Professional Documents

Culture Documents

Articulo Biorreactores

Uploaded by

Thomas Ramos0 ratings0% found this document useful (0 votes)

18 views7 pagesElectric current reduced (52 +11%) growth of the culture Aspergillus niger. Spores were inoculated in 450-ml electrochemical cell with titanium ruthenium-oxide coated electrodes and packed with 15 g of perlite.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentElectric current reduced (52 +11%) growth of the culture Aspergillus niger. Spores were inoculated in 450-ml electrochemical cell with titanium ruthenium-oxide coated electrodes and packed with 15 g of perlite.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views7 pagesArticulo Biorreactores

Uploaded by

Thomas RamosElectric current reduced (52 +11%) growth of the culture Aspergillus niger. Spores were inoculated in 450-ml electrochemical cell with titanium ruthenium-oxide coated electrodes and packed with 15 g of perlite.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

Enhanced hexadecane degradation and low biomass production by

Aspergillus niger exposed to an electric current in a model system

Nancy Velasco-Alvarez

a

, Ignacio Gonzlez

b

, Pablo Damian-Matsumura

c

, Mariano Gutirrez-Rojas

a,

*

a

Departamento de Biotecnologa, Universidad Autnoma Metropolitana-Iztapalapa, Av. San Rafael Atlixco 186, Col. Vicentina, Iztapalapa 09340, DF, Mexico

b

Departamento de Qumica, Universidad Autnoma Metropolitana-Iztapalapa, Av. San Rafael Atlixco 186, Col. Vicentina, Iztapalapa 09340, DF, Mexico

c

Departamento de Biologa de la Reproduccin, Universidad Autnoma Metropolitana-Iztapalapa, Av. San Rafael Atlixco 186, Col. Vicentina, Iztapalapa 09340, DF, Mexico

a r t i c l e i n f o

Article history:

Received 16 March 2010

Received in revised form 27 July 2010

Accepted 28 July 2010

Available online xxxx

Keywords:

Degradation

Hexadecane

Aspergillus niger

Electric current

Electrochemical cells

a b s t r a c t

The effects of an electric current on growth and hexadecane (HXD) degradation by Aspergillus niger

growth were determined. A 450-mL electrochemical cell with titanium ruthenium-oxide coated elec-

trodes and packed with 15 g of perlite (inert biomass support) was inoculated with A. niger (2.0 10

7

spores (g of dry inert support)

1

) and incubated for 12 days (30 C; constant ventilation). 4.5 days after

starting culture a current of 0.42 mA cm

2

was applied for 24 h. The current reduced (52 11%) growth

of the culture as compared to that of a culture not exposed to current. However, HXD degradation was

96 1.4% after 8 days whereas it was 81 1.2% after 12 days in control cultures. Carbon balances of cul-

tures not exposed to current suggested an assimilative metabolism, but a non-assimilative metabolism

when the current was applied. This change can be related to an increase in total ATP content. The study

contributes to the knowledge on the effects of current on the mycelial growth phase of A. niger, and sug-

gests the possibility of manipulating the metabolism of this organism with electric current.

2010 Elsevier Ltd. All rights reserved.

1. Introduction

The behavior of microorganisms exposed to an electric eld has

been studied for decades, especially with the aim of analyzing the

loss of viability, mobility, and the resulting changes in microbial

metabolism, including permeability (Teissi et al., 2002; Virkutyte

et al., 2002). The outcomes of application of electric currents de-

pended on the current intensity and ranged from lethal to minor

metabolic modications (Thrash and Coates, 2008). When high

voltages were applied, sterilization can be achieved (Teissi et al.,

2002). This inactivation of microorganisms is either due to thermal

effect as a result of the ohmic drop associated with the electric po-

tential (Palaniappan et al., 1992) or to the production of toxic sub-

stances generated by reactions at the electrodes, such as soluble

metallic ions and formation of free chlorine (Guillou and El Murr,

2002). Tests on yeast cells (Candida utilis, Hanseniasapora guillier-

mondii and Saccharomyces cerevisiae) using 40 kW cm

1

and bacte-

rial cultures showed a signicant decline in microbial viability

because of changes in cell morphology (Palaniappan et al., 1992).

Under a high direct electric current, electrophoretic mobility of

bacteria is related to zeta potential, i.e. the potential difference be-

tween the dispersion medium and the stationary layer of uid at-

tached to the dispersed particle charge surface on the cell (Jackman

et al., 1999). An irreversible permeability phenomenon at the cell

membrane has been observed in yeasts upon applying a high-

intensity electric current (2.75 kV cm

1

; Ganeva et al., 2002).

Low-intensity electric current application (lower than

5 mA cm

2

), has been used to control the odor and hygienic state

of wastewater slurries (Zanardini et al., 2002) and to reduce or

eliminate undesirable microbes present in food preparation pro-

cesses and conservation (Bawcom et al., 1995). Such currents have

been shown to stimulate both the production of secondary metab-

olites (Shin et al., 2002), and degradation of organic molecules

(Hyo-Sang and Lee, 2001). For example, when low-intensity elec-

tric current (1.98 mA cm

2

; 21 h) was applied on two different soil

microbial consortia, including fungi, an increase in the carbon

source (phenol; 1.2 g L

1

) consumption was observed (Xin-gang

et al., 2006). In fungi and bacteria, the CO

2

production rate in-

creased by as much as 290% (0.314 mA cm

2

; 27 d) when six differ-

ent carbon sources were assayed. Moreover, fungi and bacteria

counts in cultures with and without electric current showed no

signicant differences (Lear et al., 2004). Although most explana-

tions are correlated to membrane damage or growth inhibition,

even low-intensity can cause increases in hydrogen ion concentra-

tion inside the cytoplasm and disorganization of membrane integ-

rity. For example, Ranalli et al. (2002) have found low-intensity

electric current (0.05 and 0.5 mA cm

2

; 48 h) induced grown inhi-

bition in Saccharomyces species. Lustrato et al. (2006) demon-

strated that electric current (1 mA cm

2

; 16 d), induced changes

0960-8524/$ - see front matter 2010 Elsevier Ltd. All rights reserved.

doi:10.1016/j.biortech.2010.07.111

* Corresponding author. Tel.: +52 55 58046555; fax: +52 55 58046407.

E-mail address: mgr@xanum.uam.mx (M. Gutirrez-Rojas).

Bioresource Technology xxx (2010) xxxxxx

Contents lists available at ScienceDirect

Bioresource Technology

j our nal homepage: www. el sevi er . com/ l ocat e/ bi or t ech

Please cite this article in press as: Velasco-Alvarez, N., et al. Enhanced hexadecane degradation and low biomass production by Aspergillus niger exposed to

an electric current in a model system. Bioresour. Technol. (2010), doi:10.1016/j.biortech.2010.07.111

to the concentration of ATP in S. cerevisiae, due to changes in the

electrochemical membrane potential which affect the membrane

transport and process energy transfer. Assays with E. coli showed

that low-intensity electric current with graphite electrodes (0.6

and 1.3 mA cm

2

; 72 h) provoked no signicant changes to enzy-

matic activities and growth, but at 2.6 and 5.3 mA cm

2

inhibition

in both was observed. Bacillus cereus was not inhibited by the same

level of electric current, and at 5.3 mA cm

2

; 72 h, growth was

stimulated (Valle et al., 2007).

