Professional Documents

Culture Documents

Exhaust Valves

Uploaded by

Jitendra KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exhaust Valves

Uploaded by

Jitendra KumarCopyright:

Available Formats

Exhaust valves

Large exhaust valves are provided with detachable seats made form molybdenum steel. The main parts of

the valve casing is of cast iron and water cooled, there being no particular strength requirement for this

part. It is the seat area which is subject to high temperatures and wear, hence the use of better materials.

The seat is detachable in order to allow removable for machining and replacement.

Rocker operation of valves presents certain problems;

1. a tappet clearance must be allowed to suit thermal expansion of the valve stem. Insufficient

clearance may result in the valve not fully closing whilst excessive clearance can effect timing

and the period the valve is open. Hammering will also take place at the tappet face. (The use of

self adjusting hydraulic tappets went some way to alleviating these problems

!. " side thrust is imparted to the valve stem when the valve opens. Thus causing wear at the

stem bushing and subse#uent leakage

$. wear takes place at the pushrod and valve contact face% additionally the rocker bearings

re#uire constant lubrication.

To avoid these problems hydraulic valve actuation is used there is no tappet and no tappet

clearance to set. Thermal expansion is accounted for by allowing the oil to escape at a relief valve on the

pump unit. Oil loss is made up at the pump unit from the cam lube oil supply system. The opening face is

always axial. ote! The hydraulic pipe must be sheathed to avoid the ris" of fire in the event of pipe

failure.

#ith modern fuels, vanadium and other deposits can build up on valve faces leading to

damage. These deposits can be hammered into the seating faces. If the valve is rotated and reseats in a

different place then the same dmage does not occur. $otating the valve also prevents localised

overheating due to a faulty atomiser.. If the valve is set spinning and is still rotating as it reseats a light

grinding action ta"es place. This removes deposits and ensures a good seal. %uch rotation is induced by

spinners on the valve stem upon which the escaping exhaust gas acts.. To allow for this effect the

frictional effect of the springs and valve&cover must be removed. The removal of springs means that a

closing force by some other means is required. 'ir springing can be used. This consists of a piston fitted to

the valve stem below the hydraulic unit. 's the valve opens air below the piston is compressed and this

compression provides the upward force of closing the valve. The space above the piston is vented to

atmosphere and the pressure below the piston maintained at ( bar from an air supply via a non)return

valve.

'n additional advantage with this system is that when the engine is stopped the valves will all

close after a short delay. This prevents the flow of cool scavenged air through units which with a roc"er

system would otherwise be open.*reventing this allows all cylinder to be equally warm and stops the

rotation of the turboblower which can occur.

Springs

%prings of sufficient force must be provided in order to ensure that the valve closes when the tappet force

is removed. Once the valve is closed, the pressure in the cylinder will increase the sealing force on the

valve seat.

%prings have natural frequencies and if the engine operating frequency is close to the natural

frequency of the spring then vibration will ta"e place and valve bounce will occur. %prings also twist when

they are compressed and this causes wear at the landing faces. To avoid problems, double springs may be

fitted one inside the other in parallel. These springs must be of different si+e and so have different natural

frequencies. ,alve bounce due to spring vibration is thus avoided.

The springs are wound in different directions to prevent twist and also to prevent one coil

entering the other in the event of brea"age, thereby loc"ing it up.

Long springs tend to bow out when they are compressed and this increases the ris" of stress

failure. ' solution is to have two springs in series, one above the other and separated by a centre disc

which is located via a pivoted arm arrangement so that only vertical movement is allowed. %eries ¶llel

arrangements are available.

-odern engines use pneumatic springs. Thisi both eliminates the problems of valve bounce ,

spring bra"age and also the need for rotor caps. 's the valve is free floating spinner vanes fitted on the

spindle allow the valve to be rotated by the flow of exhaust gas.

Rotocap

The rotocap is a mechanical device which produces valve rotation by a small amount as the valve opens.

The valve rotation is about .

o

when the unit is in good condition.

