Professional Documents

Culture Documents

Sep Cross Country Piping

Uploaded by

Debasis Pal0 ratings0% found this document useful (0 votes)

37 views19 pagesThis document discusses various activities towards finalization of major parameters of cross-country water piping. It aims to indicate the procedure for optimizing the system. The contents may not be copied, disclosed, or used for other than the express purpose for which it has been provided.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses various activities towards finalization of major parameters of cross-country water piping. It aims to indicate the procedure for optimizing the system. The contents may not be copied, disclosed, or used for other than the express purpose for which it has been provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

37 views19 pagesSep Cross Country Piping

Uploaded by

Debasis PalThis document discusses various activities towards finalization of major parameters of cross-country water piping. It aims to indicate the procedure for optimizing the system. The contents may not be copied, disclosed, or used for other than the express purpose for which it has been provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 19

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

Rev

0

Next

is 2

Page

1

STN GRP SL CLASS Sg1 Sg2 Sg3

RIAS CAT #

SEP NONE NONE NONE

DOC #

01201-SEP-M-133 E-MEDIA

ARCHIVED

TITLE

Design and Optimization of Cross-Country Water Piping

AUTHOR

Technology Control Cell, Mechanical

ABSTRACT

This document discusses various activities towards finalization of major

parameters of cross-country water piping and aims to indicate the

procedure for optimizing the system.

KEYWORDS 1

MS Pipe

2

Optimization

3

DI Pipe

4 FRP Pipe

5

6

2

1

0 FIRST ISSUE

REV # STATUS REV. DESCRIPTION

ENDORSEMENTS

2

1

0 30.08.12 Sanchari

Paul

DSM DSM

Initial Signature Initial Signature Initial Signature

REV # DATE PREPARED REVIEWED APPROVED

This document contains proprietary information of Development Consultants Limited and is to be returned upon

request. The contents may not be copied, disclosed to third parties, or used for other than the express purpose

for which it has been provided, without the written consent of Development Consultants Limited.

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 3

Page

2

1.0.0 INTRODUCTION

Cross-country pipeline is primarily a transmission line for transporting bulk

quantity of fluids over large distances. The transmission distance may be

a few kilometers, or even hundreds of kilometers. For example, in India,

cross-country pipeline for LPG transportation from Jamnagar, in Gujrat, to

Loni, in Pubjab, covers a distance of about 1300 km, whereas, the HBJ

pipeline covers a distance of almost 2300 km.

Cross-country pipeline has also been extensively used for transport of

water, as, often, water source is not available in close vicinity to consumer

point. Such pipeline may run thru land, rivers, marshy areas, roads,

forests etc.

This Standard Engineering Practice discusses the various activities

towards finalization of major parameters of a cross-country water piping

system and aims to indicate procedures for optimizing the cross-country

piping system related to material of construction of pipe, thickness,

corrosion protection and laying of pipe.

2.0.0 PRE-PROJECT ACTIVITIES

The pre-project activities during preparation of feasibility report and TEFR

should have already identified the source of water for meeting the

requirement of the proposed plant. For such identification, the Project

Authority needs to discuss with irrigation dept. to ensure the availability of

required quantity of water, the seasonal fluctuation, if any, examining

recommendations, such as, constructing weir to enhance assurance of

available water etc.

During execution of cross-country water project, the initial activities that

the Project Authority needs to be advised is to appoint a bathymetric

surveyor, who will interact with irrigation department to re-examine

availability of water. The bathymetric surveyor will also identify the

configuration of intake system whether on-shore or off-shore, location of

intake well / intake pump house and low water level / high water level of

the intake structure which will be subsequently utilized for preparing the

GA dwg. of intake well / intake pump house.

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 4

Page

3

On reassurance of water availability, the Project Authority also needs to

examine the seasonal fluctuation, if any, and the mitigating measures

such as making a raw water reservoir at plant site, to ensure availability of

required quantity of water for the plant, even when supply from source

(river or lake) has reduced or altogether stopped.

The next step that the Project Authority needs to be advised is to appoint

a surveyor for conducting the route survey. There can be many

alternatives for routing the pipeline from supply point to consumer point. It

is necessary to work out techno-economic comparisons of various routes

taking care of the route length, the nature of obstacles along the route etc.

Ideally, the pipe should run close to existing roads so that the erection and

maintenance activities can be carried out conveniently.