In this study, degradation of hexadecane and biomass produc-

tion by Aspergillus niger was investigated when exposed to low-

intensity electric current in a model system consisting of an elec-

trochemical cell packed with an inert support. ATP production

was evaluated in order to explain metabolic changes induced by

electric current.

2. Methods

2.1. Preparation of inert support and substrate application

Perlite (Dicalite, Mexico; particle size 1.191.68 mm), used as

inert support, was washed with hot water and dried at room tem-

perature. The support was impregnated with hexadecane (HXD,

Sigma) 180 mg, dissolved in 1.9 mL hexane (analytical grade; J.T.

Baker, Mexico) per g of dry inert support. Hexane was evaporated

in a laminar ow hood for 24 h at room temperature. Since our in-

ert support holds water up to 3.0 times its weight, support mois-

ture was adjusted up 75% with the liquid culture medium

(2.3 mL for g dry inert support).

2.2. Microorganism and culture medium

A. niger ATCC 9642 was incubated in potato dextrose agar (PDA;

Bioxon, Mexico) medium for 7 days (30 C) and preserved by plac-

ing three cubes of PDA with mycelia into cryotubes containing 15%

(v v

1

) glycerol and storage at 4 C. The strain was spread again

over PDA every 2 months. For growth and degradation studies,

spores were harvested with sterile 0.05% water solution of Tween

80 from 7 days old plate cultures. Per g of dry support, 2.0 10

7

spores and 2.3 mL of liquid culture medium (LCM) were added.

The medium was composed of (g L

1

), 21.2, NaNO

3

; 3, KH

2

PO

4

;

0.9, MgSO

4

; 3, KCl, and 6 mL L

1

of a trace element solution con-

taining (g L

1

), 0.100, FeSO

4

7H

2

O; 0.015, CuSO

4

5H

2

O; 0.161,

ZnSO

4

7H

2

O; 0.008, MnSO

4

7H

2

O (Volke Seplveda et al., 2006).

The pH of the medium was adjusted to 5 with 0.1 mol L

1

; H

3

PO

4

and the medium was autoclaved at 120 C for 15 min.

2.3. Electrochemical cell

The electrochemical cell (EC) 18 cm long and had a diameter of

6.5 cm. It was made of acrylic glass (poly(methyl methacrylate),

450 mL) and provided with two compartments, each containing

20 mL of electrolyte (0.1 mol L

1

; KH

2

PO

4

) and two electrodes in

titanium ruthenium-oxide coated setting with 14.13 cm

2

as con-

tact surface. Electric current was applied at up to 0.42 mA cm

2

,

corresponding to a 6 V cell potential. Fig. 1 shows the experimental

set up of the EC.

2.4. Culture conditions with and without electric current

The EC was packed with 15 g of dry inert support previously

impregnated with HXD and the spore suspension and LCM were

added. The packed EC was connected to a respirometer (Micro-

Oxymax; model System Sample Pump; Columbus Instruments,

USA). The O

2

consumption and CO

2

production were recorded

on-line during 12 days culture period. After 114 h (30 C and con-

stant ventilation) the electric current was applied for a 24 h period

by using a potentiostatgalvanostat (EG&G; PARC 173, USA), then

the electric current was disconnected. In order to measure re-

sponse variables, EC was divided into three equidistant longitudi-

nal sections between anode and cathode (4 cm per section; see

Fig. 1). The following response variables were measured in tripli-

cate for each section: pH, HXD consumption, and the production

of biomass and water-soluble metabolites. Measurements were

made on cultures with and without exposure to electric current

on 0, 4.5, 5.5, 8 and 12 days. At each time point, the whole EC

was sacriced, and for the subsequent samplings a newly prepared

culture was used. CO

2

production and O

2

consumption were eval-

uated through the whole EC.

2.5. Culture under different pH conditions

To distinguish between effects of electric current and pH, exper-

iments were performed without electric current as follows in three

500-mL Wheaton bottles, connected to the respirometer, and con-

taining 15 g of dry inert support impregnated with HXD, growth

medium and spore inocula. The bottles were incubated at 30 C

(constant ventilation) for 114 h. Then the pH was adjusted in a

gradual manner, i.e. all through the next 4 h, until the target pH re-

mained constant, simulating conditions of those experiments with

electric current. In order to simulate the middle and cathodic sec-

tion of the EC with electric current, the pH of the content of two

Wheaton bottles was adjusted to 6.4 and 9.1 with 0.1 mol L

1

Na

2

CO

3

, respectively. The third bottle was used to simulate the

behavior of the anodic section, and the pH was adjusted to 2.2 with

0.1 mol L

1

; H

3

PO

4

. Biomass production and HXD consumption

were measured on 0, 4.5, 5.5, 8 and 12 days. At each time point,

the content of the entire bottle was sacriced, and for the subse-

quent samplings, newly prepared cultures were used. Analyses

were performed in triplicate.

Fig. 1. Electrochemical cell model. (1) Titanium ruthenium-oxide coated

electrodes; (2) hermetic valve connected to respirometer for on-line CO

2

and O

2

monitoring; (3) electrolytic solution inlet; (4) reservoir for electrolytic solution; (5)

inoculated inert support packed section, and (6) power supply. EC was divided into

three equidistant longitudinal sections between anode and cathode (4 cm per

section). (i) Anodic section; (ii) middle section; and (iii) cathodic section.

2 N. Velasco-Alvarez et al. / Bioresource Technology xxx (2010) xxxxxx

Please cite this article in press as: Velasco-Alvarez, N., et al. Enhanced hexadecane degradation and low biomass production by Aspergillus niger exposed to

an electric current in a model system. Bioresour. Technol. (2010), doi:10.1016/j.biortech.2010.07.111

2.6. Biomass production

Biomass was quantied through soluble protein determination

with the Lowry (1951) method. In brief, 0.5 g dry samples were

ground with liquid nitrogen by mortar and pestle, suspended in

10 mL of 0.5 N NaOH and boiled in a water bath for 10 min. Soluble

protein was quantied in the hydrolysed samples with a commer-

cial kit (Bio-Rad Dc protein Assay Kit). A calibration curve was

obtained from biomass of A. niger grown in 250-mL shaken asks

(50-mL of liquid medium; 72 h). The biomass was vacuum ltered

with Whatman 42 paper and ground with liquid nitrogen. Soluble

protein was determined spectrophotometrically with a Varian

model Cary 50; Australia.

2.7. Determination of residual HXD

Residual HXD was extracted from 1 g of dry sample by using the

Soxhlet method US EPA 3540 (US EPA, 1996). The extracted HXD

was solubilized in hexane and quantied by gas chromatography

(Varian: model 3900; USA) using an Alltech 16367 column

(15 m 0.25 mm) and helium as carrier (30 mL min

1

; 40 psi).

The oven was heated at 120 C (30 C min

1

) then the temperature

was raised to 120150 C (10 C min

1

) and up to 150170 C

(15 C min

1

); the sample volume injected was 0.002 mL.

2.8. Determination of pH and water-soluble metabolites

One-gram samples of dry inert support were added to 10 mL of

distilled water and gently stirred for 5 min. The aqueous fraction

was used to determine pH (Conductronic pH 20) and water-soluble

metabolites were measured as total organic carbon (TOC) using a

TOC analyzer (Shimadzu: model 5000A; Australia).

