Professional Documents

Culture Documents

Project-Specific Quality Plan

Uploaded by

Almario SagunOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project-Specific Quality Plan

Uploaded by

Almario SagunCopyright:

Available Formats

DOCUMENT

NO.: M4CMSI-

QAP-PQP- 13-

001

REVI SI ON

NO.:

REV. 0

DOCUMENT TITLE

PROJECT QUALITY PLAN

EGRON WAITING AREA MODIFICATION

COMPANY LOGO

EFFECTI VE

DATE: DEC.

2013

PAGE NO.:

1 OF 7

PAGES

Rev. No. Page No. Revision History Originator Date

Rev. 0

8 Pages

Initial Release

A.J. Sagun

12/16/13

SIGNATURE DATE

PREPARED BY:

ALMARIO J. SAGUN

PEC Head

CHECKED BY:

ADRIAN MANLUNAS

PIC Head

REVIEWED BY:

RESTY B. DE CASTRO

PEC Head

APPROVED BY:

ENGR. CARLO M. MERCADO

President and General Manager

DOCUMENT

NO.: M4CMSI-

QAP-PQP- 13-

001

REVI SI ON

NO.:

REV. 0

DOCUMENT TITLE

PROJECT QUALITY PLAN

EGRON WAITING AREA MODIFICATION

COMPANY LOGO

EFFECTI VE

DATE: DEC.

2013

PAGE NO.:

1 OF 7

PAGES

1.0 GENERAL

1.1 OBJECTIVE

1.2 BRIEF DESCRIPTION OF THE PROJECT.

1.3 DISTRIBUTION LIST OF PROJECT QUALITY PLAN

1.4 METHOD OF REVISION FOR PROJECT QUALITY PLAN

2.0 ORGANIZATION

2.1 SITE ORGANI ZATION CHART

2.2 JOB DESCRIPTIONS & FUNCTIONAL REPORTING

3.0 PROJECT MANAGEMENT

3.1 CONTROL OF DOCUMENTS

3.1.1 INCOMING AND OUTGOING CORRESPONDENCES

3.1.2 METHOD STATEMENTS AND I .T.P.

3.1.3 DOCUMENTS NUMBERING SYSTEM

3.1.4 INTERNAL DISTRIBUTION

3.1.5 TRACEABILITY

3.1.6 INTERFACES WITH CLIENTS

3.1.8 PERMANENT QUALI TY RECORDS

3.2 CONSTRUCTION MANAGEMENT

3.3 MONITOR AND INSPECTION

3.6 HANDLING STORAGE AND INSPECTION

3.7 COMPLETION AND HANDING OVER

4.0 AUDITS

4.1 PROGRAMMES FOR AUDIT

4.2 AUDIT TEAM AND REPORTING

4.3 AREAS OF AUDIT AND AUDIT REPORT

4.4 NON COMPLIANCE / CONFORMANCE AND CORRECTIVE ACTION

DOCUMENT

NO.: M4CMSI-

QAP-PQP- 13-

001

REVI SI ON

NO.:

REV. 0

DOCUMENT TITLE

PROJECT QUALITY PLAN

EGRON WAITING AREA MODIFICATION

COMPANY LOGO

EFFECTI VE

DATE: DEC.

2013

PAGE NO.:

1 OF 7

PAGES

1.0 GENERAL

This document was prepared for the Project Management Team to review and itemized all

necessary fields for the construction of

1.1 OBJECTIVE

To provide vision to the project control in respect of Total quality achievement, and work

execution / related activity. The custodian of this document is Quality Assurance / Control

Department of CESCO Offshore Construction Services, Inc. Queries concerning the

interpretation / construction or use of this document should be directed to the Project

Manager.

1.2 BRIEF DESCRIPTION OF THE PROJECT.

Project Title: EGRON PRODUCTION WAITING AREA MODIFICATION

1.3 DISTRIBUTION LIST OF PROJECT QUALITY PLAN

The Project Quality Plan is a controlled working document applicable to specific projects,

describing the practical application of the Quality Assurance Policy and Objectives. The

custodian of this document is Quality Assurance Manager. He shall maintain a register for the

issue of this document with date and signature of the recipients. The distribution list of the

project quality plan is as follows.

