Professional Documents

Culture Documents

Chromatography IV

Uploaded by

Russell Chua0 ratings0% found this document useful (0 votes)

65 views55 pagesThis is quite an informative document on chromatography.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis is quite an informative document on chromatography.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

65 views55 pagesChromatography IV

Uploaded by

Russell ChuaThis is quite an informative document on chromatography.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 55

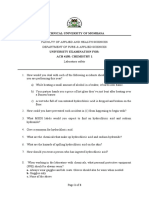

PHARMACEUTICAL ANALYSIS I

CHROMATOGRAPHY IV: GAS CHROMATOGRAPHY

a. Instrumentation/Layout

b. Principles behind Gas Liquid and Gas Solid Chromatography

c. Column types

d. Stationary phase

e. Types of detectors

f. Qualitative and quantitative analysis

g. Applications and examples

h. Derivation of samples

DR. CHIN

Instrumentation/Layout

Filters/Traps

A

i

r

H

y

d

r

o

g

e

n

G

a

s

C

a

r

r

i

e

r

Column

Data system

Syringe/Sampler

Inlets

Detectors

Regulators

H

RESET

gas system

inlet

column

detector

data system

Schematic Diagram of Gas Chromatography

Gas Chromatography

Stationary Phase:

Gas-solid chromatography : solid, underivatized support

Gas-liquid chromatography: liquid-coated support

Bonded-phase gas chromatography chemically-derivatized support

Carrier Gas

The mobile phase gas is called as carrier gas and must be

inert, pure and dry.

E.g. nitrogen, helium, argon, hydrogen and carbon dioxide.

The Oxygen is not used as carrier gas because the presence

of oxygen may induce oxidation in the stationary phase and

lead to a loss of column performance.

The carrier gas flows through the instrument from a

pressurized cylinder.

The carrier gas systems also contains a molecular sieve to

remove water and other impurities.

Carrier Gas: Flow Rate

Flow rate is controlled by 2 stage regulator on the gas

cylinder and additional controls within the instrument.

Inlet pressures usually range from 10 to 50 psi above

room pressure, which leads to flow rates of

25 to 150 mL/min with packed columns

1 to 25 mL/min with open-tubular columns

If the inlet pressure remains constant, flow rates will

be constant.

Flow rates can be established by soap-bubble flow

meter, located at the head of column

Sample Injection System

It is important because column efficiency depends on

this system.

Column efficiency requires sample of suitable size and

sample has to be introduced as a plug of vapor slow

injection of oversized samples causes band spreading

and poor resolution

Method of sample injection:

Microflash vaporizer direct injector (Commonly used)

Rotary sample valve (Reproducible results)

Solid samples: sealed into thin-walled vials that can be

inserted at the head of column and punctured or

crushed from the outside

Sample Injection

Sample is injected using a syringe

into a flowing stream of hot mobile

phase

High temperature (at least 50

o

C

above boiling point of sample)

causes vaporization of sample

Introduces a narrow plug of

sample vapor onto the column

Various designs

For packed columns, inject 1 to 5

L of sample

For capillary columns, a split valve

is used to introduce a small

fraction of sample onto column

A flash vaporization injector

Introduced as a plug of vapor

with suitable size

Slow injection or oversized

samples cause band spreading

and poor resolution

Micro syringes

Injection ports

microsyringe

Gastightsyringe

Sample Injection System

Split/Splitless Injector

Splitless Injection

(where the split vent is closed)

attempts to transfer all of the

sample to the column and is

used for trace analysis.

Split Mode

only a small portion (maybe 1-

10% of the sample moves into

the column, and the rest is sent

to waste. This is used when the

analytes are in high

concentration and would

overload the column.

Sample is injected through the

septum with a syringe.

Sample injection system

Column efficiency required that samples be of suitable

size and introduced as a plug of vapor.

Slow injection of oversized sample cause band

broadening and poor resolution.

Injector changes sample to gas and reproducibly

introduces resulting gaseous sample into column.

Types of injector system are dependent upon physical

state of sample.

For gaseous sample

Rotary Valve is preferred and that is same as in HPLC but

here sample loop is larger.

In position 1 carrier gas flows directly into column and

valve is in that position, the sample is flushed and filled

with gaseous sample.

Upon switching value to inject position 2, carrier gas

sweeps through sample loop and flushes sample into

column.

