Professional Documents

Culture Documents

JSA For Electrical Testing

Uploaded by

Achmad Djadjang0%(1)0% found this document useful (1 vote)

3K views5 pagesRon J ones and Smith Constructors, Inc. Are the project managers for the south bake furnace rebuild project in lake charles, louisiana. The work involves electrical check-out and testing in live panels.

Original Description:

Original Title

JSA for Electrical Testing

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRon J ones and Smith Constructors, Inc. Are the project managers for the south bake furnace rebuild project in lake charles, louisiana. The work involves electrical check-out and testing in live panels.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

3K views5 pagesJSA For Electrical Testing

Uploaded by

Achmad DjadjangRon J ones and Smith Constructors, Inc. Are the project managers for the south bake furnace rebuild project in lake charles, louisiana. The work involves electrical check-out and testing in live panels.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

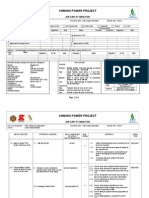

S-AF-059 19 Aug 04

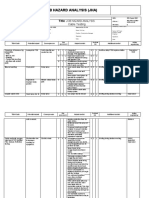

JOB SAFETY ANALYSIS Date: 06/1-/2007

Contractor Name: J ones & Smith Constructors. Project Plant Location: Lake Charles, LA Revised 06/26/2007

Sub-Tier Contractor Name: Acme Constructors

Prepared By: Ron J ones

Project: South Bake Furnace Rebuild Project No.: XXXX-0000 Contract/PO No.: XXXX-2

Location (e.g., building, area, etc.): South Bake Furnace East and West Crane

Work Scope/Description: Electrical Check-out and Testing in live panels

Specific Work Location(s): South Bake Furnace East and West Crane

Name Primary/Phone # Secondary/Phone #

Contractor Contact Person(s): Ron J ones 555-555-2222 555-555-3333

Alcoa SPA: Tom Smith 555-555-4444 555-555-5454

Plant Emergency No.: 333 555-555-4545

Prejob Walkthrough Conducted: Yes No

KNOWN OR POTENTIAL HAZARDS

Yes No Reference Yes No Reference

1. Hazardous Waste

Operations

29 CFR 1910.120 17. Noise Exposure ASP.653.3002

2. Confined Space ASP.653.3010 18. Temperature Extremes

ASP.653.3000

/.3003

3. Hot Work ASP.653.2308 19. Hoisting & Rigging ASP.653.2202

4. Roof Work ASP.653.2321

20. Ergonomics:

Repetitive Motion /

Awkward Positions /

Same Position (s)

ASP.653.3011

5. Fall Hazards (>6 ft) ASP.653.2001 21. Biological ASP.653.2102

6. Excavation/Trenching ASP.653.2311

22. Insects / Varmints /

Vermin

ASP.653.2102

7. Scaffolds / Ladders ASP.653.2302/2303 23. Signs and Barricades ASP.653.2300

8. Aerial Lifts ASP.653.2205

24. Location Specific

Emergency

Response Plan

ASP.653.1007

9. Heavy Equipment ASP.653.2200 Series 25. Air Effluent Discharges ASP.653.4003

10. Lock and Tag ASP.653.2315

26. Water/Liquid Effluent

Discharges

ASP.653.4004

11. Site/Vehicle Traffic ASP.653.1005/.2300 27. Fatality Prevention ASP.653.1400

12. Electrical Hazards ASP.653.2309/.2310

13. Asbestos Work ASP.653.3001

28. Associated w/Significant

Environmental Aspects?

ASP.653.4000

Series

14. Lead Work ASP.653.3005 = Requires formal/special training

15. Hazardous

Materials/MSDS

ASP.653.2100/.3007 = Requires a permit/form/report

16. Respiratory Hazards ASP.653.3008 = Requires certification or Competent/Qualified Person

SPECIFIC HAZARD ANALYSIS AND SAFE WORK REQUIREMENTS

Known and/or potential hazards are further evaluated, and specific measures are identified on subsequent pages. This discussion must include

identification of the work activity, the specific hazards present, and the safe work requirements/controls (including a hazards assessment for PPE)

to be used to alleviate/control the hazard(s).

MINIMUM DRESS/PPE REQUIREMENTS: hard hats, safety glasses, electrical hazard-rated metatarsal boots with hard toes, and long pants

and shirt with sleeves made of 100% cotton or wool (or cotton/blend).

