Professional Documents

Culture Documents

Midas Skew Presentation - 5-14-12

Uploaded by

aiyubpatniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Midas Skew Presentation - 5-14-12

Uploaded by

aiyubpatniCopyright:

Available Formats

Practical Design Methods for

Skewed Bridges

Travis Butz, PE

Burgess & Niple, Inc.

Recurring constructability problems during deck pours

Predicted deflections disagree with field results

Decks with exposed rebar, poor finish, inconsistent

thickness

Excessive girder twist in one case, capacity of the

structure was compromised

A study was commissioned to identify causes and to

recommend solutions

- Why is this happening?

- What analysis methods are appropriate?

- How can we prevent these problems?

Ohios Skew Problems:

Skewed Bridge Behavior

Out-of-plane effects occur in skewed bridges that cannot

be predicted by line girder analysis methods (neglecting

crossframe effects).

AASHTO/NSBA Guidelines for Design for

Constructability identifies two separate issues:

Intermediate Crossframe Effects

End Crossframe Effects

FRAMING PLAN

TRANSVERSE SECTION

Test Case, Intermediate Crossframe Effects:

Line Girder

Analysis Results

Crossframe Effects

Ignored

0

1

2

3

4

5

6

0.00 50.00 100.00 150.00 200.00

Length (ft)

D

e

f

l

e

c

t

i

o

n

(

i

n

)

G2 G1 G3 G4 G5

Crossframe

Locations

Test Structure, Deflection Due to Deck Weight

Results Show:

Large differential

deflections between

interior and exterior

girders

Abrupt changes in

differential

deflection across

the width of the

bridge

D

D

Section D-D

Differential Deflection (in)

Girder Deflection (in)

Deflections Exaggerated x 12

Framing Plan

Line Girder

Analysis Results

Crossframe Effects

Ignored

Problem: If the girders are assumed to stay

vertical, the crossframes will not permit

differential deflections of this magnitude.

Conclusion: Crossframe interaction needs to be

included to accurately model structure behavior.

Line Girder Analysis Results

Crossframe Effects Ignored

Section D-D

Differential Deflection (in)

Girder Deflection (in)

Deflections

Exaggerated x 12

Differential vertical deflection causes crossframes to

deform if the girders do not twist.

Large forces are needed to create axial deformations

in the crossframe members, so resistance to this type

of deflection is very high.

Lengthened

Shortened

Twisting of the girders allows differential deflection to

occur without deforming the crossframe.

The torsional stiffness of the girders is low compared

to the stiffness of the crossframes, so this behavior

is dominant.

Undeformed

Undeformed

Refined Analysis

Results

Intermediate

Crossframe Effects

Included

Results Show:

More uniform

differential deflection

across the width of

the bridge at

crossframe locations

(compared to line

girder analysis)

Test Structure, Deflection Due to Deck Weight

0

1

2

3

4

5

6

0.00 50.00 100.00 150.00 200.00

Length (ft)

D

e

f

l

e

c

t

i

o

n

(

i

n

)

G2 G1 G3 G4 G5

Crossframe

Locations

Refined Analysis

Results

Intermediate

Crossframe Effects

Included

Section D-D

Differential Deflection (in)

Girder Deflection (in)

Deflections

Exaggerated x 12

Section D-D

Differential Deflection (in)

Girder Deflection (in)

Line Girder

Analysis Results

Crossframe Effects

Ignored

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

A

A

Deflections

Exaggerated x 12

Section A-A

Differential

Vertical

Deflection

(inches)

B

B

Deflections

Exaggerated x 12

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

Section B-B

Differential

Vertical

Deflection

(inches)

Deflections

Exaggerated x 12

Section C-C

C

C

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

Differential

Vertical

Deflection

(inches)

D

D

Deflections

Exaggerated x 12

Section D-D

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

Differential

Vertical

Deflection

(inches)

E

E

Deflections

Exaggerated x 12

Section E-E

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

Differential

Vertical

Deflection

(inches)

F

F

Deflections

Exaggerated x 12

Section F-F

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

Differential

Vertical

Deflection

(inches)

Deflections

Exaggerated x 12

Section G-G

G

G

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

Differential

Vertical

Deflection

(inches)

H

H

Deflections

Exaggerated x 12

Section H-H

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

Differential

Vertical

Deflection

(inches)

J

J

Deflections

Exaggerated x 12

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

Section J-J

Differential

Vertical

Deflection

(inches)

K

K

Deflections

Exaggerated x 12

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

Section K-K

Differential

Vertical

Deflection

(inches)

L

L

Deflections

Exaggerated x 12

Section L-L

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

Differential

Vertical

Deflection

(inches)

M

M

Deflections

Exaggerated x 12

Section M-M

Deflected Shape Due to Intermediate Crossframe Effects (Refined Analysis):

Differential

Vertical

Deflection

(inches)

Support Reactions Due to Wet Concrete Weight, Refined Analysis:

Rear Bearings

(Fixed)

Forward Bearings

(Exp.)

