Professional Documents

Culture Documents

Computer Aided Design Validation of The Quality Function Deployment For Seat Comfort Prediction

Uploaded by

saed7000Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Computer Aided Design Validation of The Quality Function Deployment For Seat Comfort Prediction

Uploaded by

saed7000Copyright:

Available Formats

1

COMPUTER AIDED DESIGN VALIDATION OF THE

QUALITY FUNCTION DEPLOYMENT FOR SEAT

COMFORT PREDICTION

Saed Amer, Postdoctoral at Tennessee State University, USA (samer01@my.tnstate.edu)

Landon Onyebueke, Professor at Tennessee State University, USA (lonyebueke@tnstate.edu)

ABSTRACT

Seat discomfort is a major cause for occupant's health complications and is blamed for the diminished

quality of the seated activity. Although many studies were conducted in the area of seat comfort, it seems

that the ability of the seat to provide comfort is still deficient; this can be noted through the countless

products that claim to provide or improve seat comfort. Seat comfort evaluation is currently performed

through tedious procedures that consume resources using physical prototyping and human testing. This

study pertains to a technique that expedites seat comfort analyses by integrating three systems each can be

an adequate tool for seat comfort evaluation. The first system is used to retrieve information from the

customer via Quality Function Deployment (QFD) and examine the current seat design against the existing

products and market leverage. The second system is a Computer Aided Design (CAD) technique that

allows the designer to model and evaluate seat comfort in the early design stages. Finally, a prediction

model is used to integrate the two systems by fusing the subjective analyses obtained from the QFD with

the objective analyses from the CAD technique. This study aims to present a validation technique that

guarantees the subjective analysis in the QFD including the relationships between the customers needs

and the designers solutions. The proposed technique employs CAD to test the degree of relationship

depicted for the seat components comfort level as each seat parameter undergoes a controlled change. The

outcomes of the system are compared before and after the validation process to prove that the QFD

validation using CAD post the accuracy and increase the correlation when compared to traditional seat

comfort techniques.

KEYWORDS

Seat Comfort, Quality Function Deployment, QFD, Computer Aided Design, CAD, Computer Aided

Engineering, CAE, Finite Element Analysis, FEA.

INTRODUCTION

Seat comfort is defined as a system that provides adequate body posture and support without excess

physiological pressure points while maintaining overall occupant well-being [1]. Implied from the

definition, many factors are considered to increase the comfort privilege; some can be subjective i.e. driven

by the occupants psychological preferences and mood. Such factors are indefinite and may be impossible

to measure. The outmost factors are the objective ones which can be measured and controlled. Some of the

objective factors include physical factors that influence seat comfort such as Biomechanics and

Physiological factors [2], vibration evaluation [3], thermal and humidity factors [4]. The most considered

factor for comfort research is the investigations of contact pressure distribution between the human and the

seat. According to literature surveys and laboratory experimentations, the correlation between objective and

subjective data suggests that decreasing the contact pressure between the human and the seat brings about

more comfort [5]. Contact pressure measurement is usually obtained using pressure mapping systems such

as TekScan BPMS. An example of such implementation is the work performed by Ojetola et al. The study

employed the pressure mapping to evaluate the seat comfort for ejection seats with regards to three

different rail angles [6].

Seat comfort evaluations are traditionally performed on finished products and may require human testing.

The main shortcoming of such procedures is the resource consumption due to the need for finished

products; in which case, alterations are usually retrofitted into the seat and has to be mended in a new seat

production cycle [1]. According to Kolich et al., seat developing cycle may take up to three years as

illustrated in Figure 1 [7]. Another shortcoming is the dependence on human feedback which is costly and

indefinite due to the lack of consistency. Therefore, there is a need to improve seat comfort design by

develop

and enh

The ad

compet

sharing

for seat

factors

assemb

the area

The m

Compu

comfor

QFD ar

based o

models

comfor

aims to

tools.

QUAL

Seat co

answer

comfor

physica

conside

Engine

effectiv

custom

consists

design.

compre

degree

comfor

assesse

design.

custom

that are

HOWs.

design

ping an innova

hance seat com

dvancement o

titiveness and i

g which expedi

t comfort analy

in the design o

bly [8]. Tang e

as of high cont

ain study intr

uter Aided Des

rt. Though ver

re validated us

on the Finite E

of humans an

rt QFD to indu

o create a CAD

ITY FUNCTI

omfort definiti

s. The propos

rt. The main f

al, biomechanic

ered when ret

ering techniqu

vely carried ou

mer and translat

s of different m

The construct

ehensive invest

of influences

rt using QFD b

d based on the

These require

mer surveys, pro

e needed to ac

. More matrice

parameters. O

ative technique

mfort.

