Professional Documents

Culture Documents

CastAl Phy Prop1

Uploaded by

rizviabbas2012Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CastAl Phy Prop1

Uploaded by

rizviabbas2012Copyright:

Available Formats

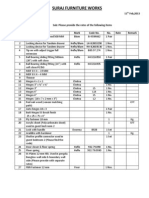

Table: Table 3a - Physical Properties of Cast Aluminum Alloys - (engineering units)

casting type

sand

permanent mold

permanent mold

permanent mold

permanent mold

sand

sand

sand

permanent mold

sand

permanent mold

permanent mold

permanent mold

sand

permanent mold

permanent mold

permanent mold

permanent mold

permanent mold

sand

sand

sand

sand

sand

permanent mold

sand

sand

sand

sand

permanent mold

sand

permanent mold

permanent mold

sand

sand

sand

oy namUNS no. temper

100.0

100.0

201.0

201.0

201.0

201.0

201.0

201.0

204.0

204.0

208.0

208.0

208.0

208.0

213.0

222.0

222.0

222.0

222.0

222.0

222.0

222.0

224.0

224.0

238.0

240.0

242.0

242.0

242.0

242.0

242.0

242.0

242.0

242.0

295.0

295.0

A02010

A02010

A02010

A02010

A02010

A02010

A02040

A02040

A02080

A02080

A02080

A02080

A02130

A02220

A02220

A02220

A02220

A02220

A02220

A02220

A02240

A02240

A02380

A02400

A02420

A02420

A02420

A02420

A02420

A02420

A02420

A02420

A02950

A02950

F

F

T43

T7

T6

T6

T43

T7

T4

T4

T7

T6

F

F

F

F

T551

T52

T61

T61

F

O

T62

T72

F

F

F

T61

T77

T571

T571

T77

T61

O

T4

T62

density

(lb/in^3)

sp. gravity

avg thermal

expansion coeff.

(10^-6 1/F)

0.096

0.096

0.101

0.101

0.101

0.101

0.101

0.101

0.101

0.101

0.101

0.101

0.101

0.101

0.110

0.107

0.107

0.107

0.107

0.101

0.107

0.107

0.102

0.102

0.110

0.100

0.102

0.102

0.102

0.102

0.102

0.102

0.102

0.102

0.102

0.102

2.70

2.70

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.80

2.79

2.79

2.79

2.80

12.8

12.8

10.7

10.7

10.7

10.7

10.7

10.7

10.7

10.7

12.4

12.4

12.4

12.2

2.95

2.95

2.95

2.95

2.95

2.95

2.95

2.81

2.81

2.95

2.78

2.81

2.81

2.81

2.81

2.81

2.81

2.81

2.81

2.81

2.81

12.3

12.3

12.3

12.3

12.3

12.3

12.3

11.9

12.3

12.6

12.6

12.6

12.6

12.6

12.6

12.6

12.6

12.7

12.7

elec.

sp. heat

Poisson's coeff. of

melting

thermal cond.

elec.

elec.

ratio

friction

range (F) (Btu in/(ft^2 h conductivity conductivity resistivity (Btu/(lb F))

(weight)

(ohm

F))

(volume)

(%IACS)

(%IACS)

cmil/ft)