Rear

Bearings

(Fixed)

Forward

Bearings

(Exp.)

End Crossframe Effects

To illustrate end crossframe behavior, we will examine a 2-

girder structure with end crossframes only (no intermediate

bracing).

This illustration is adapted from Beckmann & Medlock, 2005

PLAN VIEW

The end diaphragm can be thought of as a pair of rigid

links connecting the top flange of one girder to the

bottom flange of the adjacent girder.

2-Girder Structure:

ISOMETRIC VIEW (PARTIAL)

Deflection of a Cambered Girder:

When a girder deflects, the top flange moves

longitudinally relative to the bottom flange at the

beam ends. We will define this distance as .

The end crossframe of a skewed structure restrains

the longitudinal translation of the top flange.

2-Girder Structure:

PLAN VIEW (PARTIAL)

Dx

GIRDER A

GIRDER B

The end crossframe forces the top flange to move

radially about the adjacent bearing point. The

resulting motion produces twist in the girders.

2-Girder Structure:

PLAN VIEW (PARTIAL)

Dx

D

y

GIRDER A

GIRDER B

The movement of the top flange is approximately

perpendicular to the centerline of bearings.

2-Girder Structure:

PLAN VIEW (PARTIAL)

Dx

D

y

Dx

D

y

GIRDER B

GIRDER A

Test Structure, Girder End Twist

End Crossframes Only:

Intermediate Crossframes Only:

Sign Convention: (+ Clockwise, Looking Forward - Counterclockwise, Looking Forward)

Forward

Sign Convention: (+ Clockwise, Looking Forward - Counterclockwise, Looking Forward)

Forward

Combined Effects: Girder End Twist

End Crossframes Only / Intermediate Crossframes Only:

Combined effects:

Sign Convention: (+ Clockwise, Looking Forward - Counterclockwise, Looking Forward)

Forward

Sign Convention: (+ Clockwise, Looking Forward - Counterclockwise, Looking Forward)

Forward

Evaluation of Analysis Methods

Parametric Study:

Mz

Line Girder Analysis

Girder modeled using

beam elements

Parametric Study, Analysis Methods:

Parametric Study, Analysis Methods:

Study Conclusions:

When the effects of intermediate crossframes are considered,

significant redistribution of shear and moment occurs across

the width of the structure.

For the structures studied, line girder analysis can be used to

conservatively calculate member forces for skews up to 45.

2D Grid Analysis vs. 2D Grid Analysis w/ Truss Crossframes:

Little variation was observed between the girder and intermediate crossframe forces

obtained from 2D grid analysis with truss crossframes.

The use of 2D grid analysis was shown to be generally accurate in the calculation of

moments and shears for the cases investigated.

Note that higher levels of analysis provide more precise results, and are

recommended when higher precision is needed, or with more complex structures

(variable skews, partial length girders, etc.).

2D Grid Analysis w/ Truss Crossframes vs. 3D FEM:

The moment and shear results obtained from 3D FEM analysis show general

agreement with the results obtained from 2D grid analysis with truss crossframes..

Although the 2D grid was found to be generally accurate for calculating moments and

shears for the structures investigated, 3D FEM analysis does provide more precise

results.

3D FEM is recommended for more complex structures.

Erect girders plumb

Install crossframes

Girders rotate out of plumb during deck placement

Girders will be permanently twisted

Question: How much twist is acceptable?

Detailing Methods

Method 1 Steel dead load fit members are detailed to fit with webs

plumb with steel dead load on the structure, but not the deck load

Detailing Methods

Method 2 Full dead load fit members are detailed to fit with webs

plumb with full non-composite dead load of steel and concrete.

Erect girders out-of-plumb

Install crossframes

Girders rotate to vertical during deck placement

Girders webs will be vertical in the finished structure

Detailing Methods

Method 2 Full dead load fit members are detailed to fit with webs

plumb with full non-composite dead load of steel and concrete.