For liquid sample

A gas syringe is used.

Sample is injected with 1-.5- or 10-L graduated syringe

through septum into heated flash evaporation injector.

The sample is rapidly vaporized because injectors

temperature is maintained above B.P. of highest boiling

component in sample.

Carrier gas flushes vaporized sample from injector and

into column.

Typical liquid sample volume used with packed column

varies from 0.1 5L and injector temperature is held

at least 10C above the column temperature.

For solid sample

A solid sample is more difficult to convert to gas.

Sometimes it can be chemically converted to volatile

derivative.

E.g. Fatty acid is converted to volatile methyl ester

with BF

3

or BCl

3

in methanolic solution.

In some cases pyrolysis equipment is attached to

GC and used to vaporize solid sample.

In pyrolysis apparatus sample is placed and heated

sufficiently (1000C) to vaporize the sample or to

form volatile sample decomposition product and

volume sample swept into GC with carrier gas.

Columns

Length: <2 m to >50 m

They are made of:

Stainless steel

Glass

Fused silica

Teflon

In order to fit into an oven for thermostating, they are formed as

coils having diameters of 10 to 30 cm.

Types of analytical columns generally used in GC are:

Packed columns

Less efficiency compared to capillary columns

Capillary columns

More efficiency compared to packed columns

i. Wall coated open tubular columns

ii. Support coated open tubular columns

Columns

Packed Column

Most packed columns are 1.5 - 10m in length and have an

internal diameter of 2 - 4mm.

They have greater sample capacity compared to open tubular

columns but generates broader peaks, longer retention time

and lower resolutions.

Useful for preparative work.

Packed columns contain a finely divided, inert, solid support

material (commonly based on diatomaceous earth ) coated

with liquid stationary phase.

Most widely used support is Kieselguhr.

The support holds stationary phase in place so that as large

a surface area as possible is exposed to the carrier gas.

Usual particle size supports are 60 80 # (260 170 m) or

80 100 # (170-149m)

Capillary Columns

Capillary columns have an internal diameter of a few

tenths of a millimeter.

Increased length leads to longer separation times.

Stationary phase thickness and column diameter

increases leads to increased sample capacity and can

provide increased resolution.

Thick stationary phases bleed more and contaminate

MS detection system.

Capillary Columns

Advantages:

Highly efficient

Disadvantages:

Small sample capacity

Fragileness of columns

Mechanical problems associated with sample

introduction and

connection of the column to the detector

Difficulties in coating the column reproducibility

Short life times of poorly prepared columns

Tendencies of columns to clog

High cost

Liquid phase

Solid support

coated with liquid

phase

Porous Adsorbent

Porous Layer Open

Tubular

(PLOT)

Wall-coated Open

Tubular

(WCOT)

Support-coated Open

Tubular

(SCOT)

Capillary Columns: Open Tubular Columns

Wall Coated Open Tubular Column (WCOT)

Simply capillary tubes coated with a thin layer of stationary

phase

Made up of

Stainless steel

Aluminium

Copper

Plastic

Glass

The glass was etched with gaseous hydrochloric acid, strong

aqueous hydrochloric acid, or potassium hydrogen fluoride

to give a rough surface, which bonded to stationary phase

more tightly.

Fused Silica Open Tubular Column (FSOT)

These have much thinner walls than their glass counterparts.

The tubes are given added strength by an outside protective

polyimide coating, which is applied as the capillary tubing is

being drawn.

The resulting columns are quite flexible and can be bent into

coils having diameters of few inches.

Advantages over glass columns:

Physical strength, much lower reactivity toward sample

components and flexibility

Support Coated Open Tubular Column (SCOT)

Most widely used SCOT have inside diameters of 320

and 260 m

High resolution SCOT have inside diameters of 200 and

150 m

It needs sample splitter and high sensitive detector

Megabore columns of internal diameter 530 m

Less efficient than smaller diameter capillary columns

but more efficient than packed columns

Type of Column

FSOT WCOT SCOT Packed

Length (m) 10-100 10-100 10-100 1-6

ID (mm) 0.1-0.3, 0.53* 0.25-0.75 0.5 2-4

Efficiency (Plate/m) 2000-4000 1000-4000 600-1200 500-1000

Sample size (ng) 10-75 10-1000 10-1000 10-10

6

Relative pressure Low Low Low High

Relative speed Fast Fast Fast Slow

Flexible Yes No No No

Chemical inertness Best Poor Poorer Poorest

Comparison of Capillary Columns

Capillary Column: Stationary Phase

HO-CH

2

-CH

2

-(O-CH

2

-CH

2

)

n

-OH

polyethylene glycol

Effect of Temperature on GC

Column temperature is an important variable.