$otation to a new position avoids deposits from being hammered into the seat and repositions

the valve thus preventing local overheating. /rictional contact is provided through the springs to the valve

cover via the belleville washer which contacts at point ' and 0. 's the tappet force increases to open the

valve, the belleville washer is collapsed thus removing that frictional contact. /urther increase in tappet

force acts on the spring loaded ball bearings and the ramped slots tend to slide over the ball bearings.

These slots are in the valve cover which is connected to the stem thus as the cover moves it rotates the

valve.

's the tappet force is removed when the valve closes the belleville washer restores frictional

contact and prevents further rotation. %prings return the ball bearings to their original position ready for

the next stro"e.

Valve closing Valve opening

You might also like

- 5 Exhaust ValveDocument7 pages5 Exhaust ValveAhamed RasheenNo ratings yet

- How A Rotocap WorksDocument6 pagesHow A Rotocap WorksBharatiyulam83% (6)

- Operational Information The Two Stroke Crosshead Engine The Stuffing BoxDocument6 pagesOperational Information The Two Stroke Crosshead Engine The Stuffing BoxAbhishek Singh ChauhanNo ratings yet

- 08 Exhaust ValveDocument66 pages08 Exhaust ValveSky RNo ratings yet

- 02 Two Stroke Diesel CycleDocument31 pages02 Two Stroke Diesel CyclenareshNo ratings yet

- Operational Information The Air Start ValveDocument5 pagesOperational Information The Air Start ValveHrishikesh More100% (1)

- Starting & Reversing Problems in Marine EnginesDocument6 pagesStarting & Reversing Problems in Marine EnginesUjjwal SinghNo ratings yet

- Chapter 21 - Starting Air SystemDocument16 pagesChapter 21 - Starting Air Systemsezar100% (1)

- Puncture ValveDocument1 pagePuncture ValveAnkit DedhiyaNo ratings yet

- IC EngineDocument65 pagesIC EngineDuggi Shanmukha ViharNo ratings yet

- Mep Oral AnswersDocument28 pagesMep Oral AnswersAshjo Gamer100% (1)

- 2 Stroke Diesel Engine Components-1Document72 pages2 Stroke Diesel Engine Components-1EdemNo ratings yet

- 01 BedplateDocument11 pages01 BedplateVinay Kumar NeelamNo ratings yet

- Radial TCDocument3 pagesRadial TCArun SNo ratings yet

- Members Section Common Rail and Camshaftless Engines The MAN B&W ME Engine Exhaust Valve ActuatorDocument2 pagesMembers Section Common Rail and Camshaftless Engines The MAN B&W ME Engine Exhaust Valve ActuatorArun SNo ratings yet

- Actual Sysem Setup Alpha LubricatorDocument7 pagesActual Sysem Setup Alpha LubricatorRanjan DiptanshuNo ratings yet

- Tie Bolts or Tie RodsDocument8 pagesTie Bolts or Tie RodsAayush AgrawalNo ratings yet

- Operational Information The Two Stroke Crosshead Engine The Cylinder LinerDocument14 pagesOperational Information The Two Stroke Crosshead Engine The Cylinder LinerAayush AgrawalNo ratings yet

- Power CardDocument6 pagesPower CardArun SNo ratings yet

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Local ControlDocument3 pagesMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Local ControlArun SNo ratings yet

- Types Liner Material Problems in Liner Liner Inspection Liner Calibration Difference Between MAN B&W and SULZER LinersDocument7 pagesTypes Liner Material Problems in Liner Liner Inspection Liner Calibration Difference Between MAN B&W and SULZER LinersRicardo Garing100% (2)

- Thrust BlockDocument2 pagesThrust Blockkyaw yaNo ratings yet

- Starting and ReversingDocument55 pagesStarting and ReversingMeghanath AdkonkarNo ratings yet

- Compressor SafetiesDocument2 pagesCompressor Safetiesvic.barca2012No ratings yet

- Trunk Piston Engine The Crank ShaftDocument10 pagesTrunk Piston Engine The Crank ShaftAayush AgrawalNo ratings yet

- Propeller Shaft-Coupling BoltsDocument2 pagesPropeller Shaft-Coupling BoltsSai Sarihaddu100% (1)

- Fuel InjectorDocument3 pagesFuel InjectorPar Nd Oo100% (3)