REVIEW

KNOWN AND/OR POTENTIAL HAZARDS ARE FURTHER EVALUATED, AND SPECIFIC CONTROL MEASURES

ARE IDENTIFIED ON SUBSEQUENT PAGES

Project Engineer Date Alcoa Single Point Accountable Date

Contractor Supervision Date (Optional) Date

S-AF-059 19 Aug 04

Project: XXXX-0000

JOB SAFETY ANALYSIS

(Continuation Page)

Contract/P.O./Release No.: XXXX-2

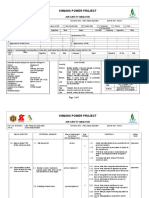

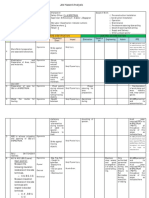

Work Activity Hazards Present Required Safety Measures/PPE

Electrical Inspection

Bridge

Trolley

Anode Hoist

Suction Pipe

Filling Pipe

Blower

Electric Shock Hazard if contacted

Arc Hazard from exposed electric equipment

Maintain safe working distance (per NFPA

70E, stated as "AVOID CONTACT" for 120

volts and one (1) foot for 480 volts for qualified

workers) and wear level 1 (Category 1) PPE

Equipment. This equipment consist of:

Hardhat, Safety Glasses, Cotton

Long Sleve Shirt and Pants, Safety

Shoes

Electrical Testing and verification of 120 volt

Control system in the MCC Room.

Bridge Panel

Trolley Panel

Anode Hoist Panel

Suction Pipe Panel

Filling Pipe Panel

Blower Panel

Electric Shock Hazard if contacted. Arc

Hazard from exposed electric equipment

120 VAC and 480 VAC components are in

close proximity

Maintain safe working distance (per NFPA

70E, stated as "AVOID CONTACT" for 120

volts and one (1) foot for 480 volts for qualified

workers) and wear level 1 (Category 1) PPE

Equipment. This equipment consist of:

Hardhat, Safety Glasses, Cotton

Long Sleve Shirt and Pants, Safety

Shoes

All 480 volt components must be guarded to

shield from accidental contact.

Complete form S-AF-061 Energized Electrical

Work Permit.

Electrical Testing and verification of 120 volt

Control system in Panels 3K & 8K:

Suction Pipe Controls

Filling Pipe Controls

Motorized valve Controls

Lighting Systems

Controls General

Electric Shock Hazard if contacted

Minimal Arc Hazard from exposed electric

equipment

120 VAC and 480 Volt AC components are in

close proximity

Maintain safe working distance (per NFPA

70E, stated as "AVOID CONTACT" for 120

volts and one (1) foot for 480 volts for qualified

workers) and wear level 1 (Category 1) PPE

Equipment. This equipment consist of:

Hardhat, Safety Glasses, Cotton

Long Sleve Shirt and Pants, Safety

Shoes

All 480 volt components must be guarded to

shield from accidental contact.

Complete form S-AF-061 Energized Electrical

Work Permit.

Electrical Testing and verification of 120 volt

Control system in New Crane Cab:

General Controls

Electric Shock Hazard if contacted

Minimal Arc Hazard from exposed electric

equipment

Maintain safe working distance (per NFPA

70E, stated as "AVOID CONTACT" for 120

volts and one (1) foot for 480 volts for qualified

workers) and wear level 1 (Category 1) PPE

Equipment. This equipment consist of:

Hardhat, Safety Glasses, Cotton

Long Sleve Shirt and Pants, Safety

Shoes

Complete form S-AF-061 Energized Electrical

Work Permit.

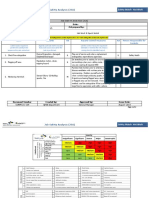

Electrical verification of 480 Power feeders in

the MCC Room to the following:

Main Crane Power

Bridge Motor

Trolley Motor

Anode Hoist Motor

Suction Pipe Motor

Filling Pipe Motor

Electric Shock Hazard if contacted

Arc Hazard from exposed electric equipment

120 VAC and 480 VAC components are in

close proximity

Maintain safe working distance (per NFPA

70E, stated as "AVOID CONTACT" for 120

volts and one (1) foot for 480 volts for qualified

workers) and or wear level 2 (Category 2) PPE

Equipment. This equipment consist of:

Hardhat, Safety Glasses, Cotton

Long Sleve Shirt and Pants, Safety

Shoes, FR Smock Cal Rating of 8,

1000 volt rated gloves, arc face shield

Complete form S-AF-061 Energized Electrical

Work Permit.