It must be controlled to a few tenths of degree

for precise work.

So, the column is housed in thermostated oven.

Optimum column temp. depends upon the b.p.

of the sample and the degree of separation

required.

A temp. equal to or a slightly above the average

b.p. of a sample results in a reasonable elution

time (2 to 30 min).

For samples with a broad boiling range,

temperature programming is employed,

whereby the column temperature is increased

either continuously or in steps as the separation

proceeds.

Optimum resolution is associated with minimal

temperature.

But lower temperature requires more time to

complete analysis, as the elution time of analytes

increase.

Types of detectors

1. Thermal Conductivity Detector(TCD)

2. Flame Ionization Detector(FID)

3. Atomic Emission Detector(AED)

4. Electron Capture Detector(ECD)

5. Nitrogen Phosphorous Detector(NPD)

6. Photo Ionization Detector(PID)

7. Flame Photometric detector(FPD)

8. Electrolytic conductivity detector (ELCD)(Hall

detector)

9. Absolute Mass Detector(AMD)

10. Infrared Detector (IRD)

Characteristics of the Ideal Detector

Adequate sensitivity

Good stability and reproducibility

A linear response over several orders of magnitude

solutes

A temperature range from room temperature to 400

o

C

A short response time that is independent of flow rate

High reliability and ease of use

Highly predictable and selective response toward one

or more classes of solutes

Nondestructive of sample

Thermal Conductivity Detector (TCD)

Principle: Change in thermal conductivity (cooling ability) of the gas

stream brought about by the presence of analyte molecules

It is also called as Katharometer

Helium and hydrogen are preferred carrier gases.

The thermal conductivities of helium and hydrogen are 6 10 times

greater than those of most organic compounds.

So, in the presence of even small amounts of organic materials, a

relatively large decrease in the thermal conductivity of the column

effluent takes place

Consequently, the detector undergoes a marked rise in temp.

The conductivities of other carrier gases are closely resemble those

of organic constituents.

Thermal Conductivity Detector

Advantages:

Simple, Universal, large

dynamic range, response to

both organic and inorganic

species, non destructive

Disadvantages:

Low sensitivity

Not recommended with

capillary columns because

only very small amounts of

samples can be introduced,

so such small amounts cant

be detected.

Thermal Conductivity Detector

A universal detector

Flame Ionization Detector (FID)

Most widely used detector.

The effluent from the column is mixed with H

2

and air and then

ignited electrically.

Most organic compounds when pyrolyzed at the temperature of

a hydrogen/air flame, produce ions and electrons that can

conduct electricity through the flame, which is measured.

No. of produced ions is proportional to the no. of reduced

carbon atoms in the flame.

It is mass-sensitive rather than concentration-sensitive because it

responds to the no. of carbon atoms entering the detector per

unit of time

It can be useful for the detection of pollutants in natural water

samples, because it is insensitive to water.

Flame Ionization Detector

For most organic compounds

Flame Ionization Detector (FID)

Advantages: High sensitivity, a

large linear response range,

low noise, rugged and easy to

use.

Disadvantage: Destructive

Less sensitive to non

hydrocarbon groups.

Insensitive to H

2

O,CO

2

,SO

2

Electron Capture Detector (ECD)

It is choice of detectors for environmental samples because this

detector selectively detects halogen containing compounds, such

as pesticides and polychlorinated biphenyls.

Working:

The effluent from the column is passed over a radioactive

emitter (Nickel63)

An electron from the emitter causes ionization of carrier gas

(N

2

) and production of a burst of electrons.

The current decreases markedly, in the presence of organic

molecules

It is highly sensitive to molecules containing electronegative

functional groups such as halogens, peroxides, quinones and nitro

groups.

Electron Capture Detector (ECD)

It is insensitive to amines,

alcohols and hydrocarbons.

Important application of this

detector is detection and

determination of chlorinated

insecticides.

