Professional Documents

Culture Documents

Concrete Projection

Uploaded by

Mooneer El AssaadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Projection

Uploaded by

Mooneer El AssaadCopyright:

Available Formats

MF 1

CREATING TOMORROWS SOLUTIONS

CONCRETE PROTECTION

FOR CONCRETE ADVANTAGES

2

COST SAVINGS AND ENVIRONMENTAL

COMPATIBILITY THROUGH INNOVATIVE

TECHNOLOGY

3

Building Materials for New Dimensions

Concrete is todays main building material.

Our age of globalization requires a stable

and fully-functional infrastructure that

connects people and markets. This infra-

structure is based on concrete. Modern

road and bridge construction would be

inconceivable without concrete, as would

skyscrapers and industrial buildings. Big-

ger, higher, wider the global construction

boom constantly sets new challenges for

materials and technology, as the size and

number of buildings increase. Thats why

concrete will remain the No. 1 building

material in the future.

Concrete in Danger

Concrete is a versatile building material,

used especially in civil engineering in

combination with steel. However, con-

crete and steel are vulnerable to harmful

substances that penetrate into the build-

ing material by means of moisture. This

can result in costly concrete damage due

to reinforcement corrosion.

Repair Is the Most Expensive Solution

Repairing concrete structures is up to

ten times more expensive than preventive

measures such as hydrophobic impreg-

nation. With WACKERs innovative tech-

nology for the water-repellent treatment of

concrete, its possible to prevent repair

and so avoid high costs and consumption

of energy and resources.

Cost Benets for Property Developers

Specialists from Karlsruhe University,

Germany, are convinced of the economic

benets of preventive measures and

recommend surface protection of concrete

structures. After all, the long-term cost

savings for property developers are huge!

Why is that? In fact the bulk of the costs

some 80% are caused not by the actual

repair work but by infrastructure measures

(e.g. trafc diversions) and setting up the

building site. In summary, we can see that

more prevention = fewer repairs =

lower overall costs.

Silane and silicone expertise

from WACKER 12

SILRES

BS Creme C 14

SILRES

BS 1701 17

SILRES

BS SMK 2101 18

SILRES

BS 290 19

Preventive concrete protection 20

References 22

Benets at a glance 25

WACKER services 26

WACKER at a glance 27

Contents

Prevention rather than renovation 2

Concrete: building material of the future 4

Concrete damage 5

Concrete has two arch-enemies 6

Hydrophobic Impregnation 7

Long lasting protection 8

Silanes stabilizer 9

Silanes reliable vehicle 10

Silanes pioneers in

water-repellent treatment 11

SILRES

BS is a registered trademark of

Wacker Chemie AG.

Concrete Needs Protection

Only effective preventive measures such

as hydrophobic impregnation provide

reliable protection for concrete structures.

To this end, WACKER has developed

environmentally compatible impregnating

agents and highly effective techniques

whose aim is to preserve the value of

old and new buildings and protect them

against weathering and structural damage.

Hydrophobic Impregnation Reduces Costs

by up to 90%

Its estimated that a water-repellent treatment

costs only 10% of extensive renovations.

Benefits of Durable Concrete

Durability of

concrete

Technology

Environmental

Aspects

Economic

Aspects

4 5

CONCRETE WONT BE

OUTDATED ANYTIME SOON

The Right Mix Is the Key

Concrete and reinforced concrete consist

mainly of cement binder, sand aggregate

and additives. In the case of reinforced

concrete, the steel reinforcement improves

the concretes tensile strength. Water is

also required for hardening the cement

and attaining the desired processing con-

sistency. One way of determining concrete

quality is by the water/cement value, the

ratio of mixing water to cement. Excess

water results in an increased number of

capillary pores in the cement and thus a

loss in rigidity. Correct processing and

mixing of the ingredients is necessary to

ensure a building material with excellent

weathering and aging resistance. Other-

wise, serious damage impends after a

relatively short time.

Concrete and reinforced concrete are building materials that have signicantly

changed construction over recent years. Their development provided architects,

builders and engineers with building materials that, in addition to offering ex-

cellent mechanical and physical properties (such as compressive and exural

strength), could be shaped in new and unprecedented ways. It became possible

to erect imposing structures such as bridges, towers and skyscrapers, as well

as more intricate structures. Its cost-effectiveness and durability also make con-

crete a vital building material for the future.

4 5

1

4

2

5 6

3

The reinforcement steel undergoes passivation in

alkaline milieu.

Dissolved salts, such as chlorides and acidic

gases (e.g. CO

2

), penetrate into the concrete

and threaten the reinforcement.

The salts reach the steel and dissolve the

protective layer. Pitting corrosion starts to occur.

The corrosion process results in a volume

expansion and pressure build-up in the structure.

Crack formation and spalling of the concrete are

the result.

The viewer sees the corrosion damages like that.

Despite concretes durability, serious

concrete damage that endangers a

buildings existence frequently occurs.

The main cause of concrete damage

is reinforcement steel corrosion due to

environmental inuences.

Chlorides Spoil the Cost Balance

Fresh concrete is highly alkaline, which

passivates the reinforcement steel

1

.

The greatest damage, which occurs, e.g.,

when the reinforcement steel corrodes,

is caused by waterborne salts, particu-

larly chloride ions. They are absorbed by

the concrete, typically in the form of road

salt or seawater). This particularly affects

highway structures, but also buildings in

coastal regions.

Corrosion Attacks Steel

Ultimately, the salt transported into the

concrete by water

2

causes the steels

passivating layer (protective layer) to dis-

solve. Under the inuence of oxygen and

moisture, the steel begins to rust and pit-

ting corrosion starts to occur

3

. Since

the irons corrosion process involves a

drastic volume expansion (bursting force)

4

, the concrete layer above the reinforce-

ment spalls

5

, resulting in serious con-

crete damage

6

.

