Professional Documents

Culture Documents

Thermal Completions Catalog - 2013 - 9907918931 - 01 - 5946139 - 01

Uploaded by

KhaledFekairOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Completions Catalog - 2013 - 9907918931 - 01 - 5946139 - 01

Uploaded by

KhaledFekairCopyright:

Available Formats

2013 Thermal Competion Products

Table of Contents

Thermal Liner Hangers

Running Tools

Remedial Tools

Reservoir Monitoring

Thermal Liner Hangers

Pressure Tight System

- TBL Thermal Liner Packer

Debris Seal System

- CE Liner Top Packer

- LRP Long Reach Liner Packer

Tailpipe Hanger

- MH Thermal Liner Hanger Packer

- LRP Long Reach Liner Packer

Rev. 00 Page 1

Size Weight Range Packer O.D.

in (mm) lb/ft (kg/m) in (mm)

4.500 x 7.000 (114.3 x 177.8) 23.0 (34.2) 6.200 (157.5)

5.500 x 8.625 (139.7 x 219.1) 36.0 (53.6) 7.635 (193.9)

7.000 x 9.625 (177.8 x 244.5) 40.0 - 43.5 (59.5 - 64.7) 8.535 (216.8)

TBL Thermal Liner Packer Specifications

Description

The TBL Thermal Liner Packer is a

hydraulically set liner hanger packer for

use in thermal applications (injection or

production). It is an engineered and

tested product with a temperature rating

of 343 C and pressure rating of 21 MPa.

The TBL is designed with matching liner

strength specifications, and is able to be

rotated and circulated into position.

The design for this product includes no

elastomers. It is engineered for harsh

environments that exceed the

temperature and pressure limits for

elastomers, such as o-rings, packing and

rubber compounds.

Operation

The TBL Thermal Liner Packer is

designed to be run and set utilizing a

hydraulic setting tool which is

engineered for producing high setting

forces, torque rates and axial loads.

Surface setting pressures are adjustable

by manipulating the initial setup for the

setting tool.

The TBL Thermal Liner Packer is

conveyed with a hydraulic setting tool

and set by dropping a ball, or utilizing a

plugging system, and pressuring up on

the work string. Once the thermal

element is packed off, the setting tool

hydraulically disconnects from the liner

without work string manipulation, and is

retrieved to surface.

Applications

The TBL Thermal Liner Packer is designed

for thermal applications when liner top

pressure integrity is required throughout

the life of the well, and the liner installation

may require high torque and axial loads to

position the liner into the wellbore. This

packer is suitable for in-situ thermal

environments such as SAGD, CSS and many

other extreme temperature applications.

Features

Large beveled upper seal bore

One piece integral mandrel

Integral clutch system

Opposing 360 full circle slips

Metal to metal seal with static element

Matched liner strength

NACE MR0175 compliant for

environments containing H

2

S

Benefits

Qualified to 343 C and 21 MPa

Ability to rotate and circulate during

deployment

Beveled tieback sleeve with latching

profile allows for:

- Installation of a tieback packer with full

bore access to the liner

- Latching and anchoring of inner strings

with pressure isolation

- Attachment and retrieval of flow control

at the liner top

- Installation of warm up phase

technology with open/closed positions

and integral thermal expansion joint

Fullbore access to liner

Liner placement control (anchored liner

top during thermal cycle loading)

Adjustable surface setting pressures

Tested and verified for well tractor

transition from intermediate casing,

through packer, and into liner without a

slave string

TBL Thermal Liner Packer

TBL Thermal Liner Packer

Rev. 00 Page 2

Size Weight Range Packer O.D.

in (mm) lb/ft (kg/m) in (mm)

7.000 x 9.625 (177.8 x 244.5) 36.0 - 47.0 (53.6 - 69.9) 8.375 (212.7)

8.625 x 11.750 (219.1 x 298.5) 54.0 - 60.0 (80.3 - 89.2) 10.500 (266.7)

CE Liner Top Packer Specifications

Description

The CE Liner Top Packer is a unique

hydraulically set packer, for use

in thermal injection or production

applications. The CE Liner Top Packer

utilizes the unique conditions of the

SAGD environment to continuously

supply energy to the dynamic sealing

element system throughout the lifecycle

of the well.

It is an engineered and tested product

with temperature and pressure ratings

in line with thermal in-situ environments.

The CE Liner Top Packer is designed with

matching liner strength specifications,

and is able to be rotated and circulated

into position.

Operation

The CE Liner Top Packer is designed to

be run and set utilizing a hydraulic

running tool which is engineered for high

torque rates and axial loads. Surface

setting pressures are adjustable by

manipulating the initial setup for the

running tool.

The CE Liner Top Packer is set by

dropping a DPWP, and pressuring up on

the work string. Once the element is

packed off, the running tool hydraulically

disconnects from the liner without work

string manipulation. The running tool is

retrieved by straight pick up.

Applications

The CE Liner Top Packer is designed for

thermal applications when liner top debris

management is required throughout the life

of the well.

This packer is suitable for in-situ thermal

environments such as SAGD, and many

others extreme temperature applications.

Features

One piece integral mandrel

Large bevelled upper seal bore

Full tieback isolation capabilities

External deployment clutch system

Full bore access to liner

Dynamically qualified sealing element

Thermally activated port isolation

technology (TAPIT)

Manufactured from materials in

compliance with NACE MR0175 for

environments containing H

2

S

Benefits

Full bore access to liner

Able to rotate and circulate during

deployment into the wellbore

Low initial setting pressures, allows for

rig pump setting

TAPIT, isolates the pressure

communication ports, eliminating the leak

path from the tubing to annulus

Fully contained deployment system,

mitigates any interference with the

setting sequence, due to circulating

pressure

CE Liner Top Packer

CE Liner Top Packer

Rev. 00 Page 3

Size Weight Range Packer O.D.

in (mm) lb/ft (kg/m) in (mm)

2.875 x 4.500 (73.0 x 114.3) 9.5 - 12.6 (14.1 - 18.7) 3.771 (95.8)

3.500 x 5.500 (88.9 x 139.7) 15.5 - 17.0 (23.1 - 25.1) 4.625 (117.5)

5.000 x 7.000 (127.0 x 177.8) 23.0 - 29.0 (34.2 - 43.2) 5.900 (149.9)

6.625 x 8.625 (168.3 x 219.1) 28.0 - 40.0 (41.7 - 59.5) 7.500 (190.5)

7.000 x 9.625 (177.8 x 244.5) 36.0 - 47.0 (53.6 - 69.9) 8.375 (212.7)

8.625 x 11.750 (219.1 x 298.5) 38.0 - 60.0 (56.6 - 89.3) 10.375 (263.5)

MH Thermal Liner Hanger Packer Specifications

Description

The MH Thermal Liner Hanger Packer is

a hydraulically set liner hanger packer

for use in thermal applications.

With a temperature rating of 343 C,

Schlumbergers metal to metal system in

conjunction with the thermal element is

capable of an initial pressure test to 21

MPa. This packer has both hanger slips

as well as top hold down slips.

The design for this product includes

no elastomers. It is engineered for

harsh environments which exceed the

temperature and pressure limits for

elastomers, such as o-rings, packing

and rubber compounds.

Operation

The MH Thermal Liner Hanger Packer is

designed to be run and set utilizing a

hydraulic setting tool which is

engineered for producing high setting

forces and handling high axial loads.

Surface setting pressures are adjustable

by manipulating the initial setup for the

setting tool.

The MH Thermal Liner Hanger Packer

is conveyed with a hydraulic setting tool

and set by dropping a ball, or utilizing a

plugging system, and pressuring up on

the work string. Once the thermal

element is packed off, the setting tool

hydraulically disconnects from the liner

packer without string manipulation, and

is retrieved to surface.

The MH Thermal Liner Hanger Packer

can be retrieved if required, by utilizing

standard retrieval equipment.

