Professional Documents

Culture Documents

Design Quad

Uploaded by

Akos Sapkas0 ratings0% found this document useful (0 votes)

36 views13 pagesreinforcement design

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentreinforcement design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views13 pagesDesign Quad

Uploaded by

Akos Sapkasreinforcement design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

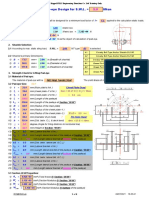

Task: Design Parameters of Area Elements

2014 / 1 Design Area Elements

Task: Design Parameters of Area Elements

2014 / 2 Design Area Elements

Main reinforcement = direction local x-axis

Transverse reinforcement = direction local y-axis

In BEMESS both the directions of the

reinforcement layers and the terms upper and

lower are oriented at the local coordinate

systems; lower is at the side of positive z axis.

Task: Design Parameters of Area Elements

2014 / 3 Design Area Elements

Minimum reinforcement

important for SLS design

Maximum reinforcement

for non linear analysis only

Task Design ULS area elements

2014 / 4 Design Area Elements

Task Design ULS Punching Check

2014 / 5 Design Area Elements

Results ULS Design

2014 / 6 Design Area Elements

Task Design SLS Area Elements

2014 / 7 Design Area Elements

Task Design SLS area elements

2014 / 8 Design Area Elements

Design ULS Prestressed Elements

2013 / 9 Design

3 tendons with distance of 1.40 m

Cross section 4,0 m x 1,0 m

modelled with QUAD elements of

1,0 m thickness

The influence of every single

tendon will be distributed by a

triangular shape with

2 * 2.0 * QUAD-thickness

Design ULS Prestressed Elements

REINFORCEMENT ACC. TO EN 1992-1-1(DK) in [cm2/m] at nodes upper/lower

General load safety factor - as defined in BEMESS: Gamma-f = 1.00

Shear: stresses VEd/d and VRd,ct/d with d=effective depth = h-hm

Shear index 2m = minimum shear reinforcement

Group 1

NODE LC MAT GEO h Reinforcement dphi Shr VEd/d Ass

Grp No No No No [m] main cross dir deg zon [MPa] [cm2/m2]

MBW VRd,ct/d

1 607 2122 1 1 1.00 2.65 13.25 90 90 1 0.273

2 90 0.620

lever arm for upper reinforcm =0.901 for lower =0.939 [m]

upside lay. 1|2=0.907 |0.894 bottom lay. 1|2=0.945 |0.933 [m]

Angle of main shear force to x axis = 178.4 []

Normal force in direction of main shear force = -1708. [kN/m]

Bending moment in direction of main shear = -1562. [kN/m]

- -> upper reinf. is taken for tension reinf. ro:

Tension reinf. in direction of main shear force 13.25 [cm2/m]

V_design= 261.77 VRD1= 594.28 VRD2= 4012.6 [kN/m] ro= 0.14

-----------------------------------------------------------------

maximum 5.65 13.25 90 1 0.273

incl.shear ro_v 5.65 5.65 90 0.620

Explanations shear state Shr zon:

1 = check without necessary shear reinforcement

2 = shear reinforcement required

m = minimum shear reinforcement

2013 / 10 Design

Design ULS Prestressed Elements

Reinforcement reduction due to tendon stress increase

element/node LC layer nten az z depsz dsigz ZZ delta_as

[cm2/m] [m] [o/oo] [MPa] [m] [cm2/m]

NODE 607 2122 top 2 3 18.02 -0.311 17.118 196.85 0.747 6.51

:

nstr = number of acting tendons in element influence radius

az = per m distributed active prestressed tendon steel area

(AZ distributed triangle wise on 2.0*element thickness right+left)

z = averaged local z coordinate (measured from element center line)