Once the route from supply to consumer point has been identified, the

route survey is intended to further furnish data such as :

a) Spot-level survey at every 50 to 100 metres & at least over 10 m on

either side of the probable route.

b) Soil conditions in the form of bore-logs, trial pits, chemical tests on

subsoil & ground water etc.

c) Alignment map with lengths, bearings, angles etc. to know the exact

route & the total length of the pipe-line.

d) Details of the route and their locating dimensions with respect to sea,

roads (crossing and along the route) rivers, nallas, pipe-lines, bridges,

rail-tracks, transmission lines, underground services including cables/

pipes etc., hills and mountains, buildings, plantation, forests,

agricultural land etc.

e) Cadestral Survey The route may be passing thru so many lands

belonging to private owners, farmers, govt. authorities, defence wings

etc. En-route information and data has to be collected for such land

pieces. Such data will include :

- Type of land and the owners name

- Length of the route thru the land

- Problems in acquiring Right of Way (R.O.W.)

- Authority which will permit/grant ROW.

- Survey maps for the land available from the local Land Authority

(such as Collector, Tahasildar, Gram-Panchayat etc.)

- Land records regarding the title and ownership of the land

- Approx. compensation required for acquiring the R.O.W.

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 5

Page

4

- Status of Habitation on the land

- Similar information of the adjacent plots on 50 to 100 m on either

side of the route

- Plans for future installations by others on the proposed route and/or

in the vicinity such as roads/rail-tracks/buildings/pipe-lines etc.

f) Availability of construction materials, labour & facilities.

[Since the pipe-line has to pass thru different areas and over a long

distance, it is essential to know the availability of construction Labour

and Materials on the way such as excavation labour, transport

facilities, access roads, construction material like stones, aggregrates,

sand, cement, steel structurals, workshop facilities etc. This

information will be useful in working out the project schedule and cost

estimates and assessing the problems during construction.]

g) Soil Resistivity Survey required for design of cathodic protection

system.

h) Names and addresses of the statutory and public bodies required to be

contacted for acquiring ROW, construction permission, blasting

licenses, interfering with the public facilities (Roads, rivers, rail-tracks

etc.) and cathodic protection work, power supply/water supply etc.

[Such authorities include the following but not limited to the listed ones.

Local land authorities Distr. Collector, Municipal Corporation,

Tahsildar, Owners of the respective land.

P.W.D. Authorities Local Office

Irrigation Department

Electricity Supply Agencies / Bodies / Boards

Water-supply and Public Health Department

Controller of Explosive and use of Hazardous Chemicals

Industrial Development Corporations

Railway Authority

Marine and Port Authority

Salt-commissioner and Controller

Competent Authorities for Land and ROW acquisition

State and Central Govt. for necessary permission, licenses,

clearances etc.

Import/Export rules / regulations authorities

Controller of Quarrying and Mining

Navy/Army/Air force (Defence Authorities)

Plants for future installations

MOEF ]

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 6

Page

5

3.0.0 PROJECT ACTIVITIES

Based on various data collected as in 2.0.0 and the cost estimates, over

all project schedule has to be prepared based on past experience, and

specific problems unique to the project under consideration. This schedule

should cover only broad activities to serve as a guide line for preparation

of detail activity schedule.

This should generally include :

a) Preliminary survey / data collection.

b) Finalising the route

c) Cost estimates / budget sanctions.

d) Acquisition of R.O.W. and land

e) Basic engineering package

f) Detail engineering work

g) Construction work (Civil/Mech./Piping/Elect., Marine Crossing, River

Crossing etc. / Cathodic Protection).

h) Testing / Flushing / Pigging

i) Commissioning and hand over

This will establish the overall completion time for the entire project work.

4.0.0 BASIC ENGINEERING

Once the route survey and bathymetric survey document is available, the

Basic Engineering can be started.

The first step required for Basic Engineering is to finalize the pipe

parameters with regard to MOC, diameter, thickness (or class), corrosion

protection and laying requirements. The life cycle cost of various

alternatives will be compared to arrive at the final selection. The basic

guideline for calculating these parameters are furnished in the subsequent

clauses.

5.0.0 MATERIAL OF CONSTRUCTION

Popularly used Material of Construction for cross-country pipe line used to

be MS. Generally, spirally welded factory made SAW type MS pipes are

preferred. The methodology of manufacture of such pipe ensures better

quality of welding with in-built 100% radiographic testing facility. Such

improvement in quality of pipes is achieved at a very normal incremental

cost and, hence, should be recommended.

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 7

Page

6

Ductile Iron pipes has been another popular MOC for cross-country water

pipes. Invented in 1949, it retains the corrosion resistance of Cast Iron, but

has more than double the tensile strength of cast iron and even more than

MS. Impact resistance, also, is quite high and comparable with MS pipe.