This method is generally recommended for skewed bridges by

industry experts.

ODOT is not comfortable with erecting girders in an out-of-plumb

position. Steel Dead Load fit is required by ODOT policy.

Detailing Methods

Method 3 Lean-on Bracing

Use of an alternative lateral bracing system to minimize or

eliminate intermediate crossframe effects.

Some crossframes are replaced with top and bottom struts only

during the deck pour

Lean-on braces allow differential vertical deflection to occur

between girders without inducing twist.

Lean-on Bracing

Two types: Internal and External

In an Internal Lean-on System, bracing is provided by a

crossframe located within the portion of the structure that is

being loaded.

X X

X

X X

X

A

A

Section A-A

Lean-on Bracing

Internal Lean-on System

In an internal system, crossframe locations can be selected

strategically to minimize twist in the system. Designers

must perform calculations to ensure adequate strength and

stiffness are provided.

Lean-on Bracing

External Lean-on System

In an External Lean-on System, the structure is braced

against an external support or a portion of the structure

that will not be loaded during the deck pour.

Can girder twist be calculated using line girder results?

For low skews, girder twist can be

estimated using line girder analysis.

From AASHTO/NSBA Steel Bridge

Erection Guide Specification, erection

tolerance = 1/8 per foot of web depth

Data shows this method to be conservative

up to a 45 skew.

ODOT Policy:

Skewed Bridge Design Process

Check That Design

Rates Using PC-BARS

Skew > 45

Girder Twist

< 1/8/ft?

Girder Twist

< 1/8/ft?

No

Girder Twist

< 1/8/ft?

No

Implement External

Lean-on Bracing

Implement Internal

Lean-on Bracing with

Refined Analysis

No

Finish Design

Using Refined Analysis:

Erect Girders Vertical

And Allow To Rotate

Check That Design

Rates Using PC-BARS

Yes

Yes

Differential

Deflections

< S/100

30 < Skew 45

Perform Line Girder

Analysis

Stiffen Design:

0% to 25%

Additional Steel

Differential

Deflections

< S/100

No

No

Design Using Line

Girder Analysis

Yes

Yes

Yes

Stiffen Design:

0% to 25%

Additional Steel

Perform

Refined

Analysis

Differential

Deflections

< S/100

30 < Skew 45

Perform Line Girder

Analysis

Design Using Line

Girder Analysis

Check That Design

Rates Using PC-BARS

Yes

S

f

f

ODOT Policy:

Skewed Bridge Design Process

Differential

Deflections

< S/100

30 < Skew 45

Perform Line Girder

Analysis

Design Using Line

Girder Analysis

Check That Design

Rates Using PC-BARS

Stiffen Design:

0% to 25%

Additional Steel

Differential

Deflections

< S/100

Yes

No

Stiffen design: Increase

Optimized steel design

0% to 25% (By Weight)

Increase depth

Increase flange sizes

Add girder(s)

ODOT Policy:

Skewed Bridge Design Process

Differential

Deflections

< S/100

30 < Skew 45

Perform Line Girder

Analysis

Stiffen Design:

0% to 25%

Additional Steel

Girder Twist

< 1/8/ft?

Finish Design

Using Refined Analysis:

Erect Girders Vertical

And Allow To Rotate

Differential

Deflections

< S/100

No

Yes

Check That Design

Rates Using PC-BARS

No

1/8

1

f

Perform

Refined

Analysis

ODOT Policy:

Skewed Bridge Design Process

Differential

Deflections

< S/100

30 < Skew 45

Perform Line Girder

Analysis

Stiffen Design:

0% to 25%

Additional Steel

Girder Twist

< 1/8/ft?

Finish Design

Using Refined Analysis:

Erect Girders Vertical

And Allow To Rotate

Differential

Deflections

< S/100

No

Check That Design

Rates Using PC-BARS

No

Girder Twist

< 1/8/ft?

No Stiffen Design:

0% to 25%

Additional Steel

Girder Twist

< 1/8/ft?

Implement Internal

Lean-on Bracing with

Refined Analysis

No

Yes

Perform

Refined

Analysis

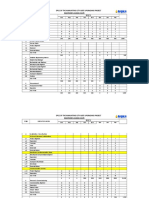

ODOT Policy:

Skewed Bridge Design Process

Differential

Deflections

< S/100

30 < Skew 45

Perform Line Girder

Analysis

Stiffen Design:

0% to 25%

Additional Steel

Girder Twist

< 1/8/ft?

