Professional Documents

Culture Documents

Overall Arrangement: Description of The Salient Parts

Uploaded by

Jitendra Kumar0 ratings0% found this document useful (0 votes)

56 views6 pagesModern marine engine designs carefully optimize component designs to maximize strength while minimizing weight. The bedplate and A-frame combine to form a rigid box structure that withstands combustion forces and maintains crankshaft alignment. Transverse members in the bedplate support main bearings and transmit loads to the ship's structure. Camshaftless engine designs simplify components and allow finite control of parameters like fuel delivery and exhaust valve timing using solenoid valves instead of cams.

Original Description:

Original Title

Overall arrangement.doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentModern marine engine designs carefully optimize component designs to maximize strength while minimizing weight. The bedplate and A-frame combine to form a rigid box structure that withstands combustion forces and maintains crankshaft alignment. Transverse members in the bedplate support main bearings and transmit loads to the ship's structure. Camshaftless engine designs simplify components and allow finite control of parameters like fuel delivery and exhaust valve timing using solenoid valves instead of cams.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

56 views6 pagesOverall Arrangement: Description of The Salient Parts

Uploaded by

Jitendra KumarModern marine engine designs carefully optimize component designs to maximize strength while minimizing weight. The bedplate and A-frame combine to form a rigid box structure that withstands combustion forces and maintains crankshaft alignment. Transverse members in the bedplate support main bearings and transmit loads to the ship's structure. Camshaftless engine designs simplify components and allow finite control of parameters like fuel delivery and exhaust valve timing using solenoid valves instead of cams.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 6

Overall arrangement

Description of the salient parts

Modern engines designed for increasing power to weight ratios are reliant on not only stronger materials

but also on careful design. Each component design must not only be optimised for its own purpose, but

also in some cases, to provide strength to the overall structure.

An example of this is how the bedplate and A-frame combine to create a strong rigid box able

to resist the forces of combustion and maintain essential alignment for the crankshaft and over moving

parts.

The entablature not only supports the cylinder liner and head it also creates areas for cooling

water and scavenging air.

abrication techni!ues are extensively used simplifying castings and speeding assembly times

by reducing the number of fastening."n order to obtain ideal strength transfer between components the

fastenings must have intermit contact with the surfaces of the components and hence fitted bolts are

used.

#ylinder blocks must be cast, due to the difficulties in casting large components generally

single cylinder blocks are created $oined to each other and to a common fabricated A-frame%bedplate box.

Bedplate

The bedplate acts as the main strength member, maintains correct alignment and supports the weight of

the components. it must be capable of withstanding the fluctuating forces created during operation and

transmit them to the ships structure.

"n addition it may also collect lubricating oil.

"n slow speed engine design, it consists of a deep longitudinal box section with stiffening in

the form of members and webs.

Transverse members are fitted between each throw of the crankshaft. These support the main

bearing saddles and Tie -rod connection. They are attached to the structure by substantial butt welds.

To reduce the engine height the sump of the bedplate may be sunken allowing it to fitted into

a recess in the ships structure.

&late and weld preparation is re!uired with welds of the double butt type if possible. 'egular

internal inspection of the parts especially the transverse girder is re!uired for fatigue cracking. Tie bolts

should be checked for tighteness.

Box girders-A box girder is stronger and more rigid then " or ( section girder of the same c.s.a.

rom the simple beam bending e!uation we have)

M %" * s %y * E%'

M*+ending moment

I*,nd moment of area of the cross section

s *-tress

y*distance from the axis of bending to the outer face

E* modulus of elasticity

R-radius of curvature of the bending.

This can be arranged into

s = (M/I) . y

"t can be seen that for the same bending moment on a symmetrical shape of same si.e, the

stress is reduced on the increasing ,nd moment of area. The second moment of area increase with

moving of material away from the axis of bending towards the extremes of the section.

+ecause of this the commonest way of construction a fabricated bedplate is by creating two

box section girders and tie them using transverse girders.

The advent of the small bore slow speed has seen the use of single side bedplates. A box

section is then created by using a box section crankcase structure rather than the more traditional A-

frame.This has the advantages of reducing width as well as weight and increasing the amount of

fabrication so reducing assembly times.

/ue to the weight penalty, the use of cast iron is generally limited to smaller units where

fabrication becomes impractical. (owever, cast iron has internal resilience allowing it to dampen down

vibrations, this has led to its usage on some medium speed installations, especially passenger carriers,

where noise and vibration suppression is important. .