Fiberglass pipe, commonly called as FRP or GRP pipes, made from glass

fiber reinforcements embedded in , or surrounded by thermosetting resin

is also becoming popular as pipe material for water transportation. A few

years back, GRP pipes used to be costly and, hence, application of GRP

pipes used to be considered only as corrosion-resistant alternative to

protect steel, stainless steel or other exotic materials. However, presently,

large scale bulk use of GRP pipes have attracted many manufacturers

producing GRP pipes. This, coupled with rapid improvement in

manufacturing technique, has brought down the prices of GRP pipes and

has become highly competitive with MS or DI pipes.

A brief comparison of pipes with above 3 material of construction is

indicated below :

MILD STEEL PIPE vs. DUCTILE IRON PIPE vs. FRP PIPE

Sl.

No.

Criteria

Mild Steel

pipeline

Ductile Iron

pipeline

Fiberglass

Reinforced

pipeline

1 Friction loss

C* = 120

Hence, friction

loss is maximum

C = 140

Hence, friction

loss is less than

MS but more than

FRP

C = 150

Hence, friction

loss is least

2 Total energy cost

Maximum, since

friction loss is

maximum

Less than MS.

More than FRP

Least

3

Corrosion

resistance

Susceptible to

corrosion. Hence,

inner and outer

lining is required

More Corrosion

resistant

compared to

MS.However,,

inner lining and

external painting

is required.

Highly resistive to

corrosion. Hence,

no lining is

required

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 8

Page

7

Sl.

No.

Criteria

Mild Steel

pipeline

Ductile Iron

pipeline

Fiberglass

Reinforced

pipeline

4 Maintenance

Outer lining may

peel off with time.

Hence, periodical

maintenance is

required

Outer painting

may erode off

with time. Hence,

periodical

maintenance is

required,but

frequency is less

than MS pipe.

Lesser

maintenance is

required

compared to MS

and DI pipes

5 Life of pipeline

Pipeline is

designed for 10-

15 years life

Pipeline is

designed for 15-

20 years life

Pipeline is

designed for 50

years life.

However, being

applied only in

recent times, it is

not yet time-

tested.

6 Design

Obtained in

standard sizes

Obtained in

standard sizes

Optimized design

can be effected

by the

manufacturer

depending upon

requirement

7

Weight &

handling

Specific gravity =

7.85

Hence, it is about

4.4 times heavier

than FRP pipes

and thereby

difficult to handle

than FRP pipes

Specific gravity =

7.05

Hence, it is about

4 times heavier

than FRP pipes

and thereby

difficult to handle

than FRP pipes

Specific gravity =

1.8 to 1.9

Hence, it is easier

to handle due to

its lighter weight

as compared to

MS & DI pipes

8

.Thrust Block

requirement

Thrust Block

requirement is

not there,as

welded

connection is

provided

As spigot /socket

tipe connection is

provided,thrust

block requirement

is there.

Special

connection can

eliminate

requirement of

thrust block.

*C-Hazen Willims Constant

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 9

Page

8

6.0.0 CALCULATION PROCEDURE FOR OPTIMIZATION OF PIPE

DIAMETER/THICKNESS FOR DIFFERENT MOCs

[In the calculation, the pipe diameter / thickness, buried piping has been

considered as per the normal practice followed for cross-country piping,

unless rock is encountered at close to top soil level.

Reasons behind this are :

1. With buried piping, cost of laying and supporting system become

economic.

2. Obtaining ROW becomes easier and compensation against such ROW

with buried piping is much less compared to overhead piping routing.]

The calculation procedure works out the design parameters and

subsequently works out the capitalized life cycle cost for each of the

alternatives and ultimately selects the most optimum choice. In case of

long cross-country water piping of length exceeding 20-30 km.,

segmenting the piping system with one/multiple no. of booster stations

may result in overall economy, as there can be substantial saving in cost

of piping. Such option for long distance piping needs to be examined.

6.1.0 Basic Inputs for Calculation

The basic input data required for the calculation are as follows:

i) System Design Flow rate

ii) Plant life

iii) Trench dimensions including height of ground cover and water

cover over the pipe crown

iv) Length of pipeline

v) Pump & motor efficiencies

vi) Pump & motor set cost[Based on the capacity,Head and Motor KW

to be calculated ]

vii) Static head and pumping station loss

viii) Number of hours the pumps will run in a year

ix) Number of working pumps

x) Prevailing power tariff

xi) Escalation of power tariff per year

xii) Civil costs (cost of excavation & backfilling)

xiii) Interest rate

xiv) Maintenance cost

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 10

Page

9

xv) Lining thickness (if any) / corrosion allowance *

xvi) Cost of material, lining (if any), fabrication, pipe laying.

* For guideline of degree of wrapping/coating, recommendations in

clause no. 8.2 of IS 10221-2008 may be referred.