of CAD in t

improves quali

ites the design

yses. For exam

of new seat pro

et al. accompli

tact pressures b

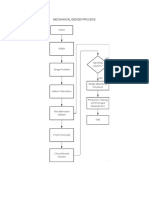

Figure 1. F

roduces a syst

sign (CAD) te

ry useful, QFD

sing measurabl

Element Analys

nd seats with p

ulge the custom

D tool validate

ION DEPLOY

on suggests th

sed system con

factors consid

cs and the perf

trieving inform

ue where the re

ut [10]. QFD

te the custome

matrices that ex

tion and popula

tigations of the

each paramet

begins by obta

e pervious inve

ments are usua

oduct reviews,

hieve the costu

es are populat

Other matrices

that reduces r

the industry e

ity by reducing

n process. Rese

mple, Mamat et

oducts that rela

ished another s

between seat cu

Flow chat for typ

tem of a Qua

chnique to per

D can be concep

le entities usin

sis (FEA) of th

roper material

mers needs an

d in the labora

YMENT (QFD

hat the occupa

nsiders nearly

dered for com

formance aspe

mation from t

equirements, p

opens the ven

ers needs into

xamine differe

ation of the QF

e parameters th

ter imposes on

aining the cust

estigations to d

ally referred to

, direct intervie

umers require

ted to examine

test these par

2

resource exploi

enhances the

g resource cons

earchers recogn

t al focused on

ates to comfort

study on using

ushion and hum

pical seat develo

ality Function

rform seat des

ptual and indis

g CAD analys

he contact pres

properties. Th

nd translate the

atory to replac

D)

ant (customer)

everything bu

mfort measurem

cts of the occu

the end-user.

parameters, syn

nue for better

design param

nt relationship

FD for seat com

hat relate to sea

n the comfort

tomers requir

decide if they w

o as the WHAT

ews and more

ements. These

e the relationsh

rameters with

itation and util

continuous d

sumptions. CA

nized these be

n the integration

t based on the

g finite elemen

man buttock-th

opment process [

Deployment

sign and intera

stinct. In this s

ses. The comfo

ssure between

he proposed te

em into design

ce the conventi

is where the

ut the psycho

ment include e

upant. Therefo

This approach

nthesis and va

r design practi

meters [11]. As

ps to link the cu

mfort analyses

at comfort. The

level. The pr

rements for co

would have an

Ts. The WHAT

. The designer

parameters ar

hips between

current produc

lizes concrete t

design with

AD also promot

enefits and put

n of CAD syst

ergonomics vi

nt analysis app

high tissue [9].

[7].

(QFD) tool i

actively analyz

study the indefi

ort evaluation p

correctly dim

chnique aims t

n parameters.

ional seat com

designers sho

logical factors

ergonomics, a

re, these aspec

h is approved

alidation are do

ice thru intera

illustrated in

ustomer inputs

was based on

e investigation

rocess of evalu

mfortable seat

ny considerable

Ts are usually

rs then set up

re denoted in t

the customers

cts, market an

tools to contro

better produc

tes information

t CAD to work

tem and human

iew and ease o

roach to detec

integrated with

zes its level o

finite aspects o

process will be

mensioned CAD

to develop sea

The study also

mfort measuring

ould search fo

s that relate to

anthropometric

cts are the ones

d as a System

ocumented and

acting with the

Figure 2, QFD

s to the produc

prolonged and

ns examined the

uating the sea

ts and are then

e impact on the

collected using

the parameters

the QFD as the

s need and the

nalyses and the

ol

ct

n

k

n

f

ct

h

f

f

e

D

at

o

g

r

o

c,

s

m

d

e

D

ct

d

e

at

n

e

g

s

e

e

e

manufa

the curr

RELIM

Prelimi

survey,

this ste

parame

and jus

with va

illustrat

The im

seat com

contain

this stag

way to

As the

reveals

COMF

Seat co

and par

perform

compot

parame

importa

stage o

precise

acturing proces

rent seat produ

MINARY CON

inary Concept

background r

ep is performe

eter to the custo

stify which of

alues of 9, 3 o

tes such relatio

mportance of the

mfort, it has be

n mostly the fac

ge carries high

achieve optim

designer reach

the importanc

FORT EVALU

omfort evaluati

rameters to the

med by associ

tators compari

eters and degr

ance are given

of the QFD is

seat attributes

ss. By combini

ucts are obtaine

Figure 2.

