Professional Documents

Culture Documents

Figure 6-18A Checking Wastegate Calibration

Uploaded by

victover100%(2)100% found this document useful (2 votes)

842 views6 pagesSERIES 60 SERVICE MANUAL All information subject to change without notice. 6-30a 6.4.3. Checking Wastegate Calibration Remove hose from Wastegate Actuator. Set up an indicator at the end of the Wastegate Actuator adjusting rod to measure actuator Rod Travel. The indicator should have a minimum travel of 0.100 in.

Original Description:

Original Title

Wastegate Turbo 2.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSERIES 60 SERVICE MANUAL All information subject to change without notice. 6-30a 6.4.3. Checking Wastegate Calibration Remove hose from Wastegate Actuator. Set up an indicator at the end of the Wastegate Actuator adjusting rod to measure actuator Rod Travel. The indicator should have a minimum travel of 0.100 in.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

842 views6 pagesFigure 6-18A Checking Wastegate Calibration

Uploaded by

victoverSERIES 60 SERVICE MANUAL All information subject to change without notice. 6-30a 6.4.3. Checking Wastegate Calibration Remove hose from Wastegate Actuator. Set up an indicator at the end of the Wastegate Actuator adjusting rod to measure actuator Rod Travel. The indicator should have a minimum travel of 0.100 in.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1996 DETROIT DIESEL CORPORATION From Bulletin 14-60-98 6-30a

6.4.3.2 Checking Wastegate Calibration

Check the wastegate calibration as follows:

1. Remove hose from wastegate actuator.

2. Set up an indicator at the end of the wastegate actuator adjusting rod to measure actuator

rod travel. The indicator should have a minimum travel of 0.100 in.

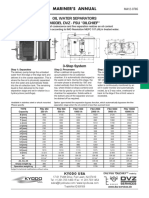

3. Connect regulator and pressure gage setup to wastegate actuator. See Figure 6-18A.

1.Hose to Wastegate Actuator 4.Supply Air Shutoff Valve

2.Pressure Regulator 5.Pressure Gage

3.Shop Air Supply 6.Vent Valve

Figure 6-18A Checking Wastegate Calibration

6.4 TURBOCHARGER (Diesel)

All information subject to change without notice.

6-30b From Bulletin 14-60-98 6SE483 9610 1998 DETROIT DIESEL CORPORATION

4. Apply specified calibration pressure as listed in Table 6-1A , to the wastegate actuator.

Model Rating Set Pressure at .04 in. Rod

Travel

11.1 L 330-350 Hp 27 lb/in.

2

(186 kPa)

12.7 L 360-500 Hp 31 lb/in.

2

(214 kPa)

Table 6-1A Wastegate Calibration Pressure at .04 Inch Rod Travel

5. Close air supply shutoff valve. The pressure should hold at the specified pressure. If not,

check air hose and fitting connections for leaks. If none are found, replace wastegate

actuator. Refer to section 6.3.3.3.

6. Open vent to relieve pressure. Check gage for zero pressure reading. Adjust regulator to

zero pressure and close vent valve.

7. Adjust dial indicator so it just contacts the actuator rod end and adjust to zero reading.

8. Open air supply shutoff valve and slowly adjust regulator until dial indicator reads 0.040

in. Switch pressure on and off, opening and closing supply air and vent valves, to ensure

dial indicator travel is from 0.00 in. to 0.040 in. and that the pressure reading is

consistent.

9. For currently calibrated wastegate actuator, a pressure within .50 lb/in.

2

(3.4 kPa) of

the value listed in Table 6-1A, will be required to obtain precisely 0.040 in. actuator

travel. If the pressure required is outside this range, wastegate adjustment is necessary.

Refer to section 6.3.3.3.

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1996 DETROIT DIESEL CORPORATION From Bulletin 14-60-98 6-30c

6.4.3.3 Removal of Wastegate Actuator

Remove the wastegate actuator as follows:

1. Remove actuator hose from top side of actuator can. See Figure 6-18A. With the

pressure gage setup, apply enough pressure to the actuator can until the rod begins to

move. Refer to section 6.4.3.4.

2. Remove the retaining clip that holds the actuator rod end on the worm pin. Lift rod off

the wastegate lever pin.