Applications

The MH Thermal Liner Hanger Packer is

designed for thermal applications. It is

primarily used when it is necessary to have

top and bottom anchoring slips, yet still be

fully retrievable. This packer is utilized as a

liner hanger, tailpipe hanger, bridge plug

(with bullnose), and can be combined with

the MH Patch Bottom to form a casing patch

for remedial well bore repair.

Features

Large beveled re-entry sleeve

Large through bore

Top and bottom anchoring slips

Metal to metal seal with static element

NACE MR0175 compliant for

environments containing H2S

Benefits

Thermal element rated to 343 C

No work string manipulation required to

set packer

Standard tools/spears used for retrieval

Liner or tailpipe placement control

(anchored during thermal cycling)

Adjustable surface setting pressures

Tested and verified for well tractor

transition from intermediate casing,

through packer, and into liner without a

slave string

MH Thermal Liner Hanger Packer

MH Thermal Liner Hanger Packer

Rev. 00 Page 4

Size Weight Range Packer O.D.

in (mm) lb/ft (kg/m) in (mm)

4.500 x 7.000 (114.3 x 177.8 ) 20.0 - 26.0 (29.7 - 38.7) 5.930 (150.6)

5.000 x 7.000 (127.0 x 177.8 ) 20.0 - 26.0 (29.7 - 38.7) 5.930 (150.6)

5.500 x 8.625 (139.7 x 219.1 ) 24.0 - 32.0 (35.7 - 47.6) 7.440 (189.0)

7.000 x 9.625 (177.8 x 244.5) 40.0 - 47.0 (53.6 - 69.9) 8.375 (212.7)

7.000 x 9.625 (177.8 x 244.5) 43.5 - 53.5 (64.7 - 79.5) 8.250 (209.6)

9.625 x 11.750 (244.5 x 298.5) 42.0 - 54.0 (62.5 - 80.3) 10.560 (268.2)

9.625 x 13.375 (244.5 x 339.7) 48.0 - 61.0 (71.4 - 90.7) 12.130 (308.1)

LRP - Long Reach Liner Packer Specifications

Description

The Long Reach Liner Packer (LRP) is

an integral liner hanger packer that

facilitates successful liner deployment

in vertical and long-reach horizontal

wellbores in thermal environments.

Hydraulic-setting capability, combined

with push, pull, and rotation capabilities,

allows controlled deployment of the

liner without excessive work string

manipulation. The LRP features an

optional internal circulating string for

wellbore fluid displacement.

Long Reach Packer elements are

available with standard or thermal

elastomers for use in steam-injection

applications. The LRP is available in

standard 80,000 psi (552 MPa) through

125,000 psi (862 MPa) yield materials.

Other yield strengths and materials are

available on request.

Operation

The LRP is deployed using the Long

Reach Setting Tool (LRST). Surface

setting pressures are adjustable by

manipulating the initial setup for the

setting tool.

The LRP is conveyed with LRST and

set by dropping a ball, dart, or utilizing

another plugging system, and pressuring

up on the work string. Once the element

is packed off, the setting tool

hydraulically disconnects from the liner

packer without string manipulation, and

is retrieved to surface.

The LRP can be retrieved if required,

by utilizing standard retrieval equipment.

Applications

Un-cemented, horizontal wells

Well applications requiring rotation when

running in hole

Operations requiring pushing and pulling

the liner to reach target depth

High-temperature environments

Hanging of light liners

Well applications requiring the liner to be

held down

Well applications requiring a hydraulic

liner top packer

Features

Integral liner hanger packer on single

mandrel

Hydraulic pusher mechanism to hang and

packoff tool

Secondary mechanical-release option

Setting tool that accepts inner-string

circulation string

Optional hold-down slips

Optional thermal elastomers

Benefits

Minimizes completion time by rotating the

liner when running in hole

Prevents upward movement of the liner

with hold-down slips for safe and secure

liner installation

Reduces trip time with large fluid bypass

LRP - Long Reach Liner Packer

LRP - Long Reach Liner Packer

Rev. 00 Page 5

Running Tools

MH MOST Setting Tool

CE Liner Running Tool

TBL HSPR Setting Tool

- HR Splined Retrievable Bushing

MH Setting Tool

- MH Setting Tool - running nut

- MH Setting Tool - collet

LRST Long Reach Setting Tool

Rev. 00 Page 6

Size O.D.

in (mm) in (mm)

9.625 (244.5) 8.375 (212.7)

11.750 (298.5) 10.375 (263.5)

MH MOST Setting Tool Specifications

Description

The MH MOST Setting Tool is engineered

to generate high setting forces with low

surface setting pressures, ideal for

thermal liner packers. The rugged design

allows for extreme axial loads to be

transmitted from the work string through

to the liner string.

The robust modular design allows for a

wide range of configurations. The setting

tool disengages from the liner string

hydraulically, making this setting tool

ideal for highly deviated well

applications.

Operation

The liner packer is conveyed with the

MH MOST Setting Tool. Utilizing a ball

drop or plugging system, pressure is

applied to the work string with the rig

pump, the liner packer is hydraulically

set, and hydraulically disconnected from

the MH MOST Setting Tool.

A positive primary pressure indication is

relayed on surface, and the setting tool is

straight pulled from the liner packer,

back to surface. No work string

manipulation is required.

Applications

The MH MOST Setting Tool is designed for

running and setting packers when high

setting force, and extreme torque and axial

loads may be required for placement of

liners in deviated wells.

Features

Modular design

Large internal thru bore

Pressure port sand control

Large setting piston area

Hydraulic release mechanism

Internal fluid by-pass release

Pressure isolation packoff between the

setting tool and the liner packer

Incorporates a reliable secondary

release mechanism

Benefits

Simple run-set-release

Rugged reliable design

No need for pressure truck

Ability to rotate and circulate during

deployment

Packer pressure test can be completed

prior to disconnecting from the liner

Adjustable surface setting pressures

Positive primary pressure indication for

downhole packer system release

No work string manipulation required to

disconnect from liner

Generates high setting force at low

surface pressures

Able to transmit extreme axial loads

Can be run in conjunction with a

redundant hydraulic circulation string

Incorporates a reliable secondary

release mechanism

MH MOST Setting Tool

MH MOST Setting Tool

Rev. 00 Page 7

Size Max. O.D.

in (mm) in (mm)

7.000 x 9.625 (177.8 x 244.5) 8.375 (212.7)

8.625 x 11.750 (219.1 x 298.5) 10.375 (263.5)

CE Liner Running Tool Specifications

Description

The CE Running Tool is a very compact

tool, engineered to accept high torque

and applied axial loads when required, in

order to convey the CE Liner Top Packer

and liner to the desired depth.

Circulation rates and differential

pressure do not affect the CE Running

Tool or CE Liner Top Packer. On the rig,

the system can be circulated through at

high rates and differential pressures

without fear of pre-setting the liner top

packer. Once on depth, a positive

displacement dart is launched from

surface. This dart shifts a sleeve that

introduces setting pressures to the

system.

The CE Liner Top Packer is set with very

low pressures compared to other liner

top packers. The robust design

disconnects from the liner string

hydraulically, making this setting tool

ideal for highly deviated well

applications.

Operation

The CE Packer is conveyed with the CE

Running Tool. Utilizing a dart, a

calculated volume is circulated to seat

the dart at the running tool. Pressure is

applied to the work string with the rig

pump. The CE Packer is hydraulically set,

and the CE Running Tool is hydraulically

disconnected from CE Packer.

A positive primary pressure indication is

relayed on surface. The CE Running Tool

can be straight pulled from the CE

Packer, or with the work string in

compression, a pressure test of the CE

Packer can be completed down the

annulus. After which, the running tool

can be retrieved to surface, as no work

string manipulation is required to

disconnect.

Applications

The CE Liner Running Tool is designed for

running and hydraulically setting liner

packers where high torque and axial loads

may be required. The compact length of this

tool makes it ideal for placement of liners in

highly deviated wells.