1. Client

2. Project Manager

3. Quality Control & Assurance Engineer

4. Project Engineer

5. Documentation Record.

1.4 METHOD OF REVISION OF PROJECT QUALITY PLAN

During periodical review of the project quality plan as well as company quality manual, if

any changes are necessary in project quality manual, appropriate changes shall be done.

Once a change in project quality manual occurs, the quality assurance manager shall issue

a new document giving the revision number, date and superseding previous one and make

submittal for approval & controlled distribution.

2.0 ORGANIZATION

2.1 PROJECT T.O. OR TABLE OF ORGANIZATION

Enclosed here is the Project Site Organization Chart or TO.

2.2 JOB DESCRIPTIONS AND FUNCTIONAL REPORTING

1. OPERATIONS MANAGER- LOGISTICS

Project Support

Handles and schedules all machinery/equipment/tools

Mobilization / De-mobilization

Accommodations

Reporting directly to the General Manager.

DOCUMENT

NO.: M4CMSI-

QAP-PQP- 13-

001

REVI SI ON

NO.:

REV. 0

DOCUMENT TITLE

PROJECT QUALITY PLAN

EGRON WAITING AREA MODIFICATION

COMPANY LOGO

EFFECTI VE

DATE: DEC.

2013

PAGE NO.:

1 OF 7

PAGES

2. OPERATIONS MANAGER - PROJECT

A. Handles all project operations:

Technical

Engineering

Construction

Project Cost / Scheduling / Planning

Manpower Requirements

Coordinate with Clients

B. Reporting directly to the General Manager.

3. PROJECT MANAGER

The Project Manager shall be the overall in charge to complete the project on time and

at the best possible quality in accordance to the applicable codes and procedures

while ensuring the safety at site at all times.

Reporting directly to the Operations Manager - Project.

4. PROJECT ENGINEER.

Project Engineer shall be responsible for Assuring and Monitoring that the works

executed and materials are in accordance with the drawings, specification and

contract.

Ensure that approved procedures are adopted within his site.

Ensure that staffs are adequately qualified and experienced in their relevant

discipline to perform the duties entrusted to them in a satisfactory manner.

Ensuring that staff are familiar with all relevant procedures and have controlled

access to these required documents.

Reporting directly to the Project Manager.

5. QA / QC ENGINEER

Carries out all QC procedures to achieve quality standards

Plans and directs activities concerned with development, application, and

maintenance of quality standards for industrial processes, materials, and products

Develops and initiates standards and methods for inspection, testing and evaluation

Effectively communicates observations and required actions throughout the business

Develops and implements methods and procedures for disposition of discrepant

material and devices methods to assess cost and responsibility

6. PROJECT ADMINISTRATOR/PLANNING ENGINEER.

Shall be responsible to participate for preparing daily and weekly reports.

Shall be responsible for preparing materials, manpower, and equipment resources

plans projection.

He shall be responsible for preparing macro and micro planning for the project.

He shall be responsible for the material submittal and approvals.

He shall be responsible for claiming of variation statement.

Responsible for preparing procurement schedule.

He shall assist & coordinate with Project Engineer.

He shall report directly to the Project Manager.

DOCUMENT

NO.: M4CMSI-

QAP-PQP- 13-

001

REVI SI ON

NO.:

REV. 0

DOCUMENT TITLE

PROJECT QUALITY PLAN

EGRON WAITING AREA MODIFICATION

COMPANY LOGO

EFFECTI VE

DATE: DEC.

2013

PAGE NO.:

1 OF 7

PAGES

7. SAFETY OFFICER / ENGINEER

He shall be responsible for preparation of site safety plan advising and ensuring that

the safety procedures for all works are according to Client HSE requirement .

Accompanying weekly safety walkabout with Project Manager, Project Engineer and

Client to identify/ improve safety related issues.