S-AF-059 19 Aug 04

Project: XXXX-0000

JOB SAFETY ANALYSIS

(Continuation Page)

Contract/P.O./Release No.: XXXX-2

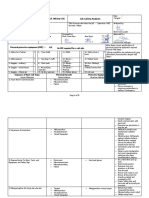

Work Activity Hazards Present Required Safety Measures/PPE

Electrical verification of 480 Power feeders in

Panels 3K & 8K:

Motorized valves

Lighting Transformer

Compressor Motor

Electric Shock Hazard if contacted

Arc Hazard from exposed electric equipment

120 VAC and 480 VAC components are in

close proximity

Maintain safe working distance (per NFPA

70E, stated as "AVOID CONTACT" for 120

volts and one (1) foot for 480 volts for qualified

workers) and/or wear level 2 (Category 2) PPE

Equipment. This equipment consist of:

Hardhat, Safety Glasses, Cotton

Long Sleve Shirt and Pants, Safety

Shoes, FR Smock Cal Rating of 8,

1000 volt rated gloves, arc face shield

Complete form S-AF-061 Energized Electrical

Work Permit.

.

Lock out disconnects at column S-1 and S-3 for

west crane and column S-17 and S-20 for the

east crane per MES procedure.

Verify zero energy at the crane buss or at

power terminal blocks in panel 1K.

Arc hazard during verification. Maintain safe working distance (per NFPA

70E, stated as "AVOID CONTACT" for 120

volts and one (1) foot for 480 volts for qualified

workers) and wear level 1 (Category 1) PPE

Equipment. This equipment consist of:

Hardhat, Safety Glasses, Cotton

Long Sleve Shirt and Pants, Safety

Shoes

Voltage test both sides of the disconnect to

verify the power is off and no voltage is

present

Ergonomics awkward position - working on

hands and knees.

Back strain

Cumulative knee trauma

Stretching before start of work. Take frequent

breaks to stretch back.Use some type of

padding under knees, take frequent breaks

Emergency events Exposure plant emergencies such as imclement

weather

Site specific training - Alcoa Lake Charles.

Site-specifc Emergency Plan is attached

including map of evacuation and staging areas

Fatality prevention Alcoa Fatality Prevention Program training

Fixed ladder use Slips, trips, and falls Use caution in and around ladder wells. Do not

carry tools while climbing ladders. Use a tool

belt or rope to pass up tools. Maintain three

point contact.

Congestion and trip hazards Trips and falls Area in crane is congested. Be aware of trip

hazards in area.

Working in high-noise areas Exposures to occupational noise All areas of the furnace are designated as

hearing protection area. Wear foam/rubber ear

plugs with NRR of at least 26

Barricade and sign area Unauthorized personnel entering into electrical

work area that could be exposes to electrical

energy

Barricade work area with RED barrier tape and

post signs to prevent unauthorized entry

S-AF-059 19 Aug 04

Project: XXXX-0000

JOB SAFETY ANALYSIS

(Continuation Page)

Contract/P.O./Release No.: XXXX-2

Work Activity Hazards Present Required Safety Measures/PPE

S-AF-073 20 J uly 06

PREJ OB SAFETY PLANNING SIGNOFF

J ob Specific J SA review Task Specific JSA review

I have read the attached J SA (and attachments) and understand the hazards and controls associated with this job.

Prejob meeting general Energized Electrical Work Permit

Fall Protection Work Plan

Hoisting & rigging prelift Confined space pre-entry meeting

Asbestos/Lead work plan

Lock/Tag/Try

Other (specify): _ ______________________________________________________________________________

Project Number ___ ____________________________ Project Location _ ____________________________

Date ID No. (optional) Name (Print) Signature

Person Conducting Briefing ___________ __________________ __________________________________

Print Name Signature

You might also like

- JSA For Electrical ActivitiesDocument14 pagesJSA For Electrical Activitiesdrparihary100% (2)

- Jsa. Cable Laying and TerminationDocument10 pagesJsa. Cable Laying and TerminationMon Trang NguyễnNo ratings yet

- JSA Cable DisconnectedDocument4 pagesJSA Cable Disconnectedwendypost730% (1)

- Job Safety Analysis: Cable Jointing & Termination in Wind TurbinesDocument1 pageJob Safety Analysis: Cable Jointing & Termination in Wind TurbinesPerwez2186% (7)

- JSA Cable Glanding & Wiring Termination Works 112Document5 pagesJSA Cable Glanding & Wiring Termination Works 112Francis Enriquez Tan83% (6)