NCEPT DEVE

Development

research, and h

ed via a relatio

omers needs. T

the HOW satis

or 1 assigned

onship for a WH

Figur

e relationship m

een established

ctors that affec

h level of impo

mum design solu

hes this stage, t

e of the custom

UATION USIN

on via QFD is

e ones of the r

iating it to a

isons, the firs

rees of import

n by a percent

implemented t

s and measurem

ing these matri

ed.

House of Qual

ELOPMENT

t depends ma

hands-on exper

onship matrix

The conceptua

sfies the WHA

for strong, mo

HAT, the seat

re 3. Seat Width

matrix is obvio

d from the liter

ct the level of c

ortance because

utions that sign

the goals are se

mer voice to se

NG QFD

carried out usi

recommended

target. Based

st stage of Q

tance each pa

tage that sugge

to obtain the p

ments that prom

3

ices a numeric

lity Rooms and R

AND THE RE

ainly on the d

rimentations ar

that illustrate

l design develo

AT using the re

oderate or wea

width, for exam

Relationship wi

ous for optimiz

rature survey th

comfort on eac

e it draws the m

nificantly help

et and the opti

at comfort ana

ing the custom

seats. In other

d on the cus

QFD provides

arameter contr

ests higher pe

parts paramet

mote seat comf

value for the

Relationships [12

ELATIONSH

designer exper

are important to

es the importan

opment planne

elationship ma

ak relationship

mple.

ith HOWs List

zing the design

hat the design p

ch customer req

map that leads

satisfy the cus

imum paths to

alysis.

mer as the ultim

r words, the se

stomers input

the designer

ributes to the

ercentage to m

ters which pro

fort. As in the

comfort level

2]

HIP MATRIX

rtise; neverthe

o perform this

nce of the sug

ed must include

atrix which ran

p respectively

n process [13]

parameters in t

quirement [11]

the designer to

stomer requirem

the solutions a

mate by compar

eat evaluation p

ts and through

with the ade

design. The

more importanc

ovide the desig

first stage, the

of the new and

eless, literature

s step. Usually

ggested design

e all the HOWs

nks the relation

[13]. Figure 3

; In the case o

the HOWs lis

]. Furthermore

o the expedited

ments [11, 14]

are clear which

ring its features

process will be

h the existing

equate produc

values of the

ce. The second

gner with more

e percentage o

d

e

y,

n

s

n

3

f

st

e,

d

].

h

s

e

g

ct

e

d

e

f

4

importance for each part parameter is calculated. The final output of the QFD includes the percentage of

importance of the products parameters and the parts parameters that constitute comfort. Consequently, the

final value for the comfort level is derived from combining the values of importance to produce a final

ranked from zero (0.0) to five (5.0) that represent the comfort level of the proposed seat.

COMPUTER AIDED DESIGN FOR SEAT COMFORT EVALUATION

CAD is defined as the exploitation of computer systems to expedite the creation, modification, analysis, or

optimization of a design [15]. It was noted in previous works and literature surveys that Computer Aided

Design\Engineering is an adequate tool for seat design and comfort analysis [16]. The advent of CAD

permits the evaluation of seat comfort in the early design stages circumventing physical prototyping which

is utterly pricey and tedious. The proposed CAD technique performs comfort evaluation by simulating

sitting postures on a new seat model and determines the physical factors that contribute to its comfort; CAE

is employed to analyze the physics that relate to seat comfort and evaluate the comfort level of projected

seat designs using different simulated seating scenarios. The Computer Aided Design system is launched

with an interaction channel that ties the QFD and the CAD systems. At this juncture, the output of the QFD

technique are the design parameters, known in QFD as the HOWs, which by far satisfy the needs of the

customers. These parameters and entities are then conveyed to the CAD technique as the blueprints for the

modeling new seat designs.

SEAT FEATURES

Laboratory experimentations and literature surveys agree that adding seat features provide more contact

area between the seat and the occupant which seems to promote comfort [8]; hence, it is important to

consider the effects of the seat features on the comfort evaluation process. In this study, seat features can be

retrofitted to the seat design or removed without losing the functions of the seat. Different seat features

were considered in this study and were created and enclosed in an easy to access CAD database. Some

features may require alteration of the basic seats parts such as lumbar support and cushion curvature, while

most can be added to the seat as separate parts such as the head rest, armrests, and the footrest. The seat

adjustment features are also considered in this technique for accommodating different individuals with

different anthropometries; such features include seat-pan height, rotation adjustments, back support angle

adjustment and more.

