr F) Alloy Wt Gain

Thermal Expansion 8.7 @ 68-400 F Grade %

( x 10

-6

in / in F) 9.2 @ 68-750 F KHR35C HiSi 22.6

9.6 @ 68-1100 F KHR35CW 20.4

9.7 @ 68-1500 F KHR35CL 23.8

10.0 @ 68-1800 F KHR45A LC 7.5

10.1 @ 68-2000 F

MECHANICAL PROPERTIES

Typical High Temperature Tensile Properties - Centrifugal Castings

570 932 1112 1292 1472 1652 1832 2012 F Minimum Values @ 70 F

U.T.S. (ksi) 68.3 68.3 62.5 55.4 38.4 24.2 14.9 10.0 63.8

Y.S. (ksi) 24.2 22.8 22.8 21.3 21.3 11.3 8.7 5.7 26.8

El. (%) 25 (c.c.), 20 (static)

Typical 100 Hour Aged Room Temperature Tensile Properties - Centrifugal Castings

Aging Temperature 932 1112 1292 1472 1652 1832 F

U.T.S. (ksi) 81.4 85.8 81.6 82.0 74.4 79.9

Y.S. (ksi) 37.2 38.7 40.8 41.3 38.0 37.6

El. (%) 26.9 23.7 12.8 13.2 11.5 15.7

RA. (%) 20.9 18.3 12.1 9.6 9.6 13.5

HEAT RESISTANT ALLOY KHR35CL Page 2

MODULUS OF ELASTICITY

68 1112 1292 1472 1652 1832 F

26.3 20.8 19.6 18.5 17.4 15.5 (x 10

3

ksi)

SERVICE TEMPERATURE

The alloy is suitable for long term service at temperatures up 1975 F, but because of the detrimental effect of

niobium on oxidation resistance, it should be used with caution above this temperature.

WELDABILITY

Procedures for welding KHR35CL are available from Kubota Metal Corporation

CREEP-RUPTURE PROPERTIES

Long term creep-rupture data was taken from Larson-Miller Parameter versus stress plots published by Kubota.

RUPTURE-STRESS-KSI

HOURS 1400 1500 1600 1700 1800 1900 2000 2100 2200 F

100 AVG. 10.15 8.63 6.97 5.29 3.73 2.43 1.93 1.53

MIN. 8.48 7.21 5.82 4.41 3.11 2.02 1.60 1.27

1,000 AVG. 10.36 8.81 7.08 5.32 3.69 2.35 1.46 0.78 0.41

MIN. 8.65 7.35 5.91 4.44 3.08 1.96 1.20 0.65 0.34

10,000 AVG 9.12 7.34 5.50 3.79 2.37 1.44 0.74 0.38

MIN 7.62 6.12 4.59 3.15 1.97 1.19 0.62 0.32

100,000 AVG. 7.75 5.83 4.01 2.50 1.48 0.75 0.37

MIN. 6.47 4.87 3.34 2.08 1.22 0.63 0.31

CREEP-STRESS-KSI

%/HOUR 1562 1652 1742 1832 F

0.0001 AVG. 5.08 3.70 2.26 1.19

Note: Creep-rupture stresses are subject to periodic revisions as the results from long term tests become available.

HEAD OFFICE, FOUNDRY & INTERNATIONAL SALES

Kubota Metal Corporation, Fahramet Division

25 Commerce Road, P.O. Box 1700,

Orillia, Ontario, Canada, L3V 6L6.

Phone (705) 325-2781

Fax (705) 325 5887

You might also like

- Material Alloy KHR32CDocument2 pagesMaterial Alloy KHR32CKHNo ratings yet

- KubotaDocument12 pagesKubotaFebri Ramdani NugrahaNo ratings yet

- Daily Points To Recall (Day 5) : Professional Training and ConsultationDocument3 pagesDaily Points To Recall (Day 5) : Professional Training and Consultationraobabar21No ratings yet

- API 510 Preparatory Training Exam QuestionsDocument13 pagesAPI 510 Preparatory Training Exam QuestionsCss SfaxienNo ratings yet

- 37DLPlus TrainingDocument192 pages37DLPlus TrainingJai PatelNo ratings yet

- Answer Key For The Inspector's Calc's ExercisesDocument4 pagesAnswer Key For The Inspector's Calc's ExercisesHeartyscorpionNo ratings yet