NOTICE:

Never remove the rod end from the wastegate lever pin without

applying pressure to the top side actuator port, or damage to the

actuator diaphragm may result.

3. Remove the locknuts that secure the actuator can to the base of the actuator bracket and

remove the can from the turbocharger assembly.

6.4.3.4 Installation of Wastegate Actuator

Further adjustment of the actuator will be necessary to achieve the correct pressure setting, listed

in Table 6-1A.

Install the wastegate actuator as follows:

1. Install actuator can on bracket; tighten locknuts.

2. Using pressure gage setup, apply enough pressure to the new service actuator can until

the rod begins to move.

3. Adjust actuator rod end by turning either clockwise or counterclockwise on rod so that

the rod end hole lines up with the wastegate lever arm. While wastegate is held shut, slip

rod over pin.

4. Before installing retaining clip, the rod end will need to be adjusted to the correct setting.

Refer to section 6.4.3.5.

6.4 TURBOCHARGER (Diesel)

All information subject to change without notice.

6-30d From Bulletin 14-60-98 6SE483 9610 1998 DETROIT DIESEL CORPORATION

6.4.3.5 Setting the Wastegate

Before following this procedure, check the actuator set pressure to see if adjustment is needed.

Refer to section 6.4.3.2.

Set pressure adjustment as follows:

1. Loosen the jam nut that secures the rod end on the actuator rod. If locking collar is

present on the actuator rod, remove and discard collar. See Figure 6-18B.

1.Wastegate Actuator Assembly 4.Adjusting Rod End

2.Locking Collar 5.Retainer Clip

3.Jam Nut 6.Wastegate Lever and Pin Assembly

Figure 6-18B Wastegate Adjustment

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1996 DETROIT DIESEL CORPORATION From Bulletin 14-60-98 6-30e

2. Remove the retaining clip that holds the actuator rod end on the wastegate lever arm pin.

3. Using pressure gage setup, apply enough pressure to the top side actuator can port until

the rod begins to move, lifting the wastegate valve off its seal. See Figure 6-18B.

4. Slip rod end off the wastegate lever arm pin.

5. Adjust rod as needed:

[a] To INCREASE pressure setting at .04 in., turn rod end CLOCKWISE.

[b] To DECREASE pressure setting at .04 in., turn rod end COUNTERCLOCKWISE.

6. With pressure still applied to actuator, replace rod end on wastegate lever arm.

7. Check actuator set pressure again. Refer to section 6.4.3.4.

8. If actuator is still out of adjustment, repeat this procedure.

9. If actuator is within specified set pressure, install retaining clip on wastegate lever arm

pin.

10. Tighten jam nut to secure rod end.

6.4 TURBOCHARGER (Diesel)

All information subject to change without notice.

6-30f From Bulletin 14-60-98 6SE483 9610 1998 DETROIT DIESEL CORPORATION

This Page Intentionally

Left Blank.

You might also like

- HU - Century Station - PAL517PDocument232 pagesHU - Century Station - PAL517PTony Monaghan100% (3)

- GM Powertrain 6.6 L l5p Engine Features SpecificationsDocument2 pagesGM Powertrain 6.6 L l5p Engine Features SpecificationsZuskerNo ratings yet

- Single-Reduction Forward Differential Carriers On Tandem and Tridem AxlesDocument132 pagesSingle-Reduction Forward Differential Carriers On Tandem and Tridem AxlesGlez BaNo ratings yet

- RTLO 16913A Fuller 13 Speed Parts Breakdown ManualDocument58 pagesRTLO 16913A Fuller 13 Speed Parts Breakdown ManualIsrael ReyesNo ratings yet

- 00 017695Document4 pages00 017695Walter LazoNo ratings yet

- Service Bulletin Trucks: Engine, ReplacementDocument29 pagesService Bulletin Trucks: Engine, Replacementvicente456No ratings yet

- Accent Compession Pressure InspectionDocument12 pagesAccent Compession Pressure Inspectionflash_24014910No ratings yet

- Instructions Egr DeleteDocument8 pagesInstructions Egr Deletegeorge100% (1)

