Professional Documents

Culture Documents

Maximum Width-To-Thickness Ratios For Compression PDF

Uploaded by

toliveira80Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maximum Width-To-Thickness Ratios For Compression PDF

Uploaded by

toliveira80Copyright:

Available Formats

C

o

p

y

r

i

g

h

t

e

d

m

a

t

e

r

i

a

l

.

L

i

c

e

n

s

e

d

t

o

t

i

a

g

o

l

i

v

e

i

r

a

@

p

o

r

t

u

g

a

l

m

a

i

l

.

p

t

o

n

0

7

/

0

6

/

2

0

1

3

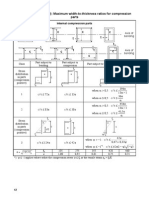

EN 1993-1-1: 2005 (E)

Table 5.2 (sheet 1 of 3): Maximum width-to-thickness ratios for compression

parts

Internal compression parts

t

c

t

c c

t

c

t

Axis of

bending

c

t

t

c

t

c

t

c

Axis of

bending

Class

Part subject to

bending

Part subject to

compression

Part subject to bending and compression

Stress

distribution

in parts

(compression

positive)

+

f

y

-

f

y

c

+

f

y

-

f

y

c

+

f

y

-

f

y

c

c

1 72 t / c 33 t / c

>

36

t / c : 5 , 0 when

1 13

396

t / c : 5 , 0 when

2 83 t / c 38 t / c

>

5 , 41

t / c : 5 , 0 when

1 13

456

t / c : 5 , 0 when

Stress

distribution

in parts

(compression

positive)

+

f

y

-

f

y

c

c/2

+

f

y

c

+

f

y

-

f

y

c

3 124 t / c 42 t / c

) ( ) 1 ( 62 t / c : 1 when

33 , 0 67 , 0

42

t / c : 1 when

*)

+

>

f

y

235 275 355 420 460

y

f / 235 =

1,00 0,92 0,81 0,75 0,71

*) -1 applies where either the compression stress f

y

or the tensile strain

y

> f

y

/E

42

C

o

p

y

r

i

g

h

t

e

d

m

a

t

e

r

i

a

l

.

L

i

c

e

n

s

e

d

t

o

t

i

a

g

o

l

i

v

e

i

r

a

@

p

o

r

t

u

g

a

l

m

a

i

l

.

p

t

o

n

0

7

/

0

6

/

2

0

1

3

EN 1993-1-1: 2005 (E)

Table 5.2 (sheet 2 of 3): Maximum width-to-thickness ratios for compression

parts

Outstand flanges

t

c

t

c

t

c

t

c

Rolled sections Welded sections

Part subject to bending and compression

Class Part subject to compression

Tip in compression Tip in tension

Stress

distribution

in parts

(compression

positive)

+

c

c

+

c

-

c

+

c

-

1 9 t / c

9

t / c

9

t / c

2 10 t / c

10

t / c

10

t / c

Stress

distribution

in parts

(compression

positive)

+

c

+

c

-

c

3 14 t / c

k 21 t / c

For k

see EN 1993-1-5

f

y

235 275 355 420 460

y

f / 235 =

1,00 0,92 0,81 0,75 0,71

43

C

o

p

y

r

i

g

h

t

e

d

m

a

t

e

r

i

a

l

.

L

i

c

e

n

s

e

d

t

o

t

i

a

g

o

l

i

v

e

i

r

a

@

p

o

r

t

u

g

a

l

m

a

i

l

.

p

t

o

n

0

7

/

0

6

/

2

0

1

3

EN 1993-1-1: 2005 (E)

Table 5.2 (sheet 3 of 3): Maximum width-to-thickness ratios for compression

parts

Refer also to Outstand flanges

(see sheet 2 of 3)

Angles

t

h

b

Does not apply to angles in

continuous contact with other

components

Class Section in compression

Stress

distribution

across

section

(compression

positive)

+

+

f

y

3

+

5 , 11

t 2

h b

: 15 t / h

Tubular sections

t

d

Class Section in bending and/or compression

1

2

50 t / d

2

2

70 t / d

3

2

90 t / d

NOTE For see EN 1993-1-6.