Benefits

Compact length

Pressure balanced dart activated primary

release

Integral secondary release

Capable of handling high circulating rates

and differential pressures

Features

Simple run-set-release

Rugged reliable design

No need for pressure truck

Ability to rotate and circulate during

deployment

Packer pressure test can be completed

prior to disconnecting from the liner

Adjustable surface setting pressures

Positive primary pressure indication for

downhole packer system release

No work string manipulation required to

disconnect from liner

Incorporates a reliable secondary

release mechanism

CE Liner Running Tool

CE Liner Running Tool

Rev. 00 Page 8

Size Max. O.D.

in (mm) in (mm)

7.000 (177.8) 5.875 (149.2)

8.625 (219.1) 7.500 (190.5)

9.625 (244.5) 8.438 (214.3)

HSPR Setting Tool Specifications

Description

The HSPR Setting Tool is engineered to

generate high setting forces with low

surface setting pressures, ideal for

thermal packers. The rugged design

allows for torque and axial loads to be

transmitted from the work string through

to the liner packer, with the ability to

circulate large volumes and rates.

The robust modular design allows for a

wide range of configurations. The setting

tool disengages from the liner string

hydraulically, making this setting tool

ideal for highly deviated well

applications, with a reliable secondary

mechanical release incorporated into

the design of the setting tool.

Operation

The packer is conveyed with the HSPR

Setting Tool. Utilizing a ball drop or

plugging system, pressure is applied to

the work; the liner packer is hydraulically

set, and hydraulically disconnected from

the HSPR Setting Tool.

A positive primary pressure indication is

relayed on surface, and the setting tool is

straight pulled from the liner packer,

back to surface. No work string

manipulation is required.

Applications

The HSPR Setting Tool is designed for

running and setting the TBL and LBL liner

packers hydraulically on tubing and is

capable of transmitting high torque and

axial loads through to the packer. This tool is

ideal for placement of liners in deviated

wells.

Benefits

Modular design

Large internal thru bore

Large setting piston area

Primary hydraulic release

mechanism

Mechanical secondary release

Integral clutch system

Pressure isolation packoff

between the setting tool and the

liner packer

Features

Simple run-set-release

Rugged reliable design

Ability to rotate and circulate

during deployment

Adjustable surface setting

pressures

Positive indication of primary

pressure for liner release

No work string manipulation

required to disconnect from liner

Generates high setting force

Capable of large circulating

volumes

Able to transmit torque and axial loads

Can run in conjunction with a redundant

hydraulic circulation string

HSPR Setting Tool

HSPR Setting Tool

Rev. 00 Page 9

Size Seal O.D.

in (mm) in (mm)

7.000 (177.8) 5.900 (149.9)

8.625 (219.1) 8.375 (212.7)

9.625 (244.5) 10.375 (263.5)

HR Splined Retrievable Bushing Specifications

Description

The HR Splined Retrievable Bushing is a

reliable and versatile external seal

system suitable for high pressure and

high temperature applications.

This bushing is designed to be run in

conjunction with the HSPR Setting Tool

enabling the transmission of torque

through the HSPR Setting Tool to the

Liner Hanger Packer.

Operation

The HR Splined Retrievable Bushing is

connected to the bottom of the HSPR

Setting Tool and the assembly is made up

onto the liner packer.

The torque transmitting mechanism of

the bushing can be hydraulically

disengaged. Once the torque

mechanism has been disengaged, the

HSPR Setting Tool can rotate

independent of the liner hanger packer,

allowing the setting tool to detach

(back-off) from the liner hanger packer

(liner string) through right hand rotation.

Applications

The HR Splined Retrievable Bushing is

designed for running and setting the TBL

and LBL thermal liner hanger packers

hydraulically on tubing where torque or

circulation may be required.

Features

Seals in the tieback receptacle of the

liner hanger packer using self lubricating

seals

Transmits torque from the drill string to

the liner through the HSPR setting tool

and liner packer

Adjustable torque mechanism release

pressure

Torque transmission mechanism locks in

released position to prevent re-engaging

Robust design

Benefits

Torque transmitting mechanism of

bushing is released hydraulically

External seal enables a circulation string

to be run through the liner

No tubing manipulation required to set

Retrieval with standard fishing tools

HR Splined Retrievable Bushing

HR Splined Retrievable Bushing

Rev. 00 Page 10

Size O.D.

in (mm) in (mm)

7.000 (177.8) 5.875 (149.2)

8.625 (219.1) 7.500 (190.5)

MH Setting Tool Specifications

Description

The MH Setting Tool is hydraulic setting

tool capable of generating high setting

forces that are required for thermal

element systems.

Operation

The MH Setting Tool is made up to the

top of an MH thermal product and run

into the well. Once on depth, the MH

Setting Tool is pressured up in stages to

engage the slips and thermal element of

the MH Packer. Once the required final

setting pressure has been achieved, the

pressure is bled off and the running

string weight is adjusted to neutral. Right

hand rotation is applied through the

running string to release the running nut

on the MH Setting Tool from the MH Liner

Packer allowing for the retrieval of the

setting tool.

Applications

The MH Setting Tool is utilized for the

deployment and setting of the MH Thermal

down hole products which include the MH

Liner Hanger Packer, MH Bridge Plug and

MH Casing Patch.

Features

Hydraulic set

No pipe manipulation required during

setting

Large setting piston area

Modular

Robust design

Benefits

Simple to run and set

Low surface setting pressure

Ability to be set in highly deviated wells

Cost effective

Field proven

Reliable

MH Setting Tool - with running nut

MH Setting Tool - with running nut

Rev. 00 Page 11

Size O.D.

in (mm) in (mm)

7.000 x 5.000 (177.8 x 127.0) 5.875 (149.2)

9.625 x 7.000 (244.5x 177.8) 8.250 (209.6)

MH Setting Tool Specifications

Description

The MH Hydraulic Setting Tool is

designed for generating high pack off

forces required for setting the Dynaseal

thermal element used on MH thermal

products. These products include the

MH Thermal Liner Hanger Packer, MH

Thermal Casing Patch and the MH

Thermal Step Casing Patch.

Operation

The MH Setting Tool is made up to the

top of an MH thermal product and run

into the well dry. For casing patches, the

addition of the bottom collet assembly

and spacer pipe is also required. Once

on depth, the MH Setting Tool is

pressured up hydraulically in stages to

engage the slips and elements of the MH

down hole tool. Once the final setting

pressure has been achieved, straight

pull at the running tool will release the

MH Setting Tool from the down hole

products. For deployment of long liners

or a long patch section, the MH Setting

Tool is made up to a running nut which

requires right hand rotation for release.

Applications

The MH Setting Tool is utilized for the

deployment and setting of the MH family of

thermal down hole products.

Benefits

Ability to be set in highly deviated wells

Cost effective

Field proven

Features

No rotation required for setting

Hydraulic set

Robust design

MH Setting Tool - with collet

MH Setting Tool - with collet

Rev. 00 Page 12

Size

in (mm)

4.500 x 7.000 (114.3 x 177.8 )

5.000 x 7.000 (127.0 x 177.8 )

5.500 x 8.625 (139.7 x 219.1 )

7.000 x 9.625 (177.8 x 244.5)

9.625 x 11.750 (244.5 x 298.5)

LRST - Long Reach Setting Tool Specifications

Description

The Long Reach Setting Tool (LRST) is

used exclusively to run liner systems that

use the Long Reach Liner Packer (LRP).

The setting tool includes a collet-type

hydraulic-release liner deployment and

release mechanism, as well as a pusher

sleeve to pack off the LRP. No rotation

is required to release the LRST from the

liner, making it suitable for horizontal and

high-inclination wells.

The LRST allows the Long Reach Liner

system to be pushed, pulled, and rotated

to achieve target depth. An internal

bypass feature reduces formation surge

pressures and allows faster running

speeds. The LRST also features a backup

mechanical-release mechanism (option)

that reduces the risk of not being able

to release the LRST from the liner. The

mechanical release is achieved by a

one-quarter turn to the left.