He shall induct to every worker joining site, a brief practical training about PPE &

General safety as well as HSE and also record the details of those trained.

He shall appoint "SMOKING ZONE".

He shall ensure site is properly safe against fire.

Preparation of safety report, accident incident ratio, total man-hours and other safety

matters.

Conducting tool box meeting / talk at the work front.

Conducting monthly safety meeting with all staff and sub contractors at site.

Investigating and reporting of any accidents / risk involving occurrence at site.

Ensuring that first aid box and referred ambulance service is available at site at all

times.

Reports directly to The Project Manager.

8.0 PROJECT SUPERVISOR

Ensuring that the work are executed as per approved procedure &comply with our

quality plan.

Ensuring that the staff are adequately experienced and are familiar with relevant

procedures.

Reporting to Project Engineer.

9. DOCUMENT CONTROLLER

Responsible for all incoming and outgoing correspondence, internal matrix

distribution and filing per quality plan.

Responsible for all incoming/ drawings and custodying the master copy, distributing

the controlled copies as per matrix.

Responsible for getting the obsolete / documents/drawings from the site and issuing

the issued for construction only.

Responsible for keeping safe custody of all contractual documents.

Responsible for keeping and numbering all transmittals forms as per approved format.

Responsible for keeping all permanent / final documents till handing over to clients.

Responsible for maintaining the document register according to approved format.

He shall establish the filing system according to the list approved by Project Manager

and endorsed by Quality Assurance. This may be amended from time to time to

current requirement.

Reporting to Project Engineer.

10. FOREMAN

Foreman shall be in-charge of his trade and deploy all the workmen to carryout daily

operations according to direction received from site engineer.

He shall arrange all tools and materials from stock / stores to work front to carry out

the job.

He shall coordinate with material control for the regular issue of the materials.

He shall assist site engineer in physical operations.

DOCUMENT

NO.: M4CMSI-

QAP-PQP- 13-

001

REVI SI ON

NO.:

REV. 0

DOCUMENT TITLE

PROJECT QUALITY PLAN

EGRON WAITING AREA MODIFICATION

COMPANY LOGO

EFFECTI VE

DATE: DEC.

2013

PAGE NO.:

1 OF 7

PAGES

3.0 PROJECT MANAGEMENT

3.1 CONTROL OF DOCUMENT

3.1.1 INCOMING AND OUTGOING CORRESPONDENCES

All Incoming correspondence from client shall be separately filed & according

to distribution matrix list, issue the copies to the concerned in records. For

outgoing transmittals to client, may it be procedure, method statement ,

drawings, or a simple list, use M-4CMSI Transmittal Record Form No. _______ as

covering letter and attached the corresponding procedure, method

statement, drawings or the simple list, fully checked, signed, and sealed with

company stamp by concerned project management team. A separate

register / electronic file shall be maintained using designated corporate

emails or personal emails as practicable. In this procedure sometimes rises the

billing disputes, so careful check on the documents. .

3.1.2 METHOD STATEMENT AND I.T.P.

All method statement shall have references and issued as controlled

document by the Site Document Controller. The revision authority of this

document is the QA/QC Engineer. The method statement shall be submitted

to client for approval before commencing the required activity.

Activities based on Construction method statements shall be prepared at site

by the Project Engineer in conjunction with the Foreman who will actually do

the job and Clearance from QA/QC Department. The various inspection

stages shall be described within the methodology.

Inspection and Test Plan (ITP) shall be prepared and submitted to client. The

custodian of this document is QA / QC Engineer.

ITP shall be designed to meet various inspection and testing requirement of all

significant activities giving points of holds and release of final inspection. All

method statement and Inspection Test Plan shall be submitted according to

activity requirement separately.

If there are prepared ITPs by the Client, the Site Document Controller will

maintain the receiving and stamping of company documents with clear

dates everytme there is a received document from the client, including the

management of internal distribution and revision history of the documents.

Revisions of documents leading to revision history shall be reviewed and

double checked by QA/QC Engineer and coordinates with the Project

Manager any relevant changes on the Drawings or any documents .