6.2.0 Calculation Procedure

The procedure for calculation, in order to determine the most suitable and

optimum pipe material, size and wall thickness for a given application, is

elaborated below. The procedure is based on the guidelines laid down in

AWWA M-11, AWWA M-45 and IS 8329 for MS Pipes, FRP Pipes and DI

Pipes respectively.

6.2.1 Mild Steel Pipe

6.2.1.1 The calculation begins with the assumption of pipe NB and pipe thickness

(t), from IS 3589.

6.2.1.2 Pipe OD is determined from IS 3589.

6.2.1.3 Pipe ID is calculated as,

ID = OD 2t 2t

L

Where, ID = Internal diameter of pipe,mm

OD = External diameter of pipe,mm

t = Pipe thickness,mm (assumed)

t

L

= Internal liner thickness (IS 3589, Annexure A-

6.2, Table 8),mm

6.2.1.4 Check 1 : Checking for velocity :

Velocity of flow is calculated as,

V = Q / A

Where, V = Velocity of flow through pipeline,M/Sec

Q = System Design Flow rate,M3/Sec

A = Cross-sectional area of pipeline,M2

= (/4) * (ID/1000)

2

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 11

Page

10

The velocity of flow should not be less than 1.2 m/s to prevent from

precipitation of solid particles.This should also not exceed 2.5 M/Sec. in

order to maintain the flow without the generation of vibration. With the

initial assumption, if the above condition fails, pipe size and/or thickness

are revised and the above calculations are repeated to satisfy the

condition.There may be multiple diameters which will maintain the velocity

criteria within the acceptable range.

6.2.1.5 Check 2 : Checking against failure due to internal pressure :

Head loss due to friction (h

f

) is calculated using Hazen Williams equation

(Ref. AWWA M-11, eqn. (3-2M)). For MS pipe, friction co-efficient in

Hazen Williams equation, C, shall be considered as 120.

Total pump head is thus,

H

p

= h

f

+ h

fm

+ H

s

+ h

L

Where, H

p

= Total pump head

h

fm

= Margin on head loss due to friction

H

s

= Static head

h

L

= Pumping station loss

Design internal pressure, P

D

shall be considered as 120% of total

pump head (H

p

) to take care of shut-off Condition.

Maximum allowable internal pressure that can be withstood by the pipe,

with the selected diameter and thickness, is calculated using the Barlow

formula (Ref. AWWA M-11, (eqn. 4-1)), with, t = assumed pipe wall

thickness, and p = Maximum allowable internal pressure.

The following condition is checked, P

D

< p

On failure of the above condition, the pipe thickness is revised and the

selected thickness is now applied in clauses 6.2.1.3 and 6.2.1.4 above to

fine-tune the results. The selected thickness should also be checked as

per clause 104.1.2 of ASME B 31.1 2001 (code for pressure piping) and

higher value of thickness shall be considered.

6.2.1.6 Check3 : Checking against buckling due to internal vacuum / live

load :

Allowable buckling pressure is calculated using eqn. (6-7), in AWWA M-

11.

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 12

Page

11

Total external load on a buried pipe subjected to internal vacuum is

calculated using eqn. (6-8), in AWWA M-11. In buried pipe applications,

it is recommended to consider that the pipeline is subjected to full

internal vacuum.

Total external load on a buried pipe subjected to live loads is calculated

using eqn. (6-9), in AWWA M-11. Live load effect is obtained from Table

6-3. However, simultaneous application of live-load and internal

vacuum transients need not normally be considered. For calculation

of allowable buckling pressure, value of modulus of Soil Reaction is

furnished in Table 6.10/AWWA M-11. However it should be

considered as 500 psi (3450 kPa), unless specifically advised.

The total external load, as calculated above, should be less than the

allowable buckling pressure. If the condition fails, the pipe wall thickness is

revised and the previous calculations in clause 6.2.1.3 through 6.2.1.6 are

repeated to satisfy the condition.

6.2.1.7 Check- 4 : Checking against failure due to stresses due to handling :

Minimum wall thickness for handling are based on the eqns. (4-5), (4-6),

or (4-7) of AWWA M-11.

6.2.1.8 Check- 5 : Checking against deflection due to external pressure :

Load per unit of pipe length, W = W

DL

+ W

LL

Where, W

DL

= Dead load per unit length of pipe

= W

P

+ W

L

+ W

W

W

P

= Weight of bare pipe per unit length

W

L

= Weight of internal + external lining per unit

length

W

W

= Weight of water-filled pipe per unit length

W

LL

= Live load per unit length of pipe, as per

AWWA M-11, Table 6-3.

Horizontal deflection of pipe is calculated using eqn. (6-5) of AWWA M-11.

Allowable deflection is preferably 2% of pipe OD, for mortar lined and

coated, 3% of pipe OD for mortar lined and flexible coated and 5% of pipe

OD for flexible lined and coated.