- API 510 - Book 5Document48 pagesAPI 510 - Book 5Hamza AlamNo ratings yet

- High-Resolution EMAT As A Diagnostic Tool For Analysis of SCC and Crack-Like Pipeline Defects - IOGPC2015-7940 Thomas Beuker / ROSEN Matthias Hilvert / ROSENDocument24 pagesHigh-Resolution EMAT As A Diagnostic Tool For Analysis of SCC and Crack-Like Pipeline Defects - IOGPC2015-7940 Thomas Beuker / ROSEN Matthias Hilvert / ROSENrajnish14feb8516No ratings yet

- Astm c633-79 - 1994 Leigh A Test C&RDocument8 pagesAstm c633-79 - 1994 Leigh A Test C&RastronotusNo ratings yet

- API 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical Industries PDFDocument1 pageAPI 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical Industries PDFAzhar Ahmad100% (1)

- Api 571 CorrosionDocument5 pagesApi 571 CorrosionArun GuptaNo ratings yet

- API 570 Exame Questions Dated 5 July 2018Document10 pagesAPI 570 Exame Questions Dated 5 July 2018Ahmed ShakirNo ratings yet

- ROSEN Group Inspection of Corrosion Under Pipe SupportsDocument8 pagesROSEN Group Inspection of Corrosion Under Pipe SupportsNurul Amirah PrinceszaNo ratings yet

- MCE Welder Performance Qualification ReportDocument2 pagesMCE Welder Performance Qualification ReporthamidjoyiaNo ratings yet

- Prepking 000-936 Exam QuestionsDocument11 pagesPrepking 000-936 Exam Questionscollen23No ratings yet

- Check ValveDocument2 pagesCheck ValveVaitheeswaran PalaniNo ratings yet

- Failure Analysis of Pressure VesselDocument5 pagesFailure Analysis of Pressure Vesseltumoye100% (1)

- Boost Your API-570 Piping Inspectors Exam ScoreDocument6 pagesBoost Your API-570 Piping Inspectors Exam Scorejaire esparzaNo ratings yet

- API 510 Case Study - 7Document2 pagesAPI 510 Case Study - 7Khaled FatnassiNo ratings yet

- (PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduDocument4 pages(PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduKumar R100% (1)

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocument7 pagesStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodMauricio FernándezNo ratings yet

- Prep Material QB-576Document5 pagesPrep Material QB-576Raheem Khan100% (1)

- Sis Book1Document99 pagesSis Book1Hamza AlamNo ratings yet

- Question Paper For Snr. WeldingDocument3 pagesQuestion Paper For Snr. WeldingThulasi RamNo ratings yet

- Saudi Aramco: Company General UseDocument74 pagesSaudi Aramco: Company General UseMohamad ShafeyNo ratings yet

- API 510 AnsDocument8 pagesAPI 510 AnsShyam SinghNo ratings yet

- API 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsDocument6 pagesAPI 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsIbtehaj ManiNo ratings yet

- ASF-PA-14-Painting Repair Procedure (United Engineering Construction)Document5 pagesASF-PA-14-Painting Repair Procedure (United Engineering Construction)SHAHIDALINo ratings yet

- Case Study - 7: Numerical in API 510 CodeDocument4 pagesCase Study - 7: Numerical in API 510 CodeVishal BailurNo ratings yet

- Safety Valve Api 576 Edition 4Document117 pagesSafety Valve Api 576 Edition 4dende martinaNo ratings yet

- Api RP 581 Risk Based Inspection Methodology: Webcorr Corrosion Consulting Services PresentsDocument2 pagesApi RP 581 Risk Based Inspection Methodology: Webcorr Corrosion Consulting Services PresentsfaisalNo ratings yet

- 6946-6-77-0005 Rev1Document24 pages6946-6-77-0005 Rev1Karthick VenkatswamyNo ratings yet

- Body of Knowledge: Certified Welding EngineerDocument4 pagesBody of Knowledge: Certified Welding EngineerMalcolm DiamondNo ratings yet

- Module 7 Metric Practice For Welding InspectionDocument2 pagesModule 7 Metric Practice For Welding InspectionMiki Jaksic100% (1)

- Asme Section II A Sa-376 Sa-376mDocument10 pagesAsme Section II A Sa-376 Sa-376mAnonymous GhPzn1xNo ratings yet