Advantages: Highly selective

and sensitive, nondestructive

Disadvantage: Low linear

response range.

Atomic Emission Detector (AED)

The eluent is introduced into a microwave-energized helium

plasma that is coupled to a diode array optical emission

spectrometer.

Molecules are energized by a plasma source.

Then molecules are separated into excited atoms.

As electrons return to their stable state, they emit light, which is

element specific.

These spectra are then observed with diode array spectrometer,

capable of detecting radiations from about 170 to 780 nm

It is relatively new detector and yields elemental information

about the separated components in a mixture.

The sample is destroyed

It is specific to P and S, can measure upto ppb.

Six elements detect simultaneously .

Determine the hetero atoms(H,P,S,O),silicon , heavy metals(Pb , Hg),tin,

arsenic ,copper ,iron.

Nitrogen phosphorous detector (NPD)

The column effluent is mixed with

hydrogen, passes through the flame tip

assembly, and is ignited.

The hot gas then flows around an

electrically heated rubidium silicate bead.

Then large no. of ions from phosphorus or

nitrogen containing compounds are

produced.

It results in the production of increased

current.

This is a detector of choice for analysis of

organophosphorus pesticides and

pharmaceuticals.

Compared with the FID , the thermionic

detector is approximately 500 times more

sensitive to phosphorus-containing

compounds and 50 times more sensitive

to nitrogen bearing species.

Flame photometric detector (FPD)

It is a selective detector that is

primarily responsive to

compounds containing sulfur

and phosphorus.

It is widely used in the analysis

of air and water pollutants,

pesticides and coal

hydrogenation products.

In this detector, the eluent is

passed into a lowtemperature

hydrogen/air flame, which

converts part of phosphorus to

HPO and Sulfur to S

2

.

Suitable filters are employed to

isolate these bands, and their

intensity is recorded

photometrically.

filters

photomultiplier

H2 + air

Column effluent

Electrolytic Conductivity Detector (ELCD)

Halogens, sulfur, or nitrogen compounds mix with a

reaction gas in a reaction tube.

The products are mixed with a suitable liquid, which

produces a conductive solution, and the change in

conductivity is monitored.

Molecules are ionized by

excitation with photons from

an UV lamp.

The charged particles are

then collected, producing

current.

This detector is used for

analyses of aromatic and UV

ionized compounds.

PHOTO IONIZATION DETECTOR(PID)

Mass Selective Detector (MSD)

Molecules are bombarded with electrons, producing ion

fragments that pass into the mass filter

The ions are filtered based on their mass/charge ratio.

It gives qualitative identification of components by matching

the compounds mass spectrum with spectra included in

libraries.

Disadvantages:

Main difficulty is changing from highly pressurized gas

mixture to vacuum containing isolated components.

The sample is destroyed.

Infrared Detector (IRD)

Molecules absorb infrared energy, the frequencies of which

are characteristic of the bonds within that molecule.

This detector is a powerful tool for distinguishing isomers.

It gives qualitative identification of components by matching

the compounds IR spectrum with spectra included in

libraries.

Non destructive

Detectors for GC

Gas-Solid Chromatography (GSC)

It is based upon adsorption of gaseous substances on solid

surfaces.

Distribution coefficients are larger than those for Gas-liquid

chromatography

It is useful for the separation of air, hydrogen sulfide, carbon

disulfide, nitrogen oxides, carbon monoxide, carbon dioxide and the

rare gases.

It is performed with both packed and open tubular columns

Open tubular columns are called porous layer open tubular

columns (PLOT)

A thin layer of adsrobent is affixed to the inner walls of capillary.

Two types of adsorbents:

Molecular sieves

Porous polymers

Molecular Sieves

The sieves are classified according to the maximum

diameter of molecules that can enter the pores.

Molecules smaller than these dimensions penetrate

into the interior of the particles where adsorption

takes place.

For such molecules the surface area available is

enormous when compared with the area available to

larger molecules.

Thus molecular sieves can be used to separate small

molecules from large.

Porous Polymers

Porous polymer beads of uniform size are

manufactured from styrene cross-linked with

divinylbenzene.

The pore size of these beads is uniform and is

controlled by the amount of cross-linking.

These will be used to separate gaseous polar species

such as hydrogen sulfide, oxdies of nitrogen, water,

carbon dioxide, methanol and vinyl chloride.