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 13

Page

12

Horizontal deflection, as calculated above, should be less than the

allowable deflection. In case the above condition fails, the pipe thickness

is revised and the previous calculations in clauses 6.2.1.3 through 6.2.1.8

are repeated until the condition is satisfied.

6.2.1.9 Check- 6 : Checking against failure due to pressure surge :

Pressure rise above normal, due to water hammer, is calculated using

eqn. (5-2M) and (5-3M) of AWWA M-11.

The total pressure during the surge is the normal working pressure plus

the pressure rise above normal (as calculated above). In case this total

pressure exceeds the maximum allowable internal pressure (as calculated

in Cl. 6.2.1.5), either pipe thickness needs to be increased or surge

suppression device needs to be incorporated. In cross-country pipeline

applications, it is more economical to use surge suppression device

to take care of the pressure surge instead of increasing pipe wall

thickness.

6.2.1.10 Cost Analysis : From the above calculations, applicable pipe size(s) and

thickness(s) are selected for the particular buried pipe application. For

every set of selected pipe size and thickness, the following steps are

undertaken to evaluate the cost of each pipe.

Capitalization factor is calculated as, CF = 1-C

Lc

1-C

Where, C = 1 + (E

p

/ 100)

1 + (R

f

/ 100)

E

p

= Escalation of power tariff per year (%)

R

f

= Interest rate (%)

L

c

= Plant life (years)

Total piping cost, C

pipe

= C

BP

+ C

L

+ C

CW

+

C

LAY

Where, C

BP

= Cost of the entire length of bare pipe

C

L

= Cost of internal and external lining for entire

pipe

C

CW

= Cost of civil works (excavation & backfilling) **

C

LAY

= Cost of laying of pipe

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 14

Page

13

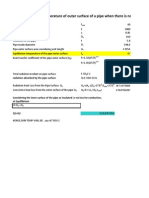

** Cost of civil works (excavation & backfilling) shall be evaluated

considering a standard trench, as shown below :

3D

o

1

0

0

0

D

0

3

0

0

2D

o

Total energy cost, C

E

= P * N * T * CF

Where, P = Power consumed in pumping

N = Number of hours the pumps work in a year

T = Power tariff

CF = Capitalization factor (as calculated above in in

this clause)

Total evaluated cost, C = C

pipe

+ C

E

+ C

P+M

+ C

M

Where, C

P+M

= Cost of pump set (pump + motor)

C

M

= Maintenance cost (May be considered as 5%

of C

E

)

For every selected set of pipe size and thickness, the above calculations

are done and the optimized set is determined. The optimized set is the

one having the least value of Total evaluated cost, C.

D

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 15

Page

14

6.2.2 Ductile Iron Pipe

6.2.2.1 The calculation begins with the assumption of pipe size (NB), from IS

8329, and pipe class (K7 / K8 / K9 / K10).

6.2.2.2 Pipe OD is determined from IS 8329, Table 2.

6.2.2.3 The internal lining (Cement-mortar) thickness is obtained from IS 8329.

The wall thickness of pipe is calculated using eqn (1) of IS 8329, Cl. No.

4.3.

6.2.2.4 Pipe ID is calculated as in Cl. 6.2.1.3.

6.2.2.5 Check- 1 : Checking for velocity : This checking is done as indicated in

Cl. 6.2.1.4.

On failure of the condition, the pipe size and class is revised and the

previous calculations are repeated to satisfy the condition. There may be

multiple sets of NB and class which will maintain the velocity criteria within

the acceptable range.

6.2.2.6 Check- 2 : Checking against failure due to internal pressure :

Head loss due to friction is calculated using Hazen Williams equation

(Ref. AWWA M-11, eqn. (3-2M)). For DI pipe, friction co-efficient in Hazen

Williams equation, C, shall be 140.

Total pump head and Design Internal Pressure is calculated as in Cl.

6.2.1.5.

The Allowable operating pressure (maximum allowable internal pressure)

for the selected pipe size and class is then obtained from IS 8329,

Annexure-E, Table 1.

The following condition is checked,

Design internal pressure < Allowable operating pressure

On failure of the above condition, the pipe class is revised and the above

calculations in clauses 6.2.2.4, 6.2.2.5 and 6.2.2.6 are repeated to satisfy

the condition.

6.2.2.7 Check-3 : Checking due to failure against pressure surge : This

checking is done as in Cl. 6.2.1.9.

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 16

Page

15

6.2.2.8 Cost Analysis : From the above calculations, applicable pipe size(s) and

pipe class(s) are selected for the particular buried pipe application. For

every set of selected pipe size and class, the following steps are

undertaken to evaluate the cost of each pipe.