- Asme b31.3 Allowable StressDocument23 pagesAsme b31.3 Allowable Stressjoaquin torrano veraNo ratings yet

- Api 510 - Book 6Document120 pagesApi 510 - Book 6Tauqeer SalimNo ratings yet

- Theoretical Background of Leak-Before-Break ConceptDocument8 pagesTheoretical Background of Leak-Before-Break Conceptpouya_ms100% (1)

- API 653 - ASME Section V - NDE Practice Questions - 68 TermsDocument7 pagesAPI 653 - ASME Section V - NDE Practice Questions - 68 TermsSERFORTEC CIA. LTDA.No ratings yet

- JW Inmarco Flexible Pure Graphite Gasket SheetDocument2 pagesJW Inmarco Flexible Pure Graphite Gasket SheetNilesh NarkhedeNo ratings yet

- FFS Assessment Nozzle Weld DefectDocument22 pagesFFS Assessment Nozzle Weld DefectRDS FDSNo ratings yet

- ASSET INTEGRITY SECTION DAILY REPORTDocument1 pageASSET INTEGRITY SECTION DAILY REPORTعصمت ضيف اللهNo ratings yet

- Api 570 272-395Document56 pagesApi 570 272-395nancyNo ratings yet

- All You Need To Know About API 571 Corrosion and MaterialsDocument13 pagesAll You Need To Know About API 571 Corrosion and MaterialsMasood KhanNo ratings yet

- 9 Multiple Choice Questions: No Answer GivenDocument3 pages9 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvRNo ratings yet

- CSWIP 3 1 Syllabus Exam PatternDocument3 pagesCSWIP 3 1 Syllabus Exam PatternTaufik AliNo ratings yet

- Spatter Reduction ChecklistDocument6 pagesSpatter Reduction ChecklistJorge perezNo ratings yet

- Boroscope InspectiónDocument14 pagesBoroscope InspectiónXiomara Hurtado FloresNo ratings yet

- High-temperature thickness measurements using ultrasonic testingDocument4 pagesHigh-temperature thickness measurements using ultrasonic testingSeung Woo LeighNo ratings yet

- Harmonised Amateur Radio Exam GuideDocument40 pagesHarmonised Amateur Radio Exam GuideserepezNo ratings yet

- API 653 PC 15may04 Exam 4 ClosedDocument5 pagesAPI 653 PC 15may04 Exam 4 ClosedShaalan AliNo ratings yet

- Welding Engineer Exam SyllubusDocument2 pagesWelding Engineer Exam SyllubuskapsarcNo ratings yet

- Standard Guide For Acoustic Emission System Performance VerificationDocument5 pagesStandard Guide For Acoustic Emission System Performance VerificationArpan NandyNo ratings yet

- Asme Viii UgDocument24 pagesAsme Viii UgajitNo ratings yet

- API 510 Section 8 QuizDocument17 pagesAPI 510 Section 8 Quizamalhaj2013No ratings yet

- API-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFDocument23 pagesAPI-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFasNo ratings yet

- Asme Viii - QDocument431 pagesAsme Viii - Qmajdi jerbiNo ratings yet

- HASTELLOY® C-22HS™alloyDocument16 pagesHASTELLOY® C-22HS™alloyYudha SatriaNo ratings yet

- Molykote 1000 Paste Safety Data SheetDocument10 pagesMolykote 1000 Paste Safety Data SheetIebe SeventynineNo ratings yet

- LB 52 18Document1 pageLB 52 18Daniel AlvesNo ratings yet

- A385 11 PDFDocument8 pagesA385 11 PDFMajid Dawood KhanNo ratings yet

- 45 ton Tadano TR450XL-4 Load Charts NYC One Man MachineDocument12 pages45 ton Tadano TR450XL-4 Load Charts NYC One Man MachineIebe SeventynineNo ratings yet

- Spi Plate Flange Guide 2009Document20 pagesSpi Plate Flange Guide 2009Iebe SeventynineNo ratings yet

- Autodesk 3ds Max Design 2010 TutorialDocument67 pagesAutodesk 3ds Max Design 2010 TutorialIvoo PeanNo ratings yet

- 2700 Catalog SectionDocument37 pages2700 Catalog SectionIebe SeventynineNo ratings yet