2

90 t / d >

f

y

235 275 355 420 460

1,00 0,92 0,81 0,75 0,71

y

f / 235 =

2

1,00 0,85 0,66 0,56 0,51

44

You might also like

- ISSMGE Bulletin Volume 4 Issue1Document52 pagesISSMGE Bulletin Volume 4 Issue1bm-naceurNo ratings yet

- C267Document6 pagesC267Rufo CascoNo ratings yet

- Hardox 450 PDFDocument2 pagesHardox 450 PDFmcrajpuraNo ratings yet

- Reporter: Trần Thanh Giảng Nguyễn Đình VinhDocument92 pagesReporter: Trần Thanh Giảng Nguyễn Đình Vinhjameson wuNo ratings yet

- 04 - Experience With Using Alab For Small Hydro (Øivind Antonsen)Document17 pages04 - Experience With Using Alab For Small Hydro (Øivind Antonsen)student_blNo ratings yet

- Tutorial and Chapter 2Document15 pagesTutorial and Chapter 2NizamuSenpaiNo ratings yet

- Midterm Exam Computer Architecture GuideDocument3 pagesMidterm Exam Computer Architecture GuidekuanzcNo ratings yet

- Thermodynamics Module 1Document9 pagesThermodynamics Module 1Edgar Allan GarciaNo ratings yet

- PSS Lab ManualDocument4 pagesPSS Lab ManualGokul ChandrasekaranNo ratings yet

- Experiment 12 - The Venturi Meter, The Determination of Discharge From A PipeDocument8 pagesExperiment 12 - The Venturi Meter, The Determination of Discharge From A Pipechanjunshen_rmcNo ratings yet

- International Carriage and Goods Group AssignmentDocument5 pagesInternational Carriage and Goods Group AssignmentInaz IdNo ratings yet

- MEC 531 Mechanical Engineering Design 1 Assignment 1: Universiti Teknologi Mara Fakulti Kejuruteraan MekanikalDocument4 pagesMEC 531 Mechanical Engineering Design 1 Assignment 1: Universiti Teknologi Mara Fakulti Kejuruteraan MekanikalFadhil AimanNo ratings yet

- Biomimicry in Structural Designs of BuildingsDocument17 pagesBiomimicry in Structural Designs of BuildingsAllen Sapinoso AlejoNo ratings yet

- Road Distress StudyDocument12 pagesRoad Distress Studyfuad haziqNo ratings yet

- Individual Assignment BFC21702 Sem 1 2018Document1 pageIndividual Assignment BFC21702 Sem 1 2018Encik ComotNo ratings yet

- Fluids Mechanics Group ProjectDocument19 pagesFluids Mechanics Group Projectsaifadamzs100% (2)

- Fedos Rekos KardosDocument34 pagesFedos Rekos KardosIlija RunjajicNo ratings yet

- Tutorial 2 - Relative PermeabilityDocument2 pagesTutorial 2 - Relative PermeabilityVigna Ruban RamNo ratings yet

- Lab ErgonomicsDocument6 pagesLab ErgonomicsPjan IzanNo ratings yet

- Individual AssignmentDocument4 pagesIndividual Assignmentamirul nazwanNo ratings yet

- Analyzing The First Malaysian Animated FilmDocument6 pagesAnalyzing The First Malaysian Animated Filmross_tecNo ratings yet

- FLOW OVER A BROAD CRESTED WEIRDocument4 pagesFLOW OVER A BROAD CRESTED WEIRRayanNo ratings yet

- BFC 32202 Engineers & Society Chapter 4 (Student Copy)Document36 pagesBFC 32202 Engineers & Society Chapter 4 (Student Copy)mhdbad aminNo ratings yet

- Curved BeamsDocument2 pagesCurved Beamsivan bolañosNo ratings yet

- Super ChargingDocument23 pagesSuper Charginghirenbabaji100% (2)