THE SIMULATION TECHNIQUE

For the purpose of this study, sitting posture is described as the manner that the human body is positioned

on the seat surface and the matter that the human body is supported to fit and feel in the seat [17]. Several

sitting postures were considered in this study aiming to understand the importance of seat features to

comfort. Figure 4 shows seven sitting postures used in laboratory experimentation and are simulated using

the CAD software. The first posture is considered the simplest where all the analyses are centered in the

cushion and the rest of the seat features are neglected. This posture describes the human sitting up on the

cushion, arms positioned on the thighs and head held up. Gradually, more seat features are added and more

of the body surface areas are in contact with the seat surface, hence, the load will be distributed on more

surface areas consequently, reducing the contact pressure.

FINITE ELEMENT ANALYSIS (FEA)

Finite Element Analysis (FEA) can be described as a technique that demonstrates the reaction of an object

in CAD due to excitations; this may include force loadings, contact pressure, thermal excitations, fluid

motions and more [18]. As established in the definition for seat comfort, the physical measurement of seat

comfort depends on the regions of high contact pressure between the occupant and the seat surface; these

regions are usually discovered using tools that identify the contact pressure points and map them with

respect to the sitting posture.

One of the conventional tools used to detect contact pressure is the Pressure Mapping Systems. In the CAD

technique, however, contact pressure regions are detected using (FEA). Research shows that FEA is a valid

technique which is highly considered in the industry [16], yet many calibrations and validation testing were

performed before endorsing it. The more high pressure regions discovered, the less the comfort level of the

seat. F

position

original

surface

CAD V

Laborat

evaluat

the we

perform

validati

of high

experim

observe

CAD b

the outc

properl

the seat

human

Figure

THE Q

The va

carried

Figu

test t

se

armr

5

headr

EA outcomes

n and magnitud

l model makin

s.

VALIDATION

tory experimen

tion study. The

eight measurin

med to examin

ion experiment

contact pressu

mentations wer

ed through the

ased technique

comes are inve

y in the Finite

t and the occup

load on the sea

e 6. CAD Valida

QUALITY FU

alidation of the

out by studyi

ure 4. Seven sittin

the effects of hav

eat comfort. 1)

rests, 3) UP with

5) BP with armre

rests, 7) BP with

are presented i

de of the high c

ng it easy to fi

N

ntations were c

e preliminary e

ng devices and

ne the distribu

tation was per

ure for a human

re carried out

e traditional se

e. The sitting s

estigated. The l

e Element Anal

pant. Therefore

at with differen

ation by Convent

NCTION DEP

e QFD techniq

ng the QFD o

ng postures were

ving different sea

Up position (UP

h footrests, 4) Ba

ests, 6) BP with

armrests, headr

in a three dime

contact pressur

nd the location

carried out in o

experiments w

d the pressure

ution of huma

formed using

n subject sittin

to validate the

eat comfort eva

scenarios are th

loading distrib

lysis technique

e, several exper

nt postures and

tional Methods

PLOYMENT

que is perform

outcomes for a

e implemented to

at features on th

P), 2) UP with

ack Position (BP)

armrests and

rests and footres

5

ensional map t

re regions. Figu

n of the high c

Figu

order to validat

were geared tow

e mapping sy

n weight load

Tekscan pressu

ng with the ack

e proposed tec

aluation techni

hen simulated

bution analyses

e which exami

riments were p

d seat paramete

VALIDATIO

med by two d

a product evalu

Figure 7. T

a sitting pe

represente

o

e

P),

sts

that gives that

gure 5 shows th

contact pressur

ure 5. Contact P

te the results o

ward calibratin

ystem. Few of

dings on the s

ure mapping s

knowledged po

chnique by exa

ique and comp

in CAD and s

s are important

ines the region

performed to ex

ers.

ON

different techni

uated with trad

Tekscan PBMS d

erson on top of a

ed as a map of h

researcher bett

he FEA results

re in relation t

Pressure in Finite

obtained from t

ng the needed t

f the experime

seat. However

system to explo

ostures (Figure

amining the co

pare them to t

similarities and

t in this study t

ns of pressure p

xamine the dis

iques. The firs

ditional evalua

delivers the conta

a seat cushion. T

high and low pre

ter sense of the

mapped on the

to the touching

e Element

the CAD based

tools including

entations were

r, the foremos

ore the regions

s 6 and 7). The

ontact pressure

the ones of the

d differences o

to be simulated

points between

stribution of the

st technique is

ation technique

act pressure of

The results are

essure region.

e

e

g

d

g

e

st

s

e

e

e

f

d

n

e

s

e

then co

matrix

techniq

implem

design

done by

increme

strong

pressur

are the

pressur

determi

QFD to

techniq

the com

Finally

QFD to

RESUL

Endeav

techniq

results

of the s

features

backres

hardwo

validati

The ne

optimum

observe

updatin

QFD v

average

ompare it to the

in the House o

que for QFD va

menting the QF

parameters (H

y taking each s

ented changes.

relationship w

re when the arm

en interpreted

re to the decrea

ines whether t

o determine th

que are presente

mfort level of t

, the validation

o replace the co

LTS AND DIS

voring to replac

que, the CAD t

manifest the s

seat design. In o

s and seat cu

st angle, armre

ood, memory f

ion.