- Pre Commissioning Electrical EquipmentDocument4 pagesPre Commissioning Electrical Equipmentmohammed a hseNo ratings yet

- Electrical Isolation JSA SheetDocument1 pageElectrical Isolation JSA SheetLal Dhwoj100% (2)

- Mie Hse Jha 004 - Installation of TransformerDocument5 pagesMie Hse Jha 004 - Installation of TransformerLuqman Osman67% (6)

- Job Hazard Assessment For Cable TestingDocument4 pagesJob Hazard Assessment For Cable TestingSamuel Carlos100% (2)

- Jha Energize Distribution DBDocument1 pageJha Energize Distribution DBAhmad Zahir100% (2)

- JSA FOR Shakthi ElectricalDocument8 pagesJSA FOR Shakthi Electricalwahyu nugroho100% (1)

- Jha - Transformer Installation PDFDocument6 pagesJha - Transformer Installation PDFperquino oasan0% (1)

- JSA Cable LayingDocument2 pagesJSA Cable Layingnishanth100% (2)

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- JSA Electrical Maintenance LCSDocument8 pagesJSA Electrical Maintenance LCSmohamed yasinNo ratings yet

- JSA Cable Pulling and Laying WorksDocument6 pagesJSA Cable Pulling and Laying Workskabir100% (1)

- Installation of Pannel JSADocument6 pagesInstallation of Pannel JSAOFFSHORE OFFSITENo ratings yet

- JSA - CABLE TERMINATION TITLEDocument4 pagesJSA - CABLE TERMINATION TITLESyed Yousuf Ali100% (1)

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- MV, HV LV Transformer Installation SafetyDocument6 pagesMV, HV LV Transformer Installation SafetyKiran Bhatt75% (4)

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Format for JHA WorksheetDocument4 pagesFormat for JHA WorksheetWaseem Ahmad100% (1)

- Jsa For Air Flushin & Mech. Cleaning of PipesDocument17 pagesJsa For Air Flushin & Mech. Cleaning of PipesKhuda Buksh100% (2)

- JSA-Use of Temporary Energization (Power Generator)Document4 pagesJSA-Use of Temporary Energization (Power Generator)MajdiSahnoun100% (1)

- JHA For Electrical Works - Rev. 01.Document16 pagesJHA For Electrical Works - Rev. 01.SreekumarNo ratings yet

- Jsa Psa & GisDocument3 pagesJsa Psa & GisMohammed NouzalNo ratings yet

- Changing Faulty Flood Light JSA (BoomLift)Document2 pagesChanging Faulty Flood Light JSA (BoomLift)black_3289No ratings yet

- Electrical Works Safety AnalysisDocument6 pagesElectrical Works Safety AnalysisShaikh Abu bakarNo ratings yet

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- JSA SplicingDocument3 pagesJSA Splicingluis100% (4)

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Gas Cutting JsaDocument4 pagesGas Cutting JsaMohammed Minhaj100% (1)

- JSA For Cable Tray Installation-Reviewed by CBREDocument10 pagesJSA For Cable Tray Installation-Reviewed by CBREPrakash Tiwari86% (7)

- Jsa For TELESCOPING BOOM AERIAL LIFTDocument2 pagesJsa For TELESCOPING BOOM AERIAL LIFTVipul Shankar100% (1)

- 004 Annexure D Job Safety SAnalysis JSADocument3 pages004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- Ultratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSADocument5 pagesUltratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSATFattah100% (1)

- Cable Laying Safety AnalysisDocument6 pagesCable Laying Safety AnalysisLuqman Osman100% (6)

- Jsa For Cable Tray ErectionDocument2 pagesJsa For Cable Tray Erectionanko heroNo ratings yet

- Jha Solar Transformer ProjectDocument6 pagesJha Solar Transformer Projectperquino oasanNo ratings yet

- DOCUMENT Loop Checking Activities JHADocument8 pagesDOCUMENT Loop Checking Activities JHAFrancis Enriquez Tan83% (6)

- 9686-6160-JSA-000-0041 - B1 JSA For UPS & Batteries Pre-Com & CommissioningDocument12 pages9686-6160-JSA-000-0041 - B1 JSA For UPS & Batteries Pre-Com & CommissioningKhan Wasim100% (1)

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- JSA for Scaffolding Erection, Dismantling and Other Construction WorksDocument9 pagesJSA for Scaffolding Erection, Dismantling and Other Construction Worksuttam mishra100% (1)