6 7

CONCRETE HAS TWO ARCH-ENEMIES:

WATER-SOLUBLE SALTS AND GASES

Freeze/Thaw Cycles, Road Salts and

Sea Salt Attack Concrete

Concrete damages always involve mois-

ture. Although water is important in making

concrete, it can also be destructive. Fur-

thermore, it carries aggressive substances

such as chloride ions from road salts into

the concrete. Water is also a reaction

medium and partner for destructive chem-

ical processes that particularly attack the

reinforcement steel by corrosion.

Concrete Absorbs Water

When concrete and other mineral building

materials come into contact with water,

they absorb an amount which depends

on their porosity. This contributes to the

following forms of damage:

Its advantages, especially its cost ef-

ciency, durability and scope for design,

has made concrete todays most widely-

used building material. Just a few years

ago, many people still believed that

concrete was resistant to every kind of

harmful inuence. However, concrete

is not resistant to every kind of harmful

inuence and can be damaged.

Concrete destruction by corrosion of

the reinforcing steel (chloride induced)

Chemical corrosion, e.g. binder

transformation by acidic gases

(SO

2

, NO

2

, CO

2

)

Cracks by swelling and shrinkage

Frost damage and freeze/thaw

damage by road salts

Eforescence and salt damage by

hydration and crystallization

Lime leaching

Rust stains

Dirt pick-up and stains

Fungal, moss, lichen and algal growth

Typical Structural Damage

6 7

Much of the damage caused by mois-

ture can be prevented, or at least

reduced or kept at bay for longer, by

means of hydrophobic impregnation.

Defense against Water and Harmful

Substances

Absorption of harmful substances, which

may lead to the structural damage de-

scribed above, is usually the outcome of

contact between the building material

and water. This is an example of capillary

water absorption, and also occurs when

splashes of water land on de-icing salt.

Forming a hydrophobic zone greatly re-

duces the amount of water and harmful

substances which are absorbed. The

building fabric remains drier as a result

and is consequently less susceptible

to the damage mechanisms described

above.

HYDROPHOBIC IMPREGNATION

ENHANCES CONCRETES DURABILITY

Silanes Can Rescue Concrete

Structures

The most efcient way of protecting con-

crete is to prevent water uptake. The past

decades have shown that silanes with

long alkyl chains (e.g. iso-octyl) are the

ideal product class for this. Their current

dominance in masonry protection stems

from their outstanding water-repellency

and durability. Silanes outperform rival

product classes in their resistance to

physical, chemical and microbiological

attack. Provided that the right product is

chosen, impregnation with silane will pre-

serve a structure for a long time.

8 9

6

7

Modern Water Repellents Achieve:

Drastic reduction in water uptake

Chloride barrier and thus protection

against reinforcement corrosion

Retention of high water-vapor

permeability

Extensive penetration

High UV resistance

Surfaces not rendered shiny or tacky,

or caused to yellow

Adequate resistance to alkalis

Safe use

Exemplary environmental compatibility

WACKER has been working on devel-

oping and enhancing particularly long-

lasting and cost-efcient concrete

protection agents for over four decades.

As hydrophobic impregnating agents,

these target known sources of damage

and fulll the tough demands made

on protective measures under difcult

conditions.

The concretes pores remain open after

water-repellent treatment, so that water-

vapor and gas diffusion are not measur-

ably inuenced. Thus, a concretes natural

properties are retained, and even when

the surface is damaged (crack formation)

it remains adequately protected. As a re-

sult, the water-repellent treatment has a

signicantly longer service life. These are

clear advantages over lm-forming coat-

ings, which easily ake off as they dont

allow water to pass out. Moreover, a

damaged protective lm quickly leads to

concrete damage, as water and aggres-

sive substances can then easily penetrate.

CONCRETE NEEDS EFFECTIVE

AND LONG-LASTING PROTECTION

6 Water-repellent treatment the capillaries

remain open.

7 Film-forming coating the capillaries are

sealed.

Hydrophobizing and Film-Forming

Measures

There are generally two methods available:

hydrophobic Impregnation and lm-forming

coatings. In both cases, protection against

moisture is central since water plays a key

role by transporting corrosive substances,

e.g. road salts, as well as facilitating the

corrosion mechanisms.

8 9

Silanes as Ideal Water-Repellent

Agents

Organosilicon compounds have a long

track record as water-repellent agents.

They feature excellent water repellency

without signicantly impairing the water-

vapor permeability, and long durability,

which stems from silanes high resistance

to external infuences such as UV radia-

tion, thermal stress, aggressive substanc-

es and microbes. This is due to extremely

stable covalent bonds between the silane

and the silicate matrix of the pores and

capillary walls in the concrete.

Silanes for water-repellent treatment of

concrete must possess two specic

properties: they must penetrate well into

the relatively dense concrete and resist

degradation by the high alkalinity found

especially in fresh concrete. The purpose

of hydrophobic impregnation is to protect

exposed exterior walls from moisture and

associated damage by applying a color-

less, non-lm-forming agent that prevents

capillary uptake of water and the aggres-

sive substances dissolved in it. Because

the capillaries remain open, the substrate

retains its vapor permeability.

SILANES STABILIZER FOR

CONCRETE STRUCTURES

The Silane Docks onto the Concrete to Develop the Water-Repellent Effect

Experts Conrm Benets

Wacker Chemie AG is in constant contact

with various research institutes, which

describe this long-term effectiveness and

signicantly enhanced lifespan in many

scientic papers.