Figure 8. Seat F

ew CAD obser

m comfort leve

ed from the CA

ng the QFD fro

validation. As

es 13% while it

e QFD observe

of Quality that

alidation is per

FD design para

OWs) and the

seat parameter

. For example,

with armrest he

mrest height is

into comfort

asing of the com

the relationship

he degree of ag

ed in one of th

the new produc

n process prov

omfort value ob

SCUSSIONS

ce the tradition

technique is pr

ystems ability

order to obtain

ushion materia

ests, headrests

foam, gel cush

Features Valida

rvations consis

els (Figure 9).

AD then the n

om the CAD d

depicted in Fi

t was recorded

ed with the cus

test the relatio

formed using t

ameters in the

consumers re

individually th

, in the QFD r

eight (HOW).

s changes to 23

values using a

mfort. The deg

p is strong, m

greement amon

he compartmen

ct compared w

vides new com

btained from th

nal seat comfo

roposed to ove

y to detect the

n proper unders

als were manip

s, and footrest

hion and air-fil

tion Graphs

st of new rela

These values a

new QFD is ins

data. The outc

igure 11, the e

d with an avera

6

stomers feedba

onship among d

the Computer A

CAD softwar

equirements (W

hen observing i

relationship ma

CAD can vali

3in, 24in then 2

a mathematica

gree of deviatio

oderate or we

ng seat param

ts of the QFD

with different p

mfort value to

he customers a

ort evaluation w

ercome the sho

effects of the

standing of the

pulated and t

s. The cushion

lled cushions.

ationship asses

are then update

serted back in

comes of the s

error observed

ge of 6% error

ack. This can b

different produ

Aided Design t

re then testing

WHATs). The Q

its comfort resp

atrix, armrest

idate that by w

25in. The obse

al model that

on of the comf

ak. CAD valid

meters. The Res

chart; the outc

products and is

be conveyed b

appraisal again

with a more ec

ortcomings of s

seat factors th

e importance of

tested for com

n materials co

Figure 8 show

ssments, optim

ed in the QFD

the cycle. Fig

system were co

d from the syst

r after CAD va

Figure 9

be obtained by

ucts. The secon

technique; this

the relationsh

QFD validation

ponse when ex

comfort (WHA

watching the a

erved contact p

relate the inc

fort values obse

dation is perfo

sults obtained

comes shows im

s compared to

back to the fir

nst existing pro

conomical and

such tedious p

hat promote the

f the proposed

mfort; these fe

onsidered in th

ws the outcom

mum seat param

with the prope

gure 10 shows

ompared befor

tem without Q

alidation.

9. CAD Validatio

y constructing a

nd and eminen

s is obtained by

hips among the

n using CAD is

xposed to smal

AT) may show

armrest contac

pressure values

creasing of the

erved via CAD

ormed in every

from the QFD

mprovement o

a set up target

rst stage of the

oducts.

d time effective

procedures. The

e comfort leve

technique, sea

eatures include

his study were

me of the CAD

meters and the

er comfort leve

the process o

re and after the

QFD validation

on Outcomes

a

nt

y

e

s

ll

w

ct

s

e

D

y

D

f

t.

e

e

e

el

at

e

e

D

e

el

f

e

n

You might also like

- Design Optimization - Past, Present, and FutureDocument11 pagesDesign Optimization - Past, Present, and Futurejwpaprk1No ratings yet

- Automobiles Seat ComfortDocument10 pagesAutomobiles Seat ComfortAnushree DeshingeNo ratings yet

- 2201.07729Document33 pages2201.07729Javid AhadzadeNo ratings yet

- 184-Article Text-405-1-10-20200814Document5 pages184-Article Text-405-1-10-20200814Apriani AprianiNo ratings yet

- CAD/CAM/CAE Systems IntroductionDocument7 pagesCAD/CAM/CAE Systems IntroductionvpritNo ratings yet

