Professional Documents

Culture Documents

HTTPWWW Rog Gik PW Edu Plphocadownloadnr8744

Uploaded by

Razvan0 ratings0% found this document useful (0 votes)

23 views10 pagessd

Original Title

Httpwww Rog Gik Pw Edu Plphocadownloadnr8744

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views10 pagesHTTPWWW Rog Gik PW Edu Plphocadownloadnr8744

Uploaded by

Razvansd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

CONCRETE FACE ROCKFILL DAMS NEW CHALENGES FOR

MONITORING AND ANALYSIS

Anna Szostak-Chrzanowski

1

, Michel Massira

2

, Nianwu Deng

1,3

Canadian Centre for Geodetic Engineering, University of New Brunswick, Canada

1

Facult dingnierie (gnie civil), Universit de Moncton, Canada

2

State Key Laboratory of Water Resources and Hydropower Engineering Science,

Wuhan University, P.R. China

3

ABSTRACT

Concrete face rockfill dams (CFRDs) are gaining a worldwide recognition as the most

economical type of dams to be constructed in extreme northern and sub-Antarctic

regions. Safety of CFRDs depends on the proper design, construction, and monitoring of

actual behaviour during the construction and during the operation of the structure. The

main concern for the safety of CFRDs is the deformation of the concrete face. During

the reservoir filling, the load of water and deformations of the dam rockfill force

upstream concrete slab to deform. The displacements of the concrete face during the

reservoir filling should not exceed the maximum allowed values in order to maintain the

structural integrity of the concrete face. Due to uncertainty of the model parameters,

careful monitoring of the dams and their surroundings are required in order to verify

and enhance the model. This paper presents a study of the behavior of the upstream

concrete face slabs and internal displacements that develop in the rockfill during

construction and during filling the reservoir. The research is based on two examples: the

Toulnustouc Dam (75 m) located in Northern Quebec, Canada, and the Shuibuya Dam

in P. R. China, the tallest (233 m) concrete face rockfill dam in the world. The results of

the study serve also as a basis for designing deformation monitoring schemes for the

concrete face rockfill dams.

Key words: concrete face rockfill dam, deformation analysis, finite element method,

monitoring.

1. INTRODUCTION

Concrete face rockfill dams (CFRDs) are gaining a worldwide recognition as the most

economical type of dams to be constructed in extreme northern and sub-Antarctic

regions. Use of the rockfill material, which is not sensitive to the frost action and the

construction technology allow lengthening the construction season. The total duration of

the construction of CFRDs with regard to the total duration of construction of earth

dams is on average reduced by one year. The reduced construction time reduces the

costs of construction and makes hydroelectric projects more economic. Cooke (1984)

indicated that the use of this type of dams seems to be inevitable in the regions of the

world, which have extreme climates. Canada has built CFRDs of a height up to 100 m.

382

China has built more than 170 CFRDs with 40 of them taller than 100 m. Examples are

Shuibuya dam of 233 m height, Jiangpinghe of 221 m, Sanbanxi of 186 m, Hongjiadu of

179.5 m, Tianshengqiao I of 178 m, and Tankeng of 162 m height.

Deformations of CFRD dams start occurring during the construction. These

deformations are caused by the increase of effective stresses during the construction by

the consecutive layers of earth material and also by effects of creep of the material.

Deformations may also be influenced by deformations of the foundation, by transfer of

stresses between the various zones of the dam and by other factors. After the

construction is completed, the considerable movements of the crest and of the body of

the dam can develop due to pressure of water during the first filling of the reservoir.

The load of water and deformations of the rockfill of the dam, force concrete slab to

deform. The concrete slab acts as an impervious membrane and any development of

cracks in the slab would allow for water to penetrate the rockfill of the dam and cause

the structure to weaken or even loose stability. According to the working state, force

distribution and hydraulic features of CFRD, proper zoning of dam filling material is

carried out to take a full utilization of the material from structure excavation and to

reduce the investment under the condition that the safety of operation is ensured. After

filling of the reservoir, the rate of movement in the dam and in the concrete face

generally diminishes with time, except for variations associated with periodic raising

and lowering the level of the reservoir. In classic CFRDs where the concrete face is

constructed after the end of construction of the rockfill embankment, it is very

important to estimate the displacements of the concrete face during the filling of the

reservoir and to verify whether these displacements are lower than displacements

compatible with the structural integrity of the concrete face. Most of the constructed

CFRDs rest on the bedrock. However, there are some CFRDs constructed on soil

foundations. Foundation conditions of the planned constructions call for studies to

determine the range of possible movements of the concrete face slab during the

construction of the dam and especially, during the filling of the reservoir.