2.9. Determination of carbon balances and yields

All experimental data (biomass, TOC, HXD, CO

2

and O

2

) used to

determine the carbon balances and yields were expressed as accu-

mulated averaged values for all the three EC sections (after 12 days

of culture). From our experimental values the following yields:

biomass to substrate (Y

X/HXD

), oxygen to substrate Y

O

2

=HXD

, and

carbon dioxide to substrate Y

CO

2

=HXD

, were calculated using stoi-

chiometrical balances based on one mole of C-atom derived from

HXD as the only source of carbon and energy (chemical composi-

tion: CH

2.125

); whereas a chemical composition of biomass for A.

niger CH

1.72

O

0.55

N

0.17

(Nielsen et al., 2003) was included as:

In such a theoretical assumption, four of the six stoichiometric

parameters were experimentally known: consumed oxygen (X2),

biomass production (X3), water-soluble metabolites (X4), and pro-

duced carbon dioxide (X5). The rest of the parameters were simul-

taneously solved by algebraic methods for all sampling times.

2.10. Measurement of total ATP content

Cell-free extracts were obtained by grinding 1 g of fresh sample

(inert support included) in liquid nitrogen. The material was sus-

pended in 5 mL of phosphate buffer (pH 7) and cells were broken

by sonication (Sonicor Instrument; model SC-100; Copiague, NY)

at 4 C; 5 min. Cell debris was removed by centrifugation

(18,000g; 4 C; 25 min), and the cell-free extracts were used to

determine the soluble protein by Lowry (1951) method (Bio-Rad

Dc protein Assay Kit). ATP content was determined according to

Tate and Jenkinson (1982) with some modications. In brief, a

commercial kit (ApoGlow

Assay Kit; Lonza Rockland, USA) was

used and aliquots (0.08 mL) of each sample from cell-free extracts

were placed in a 96-well plate, and 0.1 mL of NRR reagent was

added. The mixture was gently stirred, incubated for 5 min at room

temperature, and 0.02 mL of NMR reagent (luciferineluciferase)

was added. The mixture was place in a luminometer counting

chamber (Multimode Detector; model DTX 880; Beckman Coulter)

and integrated reading were taken immediately (1 s) and 10 min

later, a second 1-s integrated reading was taken. Finally, 0.02 mL

of ADP-CR reagent was added, the 96-well plate was incubated

5 min at room temperature, and a third 1-s integrated reading

was taken. The luminescence, expressed in digital relative lumines-

cence units (RLU), was then converted to ATP content according to

the calibration curve previously obtained from pure standards.

2.11. Statistical analyses

Data analyses were carried out by using NCSS-2000, version

2001 (Copyright 2001 by Jerry Hintze). Analysis of variance (ANO-

VA) was performed by comparing tests with a a < 0.05.

3. Results and discussion

3.1. Exposure time and electric current selection

In order to nd a non-lethal exposure time and electric current

intensity we assayed 8 and 19 mA corresponding to potential cell

(anodeperliteanode) of 6 and 20 V, respectively were tested. Cul-

tures were continuously exposed during 12 days. CO

2

production

was used as the response variable to decide if exposure time or

electric current were lethal and was monitored on-line. In all cases

lethal effects, neither CO

2

production nor spores germination, on A.

niger were observed. For further experiments, excessive exposure

times and sporulating forms were avoided. Therefore, after several

experiments at different exposure times initiated once spore ger-

mination was over, (114 h) and evaluating CO

2

production and

HXD degradation we selected the exposure time to be 24 h, and

8 mA as current intensity. When lower exposure time and current

were applied to A. niger mycelium CO

2

production and cell grow

were observed.

3.2. Biomass production and pH effect

Biomass quantication was performed to determine the effect

of electric current on fungal growth. Fig. 2a shows the kinetics of

biomass produced in the three different EC sections with and with-

out electric current. After applying electric current, A. niger growth

was considerably diminished throughout the entire EC. Signi-

cantly lower levels for biomass (even four times lower) with re-

spect to the EC without current (199 mg per g of dry inert

support), were observed. After cessation of the electric current

(24 h later), biomass increased in all the three EC sections; how-

ever, the total biomass produced was lower at the end of culture

than that in the EC without electric current. In both anodic and

Carbon source Nitrogen source Oxygen Biomass Water-soluble metabolites (TOC) Carbon dioxide Water

CH

2.125

X1 NO

3

X2 O

2

? X3 CH

1.72

O

0.55

N

0.17

X4 CH

2

O

0.125

X5 CO

2

H

2

O

N. Velasco-Alvarez et al. / Bioresource Technology xxx (2010) xxxxxx 3

Please cite this article in press as: Velasco-Alvarez, N., et al. Enhanced hexadecane degradation and low biomass production by Aspergillus niger exposed to

an electric current in a model system. Bioresour. Technol. (2010), doi:10.1016/j.biortech.2010.07.111

cathodic section, biomass production was similar 25 and 29 mg per

g of dry inert support, respectively (Fig. 2ai and aiii), whereas in the

middle section, higher biomass production of 65 mg per g of dry in-

ert support was observed after 12 days of culture (Fig. 2aii).

Such growth inhibiting could have been due to temperature-in-

duced lysis of (Palaniappan et al., 1992), production of toxic sub-

stances (Guillou and El Murr, 2002), or pH variation (Wenyan

et al., 2005). Temperature effects are unlikely since the tempera-

ture never exceeded 27 C. The production of toxic substances

was also unlikely since electrodes made with a titanium ruthe-

nium-oxide coating were used. Nevertheless, changes in pH could

have occurred at the electrodes (Xin et al., 2010). As our measure-

ments showed, signicant pH gradients were found varying from:

2.2 (anodic section), 5.5 (middle section) and 9.1 (cathodic sec-

tion). During experiments without electric current, pH only in-

creased one unit as compared to the initial value (from 5 to 6.3),

because of metabolic reactions during hexadecane degradation.

The Fig. 2b shows the kinetics of biomass production in experi-

ments without electric current, but at pH levels similar to those

in each EC section. At the end of culture, the biomass produced

was two and three times higher in the anodic and middle EC sec-

tion, respectively (Fig. 2bi and bii), than that observed in the

respective sections with electric current (Fig. 2ai and aii). In con-

trast, the biomass observed in both cathodic section and pH simu-

lated cathodic section (Fig. 2aiii and biii) was not signicantly

different. Therefore, our results demonstrated that A. niger grown

inhibition was mainly due to electric current effects and to pH gra-

dients to a lesser extent.

3.3. Hexadecane degradation and pH effect

Fig. 3a shows the kinetics of HXD degradation, with and without

electric current. Before electric current was applied (4.5 d), the

average HXD degradation was 38%. At the end of culture, without

electric current, degradation was 81 1.2% (as average of the cell

sections). Despite the fact that growth was inhibited, degradation

levels were signicantly higher, on average in the three EC sections

(96 1.4%), than those observed without current. With electric cur-

rent, HXD was almost depleted in the three EC sections in less than

8 days of culture.

When biodegradation rates of HXD were compared with and

without electric current, we observed a signicantly higher rate

of 27 2 mg of HXD per g of dry inert support per day on average

for the three cell sections, with respect to the EC without current

17 4 mg of HXD per g of dry inert support per day. Fig. 3b shows

the kinetics of HXD degradation in experiments without electric

current under pH conditions mimicking those in each EC section.