- Esd WP 2002 03 PDFDocument12 pagesEsd WP 2002 03 PDFummanNo ratings yet

- Design Rule Checker For Sheet Metal Components Using Medial Axis Transforms and Geometric ReasoningDocument33 pagesDesign Rule Checker For Sheet Metal Components Using Medial Axis Transforms and Geometric Reasoningramasamy_lNo ratings yet

- The Systems Engineering ProcessDocument4 pagesThe Systems Engineering ProcessKev WilkNo ratings yet

- Content ServerDocument22 pagesContent ServerIgnacius Garridum ContulianoNo ratings yet

- CAE Tools Aid Engineering AnalysisDocument6 pagesCAE Tools Aid Engineering Analysisamazon webserviceNo ratings yet

- Cad/Cam: Chapter TwoDocument172 pagesCad/Cam: Chapter TwoMoathNo ratings yet

- Cad Notes in Word1Document71 pagesCad Notes in Word1arunNo ratings yet

- rbtic armDocument18 pagesrbtic armmnervadesuNo ratings yet

- CATIA Full Book 2 Print - 2Document147 pagesCATIA Full Book 2 Print - 2Sum Sumne SumanthNo ratings yet

- Unit - 1: Question: Explain The Design Process With Computer and Without ComputerDocument17 pagesUnit - 1: Question: Explain The Design Process With Computer and Without Computerbrar352No ratings yet

- Simulation Modeling for Sport Facility Resource OptimizationDocument31 pagesSimulation Modeling for Sport Facility Resource OptimizationSaurav KumarNo ratings yet

- Computer-Aided Engineering (CAE) Is The Broad Usage of ComputerDocument4 pagesComputer-Aided Engineering (CAE) Is The Broad Usage of ComputerDavid AlexNo ratings yet

- ZH 33251263Document13 pagesZH 33251263AJER JOURNALNo ratings yet

- Ijaiem 2014 12 07 16Document6 pagesIjaiem 2014 12 07 16International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 2007 Process Optimization of Injection Moulding Using An Adaptive Surrogate Model With Gaussian Process ApproachDocument11 pages2007 Process Optimization of Injection Moulding Using An Adaptive Surrogate Model With Gaussian Process Approachjyp51507No ratings yet

- Sla Management Framework Using Predictions and SurvingDocument2 pagesSla Management Framework Using Predictions and SurvingSoham Raje PatilNo ratings yet

- Rapid Prototyping Optimization for Additive Manufacturing Accuracy and CostDocument9 pagesRapid Prototyping Optimization for Additive Manufacturing Accuracy and CostJohovani SuarezNo ratings yet

- Producibility and Confidence Indices During Defense AcquisitionDocument17 pagesProducibility and Confidence Indices During Defense AcquisitionAndy ReynoldsNo ratings yet

- Early Estimate The Size of Test Suites From Use CasesDocument6 pagesEarly Estimate The Size of Test Suites From Use CasesHanzasNo ratings yet

- AppDev TopTerms EguideDocument16 pagesAppDev TopTerms EguideMarco Antônio Claret TeixeiraNo ratings yet

- New Testing Paradigm for Product DevelopmentDocument5 pagesNew Testing Paradigm for Product Developmentuamiranda3518No ratings yet

- Atde 16 Atde210123Document10 pagesAtde 16 Atde210123Josip StjepandicNo ratings yet

- International Journal of Computer Science and Security (IJCSS), Volume (1), IssueDocument101 pagesInternational Journal of Computer Science and Security (IJCSS), Volume (1), IssueAI Coordinator - CSC JournalsNo ratings yet

- Quantifying The Effects of Production Maintenance Decisions Using Discrete Event SimulationDocument9 pagesQuantifying The Effects of Production Maintenance Decisions Using Discrete Event SimulationDavid NyanguNo ratings yet

- Evaluating Design ProposalsDocument6 pagesEvaluating Design ProposalsrrameshsmitNo ratings yet

- Manufacturing Cost Estimation During Early Phases of Machine DesignDocument12 pagesManufacturing Cost Estimation During Early Phases of Machine DesignKaitlynNo ratings yet

- Systems 10 00060 v3Document24 pagesSystems 10 00060 v3Reymar VillaflorNo ratings yet

- Using Predictive Models to Quickly Explore Multilevel System DesignsDocument25 pagesUsing Predictive Models to Quickly Explore Multilevel System Designse_galvanNo ratings yet

- Human Intelligence Needs Artificial Intelligence: Daniel S. Weld Mausam Peng DaiDocument6 pagesHuman Intelligence Needs Artificial Intelligence: Daniel S. Weld Mausam Peng Daikavin2193No ratings yet