3.1.3 INTERNAL DISTRIBUTION

As soon as information was received from the client, internal distribution will be

done by the Site Document Controller, and submits to the Project

Management Team all relevant documents especially with revisions,

modifications and Plan Change Memo. The Project Manager shall check,

review and take-up with the Project Management Team the changes or

movement as required for necessary action / information/ record.

3.1.4 TRACEABILITY

DOCUMENT

NO.: M4CMSI-

QAP-PQP- 13-

001

REVI SI ON

NO.:

REV. 0

DOCUMENT TITLE

PROJECT QUALITY PLAN

EGRON WAITING AREA MODIFICATION

COMPANY LOGO

EFFECTI VE

DATE: DEC.

2013

PAGE NO.:

1 OF 7

PAGES

All documents shall be filed in a systematic / functional way marking index,

contents of the file, project so as to trace the required document. A master

index shall be maintained by the Site Document controller.

3.1.5 INTERFACE WITH CLIENTS

Interface or production meetings with the clients shall be done on a weekly

basis as a minimum requirement for the job during the mobilization,

fabrication phase and prior erection/installation of the assembled/accepted

items or QA-QC inspected items. Minutes of the Meeting with date, sequential

number, topics discussed, open & closing of topics, and names of attendees

shall be recorded and signed by all attendees. There should be a dedicated

weekly day of meeting for client interface and a dedicated weekly internal

meeting of M-4 CMSI project team.

3.1.6 PERMANENT QUALITY RECORDS

All the Permanent Quality records such as guarantee /warranty certificate, all

quality test reports and final dossier shall be submitted in the approved format

after completion of the project, including AFC Drawings, signed and sealed

As-Built Drawings, etc.

3.2 CONSTRUCTION MANAGEMENT

Please refer to job description and functional reporting.

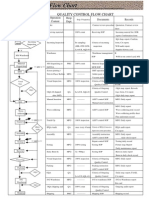

3.3 PROCUREMENT CONTROL

All material procurement shall be done as per our Quality Manual and in addition the

following enclosed schematic system shall be followed for the smooth flow of the

project titled Quality Project Purchasing (Please see attached).

3.4 MONITOR AND INSPECTION

3.4.1. MONITORING

All monitoring, inspection and testing shall be carried out as discussed in our method

statement and Inspection and Test Plan. All inspections shall be carried out by QC &

QA Personnel.

3.4.2. INSPECTION SCHEDULE

All site inspections shall be carried out by giving a schedule of 1 day in advance. An

inspection request shall accompany along with the schedule that shall be duly

signed by QC engineer and clients representative.

Before calling clients representative, our QC Engineer shall ensure that the works

executed is in accordance with our approved procedure and specification. He shall

sign the check list and check for necessary attachments, after completing all this he

shall request the client representative for inspection.

3.4.3. QUALITY RECORDS

DOCUMENT

NO.: M4CMSI-

QAP-PQP- 13-

001

REVI SI ON

NO.:

REV. 0

DOCUMENT TITLE

PROJECT QUALITY PLAN

EGRON WAITING AREA MODIFICATION

COMPANY LOGO

EFFECTI VE

DATE: DEC.

2013

PAGE NO.:

1 OF 7

PAGES

All quality records shall be submitted to client within 48hrs after completion of the

prescribed activity& after getting the approval from the client, the documents shall

be forwarded to document controller / QC Engineer for filing.

3.5 HANDLING, STORAGE AND WARE HOUSING

All handling storage and warehousing shall be per our Quality Manual.

3.6 COMPLETION AND HANDING OVER FINAL QA/QC DOSSIERS

Final dossiers shall be prepared in consultation with the client. The final dossier shall

include the following components.

3.6.1 Method Statements

3.6.2 I nspection and Test Plan

3.6.3 I nspection Reports

3.6.4 Non Conformance Reports

3.6.5 Corrective Action Reports

3.6.6 Permanent Essential Documents

3.7 Completion Certificate.

All the documents shall be clubbed together in a package in hard and soft copies.