- Soil Improvement On Soft GroundDocument39 pagesSoil Improvement On Soft GroundnurNo ratings yet

- Report Buckling of StructsDocument7 pagesReport Buckling of StructsAnonymous 59kjvq4OLBNo ratings yet

- Teaching prepositionsDocument2 pagesTeaching prepositionsAnonymous V375vJNo ratings yet

- Open Channel Labsheet PDFDocument6 pagesOpen Channel Labsheet PDFSulaksha WimalasenaNo ratings yet

- Masalih MursalahDocument267 pagesMasalih MursalahharunabdulhadiNo ratings yet

- Design Criteria: A) Overland Flow Time, T (Minutes)Document4 pagesDesign Criteria: A) Overland Flow Time, T (Minutes)Nor ImranNo ratings yet

- Elastomeric Bearings GuideDocument10 pagesElastomeric Bearings Guidesandbad2No ratings yet

- UNHCR Global Public Health StrategyDocument72 pagesUNHCR Global Public Health StrategyDinesh PoudelNo ratings yet

- BFC21103 Project SemII 20152016Document9 pagesBFC21103 Project SemII 20152016Victoria JungNo ratings yet

- Fire Door Manual-V-12 Firecore-June2018Document92 pagesFire Door Manual-V-12 Firecore-June2018trickersniperNo ratings yet

- Zub Indeterminate Truss DegDocument13 pagesZub Indeterminate Truss DegAnonymous jmo0bcjAsNo ratings yet

- Lab 9 Verification of Theory of Pure Bending: Test 1Document4 pagesLab 9 Verification of Theory of Pure Bending: Test 1Drizzling ADNo ratings yet

- Minor Losses in Bends Lab ReportDocument8 pagesMinor Losses in Bends Lab Reportalex starrett0% (1)

- Design Appendix Ecs318 (270212)Document13 pagesDesign Appendix Ecs318 (270212)Muhammad Farhan GulNo ratings yet

- Highway Engineering Notes - Chapter 5Document33 pagesHighway Engineering Notes - Chapter 5Muhammad Farhan GulNo ratings yet

- StabilityDocument5 pagesStabilityJenelia Jojo50% (2)

- Civil Engineering Beam Deflection CalculationDocument21 pagesCivil Engineering Beam Deflection CalculationNajmi AimanNo ratings yet

- Full As Contoh Member AkashahDocument29 pagesFull As Contoh Member AkashahWayen Bulat100% (1)

- Test For Buckling EulerDocument4 pagesTest For Buckling EulerGaurav GoyalNo ratings yet

- Building Projects Design MistakesDocument19 pagesBuilding Projects Design MistakescybotbNo ratings yet

- Chapter 1 BFC34303 (Lyy)Document104 pagesChapter 1 BFC34303 (Lyy)shahrull1996No ratings yet

- Roof sheeting load calculation exampleDocument10 pagesRoof sheeting load calculation examplesoareculNo ratings yet

- Lecture 8 Water Supply Network LectureDocument15 pagesLecture 8 Water Supply Network Lectureapi-247600939No ratings yet

- Buckling Load of Steel StrutsDocument9 pagesBuckling Load of Steel StrutsNur NajwaNo ratings yet

- Detention Pond Design StormDocument18 pagesDetention Pond Design StormMd Mamunur RashidNo ratings yet

- Yaesu Ftdx5000 SMDocument0 pagesYaesu Ftdx5000 SMRobert/YG2AKRNo ratings yet

- Klase Poprecnog Preseka ECDocument2 pagesKlase Poprecnog Preseka ECbobbynebaNo ratings yet

- Extracts From Ec3 For Students 2012Document6 pagesExtracts From Ec3 For Students 2012Alexandru MarincuNo ratings yet

- Tension MembersDocument35 pagesTension MembersVictor Carhuayo Paredes100% (1)

- Joint StiffnessDocument5 pagesJoint StiffnessJoon Hyuk ParkNo ratings yet

- 01 Lecture Notes Torsion (1) AS 3600Document7 pages01 Lecture Notes Torsion (1) AS 3600April IngramNo ratings yet