10 11

8

9

Fully-cured silanes close structural

resemblance to quartz is the reason

for its high afnity for silicate building

materials, and for the exceptional

durability of the hydrophobic impreg-

nation.

Tried and Trusted

Organosilicon compounds have been

recognized as the ideal active agents for

the hydrophobic impregnation of absor-

bent mineral building materials for over

40 years now. The compounds work by

binding strongly to the building material

to form extremely stable Si-O-Si struc-

tures, similar to silicone resin. We can

see the close similarity if we compare the

molecular structure of a fully reacted

silane

9

with that of natural quartz

8

.

The fully reacted silane is simply a quartz

modied with organic groups. This close

structural resemblance is the reason for

the high afnity of silicone resins for silicate

building materials, and for the exceptional

durability of the water-repellent treatment.

The organic group R makes the silane-

treated construction material outstandingly

water repellent. Since it is, moreover, ex-

tremely resistant to many chemical, phys-

ical and biological inuences, the hydro-

phobic effect lasts for decades.

SILANES RELIABLE VEHICLES

OF HYDROPHOBIC IMPREGNATION

8

Quartz unit

9 Silane molecule

10 11

Today, alkylalkoxysilanes such as iso-

octyltriethoxysilane set the standard

in terms of highly efcient penetration

and excellent resistance to high alka-

linity. They are colorless, low-molec-

ular (and thus low-viscosity), highly

penetrating liquids that are generally

applied to concrete in undiluted form.

There, they react with moisture, liber-

ating alcohol, and form extremely stable

bonds with the pores and capillary

walls of the concrete. After the reac-

tion, the iso-octyl group juts out into

the centre of the capillaries and pores,

which is the reason behind hydropho-

bic impregnations high effectiveness.

Optimum Silane Efficiency

Todays scientic ndings conrm silanes

excellent and long-lasting effectiveness

as concrete water repellents. However,

for optimum effect, two points must be

observed during processing:

SILANES & SILOXANES PIONEERS IN

HYDROPHOBIC IMPREGNATION

Liquid water repellents must generally

be applied in several coats to achieve

the required active concentration and

penetration depth;

On vertical and particularly overhead

surfaces, the material could potentially

run off before it penetrates into the

concrete. In such cases, products with

higher viscosity such as SILRES

BS

Creme C are ideal for attaining an

adequate contact time. More details

on page 14.

12 13

Wacker Chemie AG has been a leader

in masonry protection with silicones for

decades. Its broad series of masonry

protection agents covers an extensive

range of applications, from preserva-

tion of historic buildings to concrete

protection. Ongoing product develop-

ment ensures that products are

continually adapted to meet market

requirements.

Allow us to introduce our proven and re-

liable products for concrete protection,

with which you can protect your building

against moisture and associated further

damage:

WACKER CHEMIE AG

THE SILANE AND SILICONE EXPERT

IN MASONRY PROTECTION

Products

SILRES

BS Creme C the expert

SILRES

BS 1701 the generalist

SILRES

BS SMK 2101 the specialist

SILRES

BS 290 the all-rounder

12 13

SILRES

BS Creme C the Expert

Certifed to EN 1504-2

Water-repellent cream

Aqueous

Solvent-free

Silane-based

For concrete and reinforced concrete

Use undiluted

SILRES

BS 1701 the Generalist

Certifed to EN 1504-2

Liquid water repellent

Monomeric silane

For concrete and reinforced concrete

Use undiluted

SILRES

BS SMK 2101 the Specialist

Certifed to EN 1504-2

Solvent-free silicone microemulsion

concentrate

Silane/siloxane-based

Impregnating agent for concrete

and reinforced concrete

Impregnating agent for in-plant-

manufactured building materials

Use diluted in water

SILRES

BS 290 the All-Rounder

Liquid general-purpose water repellent

Liquid general-purpose primer

Solvent-free silane/siloxane mixture

For mineral and alkaline substrates

Use diluted in solvent

14 15

SILRES

BS Creme C is an aqueous,

solvent-free, water-repellent cream

based on silane. Its a high-quality

specialty product for the hydrophobic

impregnation of concrete and rein-

forced concrete.

The Formula for Deep-Pore Protection

SILRES

BS Creme C is characterized by:

Excellent penetration

Being solvent-free, aqueous and

environmentally compatible

Low volatility

Optimum resistance to alkalis

The treated concrete exhibits the follow-

ing lasting properties:

Drastic reduction in chloride and

water absorption

Retention of breathability by the

substrate

High protection against freeze/thaw

Good paint adhesion

SILRES

BS Creme Cs thixotropic con-

sistency is unique among water repellents

and its properties are excellent for the

hydrophobic impregnation of high-quality

concrete and reinforced concrete. Unlike

conventional liquid products, SILRES

BS

Creme C can be applied to the required

extent in just one or sometimes two steps.

Depending on porosity and thus concrete

quality, the silane active ingredient pen-

etrates into the substrate within a short

period of time (30 minutes to a couple of

hours) and there it reacts, liberating alcohol

with the silicate matrix of the capillaries

and pores of the concrete. The creamy

layer that was initially white disappears

completely. Since the active ingredient is

the same as in conventional liquid water

repellents, water-repellent treatment with

SILRES

BS Creme C also allows the

pores and capillaries of the substrate

to remain open, leaving the substrate

breathable.

SILRES

BS Creme C is designed so that

the active ingredient penetrates as deeply

into the concrete as possible and thus

optimally protects against the absorption

of water and aggressive substances, as

well as against damage from freeze/thaw.