Differential

Deflections

< S/100

No

Implement Internal

Lean-on Bracing with

Refined Analysis

Girder Twist

< 1/8/ft?

Check That Design

Rates Using PC-BARS

Implement External

Lean-on Bracing

No

No Perform

Refined

Analysis

Girder Twist

< 1/8/ft?

Stiffen Design:

0% to 25%

Additional Steel

No

ODOT Policy:

Skewed Bridge Design Process

Check That Design

Rates Using PC-BARS

Skew > 45

Girder Twist

< 1/8/ft?

Girder Twist

< 1/8/ft?

No

Girder Twist

< 1/8/ft?

No

Implement External

Lean-on Bracing

Implement Internal

Lean-on Bracing with

Refined Analysis

No

Finish Design

Using Refined Analysis:

Erect Girders Vertical

And Allow To Rotate

Check That Design

Rates Using PC-BARS

Yes

Yes

Differential

Deflections

< S/100

30 < Skew 45

Perform Line Girder

Analysis

Stiffen Design:

0% to 25%

Additional Steel

Differential

Deflections

< S/100

No

No

Design Using Line

Girder Analysis

Yes

Yes

Yes

Stiffen Design:

0% to 25%

Additional Steel

Perform

Refined

Analysis

ODOT Policy:

Skewed Bridge Design Process

Bottom Chord

End Armor

ODOT Policy: End Crossframes

For skews > 30 degrees, do not install end crossframe diagonals

until deck placement in the adjacent span is complete

End Armor

Bottom Chord

Diagonals

Condition at Deck

Placement:

Note that the girder

ends are unbraced.

Temporary bracing

may be required.

Final Condition:

Diagonals installed

Refined Analysis using Midas Civil:

In midas civil user can model the construction sequence considering

the girder lift, installation and the deck pouring sequence.

The shell elements works well in determination of the girder twist. A

study has been done in midas civil for the determination of the girder

twist during the deck pouring.

The following pouring sequence has been assumed:

Stage 1

Stage 2

Stage 3

The following Stages were modeled:

1. Stage 1: Steel Girders are installed and self weight of steel is activated.

2. Stage 2: The scaffolding load is activated. The load is activated in the

following fashion for the overhangs:

3. Stage 3: The deck dead load is activated for the deck pour 1.

4. Stage 4: The deck dead load is activated for the deck pour 2.

5. Stage 5: The deck dead load is activated for the deck pour 3.

Deformation Results:

Twisting during deck 1 pouring

Deformation Results:

Twisting during deck 2 pouring

Deformation Results:

Twisting during deck 3 pouring

=> Twisting can be accurately

estimated by Midas Civil so

that proper measures can be

taken

Questions?

travis.butz@burgessniple.com

You might also like

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- ACI 214.3 (R1997) SimpleVersion-RP-Eval-StrengthTestResults-Concrete PDFDocument8 pagesACI 214.3 (R1997) SimpleVersion-RP-Eval-StrengthTestResults-Concrete PDFphilipyapNo ratings yet

- Mechanics of Solids: ColumnsDocument23 pagesMechanics of Solids: ColumnsZabid UllahNo ratings yet

- FRP Profiles 2016 ShahverdiDocument38 pagesFRP Profiles 2016 ShahverdiPhạm Trung HiếuNo ratings yet

- L3 PQRforQualificationDocument1 pageL3 PQRforQualificationBernardo LeorNo ratings yet

- Hand Book Containing General Information For The Use of Engineers Architects and Builders 1914 PDFDocument460 pagesHand Book Containing General Information For The Use of Engineers Architects and Builders 1914 PDFEliNo ratings yet

- Design of Coastal Revetments, Seawalls, and BulkheadsDocument110 pagesDesign of Coastal Revetments, Seawalls, and BulkheadsSøren MørchNo ratings yet

- Singular ErrorDocument12 pagesSingular ErrorIyamperumal MurugesanNo ratings yet

- Vicroads - Mass LimitsDocument2 pagesVicroads - Mass LimitsHicran DeğerliNo ratings yet

- Recent Major Bridges in KoreaDocument12 pagesRecent Major Bridges in KoreaMario Alejandro Suarez RodriguezNo ratings yet