Applications and Examples

Separation and analysis of volatile organic compounds

(gases and liquids)

Testing purity of compounds

Compound identification

Isolation of pure compounds (microscale work) from

complex mixtures

Determine relative amounts of components in mixture

Determination of partition coefficients and absorption

isotherms.

Qualitative analysis

Retention time data should be useful for identification

of mixtures

Comparing the retention time of the sample as well as

the standard

Checking the purity of a compound: compare the

standard and sample chromatograms

If additional peaks are obtained, impurities are present

and hence the compound is not pure.

From the percentage area of the peaks obtained, the

percentage purity can also be reported.

Quantitative analysis

Direct comparison method:

comparing the area of the peak, peak height, width

of peak.

Calibration curves:

standards of varying concentration are used to

determine peak areas .

A graph of peak area vs concentration of the drug

is plotted.

From the peak area of unknown sample, by

intrapolation, the concentration of the sample can

be determined.

Advantage:The errors, if any are minimised

Quantitative Analysis: Internal Standard

Method

In this method, a compound whose retention time is near to that

of analyte is used as internal standard.

A known concentration of the internal standard is added

separately to the standard solution and sample solution whose

concentration is not known.

The peak area ratio of sample and internal standard.unknown

concentration is easily determined.

A graph of ratio of peak areas vs concentration of the standard is

plotted.

From the peak area ratio of sample and internal standard, by

intrapolation, the concentration of the unknown solution is

determined from the graph.

The ratio of analyte peak area to internal standard peak area will

remain unaffected by slight variations in injecting volumes, pipetting

and chromatographic conditions.

Derivatisations

GC is best for separation of volatile compounds which are

thermally stable.

Not always applicable for compounds of high molecular weight

or containing polar functional groups. These groups are difficult

to analyze by GC either because they are not sufficiently

volatile, tail badly, are too strongly attracted to the stationary

phase, thermally unstable or even decomposed.

It is a technique of treatment of the sample to improve the

process of separation by column or detection by detector.

Common derivatization methods can be classified into 4

groups depending on the type of reaction applied:

Silylation

Acylation

Alkylation

Esterification

Precolumn Derivatisation

There are two types:

Precolumn derivatisation

Post column derivatisation

Precolumn derivatization prior to analysis is generally done to:

increase the volatility and decrease the polarity of compounds;

reduce thermal degradation of samples by increasing their

thermal stability;

increase detector response

Improve separation and reduce tailing

Example:

Carboxylic acids, sugars, phenols, alcohols, etc. can be converted

to less polar compounds by using reagents like BSA reagent (Bis

trimethy silyl acetamide reagent)

They can also be converted to acetyl derivative or triflouro

acetyl derivative.

Post column Derivatisation

To improve the response shown by detector .

The components may not be detected by detector

unless derivatisation is done.

Usually, this is online detection technique, where the

flow rate is neither stopped nor altered.

The components may be converted in such away

that their ionisation or affinity towards electrons is

increased.

Pretreatment of solid support:

solid support is to hold the stationary phase liquid as

a thin film.

OH

O

OH

OH

HO

CH

2

OH

1

2

3

4

5

6

+

Si

CH

3

CH

3

CH

3

5Cl

O-Si(CH

3

)

3

O

O-Si(CH

3

)

3

O-Si(CH

3

)

3

(CH

3

)

3

-Si-O

CH

2

O-Si(CH

3

)

3

1

2

3

4

5

6

5 HCl +

Derivatization of Glucose with Trimethylchlorosilane

Glucose Trimethylchlorosilane

You might also like

- GC Lecture NotesDocument8 pagesGC Lecture NotespiyushNo ratings yet

- Guideline On Stability Testing For Applications For Variations To A Marketing AuthorisationDocument8 pagesGuideline On Stability Testing For Applications For Variations To A Marketing Authorisation刘朝阳No ratings yet

- 33333determination of Water - and Fat-Soluble Vitamins in D555i ErentDocument21 pages33333determination of Water - and Fat-Soluble Vitamins in D555i ErentmohammaddammagNo ratings yet

- Variation GuidelineDocument33 pagesVariation GuidelineBo RatchadapornNo ratings yet

- USP Verification of Comp en Dial Procedures CVG CADocument23 pagesUSP Verification of Comp en Dial Procedures CVG CAWilliamWang19No ratings yet