Capitalization factor, Total piping cost, Total energy cost and Total

evaluated cost is calculated as in 6.2.1.10.

For every selected set of pipe size and pipe class, the above calculations

are done and the optimized set is determined. The optimized set is the

one having the least value of Total evaluated cost, C.

6.2.3 FRP Pipe

6.2.3.1 Apart from the inputs mentioned in Cl. 6.1.0, the design of FRP pipe

requires the following additional inputs :

i) Nominal pipe size (ref. IS 12709, Table 1 or Table 2).

ii) Hydrostatic design basis (manufacturers data)

iii) Long term ring bending strain (manufacturers data)

6.2.3.2 The calculation begins with the assumption of pipe NB, Pressure class,

P

C

, (ref. IS 12709, Cl. 4.1.1) and pipe reinforced wall thickness, t.

6.2.3.3 If ID series pipes are used, then, pipe ID, for the assumed pipe NB, is

obtained from IS 12709, Table 1. If OD series pipes are used, then, pipe

OD is determined from Table 2 and pipe ID is calculated as in Cl. 6.2.1.3.

The internal lining thickness for FRP pipes is obtained from

manufacturers data. It is generally between 1-1.2mm.

6.2.3.4 Check-1 : Checking for velocity : This checking is done as indicated in

Cl. 6.2.1.4. On failure of the condition, the pipe size and wall thickness is

revised and the calculations in clauses 6.2.1.3 (pipe ID) and 6.2.1.4 are

repeated to satisfy the condition. There may be multiple sets of pipe sizes

& thickness which will maintain the velocity within the acceptable range. It

is to be noted here, that the maximum velocity that can be allowed for safe

operation of FRP pipe is determined using eqn. (4-1) of AWWA M-45. the

minimum velocity to maintain the flow shall be 1.2 m/s.

6.2.3.5 Check-2 : Checking Pressure class : The acceptability of the selected

pressure class, P

C

, is checked using eqn. (5-1) or eqn. (5-2) of AWWA M-

45. In case the condition fails, the pressure class and pipe wall thickness

is simultaneously revised and above calculations are repeated to satisfy

the condition.

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 17

Page

16

6.2.3.6 Check-3 : Checking against failure due to internal pressure :

Head loss due to friction is calculated using Hazen Williams equation

(Ref. AWWA M-11. eqn. (3-2M)). For FRP pipe, friction co-efficient in

Hazen Williams equation, C, shall be 150.

Total pump head and design internal pressure is calculated as in Cl.

6.2.1.5.

The eqn. (5-3) of AWWA M-45 is checked with Pw being the calculated

design internal pressure. In case the condition fails, the pipe wall

thickness and pressure class is simultaneously revised and the above

calculations in clauses 6.2.3.4, 6.2.3.5 & 6.2.3.6 are repeated until the

condition is satisfied.

6.2.3.7 CHECK 4 : Checking against failure due to pressure surge :

Pressure surge above normal is calculated using eqn. (4-21) of AWWA M-

45. Here, a full instantaneous change in velocity equal to the flow velocity

in the pipe shall be considered.

The eqn. (5-4) of AWWA M-45 is checked. In case the condition fails, the

pressure class and wall thickness is simultaneously revised and the above

calculations in clauses 6.2.3.4, 6.2.3.5, 6.2.3.6 & 6.2.3.7 are repeated until

the condition is satisfied. The pressure surge for FRP piping will be lower

compared to MS/DI Pipe for same parameters.

6.2.3.8 Check-5 : Checking for maximum allowable deflection due to ring-

bending :

Pipe stiffness class, PS, is assumed (Ref. AWWA M-45, Table 5-1).

From eqn. (5-5) or eqn. (5-6) of AWWA M-45, the maximum allowable

long-term vertical pipe deflection is calculated.

For proper design, maximum allowable long-term vertical pipe deflection,

as calculated above, should be greater than the permitted deflection

(generally 5%). In case the above condition fails, the pressure class, wall

thickness and pipe stiffness are simultaneously revised and the above

calculations in clauses 6.2.3.4 through 6.2.3.8 are repeated until the

condition is satisfied.

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 18

Page

17

6.2.3.9 Check-6 : Checking against failure due to deflection :

Vertical soil load, W

C

, is calculated using eqn. (5-9) of AWWA M-45, Cl.

5.7.3.5 and Live Loads on pipe, W

L

, as per the guidelines in Cl. 5.7.3.6 of

AWWA M-45..

Constrained soil modulus, M

S

, is calculated as per Cl. 5.7.3.8 of AWWA

M-45.