In all cases, only a low level of degradation of 40%, 22% and 27%

at pH 9.1, 6.3 and 2.2 respectively was observed. When results ob-

tained with the pH-adjusted cultures were compared with those

0

20

40

60

80

100

120

140

160

180

200

0 2 4 6 8 10 12

Time (days)

B

i

o

m

a

s

s

,

m

g

(

g

o

f

d

r

y

i

n

e

r

t

s

u

p

p

o

r

t

)

-

1

0

20

40

60

80

100

120

140

160

180

200

0 2 4 6 8 10 12

Time (days)

B

i

o

m

a

s

s

,

m

g

(

g

o

f

d

r

y

i

n

e

r

t

s

u

p

p

o

r

t

)

-

1

()

(i)

(ii)

(iii)

(a)

Current

ON

Current

OFF

(i)

(ii)

(iii)

pH

adjust

(b)

Fig. 2. Kinetics of biomass production: (a) experiments with and without electric

current. (b) experiments adjusting pH. (a) Symbols: () , control (without

current); (i) , anodic section, (ii) h, middle section; (iii) N, cathodic

section. (b) Symbols: (i) , pH 2.2, simulating anodic section; (ii) h, pH 6.3,

simulating middle section; (iii) N, pH 9.1, simulating cathodic section. Error bars

represent standard deviations of three replicates for all assays..

0

20

40

60

80

100

120

140

160

180

0 2 4 6 8 10 12

Time (days)

H

X

D

,

m

g

(

g

o

f

d

r

y

i

n

e

r

t

s

u

p

p

o

r

t

)

-

1

0

20

40

60

80

100

120

140

160

180

0 2 4 6 8 10 12

Time (days)

H

X

D

,

m

g

(

g

o

f

d

r

y

i

n

e

r

t

s

u

p

p

o

r

t

)

-

1

(a)

()

(i) and (ii)

(iii)

Current

ON

Current

OFF

(iii)

(ii)

(i)

pH

adjust

(b)

Fig. 3. Kinetics of hexadecane degradation: (a) Experiments with and without

electric current. (b) Experiments adjusting pH. (a) Symbols: () , control

(without current); (i) , anodic section, (ii) h, middle section; (iii) N,

cathodic section. (b) Symbols; (i) , pH 2.2, simulating anodic section; (ii) h,

pH 6.3, simulating middle section; (iii) N, pH 9.1, simulating cathodic section.

Error bars represent standard deviations of three replicates for all assays.

4 N. Velasco-Alvarez et al. / Bioresource Technology xxx (2010) xxxxxx

Please cite this article in press as: Velasco-Alvarez, N., et al. Enhanced hexadecane degradation and low biomass production by Aspergillus niger exposed to

an electric current in a model system. Bioresour. Technol. (2010), doi:10.1016/j.biortech.2010.07.111

obtained with cultures exposed to electric current, several aspects

emerged:

(i) When pH-was adjusted to 9.1, the growth was up to 17 mg

of biomass (g of inert support)

1

and HXD degradation was

the lowest attained (60%; after 12 d); while at the cathodic

section (which generated the same pH value) biomass was

as higher as 28.9 mg (g of inert support)

1

and HXD degra-

dation was 95% after 8 days of culture.

(ii) When pH-was adjusted to 6.3, the growth was 178 mg of

biomass (g of inert support)

1

and HXD degradation was

78% after 12 days of culture; while in the middle section

with electric current, biomass was 65 mg (g of inert sup-

port)

1

and HXD degradation was 95% after 8 days.

(iii) Finally, when pH-was adjusted to 2.2, the growth increased

twice as compared to anodic section where HXD degradation

was 73% after 12 d; while at the anodic HXD degradation

was 97% after 8 days.

During electric current application, without inoculum, no HXD

degradation was observed. Our results demonstrate that A. niger

is able to degrade high levels of HXD in a short period of time when

electric current is applied, suggesting that this effect is enhanced

by the electric current applied to A. niger, and does not depend

on the pH generated. Our results agree with data reported by Shin

et al. (2002) who reported that electric current (generating a volt-

age of 1.5 V) between 15 and 78 h to Clostridium thermocellum

(ATCC 35609) culture, increased ethanol production up to 52%

compared to the control (without electric current). Xin-gang

et al. (2006) demonstrated that electric current (3 V; 21 h, in

wastewater sludges), increased phenol degradation up to 33%,

compared to control (without electric current). Jackman et al.

(1999) demonstrated that under acid conditions and in the pres-

ence of an electric current (20 mA cm

2

; 80 h), growth of acido-

philic bacteria declined. All of these authors concluded that the

observed effects depended on the electric current that had passed

through the cell suspensions. Golzio et al. (2004) demonstrated

that cells can be made temporarily permeable by electric elds.

Such results suggest that HXD is probably allowed to be trans-

ported into the cell faster with electric current than without.

3.4. CO

2

production and O

2

consumption

Since O

2

consumption can be associated with the initial bio-

transformation of the carbon source (HXD), and CO

2

production

is related to mineralization of the same source, these activities

were continuously measured on-line during the 12 days of cultiva-

tion. Fig. 4 shows accumulated CO

2

production and O

2

consump-

tion kinetics.

In EC with electric current, O

2

consumption was evidently high-

er (up to fourfold) compared to control EC (without electric cur-

rent) at the end of culture (Fig. 4a). Before applying electric

current, there were no statistical differences between both condi-

tions; however, as electric current (0.42 mA cm

2

, during 24 h)

passed through the EC O

2

consumption increased (Fig. 4ai). More-

over, a higher positive-slope was maintained during and after elec-

tric current stimulation as compared to control (see Fig. 4ai and

aii). At the end of the experiments, 586 58 mg of O

2

per g of

dry inert support was consumed in EC with electric current and

151 50 mg of O

2

per g of dry inert support for the control EC.

Fig. 4b shows CO

2

production during 12 days of culture. A substan-

tial increase of up to threefold was observed in EC with electric

current as compared to the control. There were no differences in

CO

2

production during the rst 4.5 days before electric current

stimulation. After day 6, differences in CO

2

production were evi-

dent: 405 75 and 114 04 mg of CO

2

per g of dry inert support

for EC with electric current and control, (Fig. 4bi and bii), respec-

tively. These results suggest that electric stimulation induced high-

er substrate oxidation and mineralization, as compared to the

same culture in the absence of electric current.

3.5. Carbon balances and yields

Fig. 5 shows recovered carbon distributed among all carbon-

species, during 12 days of culture in EC with or without electric

current. Original carbon balances distributions were strongly mod-

ied by electric current. At the end of the culture, in the EC control

experiments (Fig. 5a), biomass production was predominantly

(76 0.09%) associated to low CO

2

yields (25 0.04%) and minimal

formation of soluble compounds (5 0.01%). On the contrary, in

current-treated EC (Fig. 5b), biomass production was as low as

13 0.01%, associated with high CO

2

yields (74 0.14%) and also

minimal formation of soluble compounds, only 4 0.01% of the to-

tal carbon distribution.

Table 1 shows yields with and without electric current, after

12 days of culture. In control EC, high Y

X/HXD

values were observed

contrasting with those with electric stimulation. The current stim-

ulation was able to increase Y

O

2

=HXD

values by more than three

times, compared to control. These results suggest that O

2

con-

0

100

200

300

400

500

600

0 2 4 6 8 10 12

Time (days)

O

2

,

m

g

(

g

o

f

d

r

y

i

n

e

r

t

s

u

p

p

o

r

t

)

-

1

0

100

200

300

400

500

600

0 2 4 6 8 10 12

Time (days)

C

O

2

,

m

g

(

g

o

f

d

r

y

i

n

e

r

t

s

u

p

p

o

r

t

)

-

1

Current

ON

Current

OFF

(a)

(i)

(ii)

(ii)

(b)

Current

ON

Current

OFF

(i)

Fig. 4. Accumulated oxygen consumption (a) and accumulated carbon dioxide

production (b), during 12 days of culture, in the presence (i), and the absence (ii) of

electric current. Error bars represent standard deviations of three replicates for all

assays.