- International Codes For Unbonded Post-Tensioned Precast Concrete StructuresDocument13 pagesInternational Codes For Unbonded Post-Tensioned Precast Concrete StructurespriyanaNo ratings yet

- HSC in As5100Document21 pagesHSC in As5100Mahbub AlamNo ratings yet

- Mechanics of Solids: Transformations of Stress and StrainDocument33 pagesMechanics of Solids: Transformations of Stress and StrainZabid UllahNo ratings yet

- 2 Track Stucture 3 (Track Engineering)Document37 pages2 Track Stucture 3 (Track Engineering)ReginaldoPinhoNo ratings yet

- Diff Strain Concrete 13 1 FinalDocument8 pagesDiff Strain Concrete 13 1 FinalDoug JenkinsNo ratings yet

- Encased ColumnsDocument14 pagesEncased ColumnsjimmyfontanaNo ratings yet

- Example 4 - Drilled-Shaft FootingDocument99 pagesExample 4 - Drilled-Shaft FootingAriel Gonzalez100% (1)

- Nisava River BridgeDocument17 pagesNisava River BridgeAlin ApoNo ratings yet

- Fatigue Strength of Welded ComponentsDocument40 pagesFatigue Strength of Welded ComponentsVinit Ahluwalia100% (1)

- AASHTO LRFD ShearConnector PDFDocument11 pagesAASHTO LRFD ShearConnector PDFAshraf Mohamed YehiaNo ratings yet

- Plant Structure TutorialDocument48 pagesPlant Structure TutorialAmitabha DebNo ratings yet

- STR Des PP Lec1Document48 pagesSTR Des PP Lec1esmailNo ratings yet

- Management of Fatigue Cracking West Gate Bridge, Melbourne PDFDocument9 pagesManagement of Fatigue Cracking West Gate Bridge, Melbourne PDFAVSSSNo ratings yet

- Large-Scale Testing of Steel Reinforced Concrete (SRC) Coupling BeamsDocument21 pagesLarge-Scale Testing of Steel Reinforced Concrete (SRC) Coupling BeamsMREFAATNo ratings yet

- Hilti HIT System - Rebar ApplicationDocument34 pagesHilti HIT System - Rebar ApplicationTerence CheeNo ratings yet

- Tapered BeamDocument3 pagesTapered Beamlamkinpark3373No ratings yet

- Kanis-The Riddle of Shear Failure and Its SolutionDocument28 pagesKanis-The Riddle of Shear Failure and Its SolutionHarish Kant SoniNo ratings yet

- Alberta Infrastructure Bridge AestheticsDocument70 pagesAlberta Infrastructure Bridge AestheticsShikhar SinghNo ratings yet

- Global Analysis of The Sutong Cable-Stayed Bridge: Jiawu Miao Rucheng Xiao Minshan PeiDocument6 pagesGlobal Analysis of The Sutong Cable-Stayed Bridge: Jiawu Miao Rucheng Xiao Minshan PeiaiyubpatniNo ratings yet

- First Prs EditedDocument38 pagesFirst Prs EditedMathew SebastianNo ratings yet

- 07 2016 RADBUG BRR Post Tensioned Box Presentation SWoodDocument31 pages07 2016 RADBUG BRR Post Tensioned Box Presentation SWoodMaria Plaza GarciaNo ratings yet

- 8 Cable Stayed Forward UnknownDocument14 pages8 Cable Stayed Forward Unknownmukasa1972No ratings yet

- Wind Tunnel Testing of BridgeDocument28 pagesWind Tunnel Testing of BridgePACO PAQUETINESNo ratings yet

- 02 Bridge Wizard 1.2Document19 pages02 Bridge Wizard 1.2Rhobbie NolloraNo ratings yet

- AD 428 - Draft Guidance - Lateral and Torsional Vibration of Half-Through Truss Footbridges, March 2019Document1 pageAD 428 - Draft Guidance - Lateral and Torsional Vibration of Half-Through Truss Footbridges, March 2019symon ellimacNo ratings yet

- State Highway FEDERAL AID PROJECT NO. STBG-9999-07 (384) : Plan and Profile of ProposedDocument66 pagesState Highway FEDERAL AID PROJECT NO. STBG-9999-07 (384) : Plan and Profile of Proposedcharles blairNo ratings yet

- Transverse Design of RC Hollow Box Bridge GirderDocument8 pagesTransverse Design of RC Hollow Box Bridge GirderEsmeraldNo ratings yet