SILRES

BS CREME C

THE EXPERT IN HYDROPHOBIC

IMPREGNATION OF CONCRETE

Responsible Care

is a global, voluntary chemical-

industry initiative. Its aim is to make tangible

contributions toward sustainable development.

WACKER Products are Certified Products

Certied to

EN 1504-2

14 15

10

11

12

Applications

SILRES

BS Creme C is particularly

recommended for the hydrophobic im-

pregnation and priming of concrete and

reinforced concrete in road, bridge and

building construction. In general, SILRES

BS Creme C is suitable for all alkaline

substrates that were conventionally treated

with concentrated or undiluted water re-

pellents such as alkoxysilanes.

Comments

Comprehensive instructions are given

in the appropriate material safety data

sheets. These are available from our

sales subsidiaries or can be printed from

WACKERs website www.wacker.com.

Capillary water uptake of drill cores taken from

the Frstenland bridge in St. Gallen, Switzerland,

at varying depths (1-mm thick slices are cut off

and inspected). Source: LPM report 17'160-2 of

May 28, 1997

10 Freshly applied SILRES

BS Creme C.

11 30 minutes after application.

12 Two hours after application.

W

a

t

e

r

a

b

s

o

r

p

t

i

o

n

[

k

g

/

m

2

]

Capillary Water Absorption

Penetration:

untreated 1 mm 3 mm

0 mm 2 mm

Time [h]

1.2

1.0

0.8

0.6

0.4

0.2

0

0.5 1.0 1.5

16

17

SILRES

BS 1701 is a mixture of

isomeric octyltriethoxysilanes with

iso-octyltriethoxysilane as the main

component. SILRES

BS 1701 is used

in undiluted form for the hydrophobic

priming and impregnation of concrete

and reinforced concrete.

Special Features

SILRES

BS 1701 is characterized by:

Excellent penetration

Being solvent-free and environmentally

compatible

Low volatility

Optimum resistance to alkalis

The treated concrete has the following

lasting properties:

Drastic reduction in chloride and

water absorption

Retention of breathability

High protection against freeze/thaw

Good paint adhesion

After application to the concrete, SILRES

BS 1701 reacts initially with atmospheric

moisture or the building materials pore

water. In the zone where the impregnating

agent has penetrated, the active agent

formed greatly reduces the concretes

absorption, but without blocking the con-

cretes pores and capillaries. The impreg-

nated building material retains its very

high water-vapor permeability.

Applications

SILRES

BS 1701 is recommended for

the hydrophobic impregnation and prim-

ing of concrete and reinforced concrete in

road, bridge and building construction.

Comments

Comprehensive instructions are given

in the appropriate material safety data

sheets. These are available from our

sales subsidiaries or can be printed from

WACKERs website www.wacker.com.

SILRES

BS 1701

THE UNIVERSAL SILANE

Responsible Care

is a global, voluntary chemical-

industry initiative. Its aim is to make tangible

contributions toward sustainable development.

WACKER Products are Certified Products

Certied to

EN 1504-2

18 19

SILRES

BS SMK 2101 is a water-

dilutable, solvent-free silicone micro-

emulsion concentrate based on a silane/

siloxane mixture. Diluted in water,

SILRES

BS SMK 2101 is a high-quality

specialty product for the hydrophobic

impregnation and priming of concrete

and reinforced concrete.

Special Features

SILRES

BS SMK 2101 is

characterized by:

Proven penetration into the concrete

Low volatility with low evaporation loss-

es during application

Dilutable with water; no solvent content

High resistance to alkalis

The treated concrete has the following

lasting properties:

Drastic reduction in water and chloride

absorption

After application to the concrete, SILRES

BS SMK 2101 reacts. In the zone where

the impregnating agent has penetrated,

the active agent formed greatly reduces

the concretes absorption, but without

blocking the concretes pores and capil-

laries. The impregnated building material

retains very high water-vapor permeability.

Applications

SILRES

BS SMK 2101 is recommended

for the hydrophobic impregnation and

priming of concrete and reinforced con-

crete in road, bridge and building con-

struction.

Comments

Comprehensive instructions are given

in the appropriate material safety data

sheets. These are available from our

sales subsidiaries or can be printed from

WACKERs website www.wacker.com.

SPECIALTY

SILRES

BS SMK 2101

Responsible Care

is a global, voluntary chemical-

industry initiative. Its aim is to make tangible

contributions toward sustainable development.

WACKER Products are Certified Products

Certied to

EN 1504-2

18 19

SILRES

BS 290 is a solvent-free

silicone concentrate based on a silane/

siloxane mixture and can be diluted

with organic solvent. Diluted in this

way, SILRES

BS 290 is a high-quality

general-purpose impregnating and

priming agent for mineral and strongly

alkaline substrates.

Special Features

SILRES

BS 290 is characterized by:

Good penetration

Rapid drying, with no tackiness

Effectiveness even on damp building

materials

High resistance to alkalis

The treated concrete has the following

lasting properties:

Drastic reduction in chloride and water

absorption

After application to the concrete, SILRES

BS 290 reacts with the atmospheric

moisture or the building materials pore

water. In the zone where the impregnating

agent has penetrated, the active agent

formed greatly reduces the concretes

absorption, but without blocking the con-

cretes pores and capillaries. The impreg-

nated building material retains very high

water-vapor permeability.

Applications

SILRES

BS 290 is suitable for the water-

repellent treatment of absorbent, porous

mineral building materials such as:

Aerated concrete

Sand-lime brick

Cement fberboards

Mineral plasters

Mineral-based natural and

composite stone

Mineral paints

Brickwork

Comments

Comprehensive instructions are given

in the appropriate material safety data

sheets. These are available from our sales

subsidiaries or can be printed from

WACKERs website www.wacker.com.