The predicted deflection is calculated using eqn. (5-8) of AWWA M-45. In

case the predicted deflection is greater than permitted deflection, the pipe

stiffness, pressure class and wall thickness is simultaneously revised and

the above calculations in clauses 6.2.3.4 through 6.2.3.9 are repeated

until the condition is satisfied.

6.2.3.10 Check-7 : Checking against failure due to combined loading of

internal pressure and deflection : The checking is done as per Cl. 5.7.4

of AWWA M-45. In case the condition fails, the pressure class, wall

thickness and pipe stiffness class is simultaneously revised and the above

calculations in clauses 6.2.3.4 through 6.2.3.10 are repeated until the

condition is satisfied.

6.2.3.11 CHECK 8 : Checking against buckling due to internal vacuum or live

load :

Allowable buckling pressure is calculated using eqn. (5-24a) of AWWA M-

45. Here, EI is calculated using eqn. (5-18) of AWWA M-45.

Total external load on a buried pipe subjected to internal vacuum is

calculated using eqn. (5-25) of AWWA M-45. In buried pipe

applications, it is recommended to consider that the pipeline is

subjected to full internal vacuum.

Total external load on a buried pipe subjected to live loads is calculated

using eqn. (5-26). Live load is calculated as per Cl. 5.7.3.6 of AWWA M-

45. However, simultaneous application of live-load and internal

vacuum transients need not normally be considered.

The total external load, as calculated above should be less than the

allowable buckling pressure. If the condition fails, the pressure class, wall

thickness and pipe stiffness is simultaneously revised and the above

calculations in clauses 6.2.3.4 through 6.2.3.11 are repeated until the

condition is satisfied.

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is 19

Page

18

6.2.3.12 Cost Analysis : From the above calculations, applicable pipe sizes with

pressure class, reinforced wall thickness and stiffness class are selected.

For every selected pipe, the following calculations are done to evaluate

the cost of each pipe.

Capitalization factor is calculated as in Cl. 6.2.1.10.

Total piping cost is, C

pipe

= (U * L) + C

CW

Where, C

CW

= Cost of civil works (excavation & backfilling)

(Calculated as in Cl. 6.2.1.10)

U = Unit rate of pipe (Rs/m) (manufacturers data)

L = Length of pipe

Total energy cost, C

E

, and, Total evaluated cost, C, is calculated as in Cl.

6.2.1.10.

For every selected pipe, the above calculations are done and the

optimized pipe is determined. The optimized pipe is the one having the

least value of Total evaluated cost, C.

7.0.0 RESULT

Based on the analysis above, the optimum choice of diameter / class

(thickness) and MOC can be found out. Such optimized parameters will

form the basis of subsequent procurement activity.

8.0.0 REFERENCES

1. AWWA M 11 : Steel Water Pipe : A Guide for Design and

(Fourth Edition) Installation.

2. AWWA M 45 : Fiberglass Pipe Design

(Second

Edition)

3. IS 3589 : Steel Pipes for Water and Sewage (168.3 to

(Third revision) 2540mm outside diameter specification)

DEVELOPMENT CONSULTANTS LIMITED

STANDARD ENGINEERING PROCEDURE

# 01201-SEP-M-133

TITLE : DESIGN AND OPTIMIZATION OF CROSS-

COUNTRY WATER PIPING

Rev

0

Next

is Nil

Page

19

4. IS 12709 : Glass Fiber Reinforced Plastics (GRP) Pipes,

(First revision) Joints and Fittings for use for Potable Water

Supply Specification

5. IS 8329 : Centrifugally Cast (Spun) Ductile Iron Pressure

(Third revision) Pipes for Water, Gas and Sewage Specification

6. FLOWTITE Test Report on Hydrostatic Design Basis (strain)

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Skin Temp of Pipe Exposed To SunDocument8 pagesSkin Temp of Pipe Exposed To SunDebasis PalNo ratings yet

- Examples ManualDocument140 pagesExamples ManualDebasis PalNo ratings yet

- KPCL Wham AnalysisDocument9 pagesKPCL Wham AnalysisDebasis PalNo ratings yet

- Examples ManualDocument140 pagesExamples ManualDebasis PalNo ratings yet

- Assorted Coins of British Republic IndiaDocument2 pagesAssorted Coins of British Republic IndiaDebasis PalNo ratings yet

- Mechanical Design Data BookDocument69 pagesMechanical Design Data BookviongdanonNo ratings yet

- Asme B16.5Document157 pagesAsme B16.5Debasis PalNo ratings yet

- Bifurcation BucklingDocument26 pagesBifurcation BucklingDebasis PalNo ratings yet

- Minm. Pipe Thickness Against Various Vaccum Pressures For Infinitely Long Unsupported PipeDocument1 pageMinm. Pipe Thickness Against Various Vaccum Pressures For Infinitely Long Unsupported PipeDebasis PalNo ratings yet