Operation

The packer is conveyed with the

LRST. Utilizing a ball drop, dart, or

another plugging system, pressure is

applied to the work string; the packer

is hydraulically set, and hydraulically

disconnects from the LRST.

A positive pressure indication is

relayed on surface, and the setting tool is

straight pulled from the liner packer, back

to surface. No work string manipulation

is required.

Applications

Horizontal wells

Well applications requiring rotation when

running in hole

Operations requiring pushing and pulling

the liner to reach target depth

Well applications requiring a hydraulic

setting and release mechanism

Features

Clutch design to transmit torque to the

liner

Hydraulic pusher sleeve to hang and pack

off tool

Setting tool that accepts inner circulation

string

Backup mechanical release to ensure

liner release (1/4 left-hand turn)

Benefits

Minimize completion time by rotating the

liner when running in hole

Reduces risk of pulling liner out of well

and saves associated time and costs with

secondary-release option

LRST - Long Reach Setting Tool

LRST - Long Reach Setting Tool

Rev. 00 Page 13

Remedial Tools

Mechanical Packers

- Cup Type Test Tool

Bridge Plugs

- Thermal Permanent Bridge Plug

- MH Thermal Retrievable Bridge Plug

Casing Patches

- MH Thermal Casing Patch

- MH Thermal Patch Bottom

Scrapers & Drift Subs

- Model A Casing Scraper

- Drift Lock Casing Scraper

- FD Drift Sub

Tubing Accessories

- Thermal Sliding Sleeve

- Burst Joint

- Thermal Expansion Joint

- Thermal Pumpout Float Valve

- Thermal Latch Down Plug

Rev. 00 Page 14

Casing Size Casing Weight Range Gauge O.D.

in (mm) lb/ft (kg/m) in (mm)

8.625 (219.1) 28.0 - 36.0 (41.7 - 53.6) 7.700 (195.6)

9.625 (244.5) 47.0 - 58.4 (59.5 - 69.9) 8.281 (210.3)

Cup Type Test Tool Specifications

Description

The Cup Type Test Tool is designed for

locating casing leaks, with the ability for

downward movement under pressure for

determining exact point of leak off.

Operation

The Cup Type Test Tool is typically made

up with a bypass valve above it, and

lowered into the wellbore. The test tool is

run to depth with the bypass valve

closed. With the pack-off head or the

pipe rams closed at surface, pressure is

applied on the annulus and charted to

determine whether there is a leak off. If a

pack-off head is used, connections may

be made up and the work string lowered

into the well until a bleed off point is

found. Once the leak point has been

determined, the test tool is retrieved by;

bleeding off the annulus pressure,

opening the bypass valve, and pulling the

assembly from the wellbore.

Applications

Pressure testing of BOPs

Pressure tesing for casing leaks

Features

Packer cup type element system

Can be run in conjunction with a Model A

Bypass Valve

Tested via annular pressure

Standard configuration utilizes redundant

cups

Benefits

Setting tool not required

Ability to maintain pressure on tool while

lowering tubing through a pack-off, to

determine the exact point of bleed off

Cup Type Test Tool

Cup Type Test Tool

Rev. 00 Page 15

Casing Size Casing Weight Range Plug O.D.

in (mm) lb/ft (kg/m) in (mm)

4.500 (114.3) 9.5 - 15.1 (14.1 - 22.5) 3.562 (90.5)

5.000 (127.0) 11.5 - 20.8 (17.1 - 31.0) 3.937 (100.0)

5.500 (139.7) 13.0 - 23.0 (19.4 - 34.3) 4.312 (109.5)

6.625 (168.3) 17.0 - 32.0 (25.3 - 47.6) 5.375 (136.5)

7.000 (177.8) 17.0 - 35.0 (25.3 - 52.1) 5.687 (144.4)

7.625 (193.7) 20.0 - 39.0 (29.8 - 58.0) 6.312 (160.3)

8.625 (219.1) 24.0 - 49.0 (35.7 - 72.9) 7.125 (181.0)

9.625 (244.5) 29.3 - 58.4 (43.6 - 86.9) 8.125 (206.4)

Thermal Permanent Bridge Plug Specifications

Description

The Thermal Permanent Bridge Plug

(TPBP) is the thermal version of the

reliable HM-1B and DB bridge plug. The

thermal permanent bridge plugs are an

economical way to suspend or abandon

a well bore while maintaining the ability

to drill out the bridge plug and re-enter

the hole.

Operation

The TPBP is run and set utilizing the

compact hydraulic setting tool. The

TPBP is run to depth on the hydraulic

setting tool and work string. The work

string is filled and pressured up to initiate

a set. The work string is pulled into

tension aiding in the pack off, and

locking the setting force into the

element. It is a best practice to hold

hydraulic pressure and pull tension into

the bridge plug, and repeat. Once the

element is packed off, right hand rotation

will release the setting tool from the

bridge plug.

Applications

Thermal applications requiring a

permanent bridge plug

Abandonments requiring a thermal

bridge plug

Features

Field proven

Simple design

Compact design allows greater casing

access

No elastomers eliminate leak paths

Benefits

Full circle, one piece slips

Hydraulic set with retrievable setting tool

Compact

Tapered nose

Thermal element rated to 350 C

No elastomers

Thermal Permanent Bridge Plug

Thermal Permanent Bridge Plug

Rev. 00 Page 16

Size Weight Range Packer O.D.

in (mm) lb/ft (kg/m) in (mm)

7.000 (177.8) 23.0 - 29.0 (34.2 - 43.2) 5.900 (149.9)

9.625 (244.5) 36.0 - 47.0 (53.6 - 69.9) 8.375 (212.7)

11.750 (298.5) 38.0 - 60.0 (56.6 -89.3) 10.375 (263.5)

MH Thermal Bridge Plug Specifications

Description

The MH Thermal Bridge Plug is part of

the MH family of thermal completion

technology. It is a hydraulically set

bridge plug for use in thermal

applications. It has a temperature rating

of 343 C, and utilizes Schlumbergers

metal to metal system in conjunction

with a thermal element.

The design for this product includes no

elastomers. It is engineered for harsh

environments that exceed the

temperature and pressure limits for

elastomers, such as o-rings, packing and

rubber compounds.

Operation

The MH Thermal Bridge Plug is designed

to be run and set utilizing a hydraulic

setting tool which is engineered for

producing high setting forces and

handling high axial loads. Surface

setting pressures are adjustable by

manipulating the initial setup for the

setting tool.

The MH Thermal Bridge Plug is

conveyed with a hydraulic setting tool

and set by dropping a ball, or utilizing a

plugging system, and pressuring up on

the work string. Once the thermal

element is packed off, the setting tool

hydraulically disconnects for the liner

packer without string manipulation, and

is retrieved to surface.

The MH Thermal Bridge Plug can be

retrieved if required, by utilizing standard

fishing equipment.

Applications

The MH Thermal Bridge Plug is designed for

thermal applications. It is designed

specifically for temporary well bore

suspension in thermal applications, or

utilized for zonal isolation.

Features

Large beveled re-entry sleeve

Top and bottom anchoring slips

MH Bridge Plug has top and bottom slips

Metal to metal seal with static element

NACE MR0175 compliant for

environments containing H

2

S

Benefits

Thermal element rated to 343 C

No work string manipulation required to

set

Standard tools/spears used for retrieval

Adjustable surface setting pressures

MH Thermal Bridge Plug

MH Thermal Bridge Plug

Rev. 00 Page 17

Description

The MH Thermal Casing Patch

incorporates the benefits of both MH

Thermal Liner Hanger packer and the

MH Thermal Patch Bottom. The system

is hydraulically set, mechanically

retrievable, and used for patching casing

integrity issues or utilized as a sand

management system at the liner top.

With a temperature rating of 343 C,

Schlumbergers metal to metal system in

conjunction with the thermal element is

capable of an initial pressure test to 21

MPa.