- Asi 02 00020Document30 pagesAsi 02 00020Sree ManasaNo ratings yet

- Axiomatic DesignDocument3 pagesAxiomatic Designkerekaype100% (1)

- Applied Mathematical Modelling: M. Sakhaii, R. Tavakkoli-Moghaddam, M. Bagheri, B. VataniDocument23 pagesApplied Mathematical Modelling: M. Sakhaii, R. Tavakkoli-Moghaddam, M. Bagheri, B. VataniitzgayaNo ratings yet

- CADM Mod 2Document39 pagesCADM Mod 2Aswin MNo ratings yet

- HRA_Mezcla de Análisis Descriptivo_SmithDocument15 pagesHRA_Mezcla de Análisis Descriptivo_SmithJose Martin ChaconNo ratings yet

- Software Cost Estimation Approaches SurveyedDocument46 pagesSoftware Cost Estimation Approaches SurveyedRavi SankarNo ratings yet

- PLCM, Module-5Document41 pagesPLCM, Module-5Sunil Kumar M50% (2)

- Literature Survey MDO FrameworkDocument8 pagesLiterature Survey MDO FrameworkKarthikeya SrivathsavNo ratings yet

- Straightness and Flatness Evaluation Using Data Envelopment AnalysisDocument10 pagesStraightness and Flatness Evaluation Using Data Envelopment Analysisakjeevanantham79No ratings yet

- CAD-Based Parametric Designer for Gas Turbine Engine MDODocument10 pagesCAD-Based Parametric Designer for Gas Turbine Engine MDOValiyakattel NilsNo ratings yet

- Mechanical Systems and Signal Processing: L. Farkas, D. Moens, S. Donders, D. VandepitteDocument10 pagesMechanical Systems and Signal Processing: L. Farkas, D. Moens, S. Donders, D. VandepitteZaid MangalgiriNo ratings yet

- Surogate ModelingDocument11 pagesSurogate ModelingGamini SureshNo ratings yet

- DETC2000/DFM-14009: Information Modeling of Conceptual Process Planning Integrated With Conceptual DesignDocument11 pagesDETC2000/DFM-14009: Information Modeling of Conceptual Process Planning Integrated With Conceptual DesignbarmarwanNo ratings yet

- Mechanical Design ProcessDocument3 pagesMechanical Design ProcessAlamsyah AkbarNo ratings yet

- Article MechanismMachineTheory Budinger PDFDocument17 pagesArticle MechanismMachineTheory Budinger PDFfei312chenNo ratings yet

- Thiet Ke Tich HopDocument17 pagesThiet Ke Tich HoptuongnvNo ratings yet

- Design Communication Using A Variation of The Design Structure MatrixDocument8 pagesDesign Communication Using A Variation of The Design Structure MatrixSadullah AvdiuNo ratings yet

- Mobile Store Management SystemDocument34 pagesMobile Store Management SystemVickram JainNo ratings yet

- Systems: Early Design Space Exploration With Model-Based System Engineering and Set-Based DesignDocument19 pagesSystems: Early Design Space Exploration With Model-Based System Engineering and Set-Based Designraul yondoNo ratings yet

- Result MakerDocument5 pagesResult Makeranimesh907No ratings yet

- HCI in The Software ProcessDocument7 pagesHCI in The Software ProcessAhyel LibunaoNo ratings yet

- Computer Aided Manufacturability Analysis of Die-Cast Parts: Pvmrao@mech - Iitd.ac - in Tkkundra@mech - Iitd.ac - inDocument12 pagesComputer Aided Manufacturability Analysis of Die-Cast Parts: Pvmrao@mech - Iitd.ac - in Tkkundra@mech - Iitd.ac - indamonlanglois100% (1)

- Chapter One 1. Fundamentals of Numerical Control: 1.1 Introduction To Computer Aided Design (CAD)Document24 pagesChapter One 1. Fundamentals of Numerical Control: 1.1 Introduction To Computer Aided Design (CAD)መሰረቴ ግርማይNo ratings yet

- Confirmatory Factor Analysis: Model Testing of Financial Ratio's With Decision Support Systems ApproachDocument7 pagesConfirmatory Factor Analysis: Model Testing of Financial Ratio's With Decision Support Systems ApproachInternational Journal of Advances in Applied Sciences (IJAAS)No ratings yet

- Pharmaceutical Quality by Design Using JMP: Solving Product Development and Manufacturing ProblemsFrom EverandPharmaceutical Quality by Design Using JMP: Solving Product Development and Manufacturing ProblemsRating: 5 out of 5 stars5/5 (2)

