Professional Documents

Culture Documents

RFQ - SPT (20110323)

Uploaded by

Almario SagunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RFQ - SPT (20110323)

Uploaded by

Almario SagunCopyright:

Available Formats

TECHNICAL SPECIFICATION

FOR

SPHERICAL TANKS

DATE : Aug. 11, 2010

REV. 1

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

REQUISITION (CONSTRUCTION)

for

SPHERICAL TANKS

of

JG SUMMIT NAPHTHA CRACKER PROJECT

in

BATANGAS, PHILIPPINES

Client : JG SUMMIT Petro. Corp.

STE Requisition No. : STE-RFQ-SPT-02-001

Mar. 23. 2011

TECHNICAL SPECIFICATION

FOR

SPHERICAL TANKS

DATE : Aug. 11, 2010

REV. 1

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

CONTENTS

1. Tank Item List

2. Scope of Work and Supply

3. General Assembly Drawings

4. Project Schedule

5. Painting Specification

TECHNICAL SPECIFICATION

FOR

SPHERICAL TANKS

DATE : Aug. 11, 2010

REV. 1

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

1. Tank Item List

TECHNICAL SPECIFICATION

FOR

SPHERICAL TANKS

DATE : Aug. 11, 2010

REV. 1

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

1. Tank Item List

[Base Case] ASME SEC.VIII, Div.1

No Item Product Type

Qt'y

(sets)

Unit

Capacity

Per Tank

(m3)

Size

Main

Material

Dia(mm)

HT (mm)

(G.L to CL)

1 C-3011

Ethylene

Off-Spec

Sphere 1 2,378 16,560 11,280 SA537-CL1+S5

2 C-3012 C3/LPG Sphere 1 310 8,400 7,200 SA516-70

[ Note ] : Please refer to General Assembly Dwgs. for more information in detail

TECHNICAL SPECIFICATION

FOR

SPHERICAL TANKS

DATE : Aug. 11, 2010

REV. 1

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

2. Scope of Supply and Work

TECHNICAL SPECIFICATION

FOR

SPHERICAL TANKS

DATE : Aug. 11, 2010

REV. 1

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

2. Scope of Supply and Work

[ Classification ] :

( S ) Mark means STEs scope

( V ) Mark means Vendors scope

( X ) Mark means out of STEs scope

2.1 Scope of Supply

( S ) Tank proper

( S ) Internal and external accessories indicated on data sheets

( S ) Internal support

( S ) All parts directly welded to equipment

( S ) Clips for platform/ladder/pipe supports directly welded on tanks or tank columns

( S ) Davits for manholes

( S ) Anchor bolts, nuts & washers and templates

( S ) Platforms, stairways, walkways, ladders and handrails

( S ) Internal ladder (if required)

( S ) Fixed Water Spray System piping, nozzles to be installed on tanks

( S ) Tank support columns with bracings and fire proofing lugs

( S ) Earth lugs (A240-304)

( S ) Name plates (A240-304) with brackets

( S ) Settlement check lugs (if required)

( S ) Stilling well pipes with nozzles and pipe supports for level indicators

( S ) Bolts/nuts, clamps, gaskets for internal

( S ) Fitting for transportation (if required)

( S ) Blind flanges together with bolts, nuts and gaskets for blinded manholes and nozzles

( S ) Special tools and jigs for site assembling, operation and maintenance

( V ) Blind flanges together with bolts, nuts and proper gaskets for hydrostatic test

( V ) Painting material for tank proper and platform & stairway

( V ) Welding consumables with welding rod at shop and site

( V ) Consumables for erection including grouting

( V ) J igs and tools for construction

( V ) Heavy Equipment for construction

( V ) Corrosion inhibitor for hydrostatic test (if required)

( V ) Test plates for welder and welding procedure qualification and production test

( S ) Spare parts for construction, pre-commissioning for blind flanges

( S ) Spare parts for commissioning and start-up for blind flanges

( S ) Spare parts for two(2) years operation for blind flanges (by option)

TECHNICAL SPECIFICATION

FOR

SPHERICAL TANKS

DATE : Aug. 11, 2010

REV. 1

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

2.2 Scope of Work

( S ) Mechanical design (strength calculation, stress analysis and design)

( S ) Detail fabrication drawings (General assembly, all kinds of appurtenance drawings)

( S ) Loading data and anchor plan for foundation

( S ) Other necessary documentations including ITP, erection procedure, etc.)