N. Velasco-Alvarez et al. / Bioresource Technology xxx (2010) xxxxxx 5

Please cite this article in press as: Velasco-Alvarez, N., et al. Enhanced hexadecane degradation and low biomass production by Aspergillus niger exposed to

an electric current in a model system. Bioresour. Technol. (2010), doi:10.1016/j.biortech.2010.07.111

sumption in control EC was mainly used to produce biomass,

whereas O

2

consumption with electric current was mainly em-

ployed to mineralize HXD, as shown by the Y

CO

2

=HXD

yield. Our re-

sults showed changes in the metabolism of A. niger in the EC with

electric current. The carbon balances without electric current sug-

gested a more assimilative metabolic activity, which completely

changed to a non-assimilative, when electric current was applied.

3.6. Total ATP content

Total ATP concentration was evaluated as an indicator of meta-

bolic activity during the treatment with electric current. The intra-

cellular ATP content before and after electric current application is

shown in Fig. 6. Without current the total ATP content decreased

61% by the end of culture (12 d) as compared with initial time

(4.5 d). This result suggests that ATP was employed to increase bio-

mass and HXD degradation. In contrast, total ATP content mark-

edly increased after applying electric current (at 5.5 d). In the

cathodic and middle sections there were no differences in total

ATP content during current application. The anodic section showed

low total ATP content compared to the cathodic and middle sec-

tions; however, it was 1.5-fold higher than that of the control.

In the cathodic and middle sections, total ATP content was,

respectively, 34% and 28% higher than that found before electric

current treatment. This effect is correlated to the increase in HXD

degradation and inhibition of biomass production observed in

the same EC section and same period of time. These results suggest

that the electric current stimulate metabolic activity, probably at

the mitochondrial level as suggested by Vajrala et al. (2008) who

demonstrated, with three-membrane model of cells containing

mitochondria, that low (1 V cm

1

) electric current can induce

mitochondrial modications.

Our results are in line with those reported by Valle et al. (2007),

who observed stimulation in the total ATP content after low-inten-

sity current application to B. cereus. Lustrato et al. (2006) and Guil-

lou et al. (2003) also observed that total ATP content increased

after low electric current application in S. cerevisiae.

In the anodic section, contrary to the cathodic and middle sec-

tions, total ATP content decreased by 34%, in the same way as

experiments without current, but with low biomass production.

This effect can be explained by the effects of the low pH of 2.2

(Escoffre et al., 2007). Total ATP values reinforce the idea that the

effect of electric current modies the metabolic activity in A. niger.

4. Conclusions

Low-intensity electric current application to A. niger stimulated

catabolic (non-assimilative) metabolism, despite pH changes gen-

erated by the electric current. This effect was linked to decreased

biomass production, transient increase in total ATP and to

increased HXD degradation as compared to the control without

electric current. A. niger is an important microorganisms for

0

1

2

3

4

5

6

7

8

0 2 4 6 8 10 12

Time (days)

A

T

P

,

n

g

(

m

g

o

f

b

i

o

m

a

s

s

)

-

1

Current

ON

(iii)

(i)

(*)

(ii)

Current

OFF

Fig. 6. Total ATP content in Aspergillus niger, as a function of time, with and without

electric current. Symbols: () , control (without current); (i) , anodic

section, (ii) h, middle section; (iii) N, cathodic section. Error bars represent

standard deviations of three replicates for all assays.

Table 1

Biomass to HXD yield (Y

X/HXD

), O

2

to HXD yield YO2=HXD, and CO

2

to HXD yield YCO2=HXD for Aspergillus niger, with and without electric current, after 12 days of culture.

Y

X/HXD

a

, mol C-biomass

(mol consumed C-HXD)

1

Y

O2=HXD

a

, mol O

2

(mol consumed C-HXD)

1

Y

CO2=HXD

a

, mol C-CO

2

(mol consumed C-HXD)

1

With current 0.13 0.01 1.48 0.14 0.74 0.14

Without current (control) 0.76 0.09 0.46 0.07 0.25 0.04

a

Averaged and standard deviation values of three replicates.

0%

20%

40%

60%

80%

100%

0.0 4.5 5.5 8.0 12.0

Time (days)

C

a

r

b

o

n

d

i

s

t

r

i

b

u

t

i

o

n

(

%

)

0%

20%

40%

60%

80%

100%

0.0 4.5 5.5 8.0 12.0

Time (days)

C

a

r

b

o

n

d

i

s

t

r

i

b

u

t

i

o

n

(

%

)

(a)

(b)

Current

ON

Current

OFF

Fig. 5. Carbon balances for hexadecane biodegradation by A. niger, after 12 days of

culture. (a) Control without electric current. (b) With electric current. Symbols;

C-HDX; C-CO

2

; C-biomass and C-TOC. Error bars represent standard

deviations of three replicates for all assays.

6 N. Velasco-Alvarez et al. / Bioresource Technology xxx (2010) xxxxxx

Please cite this article in press as: Velasco-Alvarez, N., et al. Enhanced hexadecane degradation and low biomass production by Aspergillus niger exposed to

an electric current in a model system. Bioresour. Technol. (2010), doi:10.1016/j.biortech.2010.07.111

biotechnological purposes and our data suggest the possibility of

manipulating its metabolism by using electric current.

Acknowledgements

This work was funded by CONACyT, fellowship no. 203321 and

PEMEX-Renacin.

References

Bawcom, D.W., Thompson, L.D., Miller, M.F., Ramsey, C.B., 1995. Reduction of

microorganisms of beef surfaces utilizing electricity. J. Food Protect. 58, 3538.

Escoffre, J.M., Dean, D., Hubert, M., Rols, M.P., Favard, C., 2007. Membrane

perturbations by an external electric eld: a mechanism to permit molecular

uptake. Eur. Biophys. J. 36, 973983.

Ganeva, V., Galutzov, B., Teissie, J., 2002. Electroinduced release of invertase from

Saccharomyces cerevisiae. Biotechnol. Lett. 24, 18531856.

Golzio, M., Rols, M.P., Teissi, J., 2004. In vitro and in vivo electric eld-mediated

permeabilization, gene transfer, and expresin. Methods 33, 126135.

Guillou, S., Besnard, V., El Murr, N., Federighi, M., 2003. Viability of Saccharomyces

cerevisiae cells exposed to low amperage electrolysis as assessed by staining

procedure and ATP content. Int. J. Food Microbiol. 88, 8589.

Guillou, S., El Murr, N., 2002. Inactivation of Saccharomyces cerevisiae in solution by

low-amperage electric treatment. J. Appl. Microbiol. 92, 860865.

Hyo-Sang, L., Lee, K., 2001. Bioremediation of diesel-contaminated soil by bacterial

cells transported by electrokinetics. J. Microbiol. Biotechnol. 11, 10381045.

Jackman, A.S., Maini, G., Sharman, K.A., Knowles, J.C., 1999. The effects of direct

electric current on the viability and metabolism of acidophilic bacteria. Enzyme

Microb. Technol. 24, 316324.