- Group 08 Financial Feasibility Excel 2Document8 pagesGroup 08 Financial Feasibility Excel 2Slindokuhle ThandoNo ratings yet

- DMF Guidance For Submission V 1.0Document14 pagesDMF Guidance For Submission V 1.0Raj DesaiNo ratings yet

- Clean Air and Containment Review: Issue 26 April 2016Document19 pagesClean Air and Containment Review: Issue 26 April 2016Ayman EshraNo ratings yet

- Ion Pairing Reagents and BuffersDocument6 pagesIon Pairing Reagents and BuffersipatoffNo ratings yet

- P07 CALA ApplicationDocument26 pagesP07 CALA ApplicationCDOKEP2010No ratings yet

- EddingtonStudy 2Document8 pagesEddingtonStudy 2Los BlaugranaNo ratings yet

- Overview:: Environmental Risks & ImpactDocument28 pagesOverview:: Environmental Risks & ImpactGoffiNo ratings yet

- 4 Egac SystemDocument55 pages4 Egac SystemWaleed El-azabNo ratings yet

- Suppositories SampleDocument20 pagesSuppositories SamplePriyanka S. SutarNo ratings yet

- Care Maintenance and HPLC Column TroubleshootingDocument52 pagesCare Maintenance and HPLC Column TroubleshootingJuan R MartinezNo ratings yet

- How To Ensure Trouble-Free HPLC System OperationDocument3 pagesHow To Ensure Trouble-Free HPLC System OperationKavisa GhoshNo ratings yet

- 1-6 Establishing Impurity SpecificationsDocument52 pages1-6 Establishing Impurity SpecificationsDivyesh PatelNo ratings yet

- Mettler DL36 Operating InstructionsDocument44 pagesMettler DL36 Operating InstructionsLadycorinth137No ratings yet

- Comparing COVID 19 Vaccines For Their Characteristics, EfficacyDocument61 pagesComparing COVID 19 Vaccines For Their Characteristics, EfficacyYony GutierrezNo ratings yet

- Abraham Lincoln: ContactDocument1 pageAbraham Lincoln: ContactMiguel Angel Condori RoqueNo ratings yet

- Verification of System Suitability TestDocument6 pagesVerification of System Suitability TestMubarak PatelNo ratings yet

- Sample Working Capital Per Dollar of Sales Calculation: Total Sales Income StatementDocument7 pagesSample Working Capital Per Dollar of Sales Calculation: Total Sales Income StatementsanjusarkarNo ratings yet

- 26252.9.6. Uniformity of Content of Single-Dose PreparationsDocument1 page26252.9.6. Uniformity of Content of Single-Dose PreparationsMiyyada Aichaoui100% (1)

- Impact of Employee's Behavior and Culture On OrganizationsDocument3 pagesImpact of Employee's Behavior and Culture On Organizationseclipse541No ratings yet

- Simultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFDocument7 pagesSimultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFNájla KassabNo ratings yet

- What Is 21 CFR Part 11Document26 pagesWhat Is 21 CFR Part 11chemtabNo ratings yet

- The Impact of Culture On An OrganizationDocument4 pagesThe Impact of Culture On An OrganizationSivaraman P. S.No ratings yet

- Variations TGADocument128 pagesVariations TGAJaime Andrés García BNo ratings yet

- Guidelines For Stability Testing of New Drug Substances and ProductsDocument44 pagesGuidelines For Stability Testing of New Drug Substances and Productsvijayns_250355172No ratings yet

- Gas Chromatography - 2 OVIDocument32 pagesGas Chromatography - 2 OVIyashpandya01No ratings yet

- SHIFADocument4 pagesSHIFAAbira Bilal Hanif0% (1)

- Chapter #3 Attitudes and Job SatisfactionDocument2 pagesChapter #3 Attitudes and Job SatisfactionMuhammad Hashim MemonNo ratings yet

- ملزمة رقابة - نسخةDocument68 pagesملزمة رقابة - نسخةتامر الصينيNo ratings yet

- Ich - Guideline For Residual SolventsDocument29 pagesIch - Guideline For Residual Solventscssato5No ratings yet

- Inprocess and Finished Products Quality Control Tests For Pharmaceutical Tablets According To PharmacopoeiasDocument7 pagesInprocess and Finished Products Quality Control Tests For Pharmaceutical Tablets According To PharmacopoeiasMaheshNo ratings yet