( S ) Design of riser pipes, ring pipes and connector for spray nozzles

( S ) Material procurement

( S ) Mechanical guarantee

( S ) Provision for as-built drawings and documents

( S ) Fabrication at shop

( S ) Surface preparation and painting at shop as per painting specification

( V ) Site construction

( V ) PWHT (as per ASME Code)

( V ) WPS with PQR and production test

( V ) PQT and WPQT

( V ) NDE at shop and site (RT before site PWHT and UT after site PWHT)

( V ) Inspection & test at shop and site, water drainage and drying work

( V ) Touch-up painting and site as per painting specification

( V ) N2 gas charge work

( V ) Third party inspection (excluding its fee)

( S ) Submittal of packing list (packing volume, size and weight, etc.)

( S ) Packing and protection

( S ) Inland transportation in Korea

( V ) Unloading of material at site

( V ) Temporary work of utility for construction and test

( V ) Dimensional check and acceptance of foundation including minor adjustment work

( V ) Hydrostatic test at site and water drainage as broom clean condition

( V ) Internal cleaning to make sure (by water jet)

( V ) Settlement checking during hydrostatic test

( V ) Grouting for tank foundation

( V ) Government approval in accordance with local regulation and law

( S ) Documentation for purchasers government approval

( V ) Tank calibration

TECHNICAL SPECIFICATION

FOR

SPHERICAL TANKS

DATE : Aug. 11, 2010

REV. 1

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

2.3 Out of Scope

( X ) Civil and tank foundation

( X ) Electrical

( X ) Instruments (level indicator, thermometers, pressure gauge and etc.)

( X ) Gas heat detection system (if required)

( X ) Connecting bolts, nuts and gaskets for companion flanges

( X ) Insulation material and Insulation work

( X ) Fire proofing on column and body

( X ) N2 gas for N2 charging

( X ) Inland transportation in Philippines

( X ) Ocean freight

( X ) Customs clearance and taxes & duties

( X ) Cabling and wiring materials for permanent

( X ) All valves including safety relief valve

( X ) Blind flanges with bolts, nuts and gaskets for test

( X ) Customs clearance and duties

( X ) Electricity for construction (will be provided to the main panel by Client)

( X ) Hydro-test water (will be supplied to the first block valve by Client)

TECHNICAL SPECIFICATION

FOR

SPHERICAL TANKS

DATE : Aug. 11, 2010

REV. 1

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

3. General Assembly Drawings

TECHNICAL SPECIFICATION

FOR

SPHERICAL TANKS

DATE : Aug. 11, 2010

REV. 1

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

4. Project Schedule

Project Name : Spherical Tank for J G Summit NCC Project Date : Dec. 20. 2010

1. MILESTONES

2. ENGINEERING

-

-

-

3. PROCUREMENT

-

-

-

4. PRE-FABRICATION

-

- Upper Column Assembly

- Manhole &Nozzle Assembly

- Lower Column &Brace Fab.

-

-

5. OCEAN FREIGHT

-

6. CONSTRUCTION

Preparation

- Material and Tool-Consumable Prepare of on site

- TemporaryFacillties &shop welder test

Q'ty Weight

I.D(m) H(m) Set Ton

- C-3011 SPT 16.56 11.28 1 522

Erection

Welding

PWHT

Hydro. Test

Painting

- C-3012 SPT 8.40 7.20 1 75

Erection

Welding

Hydro. Test

Painting

PROJECT MASTER SCHEDULE

DESCRIPTION

2010 2011 2012

Remarks

12 1 2 3 6 12 1 2 3 8 9 10 11

Strength Calculation All Item

BodyDetail Drawing All Item

4 5 4 5 6 7

Steel Shape 405Ton

Others Material 63Ton

AccessoryDetail Drawing All Item

Steel Plate 2,652Ton

Others Accessories

1st Shipment 597Ton

Shell Plate Forming 2,368Ton

Water Spray&Internal Piping

S-Tank Engineering Co.,Ltd.

Gr. ItemNo Type

Tank Size

ERECTION START FABRICATION START 1ST SHIPMENT HYDRO TEST START MECHANICAL COMPLETE

TECHNICAL SPECIFICATION

FOR

SPHERICAL TANKS

DATE : Aug. 11, 2010

REV. 1

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

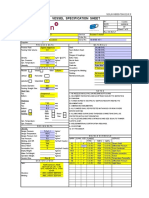

5. Painting Specification

PROJECT NAME : <DIC> Spherical Tank for JG Summit NCC Project

P R I C E F O R M

'11. 01. 26 (Rev.0)

S-Tank Engineering Co., Ltd.

