Professional Documents

Culture Documents

TDS Pattex Repair Extreme 031223

Uploaded by

jfman0 ratings0% found this document useful (0 votes)

157 views2 pagesElastic Adhesive

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentElastic Adhesive

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

157 views2 pagesTDS Pattex Repair Extreme 031223

Uploaded by

jfmanElastic Adhesive

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Technical Data Sheet

Pattex Repair Extreme

High Performance Elastic Adhesive

Super Multi-Purpose

I. Product:

Nature of product:

Silane cross-linking polymer

Field of application:

Bonding of absorbent surfaces,

e.g. wood, leather (shoe repair),

concrete, mortar, stone, furniture,

textile.

Bonding of non adsorbent

surfaces e.g. metal, glass,

polystyrene foam, varnished

surfaces, PVC, glass, mirror,

rubber.

Package size:

Tube of 20g.

Shipping unit:

PRX12 = 12 tubes per unit

II.

Characteristics:

Will bond two non-absorbent

surfaces together

Adhesion on many different

substrates

Good final strength

Vibration-resistant

Flexible

Gap filling

Safe and easy to use

Solvent-free, no shrinkage

1-component, moisture-curing

For interior and exterior application

Not suitable for polypropylene

polyethylene, Teflon

Final strength:

Appr. 3.0 N/mm

Gap filling tolerance:

Max. 5 mm

Density:

Approx. 1.0 g/cm (at +25C)

Colour:

translucent

Application temperature:

From +5C to +40C

Open time:

Approx. 5 min.

Setting time:

2 mm per 24 hrs., depending on

temperature and humidity conditions

Extension at break:

Approx. 200%

Temperature resistance:

From -50C up to +120C

Bonding resistance:

Ageing-, weather- and moisture-

resistant

23.12.2003

III. Directions for

use:

Application surface:

Pattex Repair Exteme is suitable for

many absorbent and non-absorbent

surfaces, except polyethylene,

polystyrene, Teflon. All

combinations of the recommended

surfaces are possible.

Surface preparation:

To ensure good adhesion, some

moisture is needed (from one of the

surfaces or from the air do not apply

water to the substrate).

The surfaces must be sound and

clean.

Remove contaminants, e.g. dust,

grease, oil or rust with alcohol,

acetone and/or sand-paper.

Check bonding strength between

coverings and the substrate, remove

loose varnishes.

Application:

Three different ways of using

1. Transparent bonding.

Apply Pattex Repair Extrem in a thin

layer to get a transparent film. Keep

the items pressed for approx.1 hour.

2. Fill gaps.

Apply Pattex Repair Extrem in a

thick layer to fill gaps up to 5mm max.

Clamp the items together for 1 3

hours and do not touch or move them.

In 24 hours, 70% of the full adhesion

strength is achieved.

3. High initial grip.

Apply Pattex Repair Extreme on

both surfaces in thin and even layers.

Leave for 4 9 minutes. Use as a

contact adhesive. After Pattex

Repair Extreme become tacky, like

pressure sensitive tape, gain the

items together immediately and press

firmly. Fixation is not necessary in

many cases.

Further information:

After setting, Pattex Repair Extreme

can be painted.

Pattex Repair Extreme should not be

used for sealing of glass that is

exposed to both UV light and

moisture.

The product cures very fast in high

humidity.

Keep the nozzle and the cap of the

tube clean.

Put the cap back on immediately after

applying the glue. Twist the cap tight

to avoid curing in the nozzle.

IV. Important

remarks:

Cleaning tools:

Clean tools with acetone or alcohol

immediately after use. Cured material

can only be removed mechanically.

Shelf life:

Up to 12 months in unopened

container.

Storage:

Store in a cool, dry place. Avoid direct

sunlight.

Removal of adhesive

remnants:

Fresh Pattex Repair Extreme can be

easily removed with a dry cloth.

Uncured adhesive is removable with

acetone or alcohol.

Note: Pattex Repair Extreme can not

be removed from clothing.

The cured adhesive is not soluble in

any solvent and can only be removed

mechanically with a suitable tool.

Precautionary measures:

-Keep out of reach of children

-If skin contact occurs , remove

immediately and wash with soap and

water.