- Omgoing Stability Testing - Innovations - in - Pharmaceutical - TechnologyDocument3 pagesOmgoing Stability Testing - Innovations - in - Pharmaceutical - TechnologyJuan RojasNo ratings yet

- Attachment 13 Analytical Equipment Calibration Certificate v3 PDFDocument40 pagesAttachment 13 Analytical Equipment Calibration Certificate v3 PDFGnanaSunderNo ratings yet

- 25 How To Determine The Total Impurities - Which Peaks Can Be DisregardedDocument5 pages25 How To Determine The Total Impurities - Which Peaks Can Be Disregardedjljimenez1969100% (1)

- OQ Raw Materials Sample TentDocument18 pagesOQ Raw Materials Sample TentAnup BajracharyaNo ratings yet

- Air Handling Systm in Pharmaceutical Manufacturing Pharm R.A. BinitieDocument86 pagesAir Handling Systm in Pharmaceutical Manufacturing Pharm R.A. BinitieApata olutolaNo ratings yet

- Analytical Methods PDFDocument9 pagesAnalytical Methods PDFBabbooNo ratings yet

- Finished Prod 1Document11 pagesFinished Prod 1Ashok KumarNo ratings yet

- Book ImpuritiesDocument448 pagesBook ImpuritiesDevang RamoliaNo ratings yet

- Periodic or Skip Testing in Pharmaceutical Industry Us and Europe Perspective 2153 2435.1000283 PDFDocument5 pagesPeriodic or Skip Testing in Pharmaceutical Industry Us and Europe Perspective 2153 2435.1000283 PDFpakdomoNo ratings yet

- Good Distribution Practice A Complete Guide - 2020 EditionFrom EverandGood Distribution Practice A Complete Guide - 2020 EditionNo ratings yet

- Ich Guideline q7 Good Manufacturing Practice Active Pharmaceutical Ingredients Questions Answers - enDocument37 pagesIch Guideline q7 Good Manufacturing Practice Active Pharmaceutical Ingredients Questions Answers - ensatishNo ratings yet

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersFrom EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNo ratings yet

- Missing Functional Level Access Control: OWASP Web App Top 10Document6 pagesMissing Functional Level Access Control: OWASP Web App Top 10erickNo ratings yet

- Internal Customer Satisfaction, Project Report Customer Satisfaction Survey ReportDocument8 pagesInternal Customer Satisfaction, Project Report Customer Satisfaction Survey ReportAnkit MalaniNo ratings yet

- Comparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese CompaniesDocument7 pagesComparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese Companiesrambabukomati472No ratings yet

- Simultaneous HPLC Analysis of Betamethasone and Clotrimazole in Cream Formulation PDFDocument4 pagesSimultaneous HPLC Analysis of Betamethasone and Clotrimazole in Cream Formulation PDFNájla KassabNo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- Quality Control in Aseptic DispensingDocument61 pagesQuality Control in Aseptic DispensingAwal D'LiraNo ratings yet

- Care of HPLC ColumnsDocument4 pagesCare of HPLC ColumnsKavisa GhoshNo ratings yet

- Periodic or Skip Testing in Pharmaceutical Industry Us and Europe Perspective 2153 2435.1000283 PDFDocument5 pagesPeriodic or Skip Testing in Pharmaceutical Industry Us and Europe Perspective 2153 2435.1000283 PDFnsk79in@gmail.comNo ratings yet

- Quality Control: Rutendo Kuwana Technical Officer, WHO, GenevaDocument26 pagesQuality Control: Rutendo Kuwana Technical Officer, WHO, GenevaUpender Rao SunkishalaNo ratings yet

- Guideline On Active Substance Master File Procedure - EuropeanDocument22 pagesGuideline On Active Substance Master File Procedure - EuropeanNhonPhanThanhNo ratings yet

- Portfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesFrom EverandPortfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesPete HarpumNo ratings yet

- Neurotoxicity of E-CigarettesDocument15 pagesNeurotoxicity of E-CigarettesRebecca MarshallNo ratings yet

- Principles of Food Processing and Halal Requirement (WEEK 11)Document48 pagesPrinciples of Food Processing and Halal Requirement (WEEK 11)aishah1997No ratings yet