- Torsion em 327: Mechanics of Materials LaboratoryDocument4 pagesTorsion em 327: Mechanics of Materials LaboratoryfrankjonoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Dr. Malik's Farms BrochureDocument18 pagesDr. Malik's Farms BrochureNeil AgshikarNo ratings yet

- Drypro832 PreInstallGude 0921YH220B 070627 FixDocument23 pagesDrypro832 PreInstallGude 0921YH220B 070627 FixRicardoNo ratings yet

- Shimano Brakes ManualDocument36 pagesShimano Brakes ManualKon Arva100% (1)

- Trimble Oem Gnss Bro Usl 0422Document3 pagesTrimble Oem Gnss Bro Usl 0422rafaelNo ratings yet

- Marijuana Grow Basics - Jorge CervantesDocument389 pagesMarijuana Grow Basics - Jorge CervantesHugo Herrera100% (1)

- ASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150Document1 pageASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150rabzihNo ratings yet

- OLA CAB MARKET ANALYSIS AND TRENDSDocument55 pagesOLA CAB MARKET ANALYSIS AND TRENDSnitin gadkariNo ratings yet

- Design and Analysis of Algorithms Prof. Madhavan Mukund Chennai Mathematical Institute Week - 01 Module - 01 Lecture - 01Document8 pagesDesign and Analysis of Algorithms Prof. Madhavan Mukund Chennai Mathematical Institute Week - 01 Module - 01 Lecture - 01SwatiNo ratings yet

- Week 6Document7 pagesWeek 6Nguyễn HoàngNo ratings yet

- Relay Coordination Using Digsilent PowerFactoryDocument12 pagesRelay Coordination Using Digsilent PowerFactoryutshab.ghosh2023No ratings yet

- What Is Rack Chock SystemDocument7 pagesWhat Is Rack Chock SystemSarah Perez100% (1)

- JR Hydraulic Eng. Waterways Bed Protection Incomat BelfastDocument2 pagesJR Hydraulic Eng. Waterways Bed Protection Incomat Belfastpablopadawan1No ratings yet

- SQL 1: Basic Statements: Yufei TaoDocument24 pagesSQL 1: Basic Statements: Yufei TaoHui Ka HoNo ratings yet

- Storytelling ScriptDocument2 pagesStorytelling ScriptAnjalai Ganasan100% (1)

- Intec Waste PresiDocument8 pagesIntec Waste Presiapi-369931794No ratings yet

- Believer - Imagine Dragons - CIFRA CLUBDocument9 pagesBeliever - Imagine Dragons - CIFRA CLUBSilvio Augusto Comercial 01No ratings yet

- MVJUSTINIANI - BAFACR16 - INTERIM ASSESSMENT 1 - 3T - AY2022 23 With Answer KeysDocument4 pagesMVJUSTINIANI - BAFACR16 - INTERIM ASSESSMENT 1 - 3T - AY2022 23 With Answer KeysDe Gala ShailynNo ratings yet

- Manual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDocument106 pagesManual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDante Renee Mendoza DelgadoNo ratings yet

- BSC6900 UMTS V900R011C00SPC700 Parameter ReferenceDocument1,010 pagesBSC6900 UMTS V900R011C00SPC700 Parameter Referenceronnie_smgNo ratings yet

- BMXNRPDocument60 pagesBMXNRPSivaprasad KcNo ratings yet

- Electronic Harassment Strahlenfolter - A Short History of Sound Weapons Pt2 - InfrasoundDocument10 pagesElectronic Harassment Strahlenfolter - A Short History of Sound Weapons Pt2 - InfrasoundFrank-BoenischNo ratings yet

- 7 Tactical Advantages of Explainer VideosDocument23 pages7 Tactical Advantages of Explainer Videos4ktazekahveNo ratings yet

- My16-Td My16-AtDocument6 pagesMy16-Td My16-AtRodrigo ChavesNo ratings yet

- Raychem Price ListDocument48 pagesRaychem Price ListramshivvermaNo ratings yet

- Classification of Textile Testing - OrDNURDocument6 pagesClassification of Textile Testing - OrDNURKazi ShorifNo ratings yet

- 3 Steel Grating Catalogue 2010 - SERIES 1 PDFDocument6 pages3 Steel Grating Catalogue 2010 - SERIES 1 PDFPablo MatrakaNo ratings yet

- Tugas B InggrisDocument6 pagesTugas B Inggrisiqbal baleNo ratings yet

- City of Brescia - Map - WWW - Bresciatourism.itDocument1 pageCity of Brescia - Map - WWW - Bresciatourism.itBrescia TourismNo ratings yet