depsz = averaged increase of tendon strain

dsigz = applied increase of stress in prestressed tendon steel, limited to

fym/gammas - sigp0 with fym=0.5*(fyc+ft) and sigp0=prestress stress

ZZ = averaged lever arm of tendons

delta_as = maximum reinforcement reduction due to tendon stress increase

2013 / 11 Design

Distributed tendon steel area in node 607

oz =

22,Su cm`

2

+ 2

22,Su cm

2

2

2uu 14u

2uu

= 18,u cm`

Node 607 centre of cross section

Jclto_os =

18,u cm

2

196,8S HPo

S2SHPo

1,1S

u,747

u,894

= 6,49 cm`

Ratio of lever arm tendon

over reinforcement steel

Reinforcement steel

stress according to strain

distribution

Design ULS Prestressed Elements

2013 / 12 Design

Applieu inciease of stiess in piestiesseu tenuon steel DSIGZ in Noue 6u7

Jcltao

z

=

u,S 1S2u,uu +177u,uu

1,1S

12S4,S9 = 14Su,4S 12S4,S9 = 196,uSHPo

RC-Bridge Example: Check Stresses

2013 / 13 Design

File: quad design\rc-bridge.sofistik

You might also like

- 17 TON PADEYE STRENGTH CHECKDocument12 pages17 TON PADEYE STRENGTH CHECKoluomo1No ratings yet

- TEDDS Calculation Version 3.0.09: - Section Is CompactDocument2 pagesTEDDS Calculation Version 3.0.09: - Section Is CompactSupun Aravinda JayawardhaneNo ratings yet

- RC Beam Design Calculation SheetDocument3 pagesRC Beam Design Calculation Sheetikanyu79100% (1)

- EC2 Beam DesignDocument4 pagesEC2 Beam Designikanyu79No ratings yet

- Mechanical Calculation - Inspection Port NeckDocument18 pagesMechanical Calculation - Inspection Port Neckfaizal rizkiNo ratings yet

- Design SectionDocument19 pagesDesign SectionKrishna KumarNo ratings yet

- Design and dynamic analysis of 70T overhead crane girderDocument8 pagesDesign and dynamic analysis of 70T overhead crane girderGogyNo ratings yet

- IS800 2007 Pipe 1 Detailed CalculationDocument5 pagesIS800 2007 Pipe 1 Detailed CalculationDeepanshu GahtoriNo ratings yet

- 5.15 Swing Barrier v.1.0Document190 pages5.15 Swing Barrier v.1.0rfvz6sNo ratings yet

- Shear Design Summary for Reinforced Concrete BeamsDocument8 pagesShear Design Summary for Reinforced Concrete BeamsShashikant Gaur0% (1)

- IS800_2007_Tube Design CalculationDocument4 pagesIS800_2007_Tube Design CalculationLandon MitchellNo ratings yet

- Lifting Sets Calculation - API RP 2ADocument11 pagesLifting Sets Calculation - API RP 2AQuang-derer100% (28)

- Design of Beam-Aci-11-01-05Document23 pagesDesign of Beam-Aci-11-01-05aomareltayeb100% (1)

- Skirt Design - For Small VesselsDocument7 pagesSkirt Design - For Small VesselsSakthi VelNo ratings yet

- Comparative Design of Biaxial R.C. Columns to CodesDocument14 pagesComparative Design of Biaxial R.C. Columns to CodesMouhamad WehbeNo ratings yet

- RC Beam Design To EC2Document3 pagesRC Beam Design To EC2suman_civilNo ratings yet

- Shear Check To Eurocode 2Document4 pagesShear Check To Eurocode 2smkumar121No ratings yet

- Strip methodDocument11 pagesStrip methodAmanuelNo ratings yet

- Concrete Design 1 - R2Document14 pagesConcrete Design 1 - R2Waleed KokabNo ratings yet

- Sloped FootingDocument19 pagesSloped FootingBala ChandarNo ratings yet

- RCC FOOTING DESIGN CALCULATIONSDocument16 pagesRCC FOOTING DESIGN CALCULATIONSengineerkranthi4055No ratings yet

- Structrual Concrete Design To Eurocode 2 University of Sheffield Structural Engineering MastersDocument12 pagesStructrual Concrete Design To Eurocode 2 University of Sheffield Structural Engineering Mastersfatabass100% (3)

- Beam - Main Beam - GM7Document87 pagesBeam - Main Beam - GM7FrederickV.VelascoNo ratings yet