GENERAL-PURPOSE

SILRES

BS 290

Responsible Care

is a global, voluntary chemical-

industry initiative. Its aim is to make tangible

contributions toward sustainable development.

20

C

h

l

o

r

i

d

e

c

o

n

c

e

n

t

r

a

t

i

o

n

[

%

]

Chloride Migration in Concrete

Chloride migration in concrete (strength class C35/45). Untreated specimens and those treated with

SILRES

BS Creme C. Specimens conditioned for 10 days in 10% NaCl solution.

Untreated 100 g/m

2

200 g/m

2

Application rate of SILRES

BS Creme C

300 g/m

2

Depth: 0 9 mm 10 19 mm 20 29 mm 30 39 mm

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0

PREVENTIVE CONCRETE PROTECTION

THE PERFECT PRODUCT FOR EVERY

APPLICATION

Hydrophobic Impregnation Agents Test Results DIN EN 1504-2

Applications

Drying rate

coefficient

Absorption ratio Absorption rate

after exposure

to alkali

Freeze-thaw salt

stress test

Depth of

penetration

DIN EN 13579 DIN EN 13580 DIN EN 13580 DIN EN 13581 DIN EN 14630

Class I: > 30% Class I: < 10 mm

< 7,5% < 10% Cycles treated vs. control

Class II: > 10% Class II: 10 mm

Actives Type Use

SILRES

BS Creme C 80% Silane Ready to use Class I + + > 20 Class II

SILRES

BS 1701 > 98% Silane Ready to use Class I + + > 20 Class II

SILRES

BS SMK 2101 100% Silane/

siloxane

Dilute to

25% actives

Class I + + Not tested Class I

Hydrophoic Impregnation Agents Test Result

Applications

Absorption ratio Absorption rate

after exposure

to alkali

Freeze-thaw salt

stress test

Depth of

penetration

Actives Type Use

SILRES

BS 290 100% Silane/

siloxane

Dilute to

20% actives

+ + Not tested Class I

21

Olympic Stadium, China

22 23

HYDROPHOBIC IMPREGNATION

OF CONCRETE OUR REFERENCES

Yangtze Bridge, China

Metroline, Dubai

Tsing-Ma Bridge, China

Highway Bridge, Germany

22 23

Deutsches Museum, Germany Stonecutters-Bridge, Hongkong

Three Gorges Dam, China

Monument to the Battle of the Nations,

Germany

24

Metropolitan Highway, China

25

$ +

WACKERs SILRES

BS high-tech

product series offers property devel-

opers three denite benets for

protecting concrete buildings and

retaining their value:

Clear advantage in terms of quality due

to unique technology

Impressive cost savings due to unrivaled

cost-effectiveness

Positive public acceptance due to

exemplary environmental compatibility

CONCRETE PROTECTION

FOR CONCRETE ADVANTAGES

Outstanding Performance

SILRES

BS protects concrete reliably

against water and moisture. Positive

effects:

Blocks water and consequently

Blocks salt:

Forms a barrier to chlorides from road

salt.

Blocks corrosion:

Reinforcement steel does not rust,

since the passivation layer remains

intact.

Blocks frost damage:

Frost damage is minimized thanks to

highly effective water repellency.

Metropolitan Highway, China

Range of Services and Benefits for Customers at a Glance

Salt Entering

Stop

Frost Damages

Stop

Corrosion

Stop

Water Stop

Total Costs

Energy

Consumption

Resources

Needed

Sustainability

Unique Advantages

Overall costs:

Prevention with SILRES

BS instead

of costly repair

Energy consumption:

Treatment reduces energy consumption

by minimizing maintenance work and

the associated site set-up costs.

Resource conservation:

Lower water and energy consumption

is kind on the environment.

Sustainability:

Buildings treated with SILRES

BS

have an extended lifespan.

26

Additional Information

This brochure has shown you what

SILRES

BS can achieve as a water-

repellent additive for concrete protection.

To nd out more about SILRES

technical

data, please ask for our product data

sheets. WACKER can, of course, of-

fer much more for building material pro-

tection with silicones. For our complete

product range in this area, see our product

overview. We will be glad to send you a

copy upon request. Or just visit us online

at www.wacker.com/silres

Customized Service

Unique challenges require unique solu-

tions. Thats why our technical service

managers are here for you personally.

They understand your production and

requirements and know our products and

their wide range of benets. With this

background, we can nd exactly the

solution you need. Just call us. We will

be glad to help you, no matter where

you are.

WE BELIEVE CUSTOMER PROXIMITY IS

THE KEY TO INNOVATIVE SOLUTIONS

WACKER Services

Technical service

Inspection and testing of products

with and without SILRES

BS

Selection of appropriate additives

and the right dosage

Go for the optimum!

WACKER is one of the worlds largest con-

struction-solution providers. Whether used

in new construction, refurbishment or ren-

ovation, WACKER products meet the most

exacting demands by offering the best bal-

ance between quality and cost-efciency.

Our comprehensive portfolio based on a

unique combination of the two fully devel-

oped technology platforms silicones and

polymer chemistry and our strong service

will help you nd the optimal solution for

your specic application. Talk to us!

www.wacker.com/construction

WACKER is one of the worlds leading

and most research-intensive chemical

companies, with total sales of 4.91 billion.