- 1971 - Vibration and Deflection of Steel BridgesDocument12 pages1971 - Vibration and Deflection of Steel Bridgesryan rakhmatNo ratings yet

- Most Critical Interior PanelDocument1 pageMost Critical Interior PanelKagwi MauriceNo ratings yet

- Ba3993 Assesment of Reinforced Concrete Half-JointedDocument22 pagesBa3993 Assesment of Reinforced Concrete Half-JointedvaleNo ratings yet

- 6 - Construction Stage Analysis For ILMDocument72 pages6 - Construction Stage Analysis For ILMkom1984No ratings yet

- AASHTO Load Distribution of Horizontally Curved BridgesDocument10 pagesAASHTO Load Distribution of Horizontally Curved BridgesmabuhamdNo ratings yet

- Lecture 1Document49 pagesLecture 1Vishwaleen RamNo ratings yet

- Effect of Torsion On Externally Prestressed Segmental Concrete Bridge With Shear Key PDFDocument7 pagesEffect of Torsion On Externally Prestressed Segmental Concrete Bridge With Shear Key PDFVinothAyyasamyNo ratings yet

- 2011 Bridge SarkadyDocument17 pages2011 Bridge SarkadyTan Duy LeNo ratings yet

- Von Mises Stresses ExpalinedDocument9 pagesVon Mises Stresses ExpalinedYaselaNo ratings yet

- Ba16 97Document83 pagesBa16 97yeezhexiang100% (1)

- Improved Live Load Deflection Criteria For Steel BridgesDocument147 pagesImproved Live Load Deflection Criteria For Steel BridgesChester SmithNo ratings yet

- Hilti Hit RE 500 - Hilti Aust Pty LTDDocument5 pagesHilti Hit RE 500 - Hilti Aust Pty LTDBiju_PottayilNo ratings yet

- Goodco Z Tech Spherical BearingsDocument20 pagesGoodco Z Tech Spherical BearingsRusandi NoorNo ratings yet

- Steel Composite Bridge-5100Document27 pagesSteel Composite Bridge-5100Mahesh SurlaNo ratings yet

- AASHTO LRFD Bridge Design Specifications: Service IV Load CombinationDocument2 pagesAASHTO LRFD Bridge Design Specifications: Service IV Load CombinationRahul ChauhanNo ratings yet

- Six Pile Cap Reinforced ConcreteDocument9 pagesSix Pile Cap Reinforced ConcreteFaheem KhanNo ratings yet

- Braking and TractionDocument50 pagesBraking and TractionNazmulNo ratings yet

- OTEC (Kanawha River Bridge) S WilliamsonDocument59 pagesOTEC (Kanawha River Bridge) S Williamsonstevewv100% (1)

- 1992 Esdep Boxgirders AdvancedmethodsDocument16 pages1992 Esdep Boxgirders Advancedmethodsvishal varshneyNo ratings yet

- Footbridge VibrationDocument11 pagesFootbridge VibrationandreaNo ratings yet

- Typical Beam SectionDocument1 pageTypical Beam SectionaiyubpatniNo ratings yet

- Crack Spacing: Early Age Crack WidthDocument4 pagesCrack Spacing: Early Age Crack WidthaiyubpatniNo ratings yet

- Egress Shaft EarthpressureCoefficientDocument1 pageEgress Shaft EarthpressureCoefficientaiyubpatniNo ratings yet

- Rom Highlight-: (ROM) (MOD) XOLO Nexus V2-For Xolo Q800/Fly IQ446/Gionee Gn708w/symphony w125Document8 pagesRom Highlight-: (ROM) (MOD) XOLO Nexus V2-For Xolo Q800/Fly IQ446/Gionee Gn708w/symphony w125aiyubpatniNo ratings yet

- MinarDocument1 pageMinaraiyubpatniNo ratings yet

- Neural Network Based RCC Column Design 771Document6 pagesNeural Network Based RCC Column Design 771aiyubpatniNo ratings yet

- Indian SpicesDocument4 pagesIndian SpicesaiyubpatniNo ratings yet

- Global Analysis of The Sutong Cable-Stayed Bridge: Jiawu Miao Rucheng Xiao Minshan PeiDocument6 pagesGlobal Analysis of The Sutong Cable-Stayed Bridge: Jiawu Miao Rucheng Xiao Minshan PeiaiyubpatniNo ratings yet