- 2018 Chevrolet Silverado 1500 SSV Order GuideDocument41 pages2018 Chevrolet Silverado 1500 SSV Order GuiderfffffNo ratings yet

- Diesel Engine Series 50 and 60: For Petroleum ApplicationsDocument16 pagesDiesel Engine Series 50 and 60: For Petroleum ApplicationsOscar FedeNo ratings yet

- Bobinas Freno de Motor Jacobs BrakeDocument2 pagesBobinas Freno de Motor Jacobs BrakePaqko EscamillaOfficialNo ratings yet

- Mack-Vs-KW Chile Tailored 080106Document92 pagesMack-Vs-KW Chile Tailored 080106yamitalbertoNo ratings yet

- Waste Gate RegulaciónDocument4 pagesWaste Gate RegulaciónKelvin RamirezNo ratings yet

- Electric Starting System - Test: Testing and AdjustingDocument5 pagesElectric Starting System - Test: Testing and Adjustingmanuel100% (1)

- C11 ACERT 261bkWDocument5 pagesC11 ACERT 261bkWJulio huanriNo ratings yet

- Perkins Diesel Engine Wiring - ElectroPakDocument7 pagesPerkins Diesel Engine Wiring - ElectroPakServicios y Repuestos Jeremy Azhael 2320 C.A100% (1)

- RT - 125xxDocument92 pagesRT - 125xxAnGel AmayaNo ratings yet

- Instruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionDocument42 pagesInstruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionVladimirNo ratings yet

- Grade 9 WorkbookDocument44 pagesGrade 9 WorkbookMaria Russeneth Joy NaloNo ratings yet

- 2005 Ram Intro PDFDocument14 pages2005 Ram Intro PDFRonaldNo ratings yet

- D12D425 VHD PDFDocument2 pagesD12D425 VHD PDFMarco Antonio Esparza CastroNo ratings yet

- Project Manager PMP PMO in Houston TX Resume Nicolaas JanssenDocument4 pagesProject Manager PMP PMO in Houston TX Resume Nicolaas JanssenNicolaasJanssenNo ratings yet

- ENGINE Fuel System - Ram Pickup PDFDocument391 pagesENGINE Fuel System - Ram Pickup PDFcharlesNo ratings yet

- Engine Electrical PDFDocument48 pagesEngine Electrical PDFMuhammad Rofi ArofahNo ratings yet

- 27 1745 Chevy Silverado Installation Instructions CaridDocument4 pages27 1745 Chevy Silverado Installation Instructions CaridenthonytopmakNo ratings yet

- Participant Observation: Qualitative Research Methods: A Data Collector's Field GuideDocument17 pagesParticipant Observation: Qualitative Research Methods: A Data Collector's Field GuideMarta CabreraNo ratings yet

- Fan Clutches 2017Document236 pagesFan Clutches 2017CCORES Diesel Technical DieselNo ratings yet

- C-18 Caterpillar Engine For PM200 Cold Planer P1M00001-UP (MACHINE) POWERED BY C-18 Engine (KEBP0335 - 04) - Product StructureDocument4 pagesC-18 Caterpillar Engine For PM200 Cold Planer P1M00001-UP (MACHINE) POWERED BY C-18 Engine (KEBP0335 - 04) - Product Structurebasem elhosanyNo ratings yet

- Noviembre 2018 TRANSMISIONES EATON FULLER PDFDocument28 pagesNoviembre 2018 TRANSMISIONES EATON FULLER PDFRicardo MontañezNo ratings yet

- Engine Coolant 2 PDFDocument3 pagesEngine Coolant 2 PDFvictoverNo ratings yet

- LKG Math Question Paper: 1. Count and Write The Number in The BoxDocument6 pagesLKG Math Question Paper: 1. Count and Write The Number in The BoxKunal Naidu60% (5)

- Tools 4l30eDocument0 pagesTools 4l30eMilton MiltonNo ratings yet

- Innovativ and Liabl :: Professional Electronic Control Unit Diagnosis From BoschDocument28 pagesInnovativ and Liabl :: Professional Electronic Control Unit Diagnosis From BoschacairalexNo ratings yet

- Internet Bill FormatDocument1 pageInternet Bill FormatGopal Singh100% (1)