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDocument4 pagesMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- 01 JSA CLEANING COMPRESSOR Rev 05 015 BIDocument8 pages01 JSA CLEANING COMPRESSOR Rev 05 015 BIMohd Khaidir100% (1)

- Safely erect and install electrical equipmentDocument3 pagesSafely erect and install electrical equipmentMon Trang Nguyễn100% (5)

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- Job Safety Analysis (Rolling For MS Plates)Document1 pageJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationSantos Rex73% (15)

- JSA For Flue Gas Duct Height WorkDocument4 pagesJSA For Flue Gas Duct Height Worksubhadipmanna8No ratings yet

- Job Safety Analysis: 1 Confined Space Entry JSA ExampleDocument7 pagesJob Safety Analysis: 1 Confined Space Entry JSA Examplerashid zamanNo ratings yet

- EEEPL - JSA Light Fitting ErectionDocument6 pagesEEEPL - JSA Light Fitting ErectionnishanthNo ratings yet

- Implementing NFPA 70E Electrical Safety Standards: ST Louis, MO May 26, 2010Document52 pagesImplementing NFPA 70E Electrical Safety Standards: ST Louis, MO May 26, 2010Krishna Kusuma100% (1)

- Nfpa PresentationDocument38 pagesNfpa PresentationReativa EngenhariaNo ratings yet

- Install and maintain inline vortex flowmeterDocument58 pagesInstall and maintain inline vortex flowmeterCarlos Esteban LopezNo ratings yet

- JSA ExcavationDocument6 pagesJSA Excavationkermech21607100% (1)

- Samsung HT-Q9 Re Product or de DVD Manual de ServicioDocument51 pagesSamsung HT-Q9 Re Product or de DVD Manual de ServicionixrinNo ratings yet

- A Comparison of IEC 479-1 and IEEE STD 80 On Grounding Safety CriteriaDocument10 pagesA Comparison of IEC 479-1 and IEEE STD 80 On Grounding Safety CriteriaGohar AliNo ratings yet

- ANALYSIS OF FUEL CONSUMPTION AT STEAM POWER PLANTSDocument4 pagesANALYSIS OF FUEL CONSUMPTION AT STEAM POWER PLANTSryan hardiantoNo ratings yet

- Tesring Procedure of Electrical InstalltionDocument104 pagesTesring Procedure of Electrical InstalltionaruntiwaryNo ratings yet

- 2008win Morgan-Totten PDFDocument10 pages2008win Morgan-Totten PDFinitbashNo ratings yet

- A Comparison of IEC 479-1 and IEEE STD 80 On Grounding Safety CriteriaDocument10 pagesA Comparison of IEC 479-1 and IEEE STD 80 On Grounding Safety CriteriaGohar AliNo ratings yet

- A Comparison of IEC 479-1 and IEEE STD 80 On Grounding Safety CriteriaDocument10 pagesA Comparison of IEC 479-1 and IEEE STD 80 On Grounding Safety CriteriaGohar AliNo ratings yet

- Cathodic Protection: The BasicsDocument8 pagesCathodic Protection: The BasicsbookbumNo ratings yet

- 2 ++Switchyard+erection+for+400kVDocument56 pages2 ++Switchyard+erection+for+400kVracing.phreakNo ratings yet

- A Comparison of IEC 479-1 and IEEE STD 80 On Grounding Safety CriteriaDocument10 pagesA Comparison of IEC 479-1 and IEEE STD 80 On Grounding Safety CriteriaGohar AliNo ratings yet

- Cathodic ProtectionDocument22 pagesCathodic ProtectionFakhr-e-Alam100% (1)

- Cathodic ProtectionDocument22 pagesCathodic ProtectionFakhr-e-Alam100% (1)

- Generator Interconnection Technical GuideDocument64 pagesGenerator Interconnection Technical GuideAchmad DjadjangNo ratings yet

- ABB DA Section 8.2Document28 pagesABB DA Section 8.2ronald_chan_2No ratings yet

- Jsa - Sample Hot Tapping PDFDocument4 pagesJsa - Sample Hot Tapping PDFrongohcoleman100% (1)

- Heat Recovery Steam Generator Operation Procedure PDFDocument45 pagesHeat Recovery Steam Generator Operation Procedure PDFabuhurairaqaziNo ratings yet

- MSDS Colaquat HRCDocument2 pagesMSDS Colaquat HRCmndmatt100% (2)

- Den-Jet Ce20-500 - Super Slim Manual - Jul 2015Document31 pagesDen-Jet Ce20-500 - Super Slim Manual - Jul 2015First LastNo ratings yet