The above instructions are based on thorough trials and on general experience gained in this field. As it is impossible to survey all

installation methods and in view of various different working conditions, we cannot, however, claim that the information given is

complete. We therefore recommend that tests should be carried out on your own to ensure the greatest possible success. We

guarantee a uniform quality standard for this product.

Henkel KGaA

23.12.2003

You might also like

- TDS Pattex BondsealfillDocument5 pagesTDS Pattex BondsealfilldknisNo ratings yet

- Kan FlexDocument3 pagesKan FlexSunny SinghNo ratings yet

- DR Fixit FastflexDocument3 pagesDR Fixit FastflexsubhaschandraNo ratings yet

- Fevicol PurDocument3 pagesFevicol PurVenkata ChadaNo ratings yet

- Betakril: Decorative Water-Based Exterior Product GroupDocument2 pagesBetakril: Decorative Water-Based Exterior Product Groupmaga2292No ratings yet

- Rely X Luting Cement InstructionsDocument3 pagesRely X Luting Cement InstructionsestherlimdmdNo ratings yet

- MASTERSEAL 550 EL v3 PDFDocument2 pagesMASTERSEAL 550 EL v3 PDFRajesh KumarNo ratings yet

- Flexible Pu SealantDocument2 pagesFlexible Pu SealantGi GoNo ratings yet

- TDS ShaliPrime ScreedDocument2 pagesTDS ShaliPrime ScreedRana MahatoNo ratings yet

- Elastocrete P8J Waterproofing Kit Technical Data SheetDocument3 pagesElastocrete P8J Waterproofing Kit Technical Data SheetZèlia FláviaNo ratings yet

- FlexicreteDocument3 pagesFlexicreteapi-302611547No ratings yet

- Metz 8Document2 pagesMetz 8usman ghaniNo ratings yet

- Acrylic Resin Based Plaster Putty For Interior & Exterior: Green Building RatingDocument2 pagesAcrylic Resin Based Plaster Putty For Interior & Exterior: Green Building RatingVetri Vel PrakashNo ratings yet

- VersaGuard Technical Data SheetDocument2 pagesVersaGuard Technical Data SheetJai ChanNo ratings yet

- TDS - Masterflow 400Document2 pagesTDS - Masterflow 400Venkata RaoNo ratings yet

- Product Data Sheet Asmacoat WP 810 Liquid Applied Polyurethane Waterproofing MembraneDocument3 pagesProduct Data Sheet Asmacoat WP 810 Liquid Applied Polyurethane Waterproofing MembraneVaittianathan MahavapillaiNo ratings yet

- 01 Grandflex 72Document2 pages01 Grandflex 72Art WadsilangNo ratings yet

- 2-Part Polyurethane Sealant for Airport Runways & Concrete JointsDocument2 pages2-Part Polyurethane Sealant for Airport Runways & Concrete JointsjoshepNo ratings yet

- Penguard Primer Datasheet " Azadjotun"Document3 pagesPenguard Primer Datasheet " Azadjotun"AzadAhmadNo ratings yet

- All-Purpose Contact AdhesiveDocument3 pagesAll-Purpose Contact AdhesiveBerno Muishond KohlmeyerNo ratings yet

- ShaliTex PrimerDocument2 pagesShaliTex PrimerPrashant BaruaNo ratings yet

- MR - DRY 830EL-v4Document4 pagesMR - DRY 830EL-v4Ankita Baban GavadeNo ratings yet

- Hydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneDocument2 pagesHydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneVenkata Raju KalidindiNo ratings yet

- Rapid Set Tds - NoRestrictionDocument4 pagesRapid Set Tds - NoRestrictionFloorkitNo ratings yet

- JTCC - Neopox LiningDocument3 pagesJTCC - Neopox LiningAdhigana QSNo ratings yet

- DR Fixit NewcoatDocument3 pagesDR Fixit NewcoatShahnaz RataniNo ratings yet

- TDS Weberdry 360 PUDocument3 pagesTDS Weberdry 360 PUMahmoudFarhatNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical Dataウィリアムズ アンディNo ratings yet

- Sealbond Optimastic PU1K 60 Polyurethane WaterproofingDocument4 pagesSealbond Optimastic PU1K 60 Polyurethane WaterproofingMel GarciaNo ratings yet

- TDS Weberfloor EposilDocument2 pagesTDS Weberfloor EposilMaha MuflehNo ratings yet