- 2700 Catalog SectionDocument37 pages2700 Catalog SectionIebe SeventynineNo ratings yet

- Trocal Stone Floor Sheet 1.2Document3 pagesTrocal Stone Floor Sheet 1.2the pilotNo ratings yet

- Samsung WF752U2BK-02917E-03 - XSEDocument88 pagesSamsung WF752U2BK-02917E-03 - XSEGala PerdanaNo ratings yet

- EXCLUSIVE INDEPENDENT FLOORS LUXURY PROJECT IN GURUGRAMDocument16 pagesEXCLUSIVE INDEPENDENT FLOORS LUXURY PROJECT IN GURUGRAMGaurav RaghuvanshiNo ratings yet

- Leed GA Practice Questions - AnswersDocument26 pagesLeed GA Practice Questions - AnswersAl-Madinah Al-MunawarahNo ratings yet

- Development of design codes for concrete structuresDocument1 pageDevelopment of design codes for concrete structuresGregory SimmonNo ratings yet

- Jacket Foundations for Offshore Wind TurbinesDocument36 pagesJacket Foundations for Offshore Wind Turbinesharsh4u100% (1)

- Pondasi BoilerDocument24 pagesPondasi BoilerMochammad ShokehNo ratings yet

- Cement Mortar LiningsDocument8 pagesCement Mortar LiningsAshok NarayanNo ratings yet

- Saes P 107Document18 pagesSaes P 107bilal hussain qureshiNo ratings yet

- Herramientas Bombas PDFDocument172 pagesHerramientas Bombas PDFrgb0906No ratings yet

- Bolt Joint Design and SpecificationsDocument29 pagesBolt Joint Design and SpecificationsPablo GalindosNo ratings yet

- Varec 4210A CatalogDocument4 pagesVarec 4210A Catalogking4lifeNo ratings yet

- TM 5-272 1944 Steel-Treadway Bridge M2Document74 pagesTM 5-272 1944 Steel-Treadway Bridge M2Advocate100% (1)

- Consol SivakuganDocument29 pagesConsol SivakuganJothi RamanathanNo ratings yet

- Asme B18.5.2.1M 1996Document8 pagesAsme B18.5.2.1M 1996Jesse ChenNo ratings yet

- The Early Chicago Tall Office Building: Artistically and Functionally ConsideredDocument9 pagesThe Early Chicago Tall Office Building: Artistically and Functionally ConsideredDorian VujnovićNo ratings yet

- 12 Guide To Durable AtticsDocument2 pages12 Guide To Durable Atticsapi-309082881No ratings yet

- Soil Investigation Report: Item Page NoDocument6 pagesSoil Investigation Report: Item Page NoWai LinnNo ratings yet

- J. Struct. Eng. 1989.115:2276-2296Document21 pagesJ. Struct. Eng. 1989.115:2276-2296afuhcivNo ratings yet

- Filltros para MP Excavadora Cat 320 B-BL-5GWDocument3 pagesFilltros para MP Excavadora Cat 320 B-BL-5GWJosé GonzalezNo ratings yet

- Structural Design Review Checklist PDFDocument2 pagesStructural Design Review Checklist PDFyosiboyNo ratings yet

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloNo ratings yet

- Matlab Code ABBD MatrixDocument4 pagesMatlab Code ABBD MatrixmehdiNo ratings yet

- Degadur® 420 and Degadur® 526Document5 pagesDegadur® 420 and Degadur® 526申易No ratings yet

- MAKAUT Tribology SyllabusDocument2 pagesMAKAUT Tribology SyllabusTamonash JanaNo ratings yet

- Fire: en 13501 The European Standard Owacoustic Ceilings Reaction To Fire Fire ResistanceDocument12 pagesFire: en 13501 The European Standard Owacoustic Ceilings Reaction To Fire Fire Resistanceradubotinesteanu100% (3)

- BS En-12952-2-2021Document46 pagesBS En-12952-2-2021TANK INSPECTNo ratings yet

- ArchitecturalDocument1 pageArchitecturalAr. Via Yu BasaNo ratings yet

- Highway MaterialsDocument45 pagesHighway Materialsfarahazura67% (9)

- Hardie Reveal Panel Installation Instructions 1597005Document29 pagesHardie Reveal Panel Installation Instructions 1597005David TorskeNo ratings yet