Products range from silicones, binders

and polymer additives for diverse industrial

sectors to bio-engineered pharmaceutical

actives and hyperpure silicon for

semiconductor and solar applications. As

a technology leader focusing on sustain-

ability, WACKER promotes products and

ideas that offer a high value-added

potential to ensure that current and future

generations enjoy a better quality of life

based on energy efciency and protection

of the climate and environment. Spanning

EXPERTISE AND SERVICE NETWORK

ON FIVE CONTINENTS

the globe with five business divisions,

operating 25 production sites, WACKER is

currently active in over 100 countries. The

Group maintains subsidiaries and sales

ofces in 29 countries across Europe, the

Americas and Asia including a solidly

established presence in China. With a

workforce of 17,200, WACKER sees itself

as a reliable innovation partner that

develops trailblazing solutions for, and in

collaboration with, its customers. WACKER

also helps them boost their own success.

Our technical centers employ local

specialists who assist customers world-

wide in the development of products

tailored to regional demands, supporting

them during every stage of their complex

production processes, if required.

WACKER e-solutions are online services

provided via our customer portal and as

integrated process solutions. Our

customers and business partners thus

benet from comprehensive information

and reliable service to enable projects

and orders to be handled fast, reliably

and highly efciently. Visit us anywhere,

anytime around the world at:

www.wacker.com

All figures are based on fiscal 2011.

Sales and production sites, plus 20 technical

centers, ensure you a local presence worldwide.

single_A4_e_020412_RZ.indd 1 22.05.12 17:57

Wacker Chemie AG

Hanns-Seidel-Platz 4

81737 Mnchen, Germany

Tel. +49 89 6279-0

info@wacker.com

www.wacker.com

The data presented in this brochure are in accordance with the present state of our knowledge but do not absolve the user from carefully checking all supplies immediately on

receipt. We reserve the right to alter product constants within the scope of technical progress or new developments. The recommendations made in this brochure should be

checked by preliminary trials because of conditions during processing over which we have no control, especially where other companies raw materials are also being used.

The information provided by us does not absolve the user from the obligation of investigating the possibility of infringement of third parties rights and, if necessary, clarifying

the position. Recommendations for use do not constitute a warranty, either express or implied, of the tness or suitability of the product for a particular purpose.

6

5

2

7

e

/

0

7

.

1

2

s

u

p

e

r

s

e

d

e

s

6

5

2

7

e

/

1

1

.

1

1

You might also like

- RFL Catalogue-HDPEDocument70 pagesRFL Catalogue-HDPETayef Talukder100% (1)

- Ycet Jammu: Seminar OnDocument19 pagesYcet Jammu: Seminar OnSherry SherNo ratings yet

- HE Project 2Document20 pagesHE Project 2Vinayak Gani100% (1)

- Sikagard - 550 W ElasticDocument4 pagesSikagard - 550 W ElasticAndrei GheoNo ratings yet

- Nanotechnology in Concrete - A ReviewDocument12 pagesNanotechnology in Concrete - A ReviewYongliang Liu100% (1)

- Renderoc LAXtraDocument2 pagesRenderoc LAXtrajaga67No ratings yet

- SIKA Tunnels & Waterproofing V2 PDFDocument99 pagesSIKA Tunnels & Waterproofing V2 PDFAngelo MoralNo ratings yet

- Pavement Types: Concrete PavementsDocument20 pagesPavement Types: Concrete PavementsMohamedNo ratings yet

- Waterproofing Admixture PDFDocument2 pagesWaterproofing Admixture PDFSegun100% (1)

- Roller Compacted Concrete (RCC) in PavementsDocument15 pagesRoller Compacted Concrete (RCC) in PavementsAlhilali ZiyadNo ratings yet

- Renderoc PlugDocument3 pagesRenderoc Plugtalatzahoor100% (1)

- Leaflet Vandex Crystalline WaterproofingDocument12 pagesLeaflet Vandex Crystalline WaterproofingEngr. Mohammad Moinul HossainNo ratings yet

- Behaviour On Geopolymer Mortar Using Granulated Blast Furnace SlagDocument5 pagesBehaviour On Geopolymer Mortar Using Granulated Blast Furnace SlagMauricio David Ruiz OdarNo ratings yet

- Mbrace: Composite Strengthening SystemDocument12 pagesMbrace: Composite Strengthening SystembudiNo ratings yet

- Cement Replacement Materials LectureDocument36 pagesCement Replacement Materials LectureCyrus HongNo ratings yet

- Qatar Conference CIC 2023Document37 pagesQatar Conference CIC 2023ravi 127No ratings yet

- TVBM 3104Document257 pagesTVBM 3104Bianca CalderónNo ratings yet

- Alcolin Contact Adhesive TDS PDFDocument3 pagesAlcolin Contact Adhesive TDS PDFBerno Muishond KohlmeyerNo ratings yet

- CompositesDocument58 pagesCompositeskasvikrajNo ratings yet

- CW July 2012Document58 pagesCW July 2012Clint FosterNo ratings yet

- Anti Crak Brochure ScreenDocument7 pagesAnti Crak Brochure ScreenPablo Quinteros PizarroNo ratings yet

- Corrosion Resistance GuideDocument26 pagesCorrosion Resistance GuideFrancisco Javier Villegas AndersonNo ratings yet

- Mechanical Strength and Water Resistance of Magnesium Oxysulfate CementDocument11 pagesMechanical Strength and Water Resistance of Magnesium Oxysulfate CementArlen Gutierrez100% (1)

- Report On Crystaline WaterproofingDocument11 pagesReport On Crystaline WaterproofingAnkita Baban GavadeNo ratings yet

- Use of Water ReducersDocument7 pagesUse of Water ReducersVaibhav MehtaNo ratings yet