- Shear stresses and shear centre analysisDocument9 pagesShear stresses and shear centre analysisNithesh ShamNo ratings yet

- Torsion in Concrete Structures AnalyzedDocument13 pagesTorsion in Concrete Structures AnalyzedIsmail A Ismail100% (1)

- Tension MembersDocument12 pagesTension MembersEarl averzosaNo ratings yet

- Machine Design: Stress Concentration FactorsDocument30 pagesMachine Design: Stress Concentration FactorsM.HNo ratings yet

- Structural Analysis HandoutDocument2 pagesStructural Analysis HandouthgorNo ratings yet

- Commentary and Worked Examples en 1993-1-5 PDFDocument242 pagesCommentary and Worked Examples en 1993-1-5 PDFtoliveira80No ratings yet

- Ruukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Document6 pagesRuukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Cad AutocadNo ratings yet

- Ec3 HandoutDocument1 pageEc3 HandoutflasnicugNo ratings yet

- European Recommendations For The Design of Simple Joints in Steel Structures - 1st Draft 2003 - JaspartDocument152 pagesEuropean Recommendations For The Design of Simple Joints in Steel Structures - 1st Draft 2003 - JaspartZelzozo Zel Zozo100% (3)

- The Design Manual For Moment and Stiff of Column PlatesDocument135 pagesThe Design Manual For Moment and Stiff of Column PlatesjdkelleyNo ratings yet

- !multi Storey Steel BuildingDocument111 pages!multi Storey Steel BuildingWexkat KulNo ratings yet

- Chapter3 PDFDocument25 pagesChapter3 PDFtoliveira80No ratings yet

- Tata Steel - Blue Book - Advance - Section - Properties - For - Students PDFDocument20 pagesTata Steel - Blue Book - Advance - Section - Properties - For - Students PDFshugd31085100% (1)

- 10 Combined Axial Compression and Bending Handout PDFDocument6 pages10 Combined Axial Compression and Bending Handout PDFtoliveira80No ratings yet

- 1 Historical Development and Characteristics of Structural SteelsDocument30 pages1 Historical Development and Characteristics of Structural Steelsron_dany100% (1)

- 10 Combined Axial Compression and Bending Handout PDFDocument6 pages10 Combined Axial Compression and Bending Handout PDFtoliveira80No ratings yet

- Templates and Reports 170 EnuDocument33 pagesTemplates and Reports 170 EnuAndres Hugo GalloNo ratings yet

- Steel Column Design Eurocode 3Document2 pagesSteel Column Design Eurocode 3Jonp4ul_MiddletonNo ratings yet

- Limit State DesignDocument12 pagesLimit State DesignEzhil KumarNo ratings yet

- Paper - High Strength Steel Can Reduce Weight ThicknessDocument24 pagesPaper - High Strength Steel Can Reduce Weight ThicknessaunyaneeNo ratings yet

- Eurocode 3 steel joint design guideDocument2 pagesEurocode 3 steel joint design guideneverreturnNo ratings yet

- COLUMN BASE PLATE DESIGN FORCE CALCULATIONSDocument3 pagesCOLUMN BASE PLATE DESIGN FORCE CALCULATIONStoliveira80No ratings yet

- Limit State DesignDocument12 pagesLimit State DesignEzhil KumarNo ratings yet

- Comp Constr PDFDocument2 pagesComp Constr PDFtoliveira80No ratings yet

- EuroCode 4Document420 pagesEuroCode 4Mohamed Tahar Allagui100% (3)

- EC4 DesignOfCompositeColumns PDFDocument27 pagesEC4 DesignOfCompositeColumns PDFtoliveira80100% (1)

- Composite Deck DesignDocument16 pagesComposite Deck Designvejanidb100% (1)

- Composite ConstructionDocument524 pagesComposite ConstructionHarold Abubo Haber67% (3)

- Composite Deck DesignDocument16 pagesComposite Deck Designvejanidb100% (1)