- Anti Carbonation PaintDocument24 pagesAnti Carbonation PaintAnonymous KeVnZt2ynBNo ratings yet

- Visko Primer VP 4005Document2 pagesVisko Primer VP 4005ricki harnistNo ratings yet

- ULTRAMIX Tds en 0619Document3 pagesULTRAMIX Tds en 0619Dorian BugejaNo ratings yet

- UltraTech SEAL & DRY waterproofing solutionDocument4 pagesUltraTech SEAL & DRY waterproofing solutionAnySikaNo ratings yet

- STP ShaliTapeFleXDocument2 pagesSTP ShaliTapeFleXRana MahatoNo ratings yet

- Ultrakote Stretchkote 2022 MinDocument2 pagesUltrakote Stretchkote 2022 MinAlex AcevedoNo ratings yet

- Shalitape Flex: DescriptionDocument2 pagesShalitape Flex: DescriptionbarunNo ratings yet

- Betec Flex S150Document2 pagesBetec Flex S150khoamartinNo ratings yet

- Proofex 12 PDFDocument2 pagesProofex 12 PDFmilanbrasinaNo ratings yet

- Cat Epoxy TD MULTIPOX MX-99 (Rev.02)Document2 pagesCat Epoxy TD MULTIPOX MX-99 (Rev.02)yesitamaNo ratings yet

- TDS - Soudal Repair Express CementDocument2 pagesTDS - Soudal Repair Express CementЗоранNo ratings yet

- Aqua Proof Data SheetsDocument3 pagesAqua Proof Data SheetsGeorge SitanayaNo ratings yet

- Idealpu78-Matt Tec EngDocument2 pagesIdealpu78-Matt Tec EngPedroNo ratings yet

- TERRAFLEXDocument1 pageTERRAFLEXChitko KoNo ratings yet

- Apcotide 1000 pc2782Document1 pageApcotide 1000 pc2782hellmanyaNo ratings yet

- BERGOSILAN Water Repellent TreatmentDocument2 pagesBERGOSILAN Water Repellent TreatmentMuthuKumarNo ratings yet

- Anticorossive Epoxy FlooringDocument2 pagesAnticorossive Epoxy Flooringtejas_tNo ratings yet

- Product Data Sheet: Product Description Product Description Product Description Product DescriptionDocument3 pagesProduct Data Sheet: Product Description Product Description Product Description Product DescriptionVaittianathan MahavapillaiNo ratings yet

- POLYTEXDocument2 pagesPOLYTEXDon AlexNo ratings yet

- Ultrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringDocument4 pagesUltrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringFloorkitNo ratings yet

- Fenomastic MattDocument3 pagesFenomastic MattarunmohanmpNo ratings yet

- Epoxy Resin Mortar for Concrete ProtectionDocument2 pagesEpoxy Resin Mortar for Concrete ProtectionsudhialakkalNo ratings yet

- Silicon Sealant Asmaco 2540Document3 pagesSilicon Sealant Asmaco 2540rimshadtpNo ratings yet

- Tex KoteDocument2 pagesTex KoteJurie_sk3608No ratings yet

- Kanseal Pu.Document4 pagesKanseal Pu.Sunny SinghNo ratings yet

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- 0002961-To 1b-52h-1-13 b-52h Ewo ManualaDocument51 pages0002961-To 1b-52h-1-13 b-52h Ewo Manualajfman100% (2)

- M4A1 ShermanDocument13 pagesM4A1 ShermanjfmanNo ratings yet

- 0002961-To 1b-52h-1-13 b-52h Ewo Manuala PDFDocument272 pages0002961-To 1b-52h-1-13 b-52h Ewo Manuala PDFjfmanNo ratings yet

- M-923 A1 Big Foot: Print FilmDocument7 pagesM-923 A1 Big Foot: Print FilmjfmanNo ratings yet

- Review - 1 - 35 T-90A Russian MBT (Meng TS-006) - Military Scale Modelling!Document10 pagesReview - 1 - 35 T-90A Russian MBT (Meng TS-006) - Military Scale Modelling!jfmanNo ratings yet

- M1a1 TuskDocument696 pagesM1a1 Tuskjfman100% (1)

- M 113Document8 pagesM 113jfmanNo ratings yet

- M1A1 Abrams Tank "Cojone EhDocument3 pagesM1A1 Abrams Tank "Cojone EhjfmanNo ratings yet