Unit

Capacity

of Tank

Design

Pressure

C.A

Shell

Thickness

Q'TY W/T Erection

Field

PWHT

Site

painting

Site

Inspection

and

Test

(Excluding

H.T

Water)

Fire

Proofing

N2

Chargin

g

Tank

Calibration

Sub

Total

( C )

Total

I.D H

m^3

(Ton)

(Barg) (mm) (mm) SET (TON) (USD) (USD) (USD) (USD) (USD) (USD) (USD) (USD) (USD)

1 C-3011

Ethylene

Off-Spec.

ASME Sec.

VIII, Div.1

2007Ed.

2009Ad.

16.56 11.28 2,378 SA537-CL1+S5 21.0 1.5 70.5~72.5 1 555

2 C-3012

C3/LPG

Off-Spec.

ASME Sec.

VIII, Div.1

2007Ed.

2009Ad.

8.40 7.20 310 SA516-70 16.5 1.5 29.0 1 75

2 630 Total

Remarks ITEM NO. NO Product

Applied

CODE

Tank

Size

(m)

Main

Material

You might also like

- Design Calculation For Pipe SupportsDocument200 pagesDesign Calculation For Pipe Supportssanggytha100% (1)

- AEDR Annual Work Accident-Illness Exposure Data ReportDocument4 pagesAEDR Annual Work Accident-Illness Exposure Data ReportAlmario Sagun100% (1)

- WAIR Employer's Work-Accident-Illness ReportDocument2 pagesWAIR Employer's Work-Accident-Illness ReportAlmario Sagun80% (5)

- Vessel Fabrication Manual PDFDocument49 pagesVessel Fabrication Manual PDFwalyat100% (2)

- 50 190 RC e 03100Document6 pages50 190 RC e 03100ThirukkumaranBalasubramanianNo ratings yet

- Painting SpecificationDocument23 pagesPainting SpecificationPrashant Malve100% (1)

- Reverse Circulation Cementing: The Complete PictureDocument104 pagesReverse Circulation Cementing: The Complete PictureJoan Corso100% (1)

- RFQ - ATM (20110323) Tanks ManualDocument35 pagesRFQ - ATM (20110323) Tanks ManualAlmario SagunNo ratings yet

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocument1 pageWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- Abr Sinai Onshore Gas Pipeline PDFDocument42 pagesAbr Sinai Onshore Gas Pipeline PDFhamza2085100% (1)

- Plot Plan PDFDocument1 pagePlot Plan PDFBadredine FarahNo ratings yet

- Field Hydrostatic Testing of Piping Systems-EGDocument9 pagesField Hydrostatic Testing of Piping Systems-EGYusufNo ratings yet

- KochDocument181 pagesKochRichard FelipNo ratings yet

- Fractal Cities - A Geometry of Form and Function PDFDocument432 pagesFractal Cities - A Geometry of Form and Function PDFDavid Diaz100% (1)

- Therapeutic EffectsofWhole-BodyDevices Applying Pulsed Electromagnetic Fields (PEMF)Document11 pagesTherapeutic EffectsofWhole-BodyDevices Applying Pulsed Electromagnetic Fields (PEMF)Jeroan MonteiroNo ratings yet

- APV STD Insp & Test Plan API6D ValvesDocument4 pagesAPV STD Insp & Test Plan API6D ValvesdbmingoNo ratings yet

- E Me 130 LPG Pressure Storage SpheresDocument24 pagesE Me 130 LPG Pressure Storage SpheresatiqulaNo ratings yet

- Spherical Tanks Erection ProcedureDocument9 pagesSpherical Tanks Erection Procedureza_heydari80% (5)

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- ZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Document6 pagesZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Vijayaraj KumarNo ratings yet

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- Equipment List Including Long Lead ItemsDocument6 pagesEquipment List Including Long Lead Itemspapilolo2008No ratings yet

- 6.1 Data Sheet For Pipeline Ball ValveDocument3 pages6.1 Data Sheet For Pipeline Ball ValveDeepak PalNo ratings yet