The most highly loaded pat of a bedplate is the transverse girder. #lassification societies

re!uire that residual stress is removed after construction.

The transverse girder acts as a simple beam with the forces of combustion acting on the

piston passing down through the bearing. The forces acting on the head are passed through the Tie rods.

"t can be seen that to reduce the bending moment the tie rods have to be brought closer to

the crankshaft. The limit to this is the securing arrangement re!uired for the main bearing keep. 0ne

method is to use two instead of one bolts which can be made of smaller diameter. -ul.er use an

alternative and very successful method in the form of $acking bolts. These $ack against the bottom of the

A-frame.

.

Superlong stokes

The increasing stroke to bore ratio has led to several problems not least of which is cylinder lubrication,

thermal gradients over stroke, starting etc. " addition there is a necessity to dampen rotational vibrations

over the engine height by means of hydraulic stays attached to the ships structure. These reduce the

movement of the engine without allowing excessive vibration to be transmitted to the hull.

Camshaftless engines

The camshaftless two stroke crosshead engine has two main advantages)

irstly it simplifies engine design in particular negating the need for chain or gear driven camshafts. This

allows a net reduction in weight, simplifies engine erection and removes some physical constraints for

future engine design.

-econdly, it allows for finite control of parameters such as fuel delivery volume and timing, and exhaust

valve opening and closing times.

Traditionally fuel, exhaust valve opening, starting air and cylinder lube oil delivery are all

controlled by camshaft lobe design. "t is possible now to control these using high reliability solenoid

valves. This method is used on the sul.er 'T-flex engine

uel control

uel is delivered to a common rail by a high efficiency fuel pump operated by a multilobe cam

driven off the main engine crankshaft.

A control unit activates electric solenoid valves to deliver fuel to the appropriate cylinder

in$ectors.

This allows control of fuel volume, fuel delivery progression 1 that is the shape of fuel

delivery- e.g slow than fast2 and precise timing. "t means that fuel ignition !uality and condition at

delivery can be taken into account.

Exhaust valves

Exhaust valves are operated in the normal way via hydraulic pushrods. (owever hydraulic oil delivery is

not by individual pump but by common rail supplied by a high capacity, high pressure servo pump. The

engine management control unit operates the exhaust valves by energising the appropriate solenoid

valve. 0ther starting air valves and cylinder lube oil are all similarly controlled by the engine management

control unit via solenoid valves

Modern developments

The modern trend has followed the smaler and lighter rule with an ever increaseing power to weight ratio.

"n addition to this simplified maintenance and production proceddures have been incorporated.

"ntelligent engines without camshafts are being introduced enabling increased efficiency with

reduced fuel !uality. "ntelligent engines also allow for increased efficiency when running at part load.

Liners

Modern requirements for the design and contruction of a cylinder liner include;

Material with sufficient hard phase and ductility

Smooth surface finish

ull honing of running surface

!ore cooling of liner and components surrounding com"ustion chanm"er# the insertion of

insulating tu"es into the "ore cooling holes of liners is sometimes necessary to pre$ent

undercooling and allow a standard liner to "e used with different ratings.

%ritical profiling of liner wall thic&ness to sta"ilise temperatures and pre$ent corosion attac&

Multi#le$el cylinder lu"rication with $aria"le speed (load dependant) pumps

'fficient water remo$al from sca$enge air

(istons

(igh topland 1 the 3st piston ring is positioned will below the upper surface of the piston2 with asociated

reduced ring heat load has given better ring pack performance by improving working conditions for the

cylinder lube oil. The disadvantage of this system is that a coke build up can occur aboth the piston which

leads to 4bore polishing4. This polishing reduces the ability of the cylinder lube oil to 4key4 into the liner

therefore increased cylinder lube oil consumption%increased liner wear can result. To combat this piston

cleaning rings are incorporated into the liner. These slightly reduce the bore removing the depoisits.

5

You might also like

- Engines Awy, Azq, BMD, BmeDocument94 pagesEngines Awy, Azq, BMD, BmeAlina Teodora100% (2)

- Crankshaft Construction DesignDocument10 pagesCrankshaft Construction DesignChockalingam AthilingamNo ratings yet

- Cranshaft, Crosshead and BearingDocument47 pagesCranshaft, Crosshead and BearingMeghanath Adkonkar0% (1)

- Bedplate PDFDocument4 pagesBedplate PDFDean DsouzaNo ratings yet

- Type of CrankshaftsDocument3 pagesType of Crankshaftsmister_no34No ratings yet

- CAT 992G Wheel LoaderDocument20 pagesCAT 992G Wheel LoaderarnoldNo ratings yet

- 4 Stroke EngineDocument6 pages4 Stroke Engineasra 10100% (2)