- Composite Section - Tutorials - (CSI Wiki)Document4 pagesComposite Section - Tutorials - (CSI Wiki)Wilson100% (1)

- ECCS Examples To Eurocode 3Document124 pagesECCS Examples To Eurocode 3toliveira80100% (5)

- River Song Apartment: Muhammed Aslem NazarDocument51 pagesRiver Song Apartment: Muhammed Aslem NazarSunidhi VermaNo ratings yet

- Manual Bosch Pts 10Document485 pagesManual Bosch Pts 10excaliburuNo ratings yet

- Urbanest London English Brochure RSDocument11 pagesUrbanest London English Brochure RSksathompsonNo ratings yet

- 09 08 Workshop Summer SwingDocument3 pages09 08 Workshop Summer SwingpatriciachaquilaNo ratings yet

- Newark To Newark - A Peoples History of Port GlasgowDocument100 pagesNewark To Newark - A Peoples History of Port GlasgowInverclyde Community Development Trust100% (3)

- PEB Specs Zamil SteelDocument12 pagesPEB Specs Zamil Steelkashyap_structuralNo ratings yet

- Historic Building AppraisalDocument394 pagesHistoric Building AppraisalBhagoo HatheyNo ratings yet

- Composite Steel DesignDocument33 pagesComposite Steel DesignscegtsNo ratings yet

- Belt Conveyor Gallery Analysis and DesignDocument73 pagesBelt Conveyor Gallery Analysis and Designtabloid07100% (1)

- The Complete Guide To Home ImproovementDocument564 pagesThe Complete Guide To Home Improovementtsofiarocha100% (20)

- Lacture 2 Special ConstructionDocument91 pagesLacture 2 Special ConstructionLau Jeh FarnNo ratings yet

- List EngDocument60 pagesList EngtonnyNo ratings yet

- 5 BHK Firstfloor Plan (40X60)Document1 page5 BHK Firstfloor Plan (40X60)ayyanmaniyar135No ratings yet

- Crain 247 Multi Purpose Wall TrimmerDocument2 pagesCrain 247 Multi Purpose Wall TrimmerFloorkitNo ratings yet

- The Future of Precast Concrete in Low-Rise HousingDocument62 pagesThe Future of Precast Concrete in Low-Rise HousingJose ManjooranNo ratings yet

- 11 BLDocument108 pages11 BLfasa9009No ratings yet

- The Haryana Building CodeDocument130 pagesThe Haryana Building CodeArjun MiddhaNo ratings yet

- Is 9459Document13 pagesIs 9459Anonymous mcHqIfbnV1No ratings yet

- Housing BriefDocument6 pagesHousing BriefManish MishraNo ratings yet

- Doubler JointsDocument3 pagesDoubler JointsManoj Manoharan100% (1)

- Detached plan with foyer floor plansDocument1 pageDetached plan with foyer floor plansDhumal Mangesh DhumalNo ratings yet

- HPP INTERNATIONAL Floor Finishing Works SWAN Office Park BucharestDocument3 pagesHPP INTERNATIONAL Floor Finishing Works SWAN Office Park BucharestIbrahim SahinNo ratings yet

- Different Types of Ceilings and Ceiling FinishesDocument7 pagesDifferent Types of Ceilings and Ceiling FinishesstenkchaiNo ratings yet

- Cladding Installation: Cembrit CembonitDocument39 pagesCladding Installation: Cembrit CembonitVranceanu Vlad-gabrielNo ratings yet

- Complete ReviewerDocument24 pagesComplete Reviewergene2693No ratings yet

- Hot Works SafetyDocument33 pagesHot Works Safetypammu18No ratings yet

- DownloadDocument47 pagesDownloadGajanVashishth100% (1)

- Final Report Industry Training (POLIKU) (DKA)Document56 pagesFinal Report Industry Training (POLIKU) (DKA)Garvin Tea81% (16)

- Portal MethodDocument10 pagesPortal MethodDoer_91No ratings yet

- Cost Data Example From CIDBDocument8 pagesCost Data Example From CIDBChan Siew ChongNo ratings yet