- Douglas Montgomery's Introduction to Statistical Quality Control: A JMP CompanionFrom EverandDouglas Montgomery's Introduction to Statistical Quality Control: A JMP CompanionNo ratings yet

- P03140 - 26 - 0G0 - 01 Installation Instructions WINMAG PlusDocument20 pagesP03140 - 26 - 0G0 - 01 Installation Instructions WINMAG PlusXivanNo ratings yet

- CBC DrivingDocument74 pagesCBC DrivingElonah Jean ConstantinoNo ratings yet

- DesignBuilder v4.2 ASHRAE140 2Document113 pagesDesignBuilder v4.2 ASHRAE140 2Yusuf AhdaNo ratings yet

- Project-II Final ReportDocument54 pagesProject-II Final Reportsharanjeet singhNo ratings yet

- Methods of TrainingDocument81 pagesMethods of Trainingdisc_brakeNo ratings yet

- Ista 2BDocument5 pagesIsta 2Bduygu9merve100% (1)

- Modeling SMT Line to Improve ThroughputDocument6 pagesModeling SMT Line to Improve Throughputgautham VNo ratings yet

- Civil Cad 2010 v-1.0 EngDocument11 pagesCivil Cad 2010 v-1.0 EngGabriel I-SotomayorNo ratings yet

- Boeing 777 First FlightDocument31 pagesBoeing 777 First Flighthmm14No ratings yet

- Session 2: Understanding Work Immersion Program: The Senior High SchoolDocument68 pagesSession 2: Understanding Work Immersion Program: The Senior High SchoolFrancois L. DeteraNo ratings yet

- Architecture ReviewsDocument22 pagesArchitecture Reviewsorc19No ratings yet

- The Effectiveness of Low Fidelity Simulation in The Training of Undergraduate Nursing Students Survey of Fourth Year Students in Buea Municipality, Fako DivisionDocument16 pagesThe Effectiveness of Low Fidelity Simulation in The Training of Undergraduate Nursing Students Survey of Fourth Year Students in Buea Municipality, Fako DivisionEditor IJTSRDNo ratings yet

- Product Data Sheet Control Studio Online Deltav en 57670Document6 pagesProduct Data Sheet Control Studio Online Deltav en 57670Armand Muteb AmkNo ratings yet

- Managing a Construction Project in MIT's Project Management SimulationDocument8 pagesManaging a Construction Project in MIT's Project Management SimulationRashi BansalNo ratings yet

- Pde 18 ADocument140 pagesPde 18 AErnesto D. AguirreNo ratings yet

- Analysis and Test of CAN ApplicationsDocument77 pagesAnalysis and Test of CAN ApplicationsPhạm TùngNo ratings yet

- Solution - Project Proposal - VR Car Driving SimulatorDocument11 pagesSolution - Project Proposal - VR Car Driving Simulatorammad ahmadNo ratings yet

- ICT619 Intelligent Systems Topic 4: Artificial Neural NetworksDocument51 pagesICT619 Intelligent Systems Topic 4: Artificial Neural NetworksMadiha UroojNo ratings yet

- CS-FSTD (A) Issue 2 - Change InformationDocument57 pagesCS-FSTD (A) Issue 2 - Change Informationadamstaw1No ratings yet

- CTJV807 Adaptive Resource Management For Analyzing Video ST PDFDocument14 pagesCTJV807 Adaptive Resource Management For Analyzing Video ST PDFbhasutkarmaheshNo ratings yet

- Modelling Analysis and Fabrication of Laptop and Projector StandDocument10 pagesModelling Analysis and Fabrication of Laptop and Projector StandSarthakChikaraNo ratings yet

- Robot Operation Manual en PDFDocument518 pagesRobot Operation Manual en PDFex-2156No ratings yet

- Work Immersion at The Municipal Treasurer Pt2Document27 pagesWork Immersion at The Municipal Treasurer Pt2Philip Andrey67% (3)

- HUCE Manual (EBOOK) PDFDocument153 pagesHUCE Manual (EBOOK) PDFlourdel_845857479100% (2)

- Gunship 2000Document140 pagesGunship 2000remow100% (3)

- Final ProjectDocument8 pagesFinal Projectapi-571540731No ratings yet

- Resume&Cover Letter Guide by Wisconsin School of BusinessDocument152 pagesResume&Cover Letter Guide by Wisconsin School of BusinessDmitriy VolynskiyNo ratings yet

- FCA WCM Intermediate 2017 ENG CatalogueDocument74 pagesFCA WCM Intermediate 2017 ENG CatalogueCarlodRujanoNo ratings yet