- Cat C 6.4 Fuel SystemDocument13 pagesCat C 6.4 Fuel Systemali83% (6)

- Lunati CatalogDocument340 pagesLunati Catalogfreek76No ratings yet

- Lenox Ge-JenbacharDocument6 pagesLenox Ge-JenbacharJamil Ahmed100% (2)

- Diesel Engine ConstructionDocument53 pagesDiesel Engine ConstructionLasse HansenNo ratings yet

- Diesel Engine ConstructionDocument42 pagesDiesel Engine Constructionanon_322442463100% (1)

- Answers Class 2 2017 OctDocument21 pagesAnswers Class 2 2017 OctThusitha DalpathaduNo ratings yet

- Crankshaft 1Document7 pagesCrankshaft 1Jitendra KumarNo ratings yet

- Fundamentals of Tractor Engine Design Author(s) : H C Buffington Source: SAE Transactions, Vol. 13, PART I (1918), Pp. 208-219 Published By: SAE International Accessed: 18-01-2022 07:03 UTCDocument13 pagesFundamentals of Tractor Engine Design Author(s) : H C Buffington Source: SAE Transactions, Vol. 13, PART I (1918), Pp. 208-219 Published By: SAE International Accessed: 18-01-2022 07:03 UTCSuraj FesgaleNo ratings yet

- Report of Cam ShaftDocument85 pagesReport of Cam ShaftkotoyayNo ratings yet

- Minor ProjectDocument7 pagesMinor ProjectNeeraj Tiwari100% (1)

- PPD ReportingDocument46 pagesPPD ReportingFernando CruzNo ratings yet

- Cam ViceDocument50 pagesCam ViceAakash Dindigul100% (1)

- MCE 4780: Mechanical Engineering Lab 1: Fahim Shahrier, 160011052, MCE 16, Group B 2nd February 2020Document19 pagesMCE 4780: Mechanical Engineering Lab 1: Fahim Shahrier, 160011052, MCE 16, Group B 2nd February 2020Fahim ShahrierNo ratings yet

- Machine Shop CNCDocument28 pagesMachine Shop CNCSonia rajpuroitNo ratings yet

- The Diesel LocomotiveDocument24 pagesThe Diesel LocomotivePool KingNo ratings yet

- Marine Diesel EngineDocument5 pagesMarine Diesel Enginemy generalNo ratings yet

- Report v12 (Numbering)Document26 pagesReport v12 (Numbering)Viken PatelNo ratings yet

- 2 Stroke Diesel Engine Components-1Document72 pages2 Stroke Diesel Engine Components-1EdemNo ratings yet

- Chapter - 3 Study of The Components of The EngineDocument14 pagesChapter - 3 Study of The Components of The EngineKenmoe T DonasNo ratings yet

- Piston - WikipediaDocument30 pagesPiston - WikipediaLAliNo ratings yet

- Design of Connecting RodDocument26 pagesDesign of Connecting RodAbijit GudaNo ratings yet

- Identification of The Diesel Engine ComponentsDocument13 pagesIdentification of The Diesel Engine Componentsguswerino240% (1)

- BearingsDocument4 pagesBearingsaloordominicNo ratings yet

- SAG Mill ComponentsDocument7 pagesSAG Mill ComponentsRodrigo GarcíaNo ratings yet

- Analysis of Crank ShaftDocument10 pagesAnalysis of Crank Shaftvenkatesh konigapoguNo ratings yet

- ASSIGNMENT 2 by b3Document16 pagesASSIGNMENT 2 by b3devmarineacademyNo ratings yet

- Final Engine ProjectDocument38 pagesFinal Engine Projectvinayharish02002No ratings yet

- Two StrokeDocument11 pagesTwo StrokeAfzal Shams100% (1)

- 4 ReportDocument89 pages4 ReportRajesh KesapragadaNo ratings yet

- Engine ConstructionDocument89 pagesEngine ConstructionVinod Cf Cruz100% (2)

- Shaft Diameter PDFDocument8 pagesShaft Diameter PDFrusruleti100% (1)

- Block - ConrodDocument22 pagesBlock - ConrodArnold ChafewaNo ratings yet

- Connecting RodDocument36 pagesConnecting Rodpramo_dass0% (1)

- Case Study: CrankshaftsDocument12 pagesCase Study: CrankshaftsDHRUV SINGHALNo ratings yet