- Laboratory Manual: BTY351 Plant Biotechnology LaboratoryDocument40 pagesLaboratory Manual: BTY351 Plant Biotechnology LaboratoryRetik KoulNo ratings yet

- Storage Tank DetailDocument22 pagesStorage Tank DetailRamu NallathambiNo ratings yet

- Final-Mr For Scaper Traps, Pig Sinallers, Quick Opeing End Closures - 20100209 - 113815Document80 pagesFinal-Mr For Scaper Traps, Pig Sinallers, Quick Opeing End Closures - 20100209 - 113815KalaiYarasanNo ratings yet

- LPG Blending Facilities - List of Documents For TenderDocument235 pagesLPG Blending Facilities - List of Documents For TenderManish MehtaNo ratings yet

- Bes 800-101Document25 pagesBes 800-101jfferrog100% (1)

- EBS1-PTFA27-SAPI-SPDI-1001-D00 - Specification For Piping Stress AnalysisDocument23 pagesEBS1-PTFA27-SAPI-SPDI-1001-D00 - Specification For Piping Stress AnalysisAhmedNo ratings yet

- TBE Master-Y3 - R-2154-101H - R0 (Storage Tank) - 20091022Document4 pagesTBE Master-Y3 - R-2154-101H - R0 (Storage Tank) - 20091022meshahan100% (1)

- Technical Notes and Specifications Part CDocument29 pagesTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- Pig Launchers Recievers PDFDocument9 pagesPig Launchers Recievers PDFgalih santosoNo ratings yet

- TBE For UG Knock Out Drum - Draft For Rev.C1Document22 pagesTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskNo ratings yet

- Painting Specification For Storage Tanks.Document27 pagesPainting Specification For Storage Tanks.Akshat Jain80% (5)

- Basis of Design - PIG LAUNCHER 16 DESIGN 2014Document27 pagesBasis of Design - PIG LAUNCHER 16 DESIGN 2014Andreas Schlager100% (1)

- Piping Design Requirements PDFDocument6 pagesPiping Design Requirements PDFkarunaNo ratings yet

- Tech. Spec. For Heat ExchangersDocument5 pagesTech. Spec. For Heat Exchangerssanjay421No ratings yet

- Specifications of LR BendDocument11 pagesSpecifications of LR BendPrafulla PatilNo ratings yet

- MIS-M-DS-04053 50m3 Slop Tank Data Sheet-BDocument2 pagesMIS-M-DS-04053 50m3 Slop Tank Data Sheet-Bhappale2002No ratings yet

- A545-736-11-42-DS-0034 - A - Flow TeeDocument2 pagesA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranNo ratings yet

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocument1 pageReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNo ratings yet

- SNO P GS 001 Rev0 EPC General RequirementDocument160 pagesSNO P GS 001 Rev0 EPC General Requirementaike_5No ratings yet

- Welding MapDocument5 pagesWelding MapDjuangNo ratings yet

- Material Requisition For Expansion Joint - Rev1Document4 pagesMaterial Requisition For Expansion Joint - Rev1altipatlarNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- AL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCDocument5 pagesAL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCCaptainToniesNo ratings yet

- Material Selection FBE Pipeline PDFDocument2 pagesMaterial Selection FBE Pipeline PDFJosua100% (2)

- Line List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubDocument1 pageLine List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubAli AsadiNo ratings yet

- Bill of Material For Mechnical & Structure For Hot Water Skid Rev.0 - 3Document5 pagesBill of Material For Mechnical & Structure For Hot Water Skid Rev.0 - 3Vu TranNo ratings yet

- Electrode Brand Name and Class MirfaDocument13 pagesElectrode Brand Name and Class MirfaAnonymous rYZyQQot55No ratings yet

- Material Requisition For Expansion Joint - Rev7Document5 pagesMaterial Requisition For Expansion Joint - Rev7altipatlarNo ratings yet

- Inspection and Test Plan (Itp) For Fabrication Pressure VesselDocument1 pageInspection and Test Plan (Itp) For Fabrication Pressure VesselNikki RobertsNo ratings yet

- Mock-Up Block Drawings Fro AUTDocument14 pagesMock-Up Block Drawings Fro AUTSiddiqui Abdul KhaliqNo ratings yet

- Ti e Protegol 32-55 RRM Nov 07Document4 pagesTi e Protegol 32-55 RRM Nov 07A MahmoodNo ratings yet