The main concern for the safety of CFRDs is the deformation of the concrete face. The

most important reason for observing the deformation of the dams is to assure that the

deformation of the concrete face dam does not exceed the critical value. Too large or

unexpected deformations can be an indication of potential problems of the dam or its

foundation. Another reason for observing the deformations of dams, of less immediate

concern but of potentially great long-range significance to engineering profession, is the

need for better understanding of basic design concepts, stress-deformation

characteristics, and geotechnical characteristics of soil and rockfill. The development of

prediction methods, which allow for a determination of expected deformations and

stress distribution and a comparison of predicted values with observed deformations,

constitute very valid tools for control safety control.

The study presented in this paper shows that fusion of the monitoring results and FEM

analysis in real time would give warning that the deformations of the concrete face have

reached critical values before the reservoir would reach the maximum level. This

information could trigger the proper action from engineering team and lead to a

prevention of cracking of the concrete face. The in real-time detection and evaluation of

differences between monitoring results and results obtained from a prediction analysis

could result in a redesign of the concrete slab and prevent its cracking. Examples of two

CFRDs, Toulnustouc Dam in Quebec, Canada, and the Shuibuya Dam in P. R. China,

are discussed below.

383

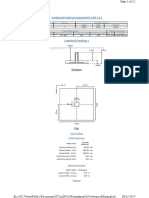

2. DESIGN OF TOULNUSTOUC DAM

The Toulnustouc dam is located north of the city of Baie-Comeau on the Toulnustouc

River in Northern Quebec, Canada. The existing dam is 75 m high and 575 m long

(Figure 1). The dam is built on bedrock foundation. The concrete face slab is of a

constant 0.3 m thickness (ICOLD, 2006).

Figure 1: CFRD Toulnustouc dam in Canada.

The dam is composed of 4 zones (Figure 2). Zones 7B and 8A consist of crushed stone.

Zones 8B and 8C are built with compacted rockfill. Geotechnical instrumentation

installed in the structure included 16 survey markers, 22 crack meters, 13 submersible

tilt meters, two strong motion accelerometers and one weir (Hammamji et al. 2005).

Concrete Face Slab

Zone 7B

Zone 8A

Zone 8B

Zone 8C

Figure 2: CFRD Toulnustouc of 75 m of height resting on bed rock.

3. DESIGN OF SHUIBUYA DAM

Shuibuya CFRD is located in P.R. China. It is presently the highest of its kind in the

world. Shuibuya dam is 233 m high and 608 m long (Figure 3). The crest width is 12 m

384

with a 5.2 m high "L" shape parapet at the crest. The concrete slab thickness varies with

the height of the dam. The slab is 0.3 m thick at the top and 1.1 m thick at the bottom.

The slab is divided into three construction stages with two construction joints. The dam

zoning is shown in Figure 4. Geotechnical monitoring with wire extensometers to

monitor interior displacements of points located in the rockfill was started at the

beginning of the filling up of the reservoir.

Figure 3: CFRD Shuibuya dam.

The dam construction encountered certain difficulties because cracks started developing

in the concrete face during filling up the reservoir. Total of 255 cracks developed and

they were observed before the water level in the reservoir reached 200 m.

(file://E:\LecturesCM\Shuibuya Water Conservancy Project.htm). The development of

the cracks of the concrete slab indicated that the actual deformations of the slab were

larger than predicted and exceeded the maximum allowed deformations. The designed

deformation of the slab of Shuibuya dam was evaluated as being too small in relation to

its 233 m height and 403 m length of the concrete slab.

(http://www.biztrans.cn/CN/Samplefiles/SbyKeytech.htm) The deformation of the

concrete slab was following the deformation field of rockfill of the dam. Most likely one

of the reasons for the larger than expected deformations of the rockfill was that the in-

situ values of geotechnical parameters were different from those assumed during the

design of the dam.