- RCC DESIGN CASE STUDYDocument25 pagesRCC DESIGN CASE STUDYWHATS APP STATUSNo ratings yet

- Design of composite slabDocument7 pagesDesign of composite slabjonathanbido100% (4)

- StaircaseDocument8 pagesStaircaseVenkat BalajiNo ratings yet

- Combined Footing Irregular CoulmnDocument6 pagesCombined Footing Irregular CoulmnKhalid BanafaNo ratings yet

- Task 2.2Document15 pagesTask 2.2Mordecai de ValoisNo ratings yet

- Solved Example On Design of Slender Columns According To EC2Document7 pagesSolved Example On Design of Slender Columns According To EC2Mouhamad Wehbe100% (1)

- End-Plate - Beam to Beam Connection Design 3Document8 pagesEnd-Plate - Beam to Beam Connection Design 3gianniorlatiNo ratings yet

- Pad-eye Design for 5 Mton Lifting LoadDocument2 pagesPad-eye Design for 5 Mton Lifting LoadPaulo MoreiraNo ratings yet

- Design of Slender Columns According To EC2Document5 pagesDesign of Slender Columns According To EC2selinaNo ratings yet

- Case Ii1Document17 pagesCase Ii1123No ratings yet

- Appendix RW - Design of R.C. Cantilever Retaining Wall: Louis Berger in Association With SABA Engineering PLCDocument12 pagesAppendix RW - Design of R.C. Cantilever Retaining Wall: Louis Berger in Association With SABA Engineering PLCHundeejireenyaNo ratings yet

- One Way Slab DesignDocument16 pagesOne Way Slab DesignAssad Mohammed AliNo ratings yet

- Design of MonorailDocument9 pagesDesign of MonorailAnonymous Q8XIGqHyCNo ratings yet

- Design of Purlins per IS800 and SP38Document2 pagesDesign of Purlins per IS800 and SP38MM93% (29)

- Foundations PDFDocument5 pagesFoundations PDFrajiuaeNo ratings yet

- Foundation DesignDocument15 pagesFoundation Designayazmad100% (1)

- Slab Full Report (Span) - GBDocument182 pagesSlab Full Report (Span) - GBbce20090001No ratings yet

- Calculation of column reinforcement area according to EN 1992Document6 pagesCalculation of column reinforcement area according to EN 1992Florian EsnaultNo ratings yet

- U Trough WO BRIDGEDocument14 pagesU Trough WO BRIDGEIgnatius PathulaNo ratings yet

- Slab Design Full Report: Material and Design DataDocument22 pagesSlab Design Full Report: Material and Design DataazwanNo ratings yet

- Design of Bolted Beam Splice Connections According To EC3Document11 pagesDesign of Bolted Beam Splice Connections According To EC3Franklyn Genove100% (2)

- Structural Design of Combined FootingsDocument6 pagesStructural Design of Combined Footingsselina100% (1)

- Designing, Planning and Analysis of VillaDocument34 pagesDesigning, Planning and Analysis of VillaMohamed FarweezNo ratings yet

- Stepped Footing - 1 PDFDocument11 pagesStepped Footing - 1 PDFSushil Dhungana93% (15)

- U Trough BRIDGEDocument17 pagesU Trough BRIDGEIgnatius PathulaNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Introducing JiFi ST Petersburg 2014Document4 pagesIntroducing JiFi ST Petersburg 2014danjohhnNo ratings yet

- Precision Thermometers CatalogueDocument44 pagesPrecision Thermometers CataloguemarthaNo ratings yet

- Magnetism Workhsheet Siap EditDocument10 pagesMagnetism Workhsheet Siap EditMamberamo ClassNo ratings yet

- Air Preheater Technical PaperDocument21 pagesAir Preheater Technical Paperchekoti koushikNo ratings yet

- TM - 11-5855-214-23&p - (N04596) PDFDocument65 pagesTM - 11-5855-214-23&p - (N04596) PDFtyra24No ratings yet

- Electrical and Optical Properties of Indium-Tin Oxide (ITO) Films by Ion-Assisted Deposition (IAD) at Room TemperatureDocument6 pagesElectrical and Optical Properties of Indium-Tin Oxide (ITO) Films by Ion-Assisted Deposition (IAD) at Room Temperaturereza mirzakhaniNo ratings yet