970-1160

1165

54

177

19

0.210

0.33

0.4

970-1160

1165

54

177

19

0.210

0.33

0.3

1060-1200

0.230

0.33

0.3

1060-1200

840

33

108

32

0.230

0.33

0.3

1060-1200

840

30

99

35

0.230

0.33

0.3

1060-1200

840

30

99

35

0.220

0.33

0.3

1060-1200

0.220

0.33

0.3

1060-1200

840

33

108

32

0.220

0.33

0.3

1060-1200

695

24

79

43

0.230

0.33

0.3

1060-1200

840

29

95

36

0.230

0.33

0.3

970-1160

0.230

0.33

0.3

970-1160

0.230

0.33

0.3

970-1160

865

31

102

34

0.230

0.33

0.3

970-1160

840

31

102

34

0.230

0.33

0.3

970-1160

0.230

0.33

0.3

970-1160

925

34

112

31

0.230

0.33

0.3

970-1160

0.230

0.33

0.3

970-1160

0.230

0.33

0.3

970-1160

895

33

108

32

0.230

0.33

0.3

970-1160

895

33

108

32

0.230

0.33

0.3

970-1160

925

34

112

31

0.230

0.33

0.3

970-1160

1095

41

135

25

0.230

0.33

0.3

1020-1190

810

30

99

35

0.230

0.33

0.3

1020-1190

0.230

0.33

0.3

945-1110

720

25

82

42

0.230

0.33

0.3

950-1110

665

23

76

45

0.230

0.33

0.3

990-1175

0.230

0.33

0.3

990-1175

925

33

108

32

0.230

0.33

0.3

990-1175

1040

38

125

27

0.230

0.33

0.3

990-1175

925

34

112

31

0.230

0.33

0.3

990-1175

925

34

112

31

0.230

0.33

0.3

990-1175

1040

38

125

27

0.230

0.33

0.3

990-1175

925

33

108

32

0.230

0.33

0.3

990-1175

925

33

108

32

0.230

0.33

0.3

970-1190

955

35

115

30

0.230

0.33

0.3

970-1190

980

35

115

30

0.230

0.33

0.3

Table: Table 3a - Physical Properties of Cast Aluminum Alloys - (engineering units)

casting type

sand

sand

permanent mold

permanent mold

permanent mold

permanent mold

permanent mold

permanent mold

sand

sand

sand

permanent mold

permanent mold

permanent mold

oy namUNS no. temper

295.0

295.0

296.0

296.0

296.0

308.0

319.0

319.0

319.0

319.0

319.0

324.0

324.0

324.0

A02950

A02950

A02960

A02960

A02960

A03080

A03190

A03190

A03190

A03190

A03190

A03240

A03240

A03240

T7

T6

T4

T6

T7

F

F

T6

T5

T6

F

T62

T5

F

density

(lb/in^3)

sp. gravity

avg thermal

expansion coeff.

(10^-6 1/F)

0.102

0.102

0.101

0.101

0.101

0.101

0.101

0.101

0.101

0.101

0.101

0.096

0.096

0.096

2.81

2.81

2.80

2.80

2.80

2.79

2.79

2.79

2.79

2.79

2.79

2.67

2.67

2.67

12.7

12.7

12.2

12.2

12.2

11.9

11.9

11.9

11.9

11.9

11.9

11.9

11.9

11.9

elec.

sp. heat

Poisson's coeff. of

melting

thermal cond.

elec.

elec.

ratio

friction

range (F) (Btu in/(ft^2 h conductivity conductivity resistivity (Btu/(lb F))

(weight)

(ohm

F))

(volume)

(%IACS)

(%IACS)

cmil/ft)

970-1190

0.230

0.33

0.3

970-1190

955

35

115

30

0.230

0.33

0.3

970-1170

925

33

108

32

0.230

0.33

0.3

970-1170

925

33

108

32

0.230

0.33

0.3

970-1170

0.230

0.33

0.3

970-1135

1010

37

122

28

0.230

0.33

0.3

960-1120

780

27

89

39

0.230

0.33

0.3

960-1120

0.230

0.33

0.3

960-1120

0.230

0.33

0.3

960-1120

0.230

0.33

0.3

960-1120

780

28

92

37

0.230

0.33

0.3

1010-1120

0.230

0.33

0.3

1010-1120

0.230

0.33

0.3

1010-1120

1070

34

112

31

0.230

0.33

0.3

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Quality ControlDocument91 pagesQuality ControlVinod67% (6)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 347R-14 Guide To Formwork For ConcreteDocument40 pages347R-14 Guide To Formwork For ConcreteJacky Leong100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Causeway BOQDocument7 pagesCauseway BOQSujan GhimireNo ratings yet