4. MONITORING INSTRUMENTATION

The purpose of installing geotechnical or geodetic instrumentation is to observe the

behavior of dams. Type, number, and distribution of instrumentation depend on

characteristics of the site of a dam (narrow valley with steep banks, rough variation of

the geometry of foundations, more or less permeable deposits in the riverbed or on the

abutments, etc.). The number and the distribution of monitoring instruments depend on

specific problems foreseen in the design stage.

385

To have an overview of the deformations which occur in the body of a dam it is

necessary to have, at least, a distribution of measuring instruments in two main cross-

sections. The cross-section, where a plane strain state may be assumed, generally,

coincides with the transverse section where the dam is the highest. The second cross-

section is the plane corresponding to the axis of the dam. Monitoring data allows to

make comparisons with bi-dimensional analyses and to verify the behavior of the dam.

ASCE Task Committee (2000) presented in detail the various measuring instruments

used to evaluate the behavior of dams. CFRDs contain typically two layers of crushed

stone of transition of at least 3 m of width at once under the concrete face slab. These

layers of transition are generally in crushed stone 0-80 mm for the first layer, and in

crushed stone 0-200 mm for the second layer of transition. It is possible to install, in the

first layer, inclinometers with telescopic joints parallel to the concrete face slab.

Furthermore in the surface of the concrete face slab, movements in three directions can

be measured punctually with submersible tilt meters connected with a reading post.

In the CFRDs, there are crack meters across the vertical joints in the slab, close to the

abutments, to measure any opening of the construction joints. In most of the CFRDs,

they are installed at the top of the dam to measure the movements of the joint in the base

of the rail. It is also recommended to use different types of instruments for the same type

of deformation. For example, settlements can be measured with tilt meters and using

inclinometer with telescopic joints.

The geodetic monitoring should be combined with geotechnical monitoring. There are

new fully automated techniques for monitoring structural stability (Duffy et al. 2001) of

the dams. The techniques combine the use of Robotic Total Stations (RTS) and Global

Positioning System (GPS). The monitoring systems are supported by ALERT DDS

software (Szostak-Chrzanowski et al. 2007) developed at the Canadian Center for

Geodetic Engineering. ALERT DDS provides fully automated data collection, data

processing, and graphical presentation of displacements. The fully automatic systems

may also include geotechnical instrumentation. In the case of CFRDs, the monitoring

scheme must be capable of monitoring the concrete face slab, which after completing the

reservoir filling will be submerged under water. One should note that the maximum

displacements are expected to be below the crest of dams. Therefore new monitoring

techniques will have to be developed to detect the expected displacements at various

elevations of the submerged concrete face slab.

5. ANALYSIS OF DEFORMATIONS OF TOULNUSTUC AND SHUIBUYA DAMS

The FEM analyses of the behaviour of two dams were performed using first the design

geotechnical parameters, followed by the analyses with geotechnical parameters verified

(calibrated) by monitoring results. The analyses of the behaviour of the Toulnustouc and

Shuibuya CFRDs were performed for two stages: end of construction and during filling

the reservoir. The finite element analysis (FEM) was performed using GeoStudio

software (Krahn, 2004) with hyperbolic model of the behaviour of the rockfill material

(Duncan and Chang, 1970).

386

Figure 4: Shuibuya Dam, FEM mesh and dam zoning.

The finite element model of the Toulnustouc dam is shown in Figure 2. The geotechnical

parameters used in the analysis were accepted as given by Massira et al. (2005). The

finite element model of Shuibuya dam is shown in figure 4. The FEM analysis was using

values of geotechnical parameters given by Szostak-Chrzanowski et al. (2008).

The calculated vertical displacements (settlements) for the Toulnustouc dam and

Shuibuya dam at the end of construction stage are shown in Figures 5 and 6

respectively. The vertical displacements at the end of the construction are much larger

in case of Shibuya dam. They are equal to -0.8 m for Toulnustouc dam and -2.2 m for

Shibuya dam.

The calculated vertical displacements (settlements) for the Toulnustouc dam and

Shuibuya dam at the end of filling the reservoir are shown in Figures 7 and 8

respectively. The calculated for Toulnustouc dam maximum vertical displacement of -

0.20 m is at the middle height of the upstream face. The calculated for Shuibuya dam

maximum vertical displacement is on the upstream face of the dam and is -0.30 m and is

at one third of the height.