The casing patch incorporates

anchoring slips at the top of the

assembly, with a high temperature

slip-less system at the bottom end. This

compensates for temperature induced

expansion and contraction of the

tubulars in thermal applications.

The design for this product includes

no elastomers. It is engineered for

harsh environments which exceed the

temperature and pressure limits for

elastomers, such as o-rings, packing

and rubber compounds.

Operation

The MH Thermal Casing Patch is

designed to be run and set utilizing a

hydraulic setting tool which is

engineered for producing high setting

forces and handling high axial loads.

Surface setting pressures are adjustable

by manipulating the initial setup for the

setting tool.

The MH Thermal Casing Patch is

conveyed utilizing a hydraulic setting

tool with the MH Collet Setting assembly

in place. The patch is set by dropping a

ball, or utilizing a plugging system, and

pressuring up on the work string. Once

the thermal elements are packed off, the

setting tool hydraulically disconnects

from the Casing Patch without string

manipulation, and is retrieved to surface.

The MH Thermal Casing Patch can be

retrieved if required, by utilizing standard

retrieval equipment.

Applications

The MH Thermal Casing Patch is designed

for remedial wellbore repair thermal

applications. It is primarily used to isolate

damaged casing, and isolate leaking liner

tops, and yet it is still fully retrievable.

Features

Large beveled upper re-entry sleeve

Large through bore

Upper anchoring slips with a slip-less

bottom end design

Half-muled and beveled lower re-entry

guide

Metal to metal seals with static element

NACE MR0175 compliant for

environments containing H2S

Benefits

Thermal element rated to 343 C

No work string manipulation required to

set

Standard tools/spears used for retrieval

Allows for expansion and contraction

independent of the casing

Spacer pipe lengths from 1.0 meter to

200+ meters

Anchored during thermal cycling

Adjustable surface setting pressures

MH Thermal Casing Patch

MH Thermal Casing Patch

Rev. 00 Page 18

Size Weight Range

in (mm) lb/ft (kg/m)

3.500 x 4.500 (88.9 x 114.3) 11.6- 12.6 (17.3 - 18.8)

4.000 x 5.500 (101.6 x 139.7) 15.5- 20.0 (23.1 - 29.8)

5.000 x 7.000 (127.0 x 177.8) 23.0 - 29.0 (34.2 - 43.2)

5.500 x 7.000 (139.7 x 177.8) 20.0 - 26.0 (29.8 - 38.7)

7.000 x 9.625 (177.8 x 244.5) 36.0 - 47.0 (53.6 - 69.9)

8.625 x 11.750 (219.1 x 298.5) 38.0 - 60.0 (56.6 - 89.3)

MH Patch Bottom Specifications

Description

The MH Thermal Patch Bottom is a

high temperature packer assembly

which allows for temperature induced

expansion and contraction of tubulars

in thermal applications. It is designed

to be run with the MH Thermal Liner

Hanger Packer, creating a reliable

retrievable casing patch solution for

thermal applications. The MH Thermal

Patch Bottom can also be run with other

thermal upper completion packers,

permanent or retrievable.

With a temperature rating of 343 C,

Schlumbergers metal to metal system in

conjunction with the thermal element is

capable of an initial pressure test to 21

MPa.

The design for this product includes

no elastomers. It is engineered for

harsh environments which exceed the

temperature and pressure limits for

elastomers, such as o-rings, packing

and rubber compounds.

Operation

The MH Thermal Patch Bottom is

typically conveyed with an upper packer,

or on the bottom end of the patch pipe.

It is set utilizing the MH Collet Setting

Assembly, and can be set in conjunction

with the upper packer, or can also be set

independent of the upper packer.

The setting assembly can be

mechanically actuated by straight

pickup of the work string, or it can be

actuated by hydraulically pressuring up

on hydraulic setting tool, which will

induce upwards force into the work

string. The applied upward force in the

work string packs off the thermal

element and releases the setting collet

from the MH Thermal Patch Bottom,

when the required setting force has

been achieved. The setting assembly is

retrieved by simple pick-up of the work

string, and retrieval to surface.

Applications

The MH Thermal Patch Bottom is designed

for thermal applications. It is primarily used

as the lower seal in a retrievable casing

patch type application in conjunction with

an upper packer. When used in tandem with

another packer, the MH Thermal Patch

Bottom can isolate damaged casing, isolate

leaking liner tops, or serve as a tieback seal

assembly.

Features

Large through bore

Slipless design

Muled, beveled re-entry guide

Metal to metal seal with static element

NACE MR0175 compliant for

environments containing H2S

Benefits

Thermal element rated to 343 C

Packoff can be re-energized

Standard tools/spears used for retrieval

Hydraulic setting tool or mechanically set

Allows for expansion and contraction

independent of the casing

MH Thermal Patch Bottom

MH Thermal Patch Bottom

Rev. 00 Page 19

Model A Casing Scraper Specifications

Casing Size Weight Range Thread Connection

in (mm) ppf (kg/m) in (mm)

4.500 (114.3) 9.5 - 13.5 (14.1 - 20.1) 2.375 (60.3) API Regular

5.000 (127.0) 11.5 - 21.4 (17.1 - 34.8) 2.375 (60.3) API Regular

5.500 (139.7) 13.0 - 26.0 (19.4 - 38.7) 2.875 (73.0) API Regular

6.625 (168.3) 23.2 - 32.0 (34.5 - 47.6) 3.500 (88.9) API Regular

7.000 (177.8) 17.0 - 32.0 (25.3 - 47.6) 3.500 (88.9) API Regular

8.628 (219.1) 28.0 - 49.0 (41.7 - 72.9) 3.500 (88.9) API Regular

9.625 (244.5) 32.3 - 47.0 (48.1 - 69.9) 4.500 (114.3) API Regular

10.750 (273.1) 32.8 - 65.7 (48.7 - 97.8) 4.500 (114.3) API Regular

11.750 (298.5) 38.0 - 71.0 (56.6 - 105.7) 4.500 (114.3) API Regular

13.375 (339.7) 48.0 - 80.7 (71.4 - 120.1) 4.500 (114.3) API Regular

Description

The Model A Casing Scraper is used to

remove cement sheath, perforating

burrs, scale, and other foreign matter

from the inside walls of the casing by

providing full 360 coverage with blade

blocks.

Operation

The Model A Casing Scraper should be

run pin thread up and box thread down.

This scraper operates equally well when

reciprocated vertically or rotated. In

areas of the casing where sheath or

burrs may exist, he casing scraper

should be worked up and down through

the area several times. This is especially

important in areas of perforations or

where a packer is to be set. If desired,

the casing scraper may be rotated

(always clockwise) while reciprocating.

Applications

Designed to utilized prior to running

packers, bridge plugs and other equipment

employing pack-offs, slips, cups, etc. These

packers etc, are manufactured to close

tolerances and require that the casing I.D.

be smooth and free from obstructions. An

obstruction or a sheath of foreign matter in

the casing I.D. may damage or interfere with

the proper setting of slips or seals and may

result in tool failure.

Features

Large bypass area between blades to

allow for circulation

Self-sharpening blades provide full 360

coverage of casing I.D.

All thrust and rotational loads are carried

by the scraper body, not by the retaining

screws

Robust design

Built for use with common pipe

connections

Benefits

Rugged, one-piece alloy steel body

Tough alloy blades are designed for extra

long wear

Blades are individually locked into the

scraper body for ease of repair

Model A Casing Scraper

Model A Casing Scraper

Rev. 00 Page 20

Drift Lock Casing Scraper Specifications

Casing Size Thread Connection

in (mm) in (mm)

4.500 (114.3) 2.375 (60.3) EUE

5.500 (139.7) 2.875 (73.0) EUE

7.000 (177.8) 3.500 (88.9) EUE

8.625 (219.1) 3.500 (88.9) EUE

9.625 (244.5) 4.500 (114.3) EUE

Description

The Drift Lock Casing Scraper was

designed and built with Heavy Oil

applications in mind. With the high

instance of casing anomalies due to

thermal stresses or strains, the Drift Lock

Casing Scraper combines the features of

both a casing scraper and drift gauge in

one design. Each Drift Lock Casing

Scraper is designed to lock the blades

extended to the drift I.D. of the specific

casing weight of a particular casing size.