- 6-15-0006 Rev 4Document7 pages6-15-0006 Rev 4cynideNo ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- Iocl Tank Spec F-601 Rev 0Document18 pagesIocl Tank Spec F-601 Rev 0Rama Krishna Reddy Donthireddy100% (1)

- Piping Isometric Check ListDocument2 pagesPiping Isometric Check ListPaulo SousaNo ratings yet

- Tube Bundle DrawingDocument1 pageTube Bundle DrawingVeera ManiNo ratings yet

- Welding HISTORY SHEETDocument9 pagesWelding HISTORY SHEETAhmedNo ratings yet

- Vessel Specification SheetDocument2 pagesVessel Specification Sheetangel gabriel perez valdezNo ratings yet

- 3 2 Purchase Material SpecificationDocument1 page3 2 Purchase Material Specificationanon_376696588No ratings yet

- HCL Fuel Tank SpecsDocument62 pagesHCL Fuel Tank SpecsM.Sreeram SanjayNo ratings yet

- BIT Project EIL 91020Document41 pagesBIT Project EIL 91020Gourab KunduNo ratings yet

- Amine Stripper Column Crack 3501-1-T-004: PQR Test CouponDocument2 pagesAmine Stripper Column Crack 3501-1-T-004: PQR Test Couponpstechnical_43312697100% (1)

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- Cost Break DownDocument1 pageCost Break Downssss2345No ratings yet

- AmrDocument5 pagesAmrGemarie Adarlo CastilloNo ratings yet

- Work Contract SampleDocument1 pageWork Contract SampleAlmario SagunNo ratings yet

- Power Center - Structural RFA StructuralDocument1 pagePower Center - Structural RFA StructuralAlmario SagunNo ratings yet

- Power Center CoverpageDocument1 pagePower Center CoverpageAlmario SagunNo ratings yet

- Power Center - Structural RFA StructuralDocument1 pagePower Center - Structural RFA StructuralAlmario SagunNo ratings yet

- Approved For Construction: Etron Bataan RefineryDocument1 pageApproved For Construction: Etron Bataan RefineryAlmario SagunNo ratings yet

- Power Center Roof PlanDocument1 pagePower Center Roof PlanAlmario SagunNo ratings yet

- Structural S 01 Petcoke BuildingDocument1 pageStructural S 01 Petcoke BuildingAlmario SagunNo ratings yet

- Petcoke Doors ScheduleDocument6 pagesPetcoke Doors ScheduleAlmario SagunNo ratings yet

- Structural S 02 Petcoke BuildingDocument1 pageStructural S 02 Petcoke BuildingAlmario SagunNo ratings yet

- Right Side Elevation C: A B C A B C B A CDocument1 pageRight Side Elevation C: A B C A B C B A CAlmario SagunNo ratings yet

- Sanitary P 01 Petcoke BuildingDocument1 pageSanitary P 01 Petcoke BuildingAlmario SagunNo ratings yet

- Power Center Building Electrical System-E-01Document1 pagePower Center Building Electrical System-E-01Almario SagunNo ratings yet

- Sanitary P 02 Petcoke BuildingDocument1 pageSanitary P 02 Petcoke BuildingAlmario SagunNo ratings yet

- Power Center Building Electrical System-E-04Document1 pagePower Center Building Electrical System-E-04Almario SagunNo ratings yet

- Power Center Building Electrical System-E-03Document1 pagePower Center Building Electrical System-E-03Almario SagunNo ratings yet

- Mechanical DWNG - M02 Petcoke BuildingDocument1 pageMechanical DWNG - M02 Petcoke BuildingAlmario SagunNo ratings yet

- Power Center Building Electrical System-E-05Document1 pagePower Center Building Electrical System-E-05Almario SagunNo ratings yet

- Power Center Building Electrical System-E-02Document1 pagePower Center Building Electrical System-E-02Almario SagunNo ratings yet

- Petcoke Transformer Plan & Elevation.p2Document1 pagePetcoke Transformer Plan & Elevation.p2Almario SagunNo ratings yet

- Power Center Building Electrical System-E-02Document1 pagePower Center Building Electrical System-E-02Almario SagunNo ratings yet

- Petcoke Transformer Plan & Elevation-01Document1 pagePetcoke Transformer Plan & Elevation-01Almario SagunNo ratings yet