Figure 5: Calculated settlements (m) at the end of construction for Toulnustouc CFRD.

-0.8

-0.6

-0.4

-0

.2

387

Figure 6: Calculated settlements (m) at the end of construction for Shuibuya CFRD.

Figure 7: Calculated settlements (m) at the end of the filling of the reservoir

for Toulnustouc CFRD.

Figure 8: Calculated settlements (m) at the end of the filling of the reservoir

for Shibuya CFRD.

The calculated total displacements for the Toulnustouc dam and Shuibuya dam at the

end of filling the reservoir for different heights of water in reservoir are shown in

Figures 9 and 10 respectively. The calculated for Toulnustouc dam maximum total

displacement of -0.23 m is at the middle height of the upstream face.

-0

.2

8

-0

.2

2

-0

.1

6

-0.12

-0.08

-0.06

-0.04

-0.02

-

0

.2

-

0

.

1

6

-

0

.

1

2

-

0

.

0

8

-

0

.

0

4

388

The calculated for Shuibuya dam maximum total displacement is on the upstream face

of the dam and is -1.18 m and is at one third of the height. Figure 10 shows the total

calculated displacement for the maximum water level using designed geotechnical

parameters. It shows that when the level of water in the reservoir reached 150 m, the

maximum modelled displacement of the dam with verified geotechnical parameters was

larger than the maximum predicted displacement.

Figure 9: Calculated total displacements (m) of the concrete face slab during

the filling of the reservoir of the CFRD.

wat er l evel s ( m)

0

50

100

150

200

250

0. 00 0. 20 0. 40 0. 60 0. 80 1. 00 1. 20 1. 40

Total displacement (mm)

E

l

e

v

a

t

i

o

n

(

m

)

0

25

50

75

100

125

150

175

200

215

215( desi gn

par amet er )

Figure 10: Calculated total displacements (m) of the Shuibuya concrete face

slab during the filling of the reservoir.

389

5. CONCLUSIONS

The study shows that the in real time fusion of the monitoring results and FEM analysis

would generate information that the deformations of the concrete face reached critical

values before the reservoir level reached the maximum level. The fusion process of the

monitoring results and FEM analysis should work in real time using data sets for

measurements results and FEM results interconnected using specific correlation

criteria. The result of real time fusion would trigger the proper action from engineering

team what would lead to prevention of the cracking of the concrete face.

In case of CFRD dams, the maximum displacements are expected to occur on upstream

face of the dam, where classical geodetic surveys cannot be implemented. Thus, in this

case permanently installed geotechnical instruments (e.g., inclinometers, extensometers)

should be used on the upstream face while geodetic surveys could be utilized on the crest

and on the downstream face. Here one should note that the maximum displacements of

the upstream (concrete) face are expected to take place below the crest. This is very

often overlooked by geodetic engineers, who tend to install their points along the crest

due to the easiest access.The maximum displacements of the concrete face slab are also a

function of the height of the dam during the filling of the reservoir.

REFERENCES

ASCE Task Committee, 2000. Guidelines for instrumentation and measurements for

monitoring dam performance. ASCE Task Committee on Instrumentation and

Dam Performance.

Cooke, J.B. 1984. Progress in rockfill dams: Journal of Geotechnical Engineering,

ASCE, 110(10): 1383-1414.

Duffy, M., Hill, C., Whitaker, C., Chrzanowski, A., Lutes, J. and Bastin, G. 2001. An

automated and integrated monitoring program for Diamond Valley Lake in

California. Proceedings of the 10

th

FIG International Symposium on Deformation

Measurements, Orange, California, pp. K-1 to K-23, (available at:

http://ccge.unb.ca).

Duncan, J.M., Chang, C.-Y., 1970. Nonlinear analysis of stress and strain in soils:

Journal of the Soil Mechanics and Foundation Division, ASCE, 96 (SM5): 1629-

1653.

Hammamji, Y., Beausjour, N., Massira, M. Vautour, J., Landry, L.-M. 2005.

Toulnustouc CFRD main dam : stress-deformation predictions and behaviour

during reservoir filling. Proceedings, CDA 2005 Annual Conference, Calgary, 3-6

October, CD Rom, Technical Session 5, 12 p.