- Elastomeric BearingsDocument10 pagesElastomeric BearingsaiyubpatniNo ratings yet

- Design and Analysis of Composite Drive Shaft For Automotive Application IJERTV3IS110410Document8 pagesDesign and Analysis of Composite Drive Shaft For Automotive Application IJERTV3IS110410frindgeNo ratings yet

- E Yanmar 2v78caDocument42 pagesE Yanmar 2v78caDannyNo ratings yet

- Metric Hex Bolt ChartsDocument1 pageMetric Hex Bolt ChartsPraburamNo ratings yet

- Permalok Steel Casing Pipe For Microtunneling and Other Jacking ApplicationsDocument36 pagesPermalok Steel Casing Pipe For Microtunneling and Other Jacking Applicationsvmi_dude100% (2)

- Plant Underground Services DesignDocument27 pagesPlant Underground Services DesignbushraNo ratings yet

- Innova M3 New: 3. InstallationDocument8 pagesInnova M3 New: 3. InstallationAndreea DanielaNo ratings yet

- Abul Hassan Haveli Case StudyDocument10 pagesAbul Hassan Haveli Case StudyAyush RawatNo ratings yet

- Project Work-2 For - Interior Design and Retail ClientDocument59 pagesProject Work-2 For - Interior Design and Retail ClientGursharan SinghNo ratings yet

- CATALOG 4660-Thermoplastic HoseDocument339 pagesCATALOG 4660-Thermoplastic HoseJose Antonio GomezNo ratings yet

- Boq G+0Document44 pagesBoq G+0elias workuNo ratings yet

- Beton DrucrciDocument7 pagesBeton DrucrciCedrick TchoundaNo ratings yet

- Product Guide Fiber Reinforced Polymer (GFRP) Bars For Concrete ReinforcementDocument9 pagesProduct Guide Fiber Reinforced Polymer (GFRP) Bars For Concrete ReinforcementBayram Aygun100% (1)

- SFSDFDocument1 pageSFSDFbillNo ratings yet

- T-216.02-8 Rev3 Nov2014Document1 pageT-216.02-8 Rev3 Nov2014Suyudi Akbari HabibiNo ratings yet

- Section 1720 Data - 2Document10 pagesSection 1720 Data - 2Andri AjaNo ratings yet

- H00707Document2 pagesH00707AQUILES CARRERANo ratings yet

- Asrafeege Calc Sheet PDFDocument8 pagesAsrafeege Calc Sheet PDFSaaidhNo ratings yet

- 3-98-00 Spec. For Steam Inerting Valve StationDocument11 pages3-98-00 Spec. For Steam Inerting Valve StationlightsonsNo ratings yet

- Deformed Reinforcing Bars Prices Per Length - PHILCON PRICES PDFDocument1 pageDeformed Reinforcing Bars Prices Per Length - PHILCON PRICES PDFjohn reyesNo ratings yet

- Underwater ConstructionDocument38 pagesUnderwater ConstructionAradhana SinghNo ratings yet

- STAAD Pro Basic CommandsDocument2 pagesSTAAD Pro Basic CommandsRajesh Kumar R K91% (11)

- Analysis and Design of Noncompact and Slender Concrete-Filled Steel Tube (CFT) Beam-ColumnsDocument20 pagesAnalysis and Design of Noncompact and Slender Concrete-Filled Steel Tube (CFT) Beam-Columnsclam2014No ratings yet

- Interactive Var Dex Ros CA DoDocument412 pagesInteractive Var Dex Ros CA Dorafa1425No ratings yet

- Manpower HistogramDocument15 pagesManpower HistogramZaem Afifi100% (3)

- Casement WindowsDocument45 pagesCasement WindowsТијана Радиновић100% (1)

- PLAXIS - 1605 1615 1715 Structural Elements ExcavationsDocument13 pagesPLAXIS - 1605 1615 1715 Structural Elements ExcavationsBojan Bogdanovic100% (2)

- Hydraulic Jacking SystemDocument21 pagesHydraulic Jacking SystemGan Chee SienNo ratings yet

- FMDS0281 Fire Protection System Inspection, Testing and MaintenanceDocument52 pagesFMDS0281 Fire Protection System Inspection, Testing and Maintenancejulioagricola35No ratings yet

- Sae 1080Document1 pageSae 1080bharathi_pmNo ratings yet

- StrengthDocument74 pagesStrengthAdrianKarlBonaNo ratings yet