Issuance of Warranty Certificate for one (1) year to client shall be done after all

Acceptance Reports had been signed, accepted and approved by the client.

4.0 AUDITS

4.1 PROGRAMMES FOR AUDIT

Programmes of Audit shall be prepared by the process owners and project

management team on site on a weekly basis at a minimum for short term projects

and monthly basis for long term projects.

4.2 AUDIT TEAM AND REPORTING

Audit Team shall be the project management t eam on site which are also the

process owners.

Audit Reports shall be prepared within 3 days after the audit was done and

dissemination shall be done as early as 2 days after the audit report was finalized.

4.3 AREAS OF AUDIT AND AUDIT REPORT

Areas of audit shall be based on the Work Methodologies, Quality Inspections, and

management processes

4.4 NON COMPLIANCE / CONFORMANCE AND PREVENTIVE/CORRECTIVE ACTION

All non-compliance found from the audit report which are non-conforming with the

established quality procedures and control shall be recorded and shall have been

issued to the concerned party for proper action.

DOCUMENT

NO.: M4CMSI-

QAP-PQP- 13-

001

REVI SI ON

NO.:

REV. 0

DOCUMENT TITLE

PROJECT QUALITY PLAN

EGRON WAITING AREA MODIFICATION

COMPANY LOGO

EFFECTI VE

DATE: DEC.

2013

PAGE NO.:

1 OF 7

PAGES

Corrective actions shall be prepared for each of the NCRs found and to be

documented in details for the the process owners.

Preventive Action plans shall be prepared from the outcome of NCR report,

SIGNATURE DATE

PREPARED BY:

ALMARIO J. SAGUN

PEC Head

CHECKED BY:

ADRIAN MANLUNAS

PIC Head

REVIEWED BY:

RESTY B. DE CASTRO

PEC Head

APPROVED BY:

ENGR. CARLO M. MERCADO

President and General Manager

You might also like

- Quality PlanDocument26 pagesQuality PlanAbu Muhammed KhwajaNo ratings yet

- SIBP Project Execution PlanDocument11 pagesSIBP Project Execution PlanEnrique Pomales0% (1)

- QC-QA PlanDocument22 pagesQC-QA Planfaisal ahmad100% (1)

- 2.0 Project Quality Control PlanDocument24 pages2.0 Project Quality Control PlanAbdul Hakam Mohamed Yusof100% (7)

- Project Quality Plan (8.7.2012)Document27 pagesProject Quality Plan (8.7.2012)Vinodh Palanichamy75% (4)

- Construction Quality Control PlanDocument18 pagesConstruction Quality Control PlanKhawaja Arslan Ahmed83% (6)

- Q3a Project Quality PlanDocument25 pagesQ3a Project Quality PlanMohammad Ummer100% (5)

- Site QAQC PlanDocument9 pagesSite QAQC PlanP SHANKAR BABU100% (1)

- Project Quality PlanDocument55 pagesProject Quality Plansamer8saif75% (4)

- PROJECT QUALITY PLAN Rev-00Document33 pagesPROJECT QUALITY PLAN Rev-00shahhassa989% (19)

- Project Quality PlanDocument76 pagesProject Quality PlanDanOtah100% (4)

- PRO-PQP-QA-0001 Project Quality Plan - Rev.0ADocument15 pagesPRO-PQP-QA-0001 Project Quality Plan - Rev.0ATadaya KasaharaNo ratings yet

- Project Quality Plan - Rev 00 (1) .ADocument66 pagesProject Quality Plan - Rev 00 (1) .AGilbertoOrdoñezCausil100% (2)

- 5A QA PL 01rev00 Project Quality ManualDocument21 pages5A QA PL 01rev00 Project Quality Manualirzaldy100% (2)

- Sample Quality PlanDocument17 pagesSample Quality PlanKhaled Abdelbaki100% (1)

- Quality PlanDocument31 pagesQuality PlannayumNo ratings yet

- Construction Project Quality Plan BLANKDocument21 pagesConstruction Project Quality Plan BLANKLa Tonya IbekilliNem Williams100% (2)