- Dynasylan VTEO enDocument3 pagesDynasylan VTEO enbhisma.nugerahNo ratings yet

- Shrinkage Compensating Admixtures by Sunanda CoatingsDocument2 pagesShrinkage Compensating Admixtures by Sunanda Coatingss.skumar10% (1)

- Performance Analysis of Air-Entrained ConcreteDocument27 pagesPerformance Analysis of Air-Entrained ConcreteHazbullah ShajiNo ratings yet

- Properties and Applications of FRP in Strengthening RC Structures A Review (2018)Document31 pagesProperties and Applications of FRP in Strengthening RC Structures A Review (2018)brahmabulNo ratings yet

- NanoCoat Leaflet PDFDocument1 pageNanoCoat Leaflet PDFProsun RoyNo ratings yet

- A Review On Basalt Fiber With Manufacturing and TestsDocument10 pagesA Review On Basalt Fiber With Manufacturing and TestsSubramanian ManivelNo ratings yet

- Grout CatalogDocument36 pagesGrout CatalogJohneey DeepNo ratings yet

- Advanced Concrete Durability (Assignment-01)Document5 pagesAdvanced Concrete Durability (Assignment-01)Suzon IkramNo ratings yet

- Review On Hydrodynamic Modelling of Desalination Plants Brine Effluent Marine OutfallsDocument10 pagesReview On Hydrodynamic Modelling of Desalination Plants Brine Effluent Marine OutfallsMonika GuptaNo ratings yet

- Water Retaining Conc RepairDocument48 pagesWater Retaining Conc Repairanele_amisNo ratings yet

- Analysis of Cement by Banana FiberDocument48 pagesAnalysis of Cement by Banana FiberKyaw KhineNo ratings yet

- BOQ Water Proofing With BASF RangeDocument1 pageBOQ Water Proofing With BASF Rangehemantrulz0% (1)

- Synmix HP 55 BrochureDocument12 pagesSynmix HP 55 BrochureRodrigo VillenaNo ratings yet

- CHRYSO - GCP - Waterproofing - Expanson Joint - SubmittalDocument22 pagesCHRYSO - GCP - Waterproofing - Expanson Joint - Submittalsubhasishg1985No ratings yet

- BB Ukraine-Baumaterial2006 enDocument245 pagesBB Ukraine-Baumaterial2006 enmelikeder100% (1)

- Xypex Chemical Corporation WaterproofingDocument292 pagesXypex Chemical Corporation WaterproofingalbijayNo ratings yet

- Experimental Investigations On Fiber Reinforced Concrete With Lathe Fibers For Sustainable ConstructionDocument14 pagesExperimental Investigations On Fiber Reinforced Concrete With Lathe Fibers For Sustainable ConstructionAditya SutarNo ratings yet

- Tau Planters CatalogDocument25 pagesTau Planters CatalogSantosh BastolaNo ratings yet

- Recycled Glass Fiber Reinforced Polymer Additions To Portland Cement ConcreteDocument13 pagesRecycled Glass Fiber Reinforced Polymer Additions To Portland Cement ConcreteEmil MattotorangNo ratings yet

- Waterglass - and PhosphatesDocument4 pagesWaterglass - and PhosphatesChris BothaNo ratings yet

- Concrete Technology Lec#01 ConcreteDocument2 pagesConcrete Technology Lec#01 ConcretefaizanNo ratings yet

- Self Healing ConcreteDocument5 pagesSelf Healing ConcreteKeshab BhattaraiNo ratings yet

- Concrete Repair With Realkalisation and The Management Thereof - W.M. Tshibangu 1998 MaDocument180 pagesConcrete Repair With Realkalisation and The Management Thereof - W.M. Tshibangu 1998 Masimolas123No ratings yet

- 39 24 225Document12 pages39 24 225A MahmoodNo ratings yet

- Impacts of Environmental and Engineered Processes On The PFAS Fingerprint of Fluorotelomer-Based AFF by Sarah Balgooyen and Christina RemucalDocument11 pagesImpacts of Environmental and Engineered Processes On The PFAS Fingerprint of Fluorotelomer-Based AFF by Sarah Balgooyen and Christina RemucalFOX 11 NewsNo ratings yet

- Semana 02 O - Portland, Blended and Other Hydraulic Cement C - PCA Chapter 3 PDFDocument38 pagesSemana 02 O - Portland, Blended and Other Hydraulic Cement C - PCA Chapter 3 PDFBrandon PonteNo ratings yet

- Ultra High Performance ConcreteDocument7 pagesUltra High Performance ConcreteMaeen AhmedNo ratings yet

- BABU e PRAKASH (1995) - Efficiency of Silica Fume in ConcreteDocument11 pagesBABU e PRAKASH (1995) - Efficiency of Silica Fume in ConcreteFelipe Pereira100% (1)

- Tarmac Permeable Concrete Solution GuideDocument34 pagesTarmac Permeable Concrete Solution GuidesiongloongNo ratings yet

- Engineering Materials: CementDocument26 pagesEngineering Materials: CementSathvika KodimyalaNo ratings yet

- Corrosion Evaluation of Geopolymer Concrete Made With Fly Ash and Bottom AshDocument16 pagesCorrosion Evaluation of Geopolymer Concrete Made With Fly Ash and Bottom Ashaboodalshouha1998No ratings yet

- Rsumners PDFDocument12 pagesRsumners PDFSaloni guptaNo ratings yet

- ECMALON - High Performance ResinsDocument5 pagesECMALON - High Performance ResinsNagendra GuptaNo ratings yet

- Lecture 8Document8 pagesLecture 8Mask KingNo ratings yet

- Grc-Jali HDocument8 pagesGrc-Jali HMooneer El AssaadNo ratings yet

- Weberanc 405 BFXDocument14 pagesWeberanc 405 BFXMooneer El AssaadNo ratings yet