ICOLD, 2006. Concrete face rockfill dams. Concepts for design and construction.

ICOLD Committee on Materials for Fill Dams. Bulletin No. 141 (rough).

Krahn, J. 2004. Stress and deformation modeling with SIGMA/W, an engineering

methodology. GEO-SLOPE International Ltd., Calgary, Alberta.

Massira, M., Szostak-Chrzanowski, A., Vautour, J. and Hammamji, Y. (2005),

Deformations of Concrete Face Rockfill Dams (CFRDs) Resting on Soil

Foundation, Technical Sciences Journal, No. 8, UWM, Olsztyn, pp. 65-78.

Szostak-Chrzanowski A., Nianwu Deng, and Massira, M. 2008. Monitoring and

Deformation Aspects of Large Concrete Face Dams, Proceedings, 4

th

IAG

Symposium on Geodesy for Geotechnical and Structural Engineering and 13-th

390

FIG Symposium on Deformation Measurements, Lisbon, Portugal, 12-15 May,

CD-Rom.

Szostak-Chrzanowski A., Chrzanowski, A., Massira, M., Bazanowski, M., Whitaker,

C., 2007. Monitoring and Analysis of Long-term Behaviour of Large Earth Dams,

Proceedings, The 100th CIG Annual Conference, The 3rd International

Symposium on Geo-information for Disaster Management, Toronto, Ontario,

Canada, May 23-25, CD- Rom.

Key Technical Issues of Shuibuya CFRD

http://www.biztrans.cn/CN/Samplefiles/SbyKeytech.htm

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 10 - 12 Arrow Shed ManualDocument39 pages10 - 12 Arrow Shed ManualJason Porter100% (2)

- Strap #1: Design AssumptionsDocument27 pagesStrap #1: Design AssumptionsLeanna Abdul Wahab100% (4)

- Structural Masonry Special InspectionDocument132 pagesStructural Masonry Special InspectionFrancisco Bonilla100% (1)

- RedGard Installation InstructionsDocument5 pagesRedGard Installation InstructionsAlex LongNo ratings yet

- Sanitary SpecificationDocument15 pagesSanitary Specificationanup thapaNo ratings yet

- Small Dams - Cap 6,7 - Earthfill and Rockfill DamsDocument127 pagesSmall Dams - Cap 6,7 - Earthfill and Rockfill Damsina_cri0% (1)

- Cement MENADocument60 pagesCement MENAazizelam11No ratings yet

- Loadings NSCP 2015 2 Storey Residential Concrete StructureDocument44 pagesLoadings NSCP 2015 2 Storey Residential Concrete Structureramel sigue100% (1)

- MAPEIDocument51 pagesMAPEIJpolyPolyNo ratings yet

- Sportzentrum Mulimattt1Document12 pagesSportzentrum Mulimattt1mi biNo ratings yet

- Isolated Footing Design (ACI 318-11) : ElevationDocument12 pagesIsolated Footing Design (ACI 318-11) : ElevationAhmed Ben HmidaNo ratings yet

- ACI 544.3R-08 Guide For Specifying, Proportioning and Production of Fiber-Reinforced ConcreteDocument16 pagesACI 544.3R-08 Guide For Specifying, Proportioning and Production of Fiber-Reinforced ConcreteChester SmithNo ratings yet

- Hydraulics of Rubber Dam Overflow: A Simple Design ApproachDocument4 pagesHydraulics of Rubber Dam Overflow: A Simple Design ApproachRazvanNo ratings yet

- Abaqus Fluid Structure Interaction Graz-AustriaDocument20 pagesAbaqus Fluid Structure Interaction Graz-AustriaRazvanNo ratings yet

- Fig.1 Finite Element Mesh of The Barzur Intake Structure-Foundation-Terrain System Used in ABAQUS CodeDocument7 pagesFig.1 Finite Element Mesh of The Barzur Intake Structure-Foundation-Terrain System Used in ABAQUS CodeRazvanNo ratings yet

- DIPRA - Design Decision Model For Corrosion Control of DI Pipelines - 2006Document10 pagesDIPRA - Design Decision Model For Corrosion Control of DI Pipelines - 2006ErwinNo ratings yet