Operation

Make up Drift Lock Casing Scraper to the

work string and run in hole. Reciprocate

up and down, and/or rotate clockwise, to

clean areas where obstructions were

detected or where the packer is to be

set.

As the Drift Lock Casing Scraper is

lowered into the well bore, the angled

scraper blades automatically rotate into

the drift-locked position against the

casing wall. The scraper blades rotate

back to the standard non-drift (fully

collapsible) position as the Drift Lock is

retrieved from the well bore.

If any casing anomalies are encountered

while running into the well bore, pick up

the Drift Lock Casing Scraper above the

anomaly, rotate turn to the left to

unlock the scraper blades from drift, and

reciprocate through the anomaly.

Applications

The Drift Lock Casing Scraper is utilized to

remove scale, cement sheath, perforating

burrs, and other foreign matter from the

casing walls. In the locked position, the

scraping blades cannot collapse below drift

size of the casing. This will ensure the

casing I.D. is smooth and free from

obstructions, prior to running any

completions. If any obstruction is detected,

the Drift Lock Casing Scraper can be

switched to the unlocked position and

reciprocated until the anomaly drifts, or is

removed.

Features

Automatically locks blades extended to

drift I.D. while running

Self-sharpening blades provide full 360

coverage to casing drift I.D.

Large bypass channels around and

between blades

Built for use with common pipe

connections

Full bore I.D.

Benefits

Confirms full drift I.D. of casing

More efficient than conventional casing

scrapers

The scraper blades lock to drift size

automatically when reciprocating down

hole

Can be adjusted while running, allowing

the scraper to pass through restrictions

Robust design

Drift Lock Casing Scraper

Drift Lock Casing Scraper

Rev. 00 Page 21

Casing Size Casing Weight Drift Sub O.D.

in (mm) ppf (kg/m) in (mm)

8.628 (219.1) 36.0 (53.6) 7.700 (195.6)

9.625 (244.5) 40.0 (59.5) 8.679 (220.5)

9.625 (244.5) 43.5 (64.7) 8.599 (218.4)

11.750 (298.5) 47.0 (69.9) 10.844 (275.4)

13.375 (339.7) 61.0 (90.8) 12.359 (313.9)

FD Drift Sub Specifications

Description

The FD Drift Sub is an economical means

of confirming down hole tool casing bore

when running liner hangers and/or

packers in deviated well bores prior to

running the liner.

Operation

The fluted FD Drift Sub is typically run

along with a casing scraper and tubing.

Deploying this bottom hole assembly

confirms torque and drag values as well

as confirming the ability to land the final

bottom hole assembly at the desired

depth. This assembly is run-in-hole to the

first deviated section of the well and then

slowly run through deviated sections of

the intermediate casing while monitoring

and recording torque and drag. Once the

bottom hole assembly has reached the

desired depth (end of the casing string),

the drill pipe drift can be dropped from

surface to land in the Totco ring. A

successful drift confirms that the

deployment string has a internal

diameter that will allow an OD specific

phenolic ball, used for setting hydraulic

liners and/or packers, to reach the liner

and/or packer setting tool.

Applications

Used to ensure casing is open to full

drift ID

For thermal and non-thermal applications

to ensure full drift ID of casing prior to

running down hole equipment

Features

Spiral fluted bypass incorporated to allow

for circulation while maintaining full

circumference drift diameter

Built for use with common pipe

connections

Robust design

Bottom hole assembly can be run in

variable lengths

Benefits

Confirms passage of future liner hangers

and packer assemblies

Torque and drag values are validated

FD Drift Sub

FD Drift Sub

Rev. 00 Page 22

Description

The CS(X)-3U-0 Thermal Sliding Sleeve is

a communication device with a ported

inner sleeve. Sizeable chokes are

available as options for adjusting the

opening to the tubing annulus.

The simplicity of the sliding sleeve

design provides a long operating life.

Equalizing slots in the inner sleeve

permit gradual equalization between the

tubing and casing annulus. The sleeves

may be ordered with Otis-style X-type

and Baker-style F- and R-type landing

profiles.

Operation

The CS(X)-3U-O Thermal Sliding Sleeve

can be opened or closed using a shifting

tool and standard wireline and coiled

tubing methods. The CS(X)-3U-O

Thermal Sliding Sleeve shifts up to open,

and down to close. The sliding sleeve is

assembled to, and forms part of the

tubing string.

Equalizing pressure between the tubing

and casing annulus is normally

accomplished by applying pressure or

filling the tubing or casing with fluid. The

sliding sleeve can also be opened even if

facilities for equalizing pressures are not

available beforehand. This requires

careful monitoring of tubing and annulus

pressures while slowly opening the

sleeve until equalization.

Applications

The CS(X)-3U-O Thermal Sliding Sleeve is

designed for steam injection / heavy oil

production applications. There are two

operating positions for the sleeve, fully open

and fully closed.

For injection applications, the number of

sliding sleeves and orifice sizes can be

setup to balance steam injection, ensuring

that steam is being placed in each interval /

segment of the wellbore.

For production applications, the sliding

sleeve can be setup to ensure production

from each zone based on the number and

size of orifices required.

Each Thermal Sliding Sleeve is available

with various orifice sizes and installed

quantity. Depending on the desired

injection / production rate, the orifices are

selected.

Features

NACE MR0175 compliant for

environments containing H

2

S

Includes sizeable orifices in the tubing

to-annulus communication ports

Non-elastomeric seals

Available with landing nipple profiles

Benefits

Compact and simple design

Replaceable chokes

Choice of nipple profiles

Qualified to:

2,000 psi @ 580 F (13.8 MPa @ 304 C)

1,000 psi @ 600 F (6.9 MPa @ 316 C)

CS(X)-3U-O Thermal Sliding Sleeve

CS(X)-3U-O Thermal Sliding Sleeve

Rev. 00 Page 23

Size Standard Thread Burst Pressure

in (mm) Configuration psi (kPa)

2.375 (60.3) EUE box x pin 3,000 (20,684)

2.875 (73.0) EUE box x pin 3,000 (20,684)

3.500 (88.9) EUE box x pin 3,000 (20,684)

4.500 (114.3) LTC pin x pin 3,000 (20,684)

5.500 (139.7) LTC pin x pin 3,000 (20,684)

Internal Cut Window Burst Joint Specifications

* Other thread configurations and burst pressures are

available upon request

Description

The Internal Cut Window Burst Joint is

designed for thermal applications where

an elastomeric type tubing drain is not

feasible.

Operation

The burst joint is made up in the tubing

string immediately above the pump

seating nipple, and run in the well as part

of the tubing string. In the event the rod

string parts, pressuring up on the tubing

string in excess of the burst pressure will

burst out the window of the burst joint,

providing a large drainage area. This will

allow for a dry trip while retrieving the

tubing, rods, and pump.

Applications

Thermal installations in place of a

standard elastomeric tubing drain

Features

Rated for temperatures to 350 C and

above

+/- 5% burst accuracy

Various burst pressures available

Benefits

Internally cut profile reduces the

potential of rod wear affecting the burst

value of the burst joint

Large drainage window

Internal Cut Window Burst Joint

Intermal Cut Window Burst Joint

Rev. 00 Page 24

Size Stroke Length O.D.

in (mm) feet (meters) in (mm)

7.000 x 5.500 (177.8 x 139.7) 13.17 (4.01) 7.656 (194.5)

Thermal Expansion Joint

Description

The Thermal Expansion Joint is a high

temperature expansion device which

compensates for temperature induced

expansion and contraction of tubulars in

thermal applications.

When in the fully extended position, a

robust clutch system allows for torque

and axial loads to be transmitted through

the expansion joint.