- Camshaft: Chilled Iron Castings: This Is A Good Choice For High Volume Production. A Chilled IronDocument5 pagesCamshaft: Chilled Iron Castings: This Is A Good Choice For High Volume Production. A Chilled IronAnonymous wC8MmcNo ratings yet

- Himsen Cat h2533Document12 pagesHimsen Cat h2533Mohsen50% (2)

- A Presentation On Connecting-Rod: University of Kirkuk College of Engineering Mech. Dept. - Third StageDocument19 pagesA Presentation On Connecting-Rod: University of Kirkuk College of Engineering Mech. Dept. - Third StageTara NafihNo ratings yet

- Final Engine Report.Document28 pagesFinal Engine Report.Chethu ChethuNo ratings yet

- Parts and Functional Description of Diesel EngineDocument12 pagesParts and Functional Description of Diesel EngineVinay GirdharNo ratings yet

- Literature Review On Connecting RodDocument6 pagesLiterature Review On Connecting Rodaflspyogf100% (1)

- Forging of CrankshaftDocument4 pagesForging of Crankshaftkhor_yin_1No ratings yet

- Two Stroke EngineDocument13 pagesTwo Stroke EngineAaron PriceNo ratings yet

- Hoag 2015Document30 pagesHoag 2015tahreem hussainNo ratings yet

- Bed Plate Main Engine BedplateDocument52 pagesBed Plate Main Engine BedplateSuhas KassaNo ratings yet

- Air Gap Piston Design and AnalysisDocument56 pagesAir Gap Piston Design and AnalysisSireeshNo ratings yet

- Cilinderkopbouten EngelsDocument18 pagesCilinderkopbouten EngelsBabei Ionut-MihaiNo ratings yet

- Final-Advance Breaking System For Hill Drive VehiclesDocument59 pagesFinal-Advance Breaking System For Hill Drive VehiclesMurali VannappanNo ratings yet

- EM 6815 EN - Solutions For Traction MotorsDocument20 pagesEM 6815 EN - Solutions For Traction MotorsIvan Dulic100% (1)

- Module-I Notes PDFDocument35 pagesModule-I Notes PDFNAVEEN H ENo ratings yet

- Basic Engine: Systems OperationDocument3 pagesBasic Engine: Systems OperationTri WahyuningsihNo ratings yet

- Crankshaft ConstructionDocument24 pagesCrankshaft ConstructionBharatiyulam100% (2)

- Hydrostatic Journal BearingDocument14 pagesHydrostatic Journal Bearingapi-19775783100% (4)

- Diesel Engine and Fuel Oil System of ALCODocument53 pagesDiesel Engine and Fuel Oil System of ALCOAditya Srivastava100% (2)

- Discussion: How To Do The Crankshaft Deflection and Draw The Deflection DiagramDocument11 pagesDiscussion: How To Do The Crankshaft Deflection and Draw The Deflection DiagramMani RajNo ratings yet

- MD PPT 150183119005,06Document28 pagesMD PPT 150183119005,06rip111176No ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Pilgrim NutDocument2 pagesPilgrim NutJitendra KumarNo ratings yet

- PID TuningDocument4 pagesPID TuningJitendra Kumar100% (1)

- Oil WhirlDocument2 pagesOil WhirlJitendra KumarNo ratings yet

- Oxygen AnalysersDocument2 pagesOxygen AnalysersJitendra KumarNo ratings yet

- Oily Water SeperatorsDocument2 pagesOily Water SeperatorsJitendra KumarNo ratings yet

- Increasing Propulsive EfficiencyDocument6 pagesIncreasing Propulsive EfficiencyJitendra KumarNo ratings yet

- Motor Ship Steam Plan1Document3 pagesMotor Ship Steam Plan1Jitendra KumarNo ratings yet

- Mechanical GovernorsDocument1 pageMechanical GovernorsJitendra KumarNo ratings yet

- Tooth Design: Forces Acting On Spur GearsDocument77 pagesTooth Design: Forces Acting On Spur GearsJitendra KumarNo ratings yet

- Motor Ship Steam Plant ControlDocument1 pageMotor Ship Steam Plant ControlJitendra KumarNo ratings yet

- Holding Down ArrangementsDocument3 pagesHolding Down ArrangementsJitendra KumarNo ratings yet

- Navigation LightingDocument1 pageNavigation LightingJitendra KumarNo ratings yet

- LNG Containment DesignsDocument3 pagesLNG Containment DesignsJitendra KumarNo ratings yet