- Interacțiunea Seismică Fluid - Structură În Cazul Barajelor ArcuiteDocument41 pagesInteracțiunea Seismică Fluid - Structură În Cazul Barajelor ArcuiteRazvanNo ratings yet

- Influence of The Dynamic Analysis Methods On The Seismic Response of A Buttress DamDocument17 pagesInfluence of The Dynamic Analysis Methods On The Seismic Response of A Buttress DamRazvan100% (1)

- Technical Visit - Vajont DamDocument42 pagesTechnical Visit - Vajont DamRazvanNo ratings yet

- Mathcad - 4. Calcul - Masiv - Ancoraj - 56 - Deg - PN - 30Document6 pagesMathcad - 4. Calcul - Masiv - Ancoraj - 56 - Deg - PN - 30RazvanNo ratings yet

- Diagnostic Analyses of Concrete Dams: Keywords: Inverse Problems, Parameter Identification, in Situ Tests, Concrete DamsDocument8 pagesDiagnostic Analyses of Concrete Dams: Keywords: Inverse Problems, Parameter Identification, in Situ Tests, Concrete DamsRazvanNo ratings yet

- Tabel Evidenta Isalnita 2012-August2Document1 pageTabel Evidenta Isalnita 2012-August2RazvanNo ratings yet

- Mathcad - CodleaDocument2 pagesMathcad - CodleaRazvanNo ratings yet

- دراسة بعض خواص الخرسانة الحاوية على خبث الأفرانDocument7 pagesدراسة بعض خواص الخرسانة الحاوية على خبث الأفرانGandhi HammoudNo ratings yet

- JDE-PT-MST-0009 - 0 Steel Structure Erection and Slab Opening Reinforcement WorksDocument45 pagesJDE-PT-MST-0009 - 0 Steel Structure Erection and Slab Opening Reinforcement WorksTashaNo ratings yet

- Worldwide Sprayed Concrete State-Of-The-Art Report 2005 - G.bracher Idiem PDFDocument11 pagesWorldwide Sprayed Concrete State-Of-The-Art Report 2005 - G.bracher Idiem PDFNicolásOCNo ratings yet

- Investment Guidelines AppenDocument24 pagesInvestment Guidelines Appenfreddy_setiaNo ratings yet

- Sika Monotop®-610: Product Data SheetDocument3 pagesSika Monotop®-610: Product Data SheetVirah Sammy ChandraNo ratings yet

- Basf Masterfiber 018 TdsDocument2 pagesBasf Masterfiber 018 TdsfffffffgggNo ratings yet

- Different Grades of ConcreteDocument3 pagesDifferent Grades of ConcreteAmjid AfridiNo ratings yet

- Experimental Tests vs. Theoretical Modeling For FRC in CompressionDocument8 pagesExperimental Tests vs. Theoretical Modeling For FRC in CompressionandresNo ratings yet

- Proposal For Testing Services: 1) Water Test For Drinking/Domestic PurposeDocument2 pagesProposal For Testing Services: 1) Water Test For Drinking/Domestic Purposeexam robotNo ratings yet

- Design of Flexible Pavement Using Provisions of IRC 37-2018 For A Stretch Between Solan-Parwanoo On NH 5Document63 pagesDesign of Flexible Pavement Using Provisions of IRC 37-2018 For A Stretch Between Solan-Parwanoo On NH 5Venkatesh ThumatiNo ratings yet

- ShaliGrout 65Document2 pagesShaliGrout 65Anupam ShilNo ratings yet

- WMM Tarring EstDocument7 pagesWMM Tarring EstMahin ThaliyathNo ratings yet

- Ebook Icecon 2022Document46 pagesEbook Icecon 2022MatthewNo ratings yet

- Concrete With Rubber Scraps & Steel Fibers From Old Car TiresDocument65 pagesConcrete With Rubber Scraps & Steel Fibers From Old Car Tiresnagham kabbaraNo ratings yet

- Analysis and Design On Pipe RacksDocument43 pagesAnalysis and Design On Pipe RacksAmanpreet Singh67% (3)

- Reddiform ManualDocument81 pagesReddiform ManualdavidNo ratings yet

- Blank BOQDocument58 pagesBlank BOQThushan Madu0% (1)

- Crushed EPS in Light Weight ConcreteDocument4 pagesCrushed EPS in Light Weight ConcreteIdrus zlnNo ratings yet