- M256 120mm Smoothbore GunDocument23 pagesM256 120mm Smoothbore GunjfmanNo ratings yet

- Oshkosh MTVR BrochureDocument12 pagesOshkosh MTVR Brochurejfman100% (1)

- LimaTankPlantDocument4 pagesLimaTankPlantpl_junkNo ratings yet

- 105mm Gun Tank M1 AbramsDocument21 pages105mm Gun Tank M1 Abramsjfman100% (1)

- MTVRDocument8 pagesMTVRjfman100% (1)

- RB ModelDocument10 pagesRB ModeljfmanNo ratings yet

- F/A-18 GRU/SJU Seat Detail Set: 1/32 Scale Detail Set For - Sada Detailù Pro Model 1/32Document3 pagesF/A-18 GRU/SJU Seat Detail Set: 1/32 Scale Detail Set For - Sada Detailù Pro Model 1/32jfmanNo ratings yet

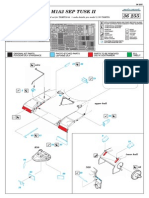

- M1A1/ A2 Abrams: 1/72 Scale Detail Set For Kit - Sada Detailù Pro Model Dragon 7215 Dragon 7215 1/72Document4 pagesM1A1/ A2 Abrams: 1/72 Scale Detail Set For Kit - Sada Detailù Pro Model Dragon 7215 Dragon 7215 1/72jfmanNo ratings yet

- B-17G Rear Interior 73 383: 5 SetsDocument4 pagesB-17G Rear Interior 73 383: 5 SetsjfmanNo ratings yet

- F/A-18 Hornet Exhaust Set: ReferencesDocument3 pagesF/A-18 Hornet Exhaust Set: ReferencesjfmanNo ratings yet

- AeroScale - How To - Homemade Vacuforming Box by Diego M. PaveseDocument5 pagesAeroScale - How To - Homemade Vacuforming Box by Diego M. PavesejfmanNo ratings yet

- M1A2 Sep Tusk IiDocument8 pagesM1A2 Sep Tusk IijfmanNo ratings yet

- A-6 Intruder Interior SetDocument4 pagesA-6 Intruder Interior SetjfmanNo ratings yet

- F/A-18 Hornet Armament: 1/32 Scale Detail Set For Kit - Sada Detailù Pro Model Academy Academy 1/32Document3 pagesF/A-18 Hornet Armament: 1/32 Scale Detail Set For Kit - Sada Detailù Pro Model Academy Academy 1/32jfmanNo ratings yet

- M1A1/ A2 Abrams: 1/72 Scale Detail Set For Kit - Sada Detailù Pro Model Dragon 7215 Dragon 7215 1/72Document4 pagesM1A1/ A2 Abrams: 1/72 Scale Detail Set For Kit - Sada Detailù Pro Model Dragon 7215 Dragon 7215 1/72jfmanNo ratings yet

- M39 A2 A3Document2 pagesM39 A2 A3jfman100% (1)

- F/A-18C Hornet Interier: 1/32 Scale Detail Set For Kit 2191 - Sada Detailù Pro Model Academy 2191 Academy 1/32Document5 pagesF/A-18C Hornet Interier: 1/32 Scale Detail Set For Kit 2191 - Sada Detailù Pro Model Academy 2191 Academy 1/32jfmanNo ratings yet

- F/A-18 Hornet Exterior: 1/32 Scale Detail Set For Kit - Sada Detailù Pro Model Academy 2191 Academy 2191 1/32Document4 pagesF/A-18 Hornet Exterior: 1/32 Scale Detail Set For Kit - Sada Detailù Pro Model Academy 2191 Academy 2191 1/32jfmanNo ratings yet

- F-100C Exterior: G6, G7 G1 G17Document2 pagesF-100C Exterior: G6, G7 G1 G17jfmanNo ratings yet

- Sulfur production and consumption by regionDocument3 pagesSulfur production and consumption by regionjfmanNo ratings yet

- Rappaport Vassiliadis Soya Broth (RVS Broth) : CompositionDocument2 pagesRappaport Vassiliadis Soya Broth (RVS Broth) : CompositionDuyên TrầnNo ratings yet

- Us 7368613Document13 pagesUs 7368613Anirban MullickNo ratings yet

- Agar Diferencial WL PDFDocument2 pagesAgar Diferencial WL PDFAndreaRiveraNo ratings yet