Lear, G., Harbottle, M.J., van der Gast, C.J., Jackman, S.A., Knowles, C.J., Sills, G.,

Thompson, I.P., 2004. The effect of electrokinetics on soil microbial

communities. Soil Biol. Biochem. 36, 17511760.

Lowry, O.H., 1951. Protein measurement with Folin phenol reagent. J. Biol. Chem.

193, 265275.

Lustrato, G., Alfano, G., Belli, C., Grazia, L., Iorizzo, M., Ranalli, G., 2006. Scaling-up in

industrial winemaking using low electric current as an alternative to sulfur

dioxide addition. J. Appl. Microbiol. 101, 682690.

Nielsen, J., Villadsen, J., Lide n, G., 2003. Bioreaction Engineering Principles, second

ed. Kluwer Acedemic/Plenum Publishers, New York. p. 56.

Palaniappan, S., Sastry, S.K., Richter, E.R., 1992. Effect of electroconductive heat

treatment and electrical pretreatment on thermal death kinetics of selected

microorganisms. Biotechnol. Bioeng. 39, 225232.

Ranalli, G., Iorizzo, M., Lustrato, G., Zanardini, E., Grazia, L., 2002. Effects of low

electric treatment on yeast microora. J. Appl. Microbiol. 93, 877883.

Shin, H.S., Zeikus, J.G., Jain, M.K., 2002. Electrically enhanced ethanol fermentation

by Clostridium thermocellum and Saccharomyces cerevisiae. Appl. Microbiol.

Biotechnol. 58, 476481.

Tate, K.R., Jenkinson, D.S., 1982. Adenosine triphosphate measurement in soil: an

improved method. Soil Biol. Biochem. 14, 331335.

Teissi, J., Eynard, N., Vernhes, M.C., Be nichou, A., Ganeva, V., Galutzov, B., Cabanes,

P.A., 2002. Recent biotechnological developments of electropulsation, a

prospective review. Bioelectrochemistry 55, 107112.

Thrash, J.C., Coates, J.D., 2008. Review: direct and indirect electrical stimulation of

microbial metabolism. Environ. Sci. Technol. 42, 39213931.

US EPA, 1996. ASW-846, Test Methods for Evaluating Solid Wastes Physical/

Chemical Methods, EPA methods 3540 and 8100, third ed. Environmental

Protection Agency, Washington DC.

Vajrala, V., Claycomb, J.R., Sanabria, H., Miller Jr., J.H., 2008. Effects of oscillatory

electric elds on internal membranes: an analytical model. Biophys. J. 94, 2043

2052.

Valle, A., Zanardini, E., Abbruscato, P., Argenzio, P., Lustrato, G., Ranalli, G., Sorlini, C.,

2007. Effects of low electric current (LEC) treatment on pure bacterial cultures.

J. Appl. Microbiol. 103, 13761385.

Virkutyte, J., Sillanpaa, M., Latostenmaa, P., 2002. Electrokinetic soil remediation

critical overview. Sci. Environ. 289, 97121.

Volke Seplveda, T.L., Gutirrez-Rojas, M., Favela-Torres, E., 2006. Biodegradation of

high concentrations of hexadecane by Aspergillus niger in a solid-state system:

Kinitec analysis. Bioresour. Technol. 97, 15831591.

Wenyan, L., Jiuhui, Q., Libin, Ch., Huijuan, L., Pengju, L., 2005. Inactivation of

Microcystis aeruginosa by continuous electrochemical cycling process in tube

using Ti/RuO

2

electrodes. Environ. Sci. Technol. 39, 46334639.

Xin, L., Yunguo, L., Guangming, Z., Yile, N., Xin, X., Weihua, X., Wenbing, X., Yun, Z.,

Jiadong, L., 2010. Direct current stimulation of Thiobacillus ferrooxidans bacterial

metabolism in a bioelectrical reactor without cation-specic membrane.

Bioresour Technol. 101, 60356038.

Xin-gang, L., Tao, W., Jin-sheng, S., Xin, H., Xiao-song, K., 2006. Biodegradation of

high concentration phenol containing heavy metal ions by functional biolm in

bioelectro-reactor. J. Environ. Sci. 18, 639643.

Zanardini, E., Valle, A., Gigliotti, C., Papagno, G., Ranalli, G., Sorlini, C., 2002.

Laboratory-scale trial of electrolytic treatment on industrial wastewaters:

microbiological aspects. J. Environ. Sci. Health Pt A Toxic/Hazard. Subst.

Environ. Eng. 37, 14631481.

N. Velasco-Alvarez et al. / Bioresource Technology xxx (2010) xxxxxx 7

Please cite this article in press as: Velasco-Alvarez, N., et al. Enhanced hexadecane degradation and low biomass production by Aspergillus niger exposed to

an electric current in a model system. Bioresour. Technol. (2010), doi:10.1016/j.biortech.2010.07.111

You might also like

- Thermal and Energetic Studies of Cellular Biological SystemsFrom EverandThermal and Energetic Studies of Cellular Biological SystemsA. M. JamesNo ratings yet

- MICROWAVE HEATING IN FOOD PROCESSING - Capítulo de LivroDocument44 pagesMICROWAVE HEATING IN FOOD PROCESSING - Capítulo de Livrojrpegoraro100% (1)

- G9 Q2 W4 Structure of Carbon AtomsDocument18 pagesG9 Q2 W4 Structure of Carbon AtomsCherrilyn EnverzoNo ratings yet

- Sample Book - 2 Free Recipes. Rest of Recipes Not CompletedDocument37 pagesSample Book - 2 Free Recipes. Rest of Recipes Not CompletedhishalNo ratings yet

- Electrochemical Water Treatment Methods: Fundamentals, Methods and Full Scale ApplicationsFrom EverandElectrochemical Water Treatment Methods: Fundamentals, Methods and Full Scale ApplicationsRating: 3.5 out of 5 stars3.5/5 (4)

- Catalase Peroxido de Hidrogenio e Termotolerancia em PimentaoDocument8 pagesCatalase Peroxido de Hidrogenio e Termotolerancia em PimentaoLuisa CazarolliNo ratings yet

- Litopenaeus Vannamei (Boone, 1931) Closed-Hatchery System: Application of An Electrolytic Water Treatment Technique in ADocument10 pagesLitopenaeus Vannamei (Boone, 1931) Closed-Hatchery System: Application of An Electrolytic Water Treatment Technique in AHiral PatelNo ratings yet

- Enhanced Electricity Generation by Using Algae Biomass and Activated Sludge in PDFDocument4 pagesEnhanced Electricity Generation by Using Algae Biomass and Activated Sludge in PDFAlex Julio Quincho RojasNo ratings yet

- Electrical Stress-Directed Evolution of Biocatalyst Texcoco Soil Community For Microbial Fuel CellDocument9 pagesElectrical Stress-Directed Evolution of Biocatalyst Texcoco Soil Community For Microbial Fuel CellKamaraj Sathish KumarNo ratings yet

- A1 2009 Velasquez Orta Etal B&BDocument9 pagesA1 2009 Velasquez Orta Etal B&BJailson FigueirêdoNo ratings yet

- Bioresource TechnologyDocument6 pagesBioresource TechnologyazerfazNo ratings yet

- 543 Chikov Et AlDocument7 pages543 Chikov Et AlIvan LjubičićNo ratings yet

- Nucleic: Efficiency E.coli by ElectroporationDocument19 pagesNucleic: Efficiency E.coli by Electroporationh_spriyaNo ratings yet