- Quality PlanDocument32 pagesQuality PlannayumNo ratings yet

- 12.5 Site Specific Quality Control Plan TemplateDocument3 pages12.5 Site Specific Quality Control Plan Templateloveanbu24100% (1)

- Sample - Project Quality PlanDocument12 pagesSample - Project Quality PlanSuraj Mani100% (1)

- Project Quality Plan DetailDocument17 pagesProject Quality Plan DetailAjay Malik91% (11)

- 9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1Document34 pages9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1anil pk100% (8)

- Quality PlanDocument23 pagesQuality PlanArun Kumar88% (8)

- Quality Control PlanDocument53 pagesQuality Control PlanMuhammad Irfan76% (17)

- Quality Control PlanDocument13 pagesQuality Control PlanMohammad Taqi HamidiNo ratings yet

- PQPDocument54 pagesPQPMustafa Liverpool50% (2)

- Project Quality PlanDocument43 pagesProject Quality Planmkmkhairi100% (4)

- Quality ManualDocument4 pagesQuality ManualAli IrvaliNo ratings yet

- Quality PlanDocument21 pagesQuality PlanTAHER AMMAR88% (8)

- Quality Plan 2 PDF FreeDocument21 pagesQuality Plan 2 PDF FreeEng.arifNo ratings yet

- 02779-Rizhao Project Quality PlanDocument19 pages02779-Rizhao Project Quality PlanmrjimmyjamNo ratings yet

- Project Close Out ReportDocument3 pagesProject Close Out ReportChristopher De WetNo ratings yet

- QA QC PLAN For CNG..Document21 pagesQA QC PLAN For CNG..Pugel Yeremias100% (1)

- Quality Control Flow ChartDocument1 pageQuality Control Flow Chart同道文档中心100% (17)

- 5A-QA-PL-02Rev00 - Project Execution and Quality PlanDocument34 pages5A-QA-PL-02Rev00 - Project Execution and Quality Planirzaldy100% (8)

- Project Qa/Qc Plan: Wade Adams Contracting LLCDocument21 pagesProject Qa/Qc Plan: Wade Adams Contracting LLCnice hossainNo ratings yet

- Qa-Qc Quality PlanDocument60 pagesQa-Qc Quality PlanNaveed Ahmed Get-Info94% (17)

- Construction Quality Control Plan PDFDocument40 pagesConstruction Quality Control Plan PDFBong Nimes Castillo100% (5)

- QUALITY CONTROL PLAN-Rev-CDocument10 pagesQUALITY CONTROL PLAN-Rev-Csivagnanam s100% (1)

- N-00-PQ-5011-PR - R0A (Material Receiving Procedure) PDFDocument10 pagesN-00-PQ-5011-PR - R0A (Material Receiving Procedure) PDFRaziKhanNo ratings yet

- Overall Project Quality Management PlanDocument62 pagesOverall Project Quality Management Planlee100% (9)

- Quality Assurance ProceduresDocument75 pagesQuality Assurance Proceduresviorelu99100% (5)

- 021-Itp For Site Preparation and Earth Works PDFDocument6 pages021-Itp For Site Preparation and Earth Works PDFKöksal Patan100% (2)

- QA - QC Plan For PEP 13-03-2017Document16 pagesQA - QC Plan For PEP 13-03-2017osersNo ratings yet

- PM - Lecture 7 Project Quality ManagementDocument43 pagesPM - Lecture 7 Project Quality ManagementMariam MansourNo ratings yet

- QAQC GuidelinesDocument19 pagesQAQC GuidelinesBonaventure Nzeyimana100% (1)

- Procedure For Control of RecordsDocument3 pagesProcedure For Control of Recordsmatrixmaze50% (2)

- Quality Control Plan SufiDocument23 pagesQuality Control Plan SufiSufi Shah Hamid JalaliNo ratings yet

- Project Quality Plan Rev 00 1 ADocument55 pagesProject Quality Plan Rev 00 1 AAhamed Naufal CaNo ratings yet