- 001 Bearing FailureDocument1 page001 Bearing FailureHiddenDNo ratings yet

- The Air Start ValveDocument5 pagesThe Air Start ValveRejoGevargheseRajan100% (1)

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start DistributorDocument1 pageMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start DistributorArun SNo ratings yet

- Main Engine (S) Unit 6 OverhaulDocument4 pagesMain Engine (S) Unit 6 OverhaulMocanu MarianNo ratings yet

- Coc Oral Boiler Safety Valve13 PDFDocument6 pagesCoc Oral Boiler Safety Valve13 PDFshamratNo ratings yet

- Cylinder Liner Gauging 1Document5 pagesCylinder Liner Gauging 1RABISH Kumar100% (1)

- Important QuestionsDocument82 pagesImportant Questionssams shuvoNo ratings yet

- 2.stern Tube Seals & LinersDocument9 pages2.stern Tube Seals & LinersNAGENDRA KUMAR D100% (1)

- Slide Fuel ValvesDocument2 pagesSlide Fuel ValvesSpasoje100% (1)

- Main EngineDocument10 pagesMain EngineFe CaprichoNo ratings yet

- Diesel Engine ComponentsDocument33 pagesDiesel Engine ComponentsLuis NunesNo ratings yet

- NewDocument4 pagesNewPrakhyati Raut100% (1)

- A Study On Torque Rich Phenomena in Ship OperationDocument11 pagesA Study On Torque Rich Phenomena in Ship OperationAnonymous XtvvG80zuNo ratings yet

- Cylinder Liner WearDocument1 pageCylinder Liner WearThuria Tun100% (1)

- Self Cleaning PurifierDocument2 pagesSelf Cleaning PurifierPar Nd Oo100% (1)

- Exhaust Valve System (Set 2015)Document42 pagesExhaust Valve System (Set 2015)Fernando SouzaNo ratings yet

- Block - ConrodDocument22 pagesBlock - ConrodArnold ChafewaNo ratings yet

- Oros PistonDocument6 pagesOros Pistonbrigolmustihotmail.com100% (1)

- BearingsDocument58 pagesBearingsSarath RaghavNo ratings yet

- Stuffing BoxDocument6 pagesStuffing BoxrajishrrrNo ratings yet

- Stuffing BoxDocument2 pagesStuffing BoxMeghali Borle67% (3)

- Cylinder LubricationDocument8 pagesCylinder LubricationVinay Kumar Neelam100% (1)

- Air Start SystemDocument5 pagesAir Start SystemPaolo FerjančićNo ratings yet

- Indicator Diagrams of Diesel EnginesDocument5 pagesIndicator Diagrams of Diesel EnginesAbdul Anis67% (3)

- Members Section Timing Chains Tensioning A Timing ChainDocument1 pageMembers Section Timing Chains Tensioning A Timing ChainArun SNo ratings yet

- Purifier Manual DesludgeDocument1 pagePurifier Manual Desludgesubscru100% (1)

- Coc Oral Exam Preparation (Part - 17) : Boiler Safety ValveDocument3 pagesCoc Oral Exam Preparation (Part - 17) : Boiler Safety ValveshashankrawatNo ratings yet

- Boiler PantingDocument3 pagesBoiler PantingAnkit DedhiyaNo ratings yet

- VIT Fuel PumpDocument16 pagesVIT Fuel PumpAbhishek Singh Chauhan50% (2)

- Chapter 15 - (Bi) Turbocharging and Air CoolingDocument20 pagesChapter 15 - (Bi) Turbocharging and Air Coolingshahin gholamiNo ratings yet

- Cylinder Lubrication Marine Engines ArticleDocument10 pagesCylinder Lubrication Marine Engines ArticleVijay Geddada100% (2)

- Parallel Operation of GeneratorsDocument5 pagesParallel Operation of GeneratorsJitendra KumarNo ratings yet

- Brochure o Pumps Deepwell Gas CarriersDocument4 pagesBrochure o Pumps Deepwell Gas CarriersJohn MarxisNo ratings yet