- How Cells Move Materials Against Concentration GradientsDocument11 pagesHow Cells Move Materials Against Concentration GradientsDARLENE JANE MAYNESNo ratings yet

- Tall Oil Production and ProcessingDocument11 pagesTall Oil Production and Processinggauravjuyal1988No ratings yet

- Aero A700 Gas Chromatograph SpecsDocument2 pagesAero A700 Gas Chromatograph SpecsSandi WijayaNo ratings yet

- Magnesium Aluminium SilicateDocument5 pagesMagnesium Aluminium SilicateWanguNo ratings yet

- Alloying Elements ExcelDocument18 pagesAlloying Elements ExcelRavindra ErabattiNo ratings yet

- Journal Pre-Proofs: Food Research InternationalDocument75 pagesJournal Pre-Proofs: Food Research InternationalLuis Jaime Perez CordobaNo ratings yet

- Chemistry 2021 PAPERDocument8 pagesChemistry 2021 PAPERcabek22797No ratings yet

- Water Analysis: Student GuideDocument34 pagesWater Analysis: Student GuideJAMES CURRANNo ratings yet

- Unit-2: Phase DiagramDocument37 pagesUnit-2: Phase DiagramPrasad Govind KumbharNo ratings yet

- Introduction to General, Organic, and Biochemistry Chapter 12 Alkenes and AlkynesDocument31 pagesIntroduction to General, Organic, and Biochemistry Chapter 12 Alkenes and AlkynesEli JahNo ratings yet

- Rubber CompoundingDocument23 pagesRubber Compoundingharsh nagarNo ratings yet

- Biomolecules and Cells Notes SummaryDocument81 pagesBiomolecules and Cells Notes SummaryLily RobinsonNo ratings yet

- E3: Kinetics of The Hydrogen Peroxide/Iodide ReactionDocument5 pagesE3: Kinetics of The Hydrogen Peroxide/Iodide ReactionAlfian HadiwijayaNo ratings yet

- Acids Bases and Salts For Students To StickDocument4 pagesAcids Bases and Salts For Students To StickARSHAD JAMILNo ratings yet

- Paper 2 June 2019Document32 pagesPaper 2 June 2019ayeshaNo ratings yet

- 2013 H2 Redox Titration (Iodometric Titration) Teachers'Document4 pages2013 H2 Redox Titration (Iodometric Titration) Teachers'csanjeevanNo ratings yet

- EFKA GuideDocument16 pagesEFKA GuideChinmoy DholeNo ratings yet

- Sulphuric Acid 98%: Safety Data SheetDocument1 pageSulphuric Acid 98%: Safety Data SheetZAHID HUSSAINNo ratings yet

- Titanium Corrosion PDFDocument3 pagesTitanium Corrosion PDFSellappan MuthusamyNo ratings yet

- Proterozoic Iron Oxide (Cu-U-Au-REE) Deposits: Further Evidence of Hydrothermal OriginsDocument4 pagesProterozoic Iron Oxide (Cu-U-Au-REE) Deposits: Further Evidence of Hydrothermal OriginsBruno Brasil MuthsNo ratings yet

- Microemulsions Yuppieraj GaloreDocument20 pagesMicroemulsions Yuppieraj GaloreSairi Madhwika. 11No ratings yet

- 2023 09 18 05 31 SolutionDocument4 pages2023 09 18 05 31 Solutionthisisravi0No ratings yet

- Toothpaste Analysis Reveals Key IngredientsDocument24 pagesToothpaste Analysis Reveals Key IngredientsSona RamunajanNo ratings yet

- Introducing HalogenoalkanesDocument36 pagesIntroducing HalogenoalkanesVictor Michael NdifeNo ratings yet

- Go Chemistry: A Card Game To Help Students Learn Chemical FormulasDocument3 pagesGo Chemistry: A Card Game To Help Students Learn Chemical FormulasYhessie OctaviaNo ratings yet

- Class 12th Chemistry Chapter 9 (Coordination Compounds) Important Unsolved QuestionsDocument6 pagesClass 12th Chemistry Chapter 9 (Coordination Compounds) Important Unsolved Questionsanuragk.kumar2006No ratings yet

- Organic Compound IdentificationDocument8 pagesOrganic Compound IdentificationpradeepNo ratings yet