- WWW WWW WWW WWW: VU/VH SeriesDocument60 pagesWWW WWW WWW WWW: VU/VH SeriesMasrawana Mohd MasranNo ratings yet

- Hazardous Substances in RefineriesDocument35 pagesHazardous Substances in RefineriesRuqiyya Israfilova100% (2)

- Price List STARDEC E-CAT (1 Jan 23)Document4 pagesPrice List STARDEC E-CAT (1 Jan 23)anissaflrNo ratings yet

- Do Not: Use This Machine Unless You Have Been Instructed in Its Safe Use and Operation and Have Been Given PermissionDocument2 pagesDo Not: Use This Machine Unless You Have Been Instructed in Its Safe Use and Operation and Have Been Given PermissionsanthoshNo ratings yet

- Method Statement For Painting Works: ProjectDocument9 pagesMethod Statement For Painting Works: Projectfaizan khan100% (1)

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.006Document5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.006Yosua SitumorangNo ratings yet

- 505 Enhanced Instruction Manual V1Document212 pages505 Enhanced Instruction Manual V1metalshock67% (3)

- Confined Space Entry Training - PPT BabtainDocument91 pagesConfined Space Entry Training - PPT BabtainKh MoNo ratings yet

- Meinhardt EPCM India Private LimitedDocument18 pagesMeinhardt EPCM India Private LimitedAnoop PrajapatiNo ratings yet

- Safety Data Sheet: Poly (Up) Resin-Sds Page 1 of 7Document7 pagesSafety Data Sheet: Poly (Up) Resin-Sds Page 1 of 7Nguyễn Tiến DũngNo ratings yet

- Hse Risk Assessment For Civil Works, Isolators and Duct InstallationDocument6 pagesHse Risk Assessment For Civil Works, Isolators and Duct Installationvenkatesh snkNo ratings yet

- Method Statement For Pipe Support Fabrication and Installation 6423dp420 00 0030000 Rev01 PDFDocument21 pagesMethod Statement For Pipe Support Fabrication and Installation 6423dp420 00 0030000 Rev01 PDFfurkanNo ratings yet

- Benzil PDFDocument5 pagesBenzil PDFAijaz NawazNo ratings yet

- MSDS Hardener - Butanox m50Document11 pagesMSDS Hardener - Butanox m50benNo ratings yet

- Achieving Safety Through AuditingDocument73 pagesAchieving Safety Through AuditingN P Srinivasarao100% (3)

- Risk and Personnel SafetyDocument16 pagesRisk and Personnel SafetyCamille Andrea SequitinNo ratings yet

- FT43, FT44, FT46 and FT47 Ball Float Steam Traps: Installation and Maintenance InstructionsDocument32 pagesFT43, FT44, FT46 and FT47 Ball Float Steam Traps: Installation and Maintenance InstructionsMarcosNo ratings yet

- DAT SP8 Adhesives Safety Data SheetDocument6 pagesDAT SP8 Adhesives Safety Data SheetTN Prey ChannelNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesOliver Reazon RueloNo ratings yet

- COVID-19 Situation Report - Sri Lanka (07 August 2021) - 210808 - 073412Document35 pagesCOVID-19 Situation Report - Sri Lanka (07 August 2021) - 210808 - 073412nishad nilangaNo ratings yet

- K-Othrine WG250 LabelDocument12 pagesK-Othrine WG250 LabelPham TuanNo ratings yet

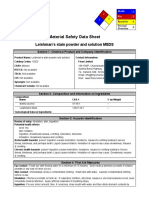

- Material Safety Data Sheet: Leishman's Stain Powder and Solution MSDSDocument5 pagesMaterial Safety Data Sheet: Leishman's Stain Powder and Solution MSDSmaha muhammedNo ratings yet

- BSE-Scrapie Antigen Test Kit MSDSDocument180 pagesBSE-Scrapie Antigen Test Kit MSDSpmarcelopontesNo ratings yet

- Hi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisDocument3 pagesHi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisPHH9834100% (1)

- Amet, TM Sample Eu Ghs CLP SdsDocument21 pagesAmet, TM Sample Eu Ghs CLP SdsEcogeneticsNo ratings yet

- Kasambahay FormsDocument6 pagesKasambahay FormsRenAraf100% (1)

- DM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFDocument5 pagesDM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFdemie figueroaNo ratings yet

- Polyacrylamide Material Safety Data SheetDocument4 pagesPolyacrylamide Material Safety Data SheetStella Avinca TantraNo ratings yet