- Pilgrim NutDocument2 pagesPilgrim NutJitendra KumarNo ratings yet

- Overview of Microbiological AttackDocument10 pagesOverview of Microbiological AttackJitendra KumarNo ratings yet

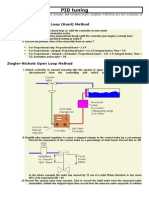

- PID TuningDocument4 pagesPID TuningJitendra Kumar100% (1)

- Oxygen AnalysersDocument2 pagesOxygen AnalysersJitendra KumarNo ratings yet

- Increasing Propulsive EfficiencyDocument6 pagesIncreasing Propulsive EfficiencyJitendra KumarNo ratings yet

- Oily Water SeperatorsDocument2 pagesOily Water SeperatorsJitendra KumarNo ratings yet

- Overall Arrangement: Description of The Salient PartsDocument6 pagesOverall Arrangement: Description of The Salient PartsJitendra KumarNo ratings yet

- Microbes of Microbiological Attac1Document3 pagesMicrobes of Microbiological Attac1Jitendra KumarNo ratings yet

- Operation of A Centrifugal Oil PurifersDocument3 pagesOperation of A Centrifugal Oil PurifersJitendra KumarNo ratings yet

- LNG Containment DesignsDocument3 pagesLNG Containment DesignsJitendra KumarNo ratings yet

- Oil WhirlDocument2 pagesOil WhirlJitendra KumarNo ratings yet

- Oil Distribution Within A Journal BearingDocument2 pagesOil Distribution Within A Journal BearingAnkit DedhiyaNo ratings yet

- Materials Used in Ships Sea Water SystemsDocument1 pageMaterials Used in Ships Sea Water SystemsAnkit DedhiyaNo ratings yet

- Molybdenum DiSulphideDocument1 pageMolybdenum DiSulphideJitendra KumarNo ratings yet

- Motor Ship Steam Plan1Document3 pagesMotor Ship Steam Plan1Jitendra KumarNo ratings yet

- Tooth Design: Forces Acting On Spur GearsDocument77 pagesTooth Design: Forces Acting On Spur GearsJitendra KumarNo ratings yet

- Marpol 73Document12 pagesMarpol 73Jitendra KumarNo ratings yet

- Navigation LightingDocument1 pageNavigation LightingJitendra KumarNo ratings yet

- Microbes of Microbiological Attac1Document3 pagesMicrobes of Microbiological Attac1Jitendra KumarNo ratings yet

- Mechanical GovernorsDocument1 pageMechanical GovernorsJitendra KumarNo ratings yet

- LNG Reliquifactio1Document1 pageLNG Reliquifactio1Jitendra KumarNo ratings yet

- Motor Ship Steam Plant ControlDocument1 pageMotor Ship Steam Plant ControlJitendra KumarNo ratings yet

- Metallurgical TestingDocument1 pageMetallurgical TestingJitendra KumarNo ratings yet

- Low Sulphur FuelsDocument1 pageLow Sulphur FuelsJitendra KumarNo ratings yet

- Lube Oil Requirements For Diesel EnginesDocument3 pagesLube Oil Requirements For Diesel EnginesJitendra KumarNo ratings yet

- Jacket Water SystemDocument2 pagesJacket Water SystemJitendra KumarNo ratings yet

- Lifting Using Accessories: Calculation of LoadDocument2 pagesLifting Using Accessories: Calculation of LoadJitendra KumarNo ratings yet

- Liquified Gas CargoesDocument2 pagesLiquified Gas CargoesJitendra KumarNo ratings yet

- Cabezas de Rotulas-RotulasDocument64 pagesCabezas de Rotulas-RotulasFRANCISCO100% (1)

- Resume Executive Summary ExampleDocument5 pagesResume Executive Summary ExampleSathish GunasekarNo ratings yet

- Hot Products 2014Document8 pagesHot Products 2014inclumarhNo ratings yet

- LiquidlevelDocument24 pagesLiquidlevelAnu Raj Anu RajNo ratings yet

- Erita Astrid - UPBDocument25 pagesErita Astrid - UPBmas_kinooooNo ratings yet

- CFD Analysis of Free Cooling of Modular Data CentersDocument4 pagesCFD Analysis of Free Cooling of Modular Data CentersEmad AbdelsamadNo ratings yet