- CUMMINS N14 Specifications - ManualzzDocument3 pagesCUMMINS N14 Specifications - ManualzzChâu TínNo ratings yet

- Ecf9 Nh3 ManualDocument20 pagesEcf9 Nh3 Manualgonza100% (1)

- BERGSTROM Manual Instalación KenworthDocument39 pagesBERGSTROM Manual Instalación KenworthCarlos AnticonaNo ratings yet

- Señalizadores EATONDocument107 pagesSeñalizadores EATONFran IgledominguezNo ratings yet

- Toyota Camry 2006-2011 2AZ-FE ChargingDocument21 pagesToyota Camry 2006-2011 2AZ-FE ChargingMichael MatthewsNo ratings yet

- Oil Water Separators Model DVZ - Fsu "Oilchief": 3-Step SystemDocument1 pageOil Water Separators Model DVZ - Fsu "Oilchief": 3-Step SystemRajishkumar RadhakrishnanNo ratings yet

- Codigos de Falla Del BHMDocument14 pagesCodigos de Falla Del BHMJusto Paniagua ChampaNo ratings yet

- Q4 Music 6 Module 2Document15 pagesQ4 Music 6 Module 2Dan Paolo AlbintoNo ratings yet

- Series 60 - Section 6.3 Intake ManifoldDocument7 pagesSeries 60 - Section 6.3 Intake ManifoldJuan RiveraNo ratings yet

- Drive Axle PDFDocument12 pagesDrive Axle PDFnamduong368No ratings yet

- 31 Series Trouble ShootingDocument4 pages31 Series Trouble ShootingrburtonshawNo ratings yet

- ESA Installation InstructionsDocument9 pagesESA Installation InstructionsCharly RamosNo ratings yet

- 2009 Commercial Truck BrochureDocument17 pages2009 Commercial Truck BrochureGateway Chevrolet Cadillac100% (1)

- Diagrama de Caja de Fusibles Ford f150 Año 1992Document3 pagesDiagrama de Caja de Fusibles Ford f150 Año 1992Oscar Gutiérrez100% (2)

- Printing From UndefinedDocument289 pagesPrinting From UndefinedING. RUBENSNo ratings yet

- Installation: 1Gr-Fe Engine Mechanical - Drive BeltDocument1 pageInstallation: 1Gr-Fe Engine Mechanical - Drive BeltPedro Javier Castro SanchezNo ratings yet

- 1776279Document82 pages1776279Tengku Nizarul AslamiNo ratings yet

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDocument4 pagesQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioHamilton miranda100% (1)

- Autohelm 6000 Power Pilot Installation and Operating Handbook PDFDocument18 pagesAutohelm 6000 Power Pilot Installation and Operating Handbook PDFМилен НанковNo ratings yet

- 5.3 Cruise Control: 5.3.1 OperationDocument9 pages5.3 Cruise Control: 5.3.1 OperationdinhvuNo ratings yet

- (TM) Great Wall Manual de Motor Great Wall gw4d20 2016 en InglesDocument61 pages(TM) Great Wall Manual de Motor Great Wall gw4d20 2016 en InglesKelvin van der MerweNo ratings yet

- A604 To LimbDocument11 pagesA604 To LimbcesarvazquezNo ratings yet

- Direct Injection (Current) PDFDocument7 pagesDirect Injection (Current) PDFToni JuanNo ratings yet

- DEH-X500BT DEH-S4150BT: CD Rds Receiver Receptor de CD Con Rds CD Player Com RdsDocument53 pagesDEH-X500BT DEH-S4150BT: CD Rds Receiver Receptor de CD Con Rds CD Player Com RdsLUIS MANUEL RINCON100% (1)

- Wiring Pigtail Kits/ Wiring Terminal Kits: MotorcraftDocument56 pagesWiring Pigtail Kits/ Wiring Terminal Kits: MotorcraftjackNo ratings yet

- Detroit S60 SpecsDocument2 pagesDetroit S60 Specsgrgramm50% (2)

- CBR600 F3Document24 pagesCBR600 F3Eloy RosNo ratings yet

- Eaton Fuller RTLOF 16918B Transmission Parts ManualDocument42 pagesEaton Fuller RTLOF 16918B Transmission Parts ManualPaty CervantesNo ratings yet