The design for this product includes no

elastomers. It is engineered for harsh

environments which exceed the

temperature and pressure limits for

elastomers, such as o-rings, packing and

rubber compounds

With a temperature rating of 650 F

(343 C), Schlumbergers metal to metal

seal system in conjunction with a

thermal seal is capable of holding 3,000

psi (21.7 MPa) of differential pressure.

The thermal expansion joint can be

manufactured to any length to suit

customer requirements and allows safe

installation and retrieval of the tubing

string and completion components.

Applications

The Thermal Expansion Joint is designed for

use in thermal cycling applications to

reduce liner stresses. Commonly used

where compensation is required for

expansion or contraction of tubulars during

enhanced oil recovery operations. It is

primarily used in the liner system below a

thermal liner hanger packer.

Features

NACE MR0175 compliant for

environments containing H2S

Non-elastomeric seals

Integral clutch system

Can be setup for any length

Benefits

Thermal seals rated to 650F (343C)

Able to rotate and circulate during

deployment

Fullbore access to liner

Adjustable shear system

Thermal Expansion Joint

Thermal Expansion Joint

Rev. 00 Page 25

Size / Connection O.D.

in (mm) in (mm)

2.875 (73.0) EUE 3.668 (93.2)

5.000 (127.0) Buttress 5.563 (141.3)

Thermal Pumpout Float Valve Specifications

Description

The Thermal Pump-out Float Valve

(TPFV) is a float valve, for use in thermal

applications. The TPFV is designed to

allow steam injection into the reservoir

while stopping the reservoir from flowing

back. After steam injection is complete,

reservoir production is initiated by

dropping a ball and pumping off the float

valve.

The design for this product includes no

elastomers. It is engineered for harsh

environments which exceed the

temperature and pressure limits for

elastomers, such as o-rings, packing and

rubber compounds

With a temperature rating of 650 F

(343 C), Schlumbergers metal to metal

seal system in conjunction with a

thermal seal is capable of holding 3,000

psi (21.7 MPa) of differential pressure.

Operation

Install the TPFV into the completion

design and run to depth. Perform the

steam injection program for the

wellbore. Once completed the steam

program, and production is required,

drop the appropriate size of ball and seat

in the valve. At the predetermine

pressure, the valve will release, and

production through the TPFV is possible.

Applications

Usually installed on the bottom of a MH

Thermal Liner Hanger Packer, the TPFV is

utilized in thermal wells, for temporary

suspension of reservoir production.

Features

Rugged, reliable design

NACE MR0175 compliant for

environments containing H2S

Non-elastomeric seals

Adjustable pump out pressure

Benefits

Thermal seals rated to 650 F (343 C)

Temporary wellbore suspension is

achievable without intervention

Operates in highly deviated wells,

negating the need for CT operations to set

plugs

Thermal Pumpout Float Valve

Thermal Pumpout Float Valve

Rev. 00 Page 26

Tubing Size Profile - Type / Size

in (mm) in (mm)

3.500 (88.9) 2.312 (58.7) X

Thermal Latch Down Plug Specifications

Description

The Thermal Latch Down Plug has been

designed for thermal applications where

liners are circulated into place, and

isolation of the flow port is required. The

plug will seal and isolate flow out

through the toe of the liner, or at any

position in the string, where the landing

sub or profile is placed.

It is engineered for harsh environments

which exceed the temperature and

pressure limits for elastomers, such as

o-rings, packing and rubber compounds

With a temperature rating of 650 F

(343 C), Schlumbergers metal to metal

seal system in conjunction with a

thermal seal is capable of holding 3,000

psi (21.7 MPa) of differential pressure.

Operation

Install the landing sub into the liner, or

workstring, and deploy to desired depth.

Once all completion operations or

stimulation operations have been

completed, pick up the Thermal Latch

Down Plug with the running tool, and run

the assembly. Once on depth, pick up to

set the thermal seals, and shear off the

running tool to POOH.

Applications

The Thermal Latch Down Plug is used for

thermal applications where a latch down

plug is required.

Features

Mechanical deployment and retrieval

NACE MR0175 compliant for

environments containing H

2

S

Adjustable release loads

Benefits

Thermal seals rated to 650 F (343 C)

Positive shutoff for the liner shoe

Lands in standard size profile sub

Pressure testable for tubular isolation

Straight pull retrieval

Thermal Latch Down Plug

Thermal Latch Down Plug

Rev. 00 Page 27

Reservoir Monitoring

Distributed Temperature Systems

- WellWatcher BriteBlue HT

Acquisition Systems

- WellWatcher Ultra

- WellWatcher Ultra ASE

Monitoring Accessories

- Turn Around Sub

- Bullnose Pressure Port

- Thermal Disconnect

- Shower Head

- Wellhead Outlet

Rev. 00 Page 28

Rev. 00 Page 29

Rev. 00 Page 30

Rev. 00 Page 31

Rev. 00 Page 32

APPLICATIONS

Heavy oil thermal recovery monitoring

Distributed temperature

measurements

Control of production rates

and drawdown

Production allocation

BENEFITS

Longer fiber logging and increased sys-

tem life due to improved interrogation

Reduction of system costs through

reduced fiber length

Long-term, reliable, permanent in-well

reservoir monitoring

Enhanced recovery and production

management through improved reservoir

surveillance

Fast identification of production prob-

lems through best-in-class temperature

measurements

Minimized service interventions

FEATURES

Multiple laser interrogation

Dynamic fiber loss correction along

every meter of fiber for every acquired

temperature profile

Compatibility with WellWatcher

BriteBlue* multimode fiber, for maximum

system life

No downhole electronics

Simple-to-use surface software with

auto setup and

optimization

Reliability, robustness, and extended

system life

Range: 6 km [3.73 mi]

12 single-ended channels

In harsh environments, such as thermal

recovery and high-pressure, high-temperature

applications, measuring from only one end of

a fiber can lead to a deterioration in accuracy

when the fiber begins showing signs of hydro-

gen degradation.

The extremely versatile WellWatcher Ultra

ASE* distributed temperature sensing (DTS)

system dynamically corrects for such fiber

loss along the entire length of the sensing

multimode fiber. This system provides an

accurate single-ended fiber-loss-corrected

temperature profile for reservoir monitoring.

It measures up to 6 km [3.73 mi] of fiber at a

meters resolution, updates data in just a few

seconds, and interrogates numerous fibers

from one surface system. As a result, the

WellWatcher Ultra ASE lasts longer and allows

simplified completion designs, compared with

standard DTS systems.

The data obtained are available as soon

as the measurement is taken. They are

communicated via various industry-

standard protocols or those customized by

Schlumbergers engineering team to the

specifics of a particular installation. The

data are combinable with data obtained by

other Schlumberger sensors, and experts

are available to help derive the best solution

from the data to allow operators to make key

decisions with confidence.

Acquisition Results

The WellWatcher Ultra ASE acquisition sys-

tem can revitalize wells in which the optical

fiber has degraded. Accurate temperature

profiles can be obtained without the expense

of fiber replacement.

To enhance system life in the harshest well-

bore conditions, a custom-designed fiber-op-

tic solution can be obtained by combining the

ASE system with the WellWatcher BriteBlue

multimode fiber.

The graph shows distributed temperature measurements in a typical heavy-oil thermal recovery well. The surface

fiber connects to the wellhead at 150 m, after which the fiber goes downhole, carried by a control line clamped

to the completion. The temperature variation at 400 m indicates a change in the wellbore fluid level. The con-

ventional DTS system temperature plot is affected by fiber degradation, and a temperature error is induced. The

WellWatcher Ultra ASE system, on the other hand, accounts for this degradation; the graph clearly shows how the

system has corrected for an error of >45 degC.

WellWatcher Ultra ASE

Accurate single-ended distributed temperature system

The WellWatcher Ultra ASE system is designed for

challenging field conditions. It incorporates rugged

design, portability, and ease of use for field personnel.