- KataraClub SpaMenu PDFDocument15 pagesKataraClub SpaMenu PDFMooneer El AssaadNo ratings yet

- Project Management FrameworkDocument1 pageProject Management FrameworkMooneer El AssaadNo ratings yet

- UCE CompanyDocument52 pagesUCE CompanyMooneer El AssaadNo ratings yet

- 1 - Mmup Process If School Is Not ListedDocument1 page1 - Mmup Process If School Is Not ListedMooneer El Assaad0% (1)

- Material Histogram - Site ClearenceDocument1 pageMaterial Histogram - Site ClearenceMooneer El AssaadNo ratings yet

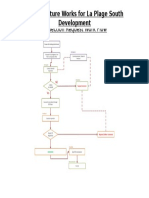

- Inspection Request Work FlowDocument1 pageInspection Request Work FlowMooneer El AssaadNo ratings yet

- Transformation & Organizational Restructuring. Rule Making: NameDocument1 pageTransformation & Organizational Restructuring. Rule Making: NameMooneer El AssaadNo ratings yet

- Modern Physics - COME 361 Assignment 2: Exercise 1Document2 pagesModern Physics - COME 361 Assignment 2: Exercise 1Mooneer El AssaadNo ratings yet

- Arab Interns - StartupDocument3 pagesArab Interns - StartupMooneer El AssaadNo ratings yet

- Straight LineDocument15 pagesStraight LineAyanNo ratings yet

- Socialized HousingDocument48 pagesSocialized HousingJessieReiVicedoNo ratings yet

- 300 PSI CTS (MP-1115) Operation Manual Rev1.3Document18 pages300 PSI CTS (MP-1115) Operation Manual Rev1.3Juan Manuel VizosoNo ratings yet

- PPT DIARHEA IN CHILDRENDocument31 pagesPPT DIARHEA IN CHILDRENRifka AnisaNo ratings yet

- Native Data Sheet Asme b73.1Document4 pagesNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- Surface TensionDocument13 pagesSurface TensionElizebeth GNo ratings yet

- Extract From The Painted Door' by Sinclair RossDocument2 pagesExtract From The Painted Door' by Sinclair RosssajifisaNo ratings yet

- MTH100Document3 pagesMTH100Syed Abdul Mussaver ShahNo ratings yet

- Anxiety Disorders - Causes, Types, Symptoms, & TreatmentsDocument5 pagesAnxiety Disorders - Causes, Types, Symptoms, & Treatmentsrehaan662No ratings yet

- TM-8000 HD Manual PDFDocument37 pagesTM-8000 HD Manual PDFRoxana BirtumNo ratings yet

- Midterm Exam Gor Grade 11Document2 pagesMidterm Exam Gor Grade 11Algelle AbrantesNo ratings yet

- Cambridge IGCSE Paper 2Document4 pagesCambridge IGCSE Paper 2irajooo epik zizterNo ratings yet

- Advanta V12 Data SheetDocument2 pagesAdvanta V12 Data SheetJuliana MiyagiNo ratings yet

- Assignment 2 Unit 20 Fully Completed - ReviewedDocument5 pagesAssignment 2 Unit 20 Fully Completed - Reviewedchris.orisawayiNo ratings yet

- Astm C892 - 00Document5 pagesAstm C892 - 00reneeNo ratings yet

- AssessmentDocument3 pagesAssessmentpalflaxNo ratings yet

- Piriformis Syndrome: Hardi Adiyatma, Shahdevi Nandar KusumaDocument6 pagesPiriformis Syndrome: Hardi Adiyatma, Shahdevi Nandar Kusumaismael wandikboNo ratings yet

- Lecture 12Document8 pagesLecture 12Mechanical ZombieNo ratings yet

- 02-Building Cooling LoadsDocument3 pages02-Building Cooling LoadspratheeshNo ratings yet

- Manual Wire Rope Winches Wall-Mounted Wire Rope Winch SW-W: Equipment and ProcessingDocument1 pageManual Wire Rope Winches Wall-Mounted Wire Rope Winch SW-W: Equipment and Processingdrg gocNo ratings yet

- Emw 2007 FP 02093Document390 pagesEmw 2007 FP 02093boj87No ratings yet

- Arduino Oscilloscope ProjectDocument12 pagesArduino Oscilloscope ProjectSathya Narayan100% (1)

- Physical and Morphological Characterisation of Typha Australis FibresDocument12 pagesPhysical and Morphological Characterisation of Typha Australis FibresIJAR JOURNALNo ratings yet

- Irina Maleeva - Ariel Snowflake x6 - ENG - FreeDocument4 pagesIrina Maleeva - Ariel Snowflake x6 - ENG - FreeMarinaKorzinaNo ratings yet

- WPBSA Official Rules of The Games of Snooker and Billiards 2020 PDFDocument88 pagesWPBSA Official Rules of The Games of Snooker and Billiards 2020 PDFbabuzducNo ratings yet

- FRP Handrail Fittings CatalogDocument6 pagesFRP Handrail Fittings CatalogAl Adel MorenoNo ratings yet

- AKI in ChildrenDocument43 pagesAKI in ChildrenYonas AwgichewNo ratings yet

- Dawn of Solar PV CookingDocument5 pagesDawn of Solar PV CookingAbhinav AgrawalNo ratings yet

- Biology Accel Syllabus 2011-2012Document3 pagesBiology Accel Syllabus 2011-2012Mike DeleonNo ratings yet

- Module-4 (PDFDrive)Document67 pagesModule-4 (PDFDrive)Divya priya KNo ratings yet