- Stick ElectrodeDocument1 pageStick Electroderizviabbas2012No ratings yet

- AlcoTec Alloy Filler ChartDocument1 pageAlcoTec Alloy Filler CharttxspacecadetNo ratings yet

- Isogen LessonDocument40 pagesIsogen LessonDxtr Medina50% (2)

- Technical Delivery Conditions For Seamless Carbon Steel FittingsDocument2 pagesTechnical Delivery Conditions For Seamless Carbon Steel FittingsTanpreet Singh100% (1)

- Design of Steel StructuresDocument2 pagesDesign of Steel Structuressou_kgec100% (3)

- DESIGN OF PRESSURE VESSEL Full Report DEDocument48 pagesDESIGN OF PRESSURE VESSEL Full Report DELuis Muñoz100% (1)

- Plate Type Heat ExchangerDocument6 pagesPlate Type Heat ExchangerarjmandquestNo ratings yet

- B-Line Pipe Supports, Guides, Shields & SaddlesDocument44 pagesB-Line Pipe Supports, Guides, Shields & SaddlesMfon UdoitaNo ratings yet

- Benefits of ISO 9000Document9 pagesBenefits of ISO 9000rizviabbas2012No ratings yet

- ReadmeDocument1 pageReadmerizviabbas2012No ratings yet

- Kashaf Ul SalaatDocument80 pagesKashaf Ul Salaatshianews100% (1)

- Tib e Imam Raza (A.s)Document79 pagesTib e Imam Raza (A.s)Salman Book Centre100% (3)

- ABS Behind The Scenes WP Mar05Document11 pagesABS Behind The Scenes WP Mar05Mohamad A. GharebNo ratings yet

- FINEPIX JV250 Series FINEPIX JV200 Series: Owner's ManualDocument112 pagesFINEPIX JV250 Series FINEPIX JV200 Series: Owner's Manualrizviabbas2012No ratings yet

- Micro Station Power Draft Training Guide by Bentley SystemsDocument162 pagesMicro Station Power Draft Training Guide by Bentley Systems00152100% (2)

- EulaDocument3 pagesEularizviabbas2012No ratings yet

- BANK SCHEDULE OF CHARGESDocument26 pagesBANK SCHEDULE OF CHARGESrizviabbas2012No ratings yet

- Namaz Ki Tafseer - Ustaad Mohsin Qarati - UrduDocument112 pagesNamaz Ki Tafseer - Ustaad Mohsin Qarati - UrduHassan Taha WastiNo ratings yet

- Kaun Se Loag Janwaron Ki Shakl May Mehshoor Hoon GayDocument72 pagesKaun Se Loag Janwaron Ki Shakl May Mehshoor Hoon GayShian-e-Ali NetworkNo ratings yet

- Zindagi Kese Guzari JayeDocument0 pagesZindagi Kese Guzari JayeHaider E KarrarNo ratings yet

- BANK SCHEDULE OF CHARGESDocument26 pagesBANK SCHEDULE OF CHARGESrizviabbas2012No ratings yet

- Ismaili FitnaDocument20 pagesIsmaili Fitnarizviabbas2012No ratings yet

- Nuclear Power Plants: Understanding RadiationDocument4 pagesNuclear Power Plants: Understanding RadiationKunal MukherjeeNo ratings yet

- Modern Drafting Standards Manual SectionsDocument6 pagesModern Drafting Standards Manual Sectionsrizviabbas2012No ratings yet

- Takhleeq-E-Pakistan Urdu History Islamic BookDocument79 pagesTakhleeq-E-Pakistan Urdu History Islamic BookMalik UmarNo ratings yet

- Entries PDFDocument313 pagesEntries PDFDemid OdkhuuNo ratings yet

- Pford 2Document6 pagesPford 2rizviabbas2012No ratings yet

- SIMS-201: The Telephone SystemDocument18 pagesSIMS-201: The Telephone SystemSheenly Joy AbalajenNo ratings yet