Fiber length, m

T

e

m

p

e

r

a

t

u

r

e

,

d

e

g

C

250

200

150

100

50

0

100 200 300 400 500 600 700 800

New downhole thermocouples

WellWatcher Ultra ASE system

Conventional DTS system

Error

correction

Rev. 00 Page 33

www.slb.com/wellwatcher

WellWatcher Ultra ASE

WellWatcher Ultra ASE Specifications

Range, km [mi] 6 [3.73]

Spatial resolution, m [ft] 12 [3.36.6]

Sample interval, m [ft] 0.51 [1.643.3]

Calibration accuracy, degC [degF] 2 [3.6] at (06 km on Schlumberger fibers)

Number of loops or fibers 12 single-ended

Fiber type 50 um, multimode

DTS physical dimensions 3U 19-in, rack mounted or mobile

Operating temperature, degC [degF] 0 to 40 [32 to 104]

Storage temperature, degC [degF] 20 to 65 [4 to 149]

Relative humidity, % 585 (noncondensing)

Power AC, 90253 V (optional DC, 24 V); typical steady state: 50 W; maximum: 150 W

DTS communications

DTS to PC Ethernet 100/1,000 Base T

DTS to Modbus PLC Ethernet 10/100 Base T

Laser classification Class 1m (IEC/EN 60825-1 [2001])

*Mark of Schlumberger

Copyright 2010 Schlumberger. All rights reserved. 10-CO-0148

Invisible laser radiation

Do not view directly

with optical instruments

Class 1M laser product

INVISIBLE LASER RADIATION

DO NOT VIEW DIRECTLY

WITH OPTICAL INSTRUMENTS

CLASS 1M LASER PRODUCT

This product is affixed with

the above label.

100 450 500 550 600

200

195

190

185

180

175

WellWatcher Ultra ASE system

New downhole thermocouples

Fiber length, m

T

e

m

p

e

r

a

t

u

r

e

,

d

e

g

C

This temperature profile, acquired with the WellWatcher Ultra ASE DTS system, shows that after the system corrected for the

error induced from a degraded fiber, its measurements agreed with two independent reference points obtained from newly

installed downhole thermocouples.

Rev. 00 Page 34

Description

The Turn Around Sub is a completion

accessory tool used to provide a

downhole connection between two

control lines in order to facilitate

hydraulic communication. It comprises

of a tubing sized sub which has a

protection sleeve that covers the control

line termination.

Operation

The Turn Around Sub is made up to the

tubing string. The control lines are

terminated to an internal mini loop to

provide a hydraulic connection between

the control lines. The radius of the mini

loop is sufficient to ensure successful

deployment of double ended fiber optic

systems. The protection sleeve is then

slid up to cover the mini loop and

hydraulic connections. The sleeve is

held in place with set screws. The Turn

Around Sub is then run in hole as part of

the completion string.

Applications

Double Ended Fiber Optic Systems

Benefits

Fully protected hydraulic connections

Full tubing bore I.D.

Optimized O.D.

Features

Large bend radius for fiber

Wide range of metallurgy options

available

Threaded as per customer requirements

Available in 2-3/8 to 7 sizes

Turn Around Sub

Turn Around Sub

Standard - Hydraulic

Rev. 00 Page 35

Description

The Bullnose Pressure Port is designed

for use in Coil Tubing deployed pressure

monitoring systems. It provides a

termination of the coil tubing that allows

wellbore pressure to be transferred to a

pressure monitoring gauge installed in

the string whilst maintaining the coil

tubings pressure integrity.

Operation

This bullnose is made up of a welded coil

tubing connector and control line

pressure transfer connector. A short

length of control line is terminated to the

pressure port on the pressure monitoring

gauge. The bullnose then slides back

into the coil and is welded onto the coil

tubing.

The bullnose portion of the tool has holes

which allow well bore pressure to be

transferred to the pressure gauge via the

control line.

Applications

Coil Tubing deployed pressure monitoring

systems

Benefits

Low profile bullnose

Features

Proven Coil Tubing connector

Welded pressure barrier

Bullnose Pressure Port

Bullnose Pressure Port

Rev. 00 Page 36

Description

The Thermal Disconnect tool is utilized to

allow the deployment of coil tubing

monitoring strings alongside conventional

tubing strings. Due to differing thermal

expansion rates, the Thermal Disconnect

tool ensures that the coil tubing string will

separate from the tubing sting in a

controlled manner as thermal expansion

takes place.

Operation

This Thermal Disconnect is connected to

the lower portion of the coil tubing string

being deployed via conventional dimple

connector. The tool is then welded onto

the tubing string allowing the tubing to

drag the coil string into the well. Once

the string is deployed, as the wellbore

temperature increases, the Thermal

Disconnected tool will part the coil string

from the tubing string at a specific

temperature range. Thus the coil string

will be free from the tubing string.

Applications

Coil Tubing deployed monitoring systems

Benefits

Adjustable shear temperature

Controlled disconnect

Features

Available for all Coil Tubing sizes

Allows rotation via knuckle joint

Standard dimple connector used

Ratchet system

Thermal Disconnect

Thermal Disconnect

Rev. 00 Page 37

Description

The Shower Head provides control line

feed through for monitoring systems

deployed via coil tubing. Up to four

control lines can be managed.

Operation

The control lines exiting the coil tubing

are fed through the shower head. The

shower head is then terminated onto the

coil tubing via a swagelok connector.

Each control line passing through the

shower head is sealed to the shower

head utilizing NPT connections, thus

providing a pressure barrier between the

control lines and the coil tubing.

Applications

Coil tubing deployed monitoring systems

Benefits

Maintains pressure integrity of coil tubing

Features

Wide range of sizes to suit coil tubing

Multiple control line configurations

Simple installation at wellhead

Shower Head

Shower Head

Rev. 00 Page 38

Description

The Wellhead Outlet provides a pressure

barrier between the instrumentation

control line and the wellhead.

Operation

Multiple options are available to suit the

required Wellhead sealing configuration

including threaded and flanged profiles.

The instrumentation control line is

passed through the wellhead, the

flanged or threaded profile sealing

between the wellhead and wellhead

outlet. Inside the wellhead outlet, the

control lines are terminated to

feed-throughs that are pressure

contained. Therefore the potential for

pressure to be transmitted from the

control line to surface is contained with

the wellhead outlet.

Applications

Reservoir Monitoring and Control installations.

Benefits

Maximizes well control

Features

Multiple sealing configurations to suit

wellhead design

High pressure and temperature rating

available

Electrical / Optical feed-throughs

Wellhead Outlet

Wellhead Outlet

Rev. 00 Page 39

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Geology of BahrainDocument10 pagesGeology of BahrainKhaledFekairNo ratings yet

- Basic Geology For Oil ExplorationDocument55 pagesBasic Geology For Oil ExplorationKhaledFekair100% (1)

- Matricies ArDocument336 pagesMatricies ArKhaledFekairNo ratings yet

- Documents - MX How To Run and Cement Liners Part 1.PDFDocument6 pagesDocuments - MX How To Run and Cement Liners Part 1.PDFKhaledFekairNo ratings yet

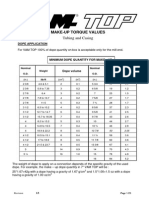

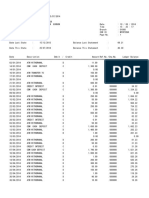

- VAM FJL Torque TableDocument17 pagesVAM FJL Torque TableKhaledFekairNo ratings yet

- VAM TOP HT Torque TableDocument16 pagesVAM TOP HT Torque TableKhaledFekairNo ratings yet

- Vam Top HC Torque TableDocument9 pagesVam Top HC Torque TableKhaledFekairNo ratings yet

- 12 Automation DraworksDocument12 pages12 Automation DraworksKhaledFekairNo ratings yet

- VAM TOP Torque TableDocument25 pagesVAM TOP Torque TableKhaledFekairNo ratings yet

- 7 Drilling Automation WITSMLDocument22 pages7 Drilling Automation WITSMLVivekSonkerNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)