- Air SeperatorDocument35 pagesAir SeperatorhasanNo ratings yet

- Assignment 1 DESA 1004 - Paulo Ricardo Rangel Maciel PimentaDocument4 pagesAssignment 1 DESA 1004 - Paulo Ricardo Rangel Maciel PimentaPaulo PimentaNo ratings yet

- Determining Dielectric Constants Using A Parallel Plate CapacitorDocument5 pagesDetermining Dielectric Constants Using A Parallel Plate CapacitorAhmAd GhAziNo ratings yet

- Reability PDFDocument396 pagesReability PDFMarcelo Ziulkoski100% (1)

- Induction Heating - VerDocument2 pagesInduction Heating - Verdenivaldo2009No ratings yet

- Fjbzr6wn50 - Class 7 Timetable - Fua 2024Document2 pagesFjbzr6wn50 - Class 7 Timetable - Fua 2024mrs.prernajainNo ratings yet

- 1981 - Leeper - Wet Cooling Tower - Rule of Thumb Design and SimulationDocument32 pages1981 - Leeper - Wet Cooling Tower - Rule of Thumb Design and SimulationGuilherme Venturi RonchiNo ratings yet

- Mousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeDocument1 pageMousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeMorteza AtaeiNo ratings yet

- Fluidized Bed CombustionDocument600 pagesFluidized Bed Combustionvikasnar100% (7)

- Sublimation and Melting Point DeterminationDocument3 pagesSublimation and Melting Point DeterminationRhone RoqueNo ratings yet

- Soil Nail Wall - Soil Nailing - Deep ExcavationDocument7 pagesSoil Nail Wall - Soil Nailing - Deep ExcavationAlok Mehta0% (1)

- Printed Vesiontunable Optical Properties of Bi12Na12TiO3 Materials Via Sm12Na12TiO3Document8 pagesPrinted Vesiontunable Optical Properties of Bi12Na12TiO3 Materials Via Sm12Na12TiO3Vinh PhamNo ratings yet

- HW2 Solutions FinalDocument5 pagesHW2 Solutions Finalpande_100No ratings yet

- Hooke's Law and Property of MaterialsnotesDocument5 pagesHooke's Law and Property of MaterialsnotesPrithu PareekNo ratings yet

- Trư NG Thcs : Question IV. Find and Correct The Mistake in Each Sentence. (1p)Document2 pagesTrư NG Thcs : Question IV. Find and Correct The Mistake in Each Sentence. (1p)Anh ThưNo ratings yet

- Stiffness of Cable-Based Parallel Manipulators With Application To Stability AnalysisDocument8 pagesStiffness of Cable-Based Parallel Manipulators With Application To Stability AnalysisNhật MinhNo ratings yet

- Why Do We Study Physics - Socratic PDFDocument1 pageWhy Do We Study Physics - Socratic PDFMon LuffyNo ratings yet

- NTMM LAB: MATERIAL REMOVAL RATE TEST ON ULTRASONIC MACHINEDocument23 pagesNTMM LAB: MATERIAL REMOVAL RATE TEST ON ULTRASONIC MACHINETarundeep SinghNo ratings yet

- Carrefour-SA Shopping Center TurkeyDocument2 pagesCarrefour-SA Shopping Center TurkeyVineet JogalekarNo ratings yet

- Chemical Engineering Magazine Abril 2009 PDFDocument108 pagesChemical Engineering Magazine Abril 2009 PDFFélix Vargas Santillán100% (1)

- Quatitative Microscopy Cog PDFDocument6 pagesQuatitative Microscopy Cog PDFNiyati GuptaNo ratings yet

- EagleBurgmann Statotherm P Foil 9591 P enDocument1 pageEagleBurgmann Statotherm P Foil 9591 P enkeyur1109No ratings yet

- 400 KV Tender Docs PDFDocument356 pages400 KV Tender Docs PDFtanujaayerNo ratings yet

- ME 555 Stress Analysis Unit 4Document57 pagesME 555 Stress Analysis Unit 4TheoNo ratings yet