- Aluminium Active ChannelDocument6 pagesAluminium Active ChannelEliyana AbdullahNo ratings yet

- Response of Photosynthetic Apparatus and Antioxidant Defense Systems in Triticum Aestivum L. Genotypes Subjected To Drought StressDocument11 pagesResponse of Photosynthetic Apparatus and Antioxidant Defense Systems in Triticum Aestivum L. Genotypes Subjected To Drought StressChandra Obul Reddy PuliNo ratings yet

- Disinfection of Seawater For Hatchery Aquaculture Systems Using Electrolytic Water TreatmentDocument12 pagesDisinfection of Seawater For Hatchery Aquaculture Systems Using Electrolytic Water TreatmentzhanghesenNo ratings yet

- Study On Treatment of Slaughterhouse Wastewater by Electro-Coagulation TechniqueDocument4 pagesStudy On Treatment of Slaughterhouse Wastewater by Electro-Coagulation TechniqueazerfazNo ratings yet

- A Novel Multi-Electrode System For Electrolytic and Biological Water Treatments Electric Charge Transfer and Application To DenitrificationDocument11 pagesA Novel Multi-Electrode System For Electrolytic and Biological Water Treatments Electric Charge Transfer and Application To Denitrificationyiwen xiangNo ratings yet

- MikrobiologiDocument4 pagesMikrobiologiDuta MspNo ratings yet

- P4 1 PDFDocument6 pagesP4 1 PDFDita Listya ChairunnisaNo ratings yet

- 1 s2.0 S096085242031350X MainDocument10 pages1 s2.0 S096085242031350X MainElena CazzulaniNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document6 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- Effect of Water On The Aging of Activated Carbon Based Electrochemical Double Layer Capacitors During Constant Voltage Load TestsDocument9 pagesEffect of Water On The Aging of Activated Carbon Based Electrochemical Double Layer Capacitors During Constant Voltage Load TestsHân TrầnNo ratings yet

- Zuschriften: A Generation of Microbial Fuel Cells With Current Outputs Boosted by More Than One Order of MagnitudeDocument4 pagesZuschriften: A Generation of Microbial Fuel Cells With Current Outputs Boosted by More Than One Order of MagnitudeIshwar ChandraNo ratings yet

- Review of Related LiteratureDocument4 pagesReview of Related LiteraturebutterfliesandnotNo ratings yet

- Comparative Transcriptomics of Rice Plants Under Cold, Iron, and Salt StressesDocument13 pagesComparative Transcriptomics of Rice Plants Under Cold, Iron, and Salt StressesDiana Marcela HernandezNo ratings yet

- J Neurophysiol 2000 Xiong 3519 24Document7 pagesJ Neurophysiol 2000 Xiong 3519 24Renato MoraesNo ratings yet

- Impacts of Sterilization, Microwave and Ultrasonication Pretreatment On Hydrogen Producing Using Waste SludgeDocument8 pagesImpacts of Sterilization, Microwave and Ultrasonication Pretreatment On Hydrogen Producing Using Waste SludgeMoh.BudiartoNo ratings yet

- Comparison of Microbial Electrolysis Cells Operated WithDocument7 pagesComparison of Microbial Electrolysis Cells Operated WithCici SafitriNo ratings yet

- Electrolysis-Enhanced Anaerobic Digestion of Wastewater: Bioresource Technology March 2011Document9 pagesElectrolysis-Enhanced Anaerobic Digestion of Wastewater: Bioresource Technology March 2011GurusangmeshHiremathNo ratings yet

- Improving Energy Accumulation of Microbial Fuel Cells by Metabolism Regulation Using Rhodoferax Ferrireducens As BiocatalystDocument6 pagesImproving Energy Accumulation of Microbial Fuel Cells by Metabolism Regulation Using Rhodoferax Ferrireducens As BiocatalystR Kibik ShtNo ratings yet

- Method 3 PDFDocument8 pagesMethod 3 PDFsegNo ratings yet

- Bioresource Technology PDFDocument42 pagesBioresource Technology PDFpatty mariafeNo ratings yet

- The Influence of Low Temperature On Photosynthesis and Antioxidant Enzymes in Sensitive Banana and Tolerant Plantain (Musa SP.) CultivarsDocument8 pagesThe Influence of Low Temperature On Photosynthesis and Antioxidant Enzymes in Sensitive Banana and Tolerant Plantain (Musa SP.) CultivarsPuta 1.47No ratings yet

- Bacterial Inactivation Using A Low-Temperature Atmospheric Plasma Brush Sustained With Argon GasDocument9 pagesBacterial Inactivation Using A Low-Temperature Atmospheric Plasma Brush Sustained With Argon GasIsmi AisyahNo ratings yet

- Inactivation IN Milk High Intensity Pulsed Electric Fields: Eschemchza ColzDocument20 pagesInactivation IN Milk High Intensity Pulsed Electric Fields: Eschemchza ColzShatumbu WilbardNo ratings yet

- Cellulose AcetateDocument7 pagesCellulose Acetateglucose glucoseNo ratings yet

- Sustained Generation of Electricity by The Spore-Forming, Gram-Positive, Desulfitobacterium Hafniense Strain DCB2Document10 pagesSustained Generation of Electricity by The Spore-Forming, Gram-Positive, Desulfitobacterium Hafniense Strain DCB2Dip MajumderNo ratings yet

- Cytokinin-Dependent Photorespiration and The Protection of Photosynthesis During Water DeficitDocument11 pagesCytokinin-Dependent Photorespiration and The Protection of Photosynthesis During Water DeficitAlan HartogNo ratings yet

- Alvarado 2008Document5 pagesAlvarado 2008LuisCalleNo ratings yet

- Article in Press: Coupling UV Irradiation and Electrocoagulation For Reclamation of Urban WastewaterDocument8 pagesArticle in Press: Coupling UV Irradiation and Electrocoagulation For Reclamation of Urban WastewaterJose Eduardo Salazar SandovalNo ratings yet

- Art-3a10 1007Document9 pagesArt-3a10 1007Djimi DjaalebNo ratings yet

- An Electrically Assisted Device For Protein Crystallization in A Vapor-Diffusion SetupDocument3 pagesAn Electrically Assisted Device For Protein Crystallization in A Vapor-Diffusion SetupClaudia ParejaaNo ratings yet

- 2005 Min Etal Watres 2Document8 pages2005 Min Etal Watres 2Rachmad ArdhiantoNo ratings yet

- Jxb/ern 348Document16 pagesJxb/ern 348Huỳnh Thị Thanh TuyềnNo ratings yet

- Pengaruh Medan Magnet THD AirDocument8 pagesPengaruh Medan Magnet THD AiravisenicNo ratings yet

- Paper 14Document6 pagesPaper 14Raju Goud MadagoniNo ratings yet

- Application of A Smart Pilot Electrochemical System For Recycling Aquaculture SeawaterDocument17 pagesApplication of A Smart Pilot Electrochemical System For Recycling Aquaculture SeawaterrizazNo ratings yet

- 03-Hydraulic Continuity and Biological Effects of Low Strength Very Low Frequency Electromagnetic WavesDocument11 pages03-Hydraulic Continuity and Biological Effects of Low Strength Very Low Frequency Electromagnetic Wavesرباب تواتيNo ratings yet

- PIIS0021925820832050Document5 pagesPIIS0021925820832050Lisabel M. SoaresNo ratings yet