- Sale Agreement 0Document12 pagesSale Agreement 0rizviabbas2012No ratings yet

- Internal Vs External Combustion EnginesDocument5 pagesInternal Vs External Combustion Enginesrizviabbas2012No ratings yet

- Er70S-6 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-6 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Asthma Medication and Dosage List K Capehart Revised 8-2011Document4 pagesAsthma Medication and Dosage List K Capehart Revised 8-2011rizviabbas2012No ratings yet

- Change of Bank NameDocument1 pageChange of Bank Namerizviabbas2012No ratings yet

- Features and SpecificationsDocument1 pageFeatures and Specificationsrizviabbas2012No ratings yet

- Schletter Product Component ListDocument39 pagesSchletter Product Component ListKirsten HernandezNo ratings yet

- TECHNOLOGICAL UNIVERSITY OF THE PHILIPPINES LAB REPORTDocument24 pagesTECHNOLOGICAL UNIVERSITY OF THE PHILIPPINES LAB REPORTJeshua LloreraNo ratings yet

- Support Issues at AEP Lawrenceburg and Waterford PlantsDocument11 pagesSupport Issues at AEP Lawrenceburg and Waterford Plantsfaizan abbasiNo ratings yet

- Tricocat PDFDocument44 pagesTricocat PDFJuan PabloNo ratings yet

- M. Doors and WindowsDocument6 pagesM. Doors and WindowsTharaka PereraNo ratings yet

- Corosion Assignment FullDocument104 pagesCorosion Assignment FullVelavan KNo ratings yet

- 4D PrintingDocument27 pages4D Printingmanoj manuNo ratings yet

- Technical data sheet translation noteDocument2 pagesTechnical data sheet translation noteCarlesNo ratings yet

- Amex Seals Product Data SheetsDocument13 pagesAmex Seals Product Data SheetscloantafNo ratings yet

- TE 1 Notes PDFDocument196 pagesTE 1 Notes PDFfatigue puttaNo ratings yet

- Material PTFE PT009807: Technical Data Sheet in Accordance With ASTMDocument2 pagesMaterial PTFE PT009807: Technical Data Sheet in Accordance With ASTMCAT CYLINDERNo ratings yet

- Steel Racking Solutions, Inc.: 136 Production Court, Louisville Ky 40299Document11 pagesSteel Racking Solutions, Inc.: 136 Production Court, Louisville Ky 40299Clyde FairbanksNo ratings yet

- High-Performance Cold Work Tool Steel K110Document2 pagesHigh-Performance Cold Work Tool Steel K110Greg SanjayaNo ratings yet

- Tripole University: Glass-Ceramic "MME660"Document3 pagesTripole University: Glass-Ceramic "MME660"amnajamNo ratings yet

- Jurnal ItayoDocument5 pagesJurnal ItayoFlorence Brenda PoppyNo ratings yet

- Dokumen - Tips - Pompe de Caldura BuclaDocument96 pagesDokumen - Tips - Pompe de Caldura BuclaAnonymous oKTCFZNTmNo ratings yet

- ENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3Document73 pagesENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3shariq talatNo ratings yet

- Secondary Seal For Sealed Insulating Glass Units For Structural Sealant Glazing ApplicationsDocument12 pagesSecondary Seal For Sealed Insulating Glass Units For Structural Sealant Glazing ApplicationsAbdullah NajjarNo ratings yet

- Nano CompositeDocument26 pagesNano Compositenandan akNo ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSTeknik produksi wikonNo ratings yet

- AC PRICE QUOTEDocument4 pagesAC PRICE QUOTEFaizal Septia HadiNo ratings yet

- Matrial ListDocument1 pageMatrial ListRukksana SayyedNo ratings yet

- Module-1 Home-Eval 1Document9 pagesModule-1 Home-Eval 1Michael James ll BanawisNo ratings yet