- Valvula Diluvio F470Document16 pagesValvula Diluvio F470eduardoNo ratings yet

- Specifications: General InformationDocument15 pagesSpecifications: General InformationyemenNo ratings yet

- Cylinder PDFDocument3 pagesCylinder PDFdinhvuNo ratings yet

- Alloytech VACCDocument8 pagesAlloytech VACCDaniel Hernandez100% (2)

- 2004 6.0L F-Error de ArranqueDocument1 page2004 6.0L F-Error de ArranqueAlejandraNo ratings yet

- SB388CDocument13 pagesSB388CBenjamin LeedsNo ratings yet

- Water Pump PDFDocument2 pagesWater Pump PDFvictoverNo ratings yet

- 8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionDocument2 pages8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionvictoverNo ratings yet

- 1.16.1 Repair or Replacement of Flywheel HousingDocument2 pages1.16.1 Repair or Replacement of Flywheel HousingvictoverNo ratings yet

- Connecting Rod PDFDocument9 pagesConnecting Rod PDFvictoverNo ratings yet

- Migne. Patrologiae Cursus Completus: Series Latina. 1800. Volume 51.Document516 pagesMigne. Patrologiae Cursus Completus: Series Latina. 1800. Volume 51.Patrologia Latina, Graeca et OrientalisNo ratings yet

- Land of PakistanDocument23 pagesLand of PakistanAbdul Samad ShaikhNo ratings yet

- Mode of Action of Vancomycin: L D D D D DDocument8 pagesMode of Action of Vancomycin: L D D D D DNolanNo ratings yet

- 2a Unani Medicine in India - An OverviewDocument123 pages2a Unani Medicine in India - An OverviewGautam NatrajanNo ratings yet

- 3rd Page 5Document1 page3rd Page 5api-282737728No ratings yet

- Mule 4 Error Handling DemystifiedDocument8 pagesMule 4 Error Handling DemystifiedNicolas boulangerNo ratings yet

- Britannia Volume 12 Issue 1981 (Doi 10.2307/526240) Michael P. Speidel - Princeps As A Title For 'Ad Hoc' CommandersDocument8 pagesBritannia Volume 12 Issue 1981 (Doi 10.2307/526240) Michael P. Speidel - Princeps As A Title For 'Ad Hoc' CommandersSteftyraNo ratings yet

- M.Plan SYLLABUS 2022-24Document54 pagesM.Plan SYLLABUS 2022-24Mili DawsonNo ratings yet

- Ideal Gas Law Lesson Plan FinalDocument5 pagesIdeal Gas Law Lesson Plan FinalLonel SisonNo ratings yet

- The Grass Rink Summer Final 2019Document9 pagesThe Grass Rink Summer Final 2019api-241553699No ratings yet

- Model TB-16Document20 pagesModel TB-16xuanphuong2710No ratings yet

- 200150, 200155 & 200157 Accelerometers: DescriptionDocument16 pages200150, 200155 & 200157 Accelerometers: DescriptionJOSE MARIA DANIEL CANALESNo ratings yet

- Paramount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceDocument1 pageParamount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceSwapnil TiwariNo ratings yet

- Kidney Stone Diet 508Document8 pagesKidney Stone Diet 508aprilNo ratings yet

- ICD10WHO2007 TnI4Document1,656 pagesICD10WHO2007 TnI4Kanok SongprapaiNo ratings yet

- Distribution BoardDocument7 pagesDistribution BoardmuralichandrasekarNo ratings yet

- III.A.1. University of Hawaii at Manoa Cancer Center Report and Business PlanDocument35 pagesIII.A.1. University of Hawaii at Manoa Cancer Center Report and Business Planurindo mars29No ratings yet

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNo ratings yet

- Research Paper On Air QualityDocument4 pagesResearch Paper On Air Qualityluwahudujos3100% (1)

- Bajaj CNSDocument3 pagesBajaj CNSAbhijit PaikarayNo ratings yet

- Bag Technique and Benedict ToolDocument2 pagesBag Technique and Benedict ToolAriel Delos Reyes100% (1)