- tmpAB30 TMPDocument7 pagestmpAB30 TMPFrontiersNo ratings yet

- Escobar 2006Document8 pagesEscobar 2006Risanto WibowoNo ratings yet

- Bai Linqin1994Document11 pagesBai Linqin1994زياد مغلسNo ratings yet

- The Beneficial Effect of Salicylic Acid On Rose Plants Exposed To Iso-Osmotic StressDocument6 pagesThe Beneficial Effect of Salicylic Acid On Rose Plants Exposed To Iso-Osmotic StressShailendra RajanNo ratings yet

- The Mechanisms of Hydrothermal Deconstruction of Lignocellulose: New Insights From Thermal-Analytical and Complementary StudiesDocument7 pagesThe Mechanisms of Hydrothermal Deconstruction of Lignocellulose: New Insights From Thermal-Analytical and Complementary StudiesSara Sanchez AtahualpaNo ratings yet

- Antibacterial Effects of Chitosan Flakes: Approach of Mechanism and Applications To Water TreatmentsDocument22 pagesAntibacterial Effects of Chitosan Flakes: Approach of Mechanism and Applications To Water TreatmentsAditio DurandtNo ratings yet

- Fceklfjoifm KlrgiDocument9 pagesFceklfjoifm KlrgiFranco SantinNo ratings yet

- Impedance Microbiology-A Rapid Change For MicrobiologistsDocument11 pagesImpedance Microbiology-A Rapid Change For Microbiologistsgiuseppegnr100% (1)

- E Ffect of Electric Intensity On The Microbial Degradation of Petroleum Pollutants in SoilDocument6 pagesE Ffect of Electric Intensity On The Microbial Degradation of Petroleum Pollutants in SoilEspacio UniversitarioNo ratings yet

- Maximum Photosynthetic Yield of Green Microalgae in PhotobioreactorsDocument11 pagesMaximum Photosynthetic Yield of Green Microalgae in PhotobioreactorsKhalid SiddiquiNo ratings yet

- Biohydrogen III: Renewable Energy System by Biological Solar Energy ConversionFrom EverandBiohydrogen III: Renewable Energy System by Biological Solar Energy ConversionNo ratings yet

- Atoms, Elements & Compounds 1 QP PDFDocument10 pagesAtoms, Elements & Compounds 1 QP PDFClinton ChikengezhaNo ratings yet

- Carbon Compound 1Document9 pagesCarbon Compound 1Kym LowNo ratings yet

- Super Final NCERT Based Test Series 2024 Test - 2 FINAL 19.11.2023Document19 pagesSuper Final NCERT Based Test Series 2024 Test - 2 FINAL 19.11.2023Arsaniya KumariNo ratings yet

- FTS-8 - JEE (Main) - Phase-1 - 04-12-2020 - QuestionDocument10 pagesFTS-8 - JEE (Main) - Phase-1 - 04-12-2020 - QuestionjitendraghanchiNo ratings yet

- Section 03100-Concrete Forms and AccessoriesDocument4 pagesSection 03100-Concrete Forms and AccessoriesMØhãmmed ØwięsNo ratings yet

- Furazolidone and Nitrofurazone Dengan HPLCDocument3 pagesFurazolidone and Nitrofurazone Dengan HPLCdewiNo ratings yet

- Photocatalytic Degradation of Pharmaceutically Active Compounds P - 2020 - SolaDocument13 pagesPhotocatalytic Degradation of Pharmaceutically Active Compounds P - 2020 - SolaDuvan Leandro Parra VelandiaNo ratings yet

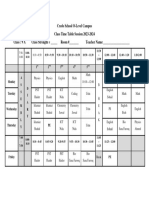

- Credo School O-Level Campus Class Time Table Session 2023-2024 Class: 9 A Class Strength - Room # - Teacher NameDocument1 pageCredo School O-Level Campus Class Time Table Session 2023-2024 Class: 9 A Class Strength - Room # - Teacher Nameahmed.zuberimohammadNo ratings yet

- Untitled Document 19Document8 pagesUntitled Document 19api-668314631No ratings yet

- NORSOK M-710-2014-AC-2019 - enDocument8 pagesNORSOK M-710-2014-AC-2019 - enJose2806No ratings yet

- Origin of Life Theories Worksheet 6tha - ArizaDocument8 pagesOrigin of Life Theories Worksheet 6tha - ArizaMaritza Mora VelozaNo ratings yet

- Al3177hv Al3177 3091280Document14 pagesAl3177hv Al3177 3091280JimmyNo ratings yet

- Análisis de Los Parámetros Hidráulicos de Lagunas FacultativasDocument12 pagesAnálisis de Los Parámetros Hidráulicos de Lagunas FacultativasgonleoNo ratings yet

- Introduction-WPS OfficeDocument5 pagesIntroduction-WPS OfficeHIMANSHU VARDHANNo ratings yet

- Copper Selenide (CuSe and Cu2Se) Nanocrystals - Controllable Synthesis Through A Facile Ultrasonic Chemical RouteDocument3 pagesCopper Selenide (CuSe and Cu2Se) Nanocrystals - Controllable Synthesis Through A Facile Ultrasonic Chemical RoutejacoboNo ratings yet

- 17 Samss 007Document12 pages17 Samss 007Eagle SpiritNo ratings yet

- Chapter 4 Energy Analysis For A Control VolumeDocument103 pagesChapter 4 Energy Analysis For A Control Volumeshriramdhumal24744No ratings yet

- Chemistry Lab 3 Final DocumentDocument12 pagesChemistry Lab 3 Final DocumentshanonintegrityNo ratings yet

- Hot Consolidation and Mechanical Properties of Nanocrystalline Equiatomic Alfeticrzncu High Entropy Alloy After Mechanical AlloyingDocument6 pagesHot Consolidation and Mechanical Properties of Nanocrystalline Equiatomic Alfeticrzncu High Entropy Alloy After Mechanical AlloyingBuluc GheorgheNo ratings yet

- 1.2 Chemical Reagents and Laboratory Supplies 1Document4 pages1.2 Chemical Reagents and Laboratory Supplies 1Justine Mel Concepcion IlardeNo ratings yet

- Bpxe AbpcktDocument2 pagesBpxe Abpcktmilo ,miloNo ratings yet

- g11 Module 1 in General Chemistry 1pdfDocument39 pagesg11 Module 1 in General Chemistry 1pdfAlthea EdulanNo ratings yet

- Hydrocarbons.Document70 pagesHydrocarbons.Mandar Sheth100% (1)

- Chemicals Zetag MSDS Inverse Emulsion Zetag 8814 - 0710Document6 pagesChemicals Zetag MSDS Inverse Emulsion Zetag 8814 - 0710PromagEnviro.comNo ratings yet

- Master List of Formats: SR No. Format No. Format Name New Format Number Rev. No./DateDocument14 pagesMaster List of Formats: SR No. Format No. Format Name New Format Number Rev. No./DateAbhishek DahiyaNo ratings yet

- Chemistry: Unit: 4CH0 Science (Double Award) 4SC0 Paper: 1CDocument36 pagesChemistry: Unit: 4CH0 Science (Double Award) 4SC0 Paper: 1CAyishaNo ratings yet

- Aqa 74041 SQPDocument20 pagesAqa 74041 SQPAttique IftikharNo ratings yet

- Periodic Table Stories PDFDocument47 pagesPeriodic Table Stories PDFErra Peñaflorida100% (1)