- 11-Qa - QC ProcedureDocument18 pages11-Qa - QC Procedureerwin hidayat100% (1)

- Project Qa QCDocument27 pagesProject Qa QCOctora Perdani100% (4)

- Example Quality PlanDocument10 pagesExample Quality PlanAfifa Al-HashimNo ratings yet

- PQP - Section 6Document6 pagesPQP - Section 6Hakimi MuhammadNo ratings yet

- Quality ControlDocument9 pagesQuality ControlSuzan Ali ZakariaNo ratings yet

- Quality Assurance Plan - SRMS Slope Protection & FencingDocument10 pagesQuality Assurance Plan - SRMS Slope Protection & FencingTimothy AdzatiNo ratings yet

- Assignment: Subject Code: PGPM 11Document16 pagesAssignment: Subject Code: PGPM 11Sunil ShettigarNo ratings yet

- MS - Porcelane Works - Al HufofDocument19 pagesMS - Porcelane Works - Al HufofFaizan TanveerNo ratings yet

- WNS00 PP PC 0001Document11 pagesWNS00 PP PC 0001Subramanian Saravanan100% (1)

- 9 Method Statement For Floor TilesDocument10 pages9 Method Statement For Floor Tilesirfan khanNo ratings yet

- Roles & Responsibilities of Construction ProfessionalsDocument6 pagesRoles & Responsibilities of Construction Professionalsabhayavhad51100% (1)

- WAIR Employer's Work-Accident-Illness ReportDocument2 pagesWAIR Employer's Work-Accident-Illness ReportAlmario Sagun80% (5)

- AEDR Annual Work Accident-Illness Exposure Data ReportDocument4 pagesAEDR Annual Work Accident-Illness Exposure Data ReportAlmario Sagun100% (1)

- AmrDocument5 pagesAmrGemarie Adarlo CastilloNo ratings yet

- Power Center CoverpageDocument1 pagePower Center CoverpageAlmario SagunNo ratings yet

- Power Center - Structural RFA StructuralDocument1 pagePower Center - Structural RFA StructuralAlmario SagunNo ratings yet

- Right Side Elevation C: A B C A B C B A CDocument1 pageRight Side Elevation C: A B C A B C B A CAlmario SagunNo ratings yet

- Approved For Construction: Etron Bataan RefineryDocument1 pageApproved For Construction: Etron Bataan RefineryAlmario SagunNo ratings yet

- Hilti HIT Rebar Design MethodDocument2 pagesHilti HIT Rebar Design MethodAlmario SagunNo ratings yet

- Power Center Roof PlanDocument1 pagePower Center Roof PlanAlmario SagunNo ratings yet

- Minutes of Pre-Bid Meeting & Scope of WorkDocument7 pagesMinutes of Pre-Bid Meeting & Scope of WorkAlmario Sagun100% (1)

- CEAM Technical Services Corp.: Petron Bataan RefineryDocument2 pagesCEAM Technical Services Corp.: Petron Bataan RefineryAlmario SagunNo ratings yet

- Warehouse Procedure of Project ConsumablesDocument28 pagesWarehouse Procedure of Project ConsumablesAlmario Sagun100% (4)

- M4 Bid Limestone Site DevtDocument12 pagesM4 Bid Limestone Site DevtAlmario SagunNo ratings yet

- Assignment 4Document5 pagesAssignment 4Hafiz AhmadNo ratings yet

- 10 Killer Tips For Transcribing Jazz Solos - Jazz AdviceDocument21 pages10 Killer Tips For Transcribing Jazz Solos - Jazz Advicecdmb100% (2)

- Project Document EiDocument66 pagesProject Document EiPrathap ReddyNo ratings yet

- Pioneer vsx-1020-k 1025-k SM PDFDocument132 pagesPioneer vsx-1020-k 1025-k SM PDFluisclaudio31No ratings yet

- Lesson Plan For Implementing NETSDocument5 pagesLesson Plan For Implementing NETSLisa PizzutoNo ratings yet