- Liquified Gas CargoesDocument2 pagesLiquified Gas CargoesJitendra KumarNo ratings yet

- Lifting Using Accessories: Calculation of LoadDocument2 pagesLifting Using Accessories: Calculation of LoadJitendra KumarNo ratings yet

- Hull ConstructionDocument4 pagesHull ConstructionJitendra KumarNo ratings yet

- Hydraulic SystemsDocument4 pagesHydraulic SystemsJitendra KumarNo ratings yet

- Jacket Water SystemDocument2 pagesJacket Water SystemJitendra KumarNo ratings yet

- LiftingDocument5 pagesLiftingJitendra KumarNo ratings yet

- Hydraulic GovernorsDocument6 pagesHydraulic GovernorsJitendra KumarNo ratings yet

- Halon 1301 Bromotrichlhoromethane CF3BrDocument2 pagesHalon 1301 Bromotrichlhoromethane CF3BrJitendra Kumar0% (1)

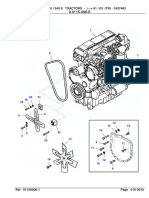

- Massey Ferguson 240 TRACTOR Service Parts Catalogue Manual (Part Number 1637463)Document15 pagesMassey Ferguson 240 TRACTOR Service Parts Catalogue Manual (Part Number 1637463)zhuangfuqian31No ratings yet

- TURBOCHARGERDocument5 pagesTURBOCHARGERAnand Raju100% (1)

- Propeller Pitch GaugeDocument1 pagePropeller Pitch GaugeEndie WibowoNo ratings yet

- Catálogo de Peças PC 200 - 8Document458 pagesCatálogo de Peças PC 200 - 8RodrigoNo ratings yet

- Soal Airframe FixDocument8 pagesSoal Airframe FixMonita DiazsNo ratings yet

- 0900 - 1081 - 00 C500 D6 (QSX15G9 With PCC3201)Document2 pages0900 - 1081 - 00 C500 D6 (QSX15G9 With PCC3201)ibrahemNo ratings yet

- Catalogue WisecoDocument8 pagesCatalogue WisecoPierre LemaireNo ratings yet

- Schlumberger CPS-361Document1 pageSchlumberger CPS-361Игорь ШиренинNo ratings yet

- Filtros para MTTODocument6 pagesFiltros para MTTOIH MedranoNo ratings yet

- Module X2 (L99 or LS3 or LS7)Document4 pagesModule X2 (L99 or LS3 or LS7)Data TécnicaNo ratings yet

- Ata 71 - B1 - Iae V2500Document61 pagesAta 71 - B1 - Iae V2500Abil Gilang -No ratings yet

- The Jet EngineDocument1 pageThe Jet EngineRazvan CristeaNo ratings yet

- Lycoming Service Letter No. L185BDocument3 pagesLycoming Service Letter No. L185BLo AdsoNo ratings yet

- Installation Instructions For 20950, 20951, 20952, 20953 LS Series Roller Rocker ArmsDocument1 pageInstallation Instructions For 20950, 20951, 20952, 20953 LS Series Roller Rocker ArmsWayne LundNo ratings yet

- MAN B&W Diesel A/S: Service LetterDocument4 pagesMAN B&W Diesel A/S: Service LetterAleksandar Sasa SeferovicNo ratings yet

- QSB 6.7 230 3000 Id-08may13 PDFDocument3 pagesQSB 6.7 230 3000 Id-08may13 PDFmech118No ratings yet

- 300 TDI + PotenciaDocument20 pages300 TDI + PotenciaFelip Masses GarciaNo ratings yet

- 316 Service ManualDocument20 pages316 Service ManualBalast MetheeNo ratings yet

- Self-Diagnosis Data Self-Diagnosis ParametersDocument2 pagesSelf-Diagnosis Data Self-Diagnosis Parametersneoporsche15No ratings yet

- Piston AssemblyDocument17 pagesPiston AssemblySelazinap LptNo ratings yet

- SNM 13 - 022 Kev2 spn5394 Fmi17 DiagnosticDocument9 pagesSNM 13 - 022 Kev2 spn5394 Fmi17 DiagnosticMaxime PoirierNo ratings yet

- F250GDocument95 pagesF250GMuhammad Safri Adi ZamilNo ratings yet

- Manual KTM 350 SXFDocument12 pagesManual KTM 350 SXFLeonardo LinaresNo ratings yet

- Cylinder Lubrication Marine Engines ArticleDocument10 pagesCylinder Lubrication Marine Engines ArticleVijay Geddada100% (2)