- Software: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsDocument8 pagesSoftware: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsBrandi DaleNo ratings yet

- The Mpeg Dash StandardDocument6 pagesThe Mpeg Dash Standard9716755397No ratings yet

- Section: Engine MechanicalDocument76 pagesSection: Engine MechanicalcesarNo ratings yet

- Anern Integrated Solar Garden Light-201604Document1 pageAnern Integrated Solar Garden Light-201604Godofredo VillenaNo ratings yet

- Opamp 5Document42 pagesOpamp 5Ann RazonNo ratings yet

- About Procurement ConsultingDocument3 pagesAbout Procurement ConsultingBiswadeep SarkarNo ratings yet

- Microsoft SQL DatabaseDocument401 pagesMicrosoft SQL Databasemtamilmani50% (2)

- Three-Phase Induction Motor Dynamic Mathematical ModelDocument3 pagesThree-Phase Induction Motor Dynamic Mathematical Modelsajs201100% (3)

- Contoh Ringkasan Mengajar Bahasa Inggeris Tahun 2 Dan 3Document2 pagesContoh Ringkasan Mengajar Bahasa Inggeris Tahun 2 Dan 3Izla MajidNo ratings yet

- Barrett Light 50Document23 pagesBarrett Light 50Zayd Iskandar Dzolkarnain Al-HadramiNo ratings yet

- A01 04 Assessmentk UndercarriageDocument7 pagesA01 04 Assessmentk UndercarriageMARIO DEL PINO MUÑOZNo ratings yet

- Safety Integrity Level (SIL) Determination Using LOPA Methods To Comply With IEC 61511 and ISA 84Document3 pagesSafety Integrity Level (SIL) Determination Using LOPA Methods To Comply With IEC 61511 and ISA 84naren_013No ratings yet

- Fundamentals of Petroleum Engineering BookDocument10 pagesFundamentals of Petroleum Engineering BookRizwan FaridNo ratings yet

- Optical Fiber Communication 06EC7 2: Citstudents - inDocument4 pagesOptical Fiber Communication 06EC7 2: Citstudents - inShailaja UdtewarNo ratings yet

- T8000 Type2 USER MANUAL - 47501358-A0 EN 2016-6-1Document10 pagesT8000 Type2 USER MANUAL - 47501358-A0 EN 2016-6-1AerdiaNo ratings yet

- Tank Specification - Fiberglass Tanks 0408Document13 pagesTank Specification - Fiberglass Tanks 0408shankarkl100% (2)

- Aj 245 LTDocument1 pageAj 245 LTHernan B.No ratings yet

- Invoice Cod Invoice Cod: Agen Pos Agen PosDocument4 pagesInvoice Cod Invoice Cod: Agen Pos Agen Poswahids0204No ratings yet

- ICEpublishing Complete 2014 Books CatalogueDocument44 pagesICEpublishing Complete 2014 Books CatalogueLamija LamyNo ratings yet

- VLSI Design FlowDocument20 pagesVLSI Design FlowPranav DarganNo ratings yet

- Japan Servo CatalogDocument39 pagesJapan Servo CatalogKofaKing100% (1)

- Blue Brain-The Future TechnologyDocument27 pagesBlue Brain-The Future TechnologyZuber MdNo ratings yet

- Chapter 3 Hydro Thermal SchedulingDocument65 pagesChapter 3 Hydro Thermal Schedulingbik_mesiloveNo ratings yet

- Types of CCTVDocument12 pagesTypes of CCTVpradeeplava950No ratings yet

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersFrom EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersRating: 4.5 out of 5 stars4.5/5 (2)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceFrom EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- A Pathway to Decarbonise the Shipping Sector by 2050From EverandA Pathway to Decarbonise the Shipping Sector by 2050No ratings yet

- Grid-Scale Energy Storage Systems and ApplicationsFrom EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNo ratings yet

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Global Landscape of Renewable Energy FinanceFrom EverandGlobal Landscape of Renewable Energy FinanceNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977From EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977No ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerFrom EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNo ratings yet

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)