- Organization Culture Impacts On Employee Motivation: A Case Study On An Apparel Company in Sri LankaDocument4 pagesOrganization Culture Impacts On Employee Motivation: A Case Study On An Apparel Company in Sri LankaSupreet PurohitNo ratings yet

- Exotic DVM 11 3 CompleteDocument12 pagesExotic DVM 11 3 CompleteLuc CardNo ratings yet

- Kosher Leche Descremada Dairy America Usa Planta TiptonDocument2 pagesKosher Leche Descremada Dairy America Usa Planta Tiptontania SaezNo ratings yet

- 2 To 20 Years - Girls Stature-For-Age and Weight-For-Age PercentilesDocument1 page2 To 20 Years - Girls Stature-For-Age and Weight-For-Age PercentilesRajalakshmi Vengadasamy0% (1)

- 2016 IT - Sheilding Guide PDFDocument40 pages2016 IT - Sheilding Guide PDFlazarosNo ratings yet

- Sankranthi PDFDocument39 pagesSankranthi PDFMaruthiNo ratings yet

- Dominion Wargame RulesDocument301 pagesDominion Wargame Rules4544juutf100% (4)

- Introduction To DifferentiationDocument10 pagesIntroduction To DifferentiationaurennosNo ratings yet

- Mozal Finance EXCEL Group 15dec2013Document15 pagesMozal Finance EXCEL Group 15dec2013Abhijit TailangNo ratings yet

- Dec JanDocument6 pagesDec Janmadhujayan100% (1)

- WHO Guidelines For Drinking Water: Parameters Standard Limits As Per WHO Guidelines (MG/L)Document3 pagesWHO Guidelines For Drinking Water: Parameters Standard Limits As Per WHO Guidelines (MG/L)114912No ratings yet

- Jee MainsDocument32 pagesJee Mainsjhaayushbhardwaj9632No ratings yet

- Poetry UnitDocument212 pagesPoetry Unittrovatore48100% (2)

- Product NDC # Compare To Strength Size Form Case Pack Abcoe# Cardinal Cin # Mckesson Oe # M&Doe#Document14 pagesProduct NDC # Compare To Strength Size Form Case Pack Abcoe# Cardinal Cin # Mckesson Oe # M&Doe#Paras ShardaNo ratings yet

- Back Propagation Neural NetworkDocument10 pagesBack Propagation Neural NetworkAhmad Bisyrul HafiNo ratings yet

- UNCITRAL Guide United Nations Commission On International Trade LawDocument56 pagesUNCITRAL Guide United Nations Commission On International Trade Lawsabiont100% (2)

- Airport & Harbour Engg-AssignmentDocument3 pagesAirport & Harbour Engg-AssignmentAshok Kumar RajanavarNo ratings yet

- Bcci ScandalDocument6 pagesBcci ScandalNausaf AhmedNo ratings yet

- Wwii TictactoeDocument2 pagesWwii Tictactoeapi-557780348No ratings yet

- Building and Structural Construction N6 T1 2024 T2Document9 pagesBuilding and Structural Construction N6 T1 2024 T2FranceNo ratings yet

- C4 Vectors - Vector Lines PDFDocument33 pagesC4 Vectors - Vector Lines PDFMohsin NaveedNo ratings yet

- Playing With Pop-Ups - The Art of Dimensional, Moving Paper DesignsDocument147 pagesPlaying With Pop-Ups - The Art of Dimensional, Moving Paper DesignsSara100% (4)

- Marketing Channels: A Strategic Tool of Growing Importance For The Next MillenniumDocument59 pagesMarketing Channels: A Strategic Tool of Growing Importance For The Next MillenniumAnonymous ibmeej9No ratings yet

- Computers in Industry: Hugh Boyes, Bil Hallaq, Joe Cunningham, Tim Watson TDocument12 pagesComputers in Industry: Hugh Boyes, Bil Hallaq, Joe Cunningham, Tim Watson TNawabMasidNo ratings yet

- Student Management SystemDocument232 pagesStudent Management Systemslu_mangal73% (37)