- Iron Oxide Copper Gold PDFDocument23 pagesIron Oxide Copper Gold PDFMurilo Santiago100% (2)

- Bio T4 DLP KSSM Chapter 13 Homeotasis and The Human Urinary SystemDocument66 pagesBio T4 DLP KSSM Chapter 13 Homeotasis and The Human Urinary SystemNurasyikin SaidinNo ratings yet

- What Is DrugDocument9 pagesWhat Is DrugFebz CanutabNo ratings yet

- Sanitary Engineering Lec.: November 2015Document110 pagesSanitary Engineering Lec.: November 2015Dynamo DSNo ratings yet

- Laboratory SafetyDocument2 pagesLaboratory Safetyann wamburaNo ratings yet

- Engineering Vol 56 1893-10-06Document33 pagesEngineering Vol 56 1893-10-06ian_newNo ratings yet

- ASTM G 109 Determining The Effects of Chemical Admixtures On The PDFDocument6 pagesASTM G 109 Determining The Effects of Chemical Admixtures On The PDFAlejandro Garcia LopezNo ratings yet

- Republic Act No. 6969 An Act To Control Toxic Substances and Hazardous and Nuclear Wastes, Providing Penalties For Violations Thereof, and For Other PurposesDocument3 pagesRepublic Act No. 6969 An Act To Control Toxic Substances and Hazardous and Nuclear Wastes, Providing Penalties For Violations Thereof, and For Other PurposesLizzy WayNo ratings yet

- Por Si Te Puede ServirDocument7 pagesPor Si Te Puede ServirJordi ClaudioNo ratings yet

- Competition & Luxury Vehicle Club of Darlington SuitDocument31 pagesCompetition & Luxury Vehicle Club of Darlington SuitBenjamin DuerNo ratings yet

- Calculate Jockey Pump Capacity in Fire Fighting SystemDocument1 pageCalculate Jockey Pump Capacity in Fire Fighting SystemkarpakkiNo ratings yet

- FlotacionDocument2 pagesFlotacionJose Ariel TorrezNo ratings yet

- Bulan AgustusDocument22 pagesBulan AgustusaristhanovyraNo ratings yet

- Shell Rl3 MsdsDocument8 pagesShell Rl3 MsdsHitesh ShahNo ratings yet

- Eazistrip Reinforcement Continuity SystemsDocument12 pagesEazistrip Reinforcement Continuity SystemscormolioNo ratings yet

- Hygienic Air Handling Unit CatalogueDocument27 pagesHygienic Air Handling Unit Cataloguemoataz medhatNo ratings yet

- Vanadium and Vanadium CompoundsDocument21 pagesVanadium and Vanadium CompoundsПлейнNo ratings yet

- Main PropulsionDocument27 pagesMain PropulsionalsitorNo ratings yet

- Laboratory Title: Determination of Ash Date of Experiment: 11/11/2019 Laboratory Group: MondayDocument5 pagesLaboratory Title: Determination of Ash Date of Experiment: 11/11/2019 Laboratory Group: MondayCtNo ratings yet

- Sika Injection 20Document3 pagesSika Injection 20the pilotNo ratings yet

- Solution Manual For Chemistry 10th Edition by Kenneth W Whitten Larry Peck Raymond e Davis and George G StanleyDocument14 pagesSolution Manual For Chemistry 10th Edition by Kenneth W Whitten Larry Peck Raymond e Davis and George G Stanleycuonganh51wNo ratings yet

- Articol Excelent ZerDocument20 pagesArticol Excelent Zerlylya_bejenaruNo ratings yet

- Remazol Ultra RGB Feb 2010Document23 pagesRemazol Ultra RGB Feb 2010rauftextile0% (2)

- Rapid Fire NewDocument85 pagesRapid Fire NewvarunsanghiNo ratings yet

- Storage Tank Design For Lactic Acid ProductionDocument30 pagesStorage Tank Design For Lactic Acid ProductionPrabuddha GopeNo ratings yet

- Psychedelic LichensDocument4 pagesPsychedelic LichensJon. . .No ratings yet

- The Calorific Value of A Fuel Is TheDocument4 pagesThe Calorific Value of A Fuel Is TheRana PrathapNo ratings yet

- Aluminium Silicate - WikipediaDocument2 pagesAluminium Silicate - Wikipediamovie hunterNo ratings yet