- Architectural Drawing 01 - Petcoke BuildingDocument1 pageArchitectural Drawing 01 - Petcoke BuildingAlmario SagunNo ratings yet

- Fire Rated Stainless Steel Double Panel DoorDocument2 pagesFire Rated Stainless Steel Double Panel DoorAlmario SagunNo ratings yet

- Perspective - Petcoke BuildingDocument1 pagePerspective - Petcoke BuildingAlmario SagunNo ratings yet

- Mechanical DWNG M-01 Petcoke BuildingDocument1 pageMechanical DWNG M-01 Petcoke BuildingAlmario SagunNo ratings yet

- Architectural 01 - Petcoke BuildingDocument1 pageArchitectural 01 - Petcoke BuildingAlmario SagunNo ratings yet

- Proposed Man Ladder DesignDocument1 pageProposed Man Ladder DesignAlmario SagunNo ratings yet

- CHMT 2009 Week 5 Coal PropertiesDocument38 pagesCHMT 2009 Week 5 Coal PropertiesTiisetso MokwaneNo ratings yet

- Geomorphic Evidences of Recent Tectonic Activity in The Forearc, Southern PeruDocument11 pagesGeomorphic Evidences of Recent Tectonic Activity in The Forearc, Southern PeruVayolait BardNo ratings yet

- STD XTH Geometry Maharashtra BoardDocument35 pagesSTD XTH Geometry Maharashtra Boardphanikumar50% (2)

- Practice Question ElectricityDocument3 pagesPractice Question ElectricityIvan SetyawanNo ratings yet

- MOVIDRIVE-B Lab7Document6 pagesMOVIDRIVE-B Lab7GrungeokêNo ratings yet

- Zener Barrier: 2002 IS CatalogDocument1 pageZener Barrier: 2002 IS CatalogabcNo ratings yet

- M. Fatur - H1C018040 - PETROLOGIDocument15 pagesM. Fatur - H1C018040 - PETROLOGIFaturrachmanNo ratings yet

- PHYSICSDocument24 pagesPHYSICS21SO204 AnvithaNo ratings yet

- SkyCiv Beam - Hand Calculations - AJW8CTBuLE8YKrkKaG8KTtPAw8k74LSYDocument13 pagesSkyCiv Beam - Hand Calculations - AJW8CTBuLE8YKrkKaG8KTtPAw8k74LSYsaad rajawiNo ratings yet

- CSC:361-Software Engineering: Semester: Fall2020Document39 pagesCSC:361-Software Engineering: Semester: Fall2020hamsfayyazNo ratings yet

- Hitachi HDDs Repair Scheme Based On MRT ProDocument21 pagesHitachi HDDs Repair Scheme Based On MRT ProvicvpNo ratings yet

- ST7201-Finite Element MethodDocument14 pagesST7201-Finite Element MethodVishal RanganathanNo ratings yet

- Flexenclosure Esite Brochure PDFDocument5 pagesFlexenclosure Esite Brochure PDFajdCruiseNo ratings yet

- Science BDocument2 pagesScience BIyer JuniorNo ratings yet

- Review Skills 1-8Document1 pageReview Skills 1-8TegarNo ratings yet

- Mbs PartitionwallDocument91 pagesMbs PartitionwallRamsey RasmeyNo ratings yet

- 1SFC132367M0201 PSE Internal Modbus RTUDocument22 pages1SFC132367M0201 PSE Internal Modbus RTUAhmed OsmanNo ratings yet

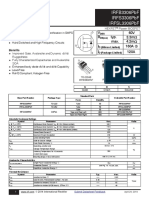

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADocument12 pagesIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligNo ratings yet

- Articles On SidisDocument146 pagesArticles On SidisMircea492003100% (1)

- Corner ReflectorDocument1 pageCorner ReflectorYashNo ratings yet

- 02 WholeDocument344 pages02 WholeedithgclemonsNo ratings yet

- Z Series: VZ-80 Series Portable Radio - VHF/UHFDocument2 pagesZ Series: VZ-80 Series Portable Radio - VHF/UHFPrima SonyNo ratings yet

- Unit Exam 5Document3 pagesUnit Exam 5Rose AstoNo ratings yet

- Acuvim II Profibus Modules Users Manual v1.10Document36 pagesAcuvim II Profibus Modules Users Manual v1.10kamran719No ratings yet

- ProjectDocument6 pagesProjecthazimsyakir69No ratings yet