Professional Documents

Culture Documents

Basic Construction Training Manual Swiss Red Cross Skat Foundation

Uploaded by

Anonymous M0tjyWCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basic Construction Training Manual Swiss Red Cross Skat Foundation

Uploaded by

Anonymous M0tjyWCopyright:

Available Formats

Basic Construction Training Manual

for Trainers

Heini Mller

Basic Construction Training Manual

for Trainers

Heini Mller

References of sketches

1. Elem entary course on B uilding C onstruction and M aterials

SATA

2. B rick w ork M anual

Laurie B aker

3. B uilding C onstruction M anual

SKAT

4. Joints in M asonry

M odule M M 13

H abitat Polytech, R ichm ar

Impessum

A uthor: H eini M ller

C opyright: Skat Foundation, St.G allen, Sw itzerland

2004, 1

st

edition, 200 C opies

C opyright w aiver: Perm ission is granted to use the m aterial found in this volum e for educational

and developm ent purposes. A cknow ledgem ent is requested.

Layout: M artin Lng, A lex B chi; Skat Foundation

SRC

Sw iss Red C ross

P.O . Box 2699

R ainm attstrasse 10

C H -3001 Bern, Sw itzerland

http://w w w .redcross.ch

em ail: iz@ redcross.ch

SEW A

Self Em ployed W om ens A ssociation

Sew a Reception C entre

O pp. Lok M anya Tilak Baug, B hadra

A hm edabad 380 001, India

em ail: sew a.m ahila@ w ilnetonline.net

Skat Foundation

Vadianstrasse 42

C H -9000 St. G allen

Sw itzerland

http://w w w .skat.ch

em ail: info@ skat.ch

Sw iss Solidarity

B.P. 132

Rue des M arachers 8

C H -1211 G enve 8

Sw itzerland

http://w w w .bonheur.ch

em ail: info@ bonheur.ch

Foreword

The devastating earthquake of January 26, 2001 caused trem endous dam age to the lives and

property of the population living in the northern and northw estern districts of G ujarat. In the

w ake of this hum anitarian tragedy a large num ber of local, national and international organisa-

tions engaged in relief and rehabilitation operations.

A diverse range of strategies w as adopted to m eet the urgent needs of the suffering population

to rehabilitate their lives and reconstruct their houses. In line w ith its principles, Sw iss R ed

C ross prom oted a process-oriented and com m unity-centred approach, taking into consideration

the actual needs of the people and the specific conditions of the area. A ccordingly, the rural

villagers, especially w om en, w ere identified as a pro-active force building on their ow n strength

rather than becom ing passive recipients of external aid.

A fter a participatory assessm ent in three rem ote villages A ntarnesh, B akutra and G adsai of

Patan district, Sw iss R ed C ross decided to contribute to the rehabilitation of the lives of nine

hundred fam ilies, through providing them w ith new , earthquake save houses, kitchens, toilets

and w ater harvesting system s, called N aya G har (N ew housing). This infrastructure-focused

im provem ent w as m ainly seen under the aspect of securing peoples livelihood by creating

em ploym ent opportunities in the building sector.

The follow ing com plem entary organisations w ere engaged in the Sw iss R ed C ross and Sw iss

Solidarity supported N aya G harProject:

n SEW A , (Self-em ployed W om ens A ssociation) w ith its w ide netw ork of m ore than

500000 m em bers in G ujarat w as selected as the m ain local project im plem enting partner

organisation.

n D A (D evelopm ent A lternatives), an India based N G O , in cooperation w ith Skat C onsulting

from Sw itzerland, w ere selected to ensuring the practicability and quality of the

construction w ork.

The earthquake unfortunately proved that local construction techniques and skill did not prevent

houses from collapsing during the incident. This clearly indicated the urgent need to im prove

on both, construction technologies and especially on construction skill.

For this reason the B asic C onstruction Training M anual for Trainershas been developed by

Skat in close cooperation w ith field based SEW A construction engineers to ensure that their

needs and expectations are m et. This Training M anual is the sum m ary of basic practical con-

struction know -how that is of crucial im portance to transfer appropriate and new skills to local

m asons, supervisors and SEW A m em bers in building earthquake resistant houses. It w ill help

construction trainers to pass on relevant skills in constructing houses and im proving infrastruc-

ture in a practical m anner, and offers a w ide range of essential inform ation.

B eside the Sw iss R ed C ross and Sw iss Solidarity supported N aya G har Project, this B asic C on-

struction Training M anual for Trainersw ill also serve other SEW A construction related projects.

A ll partners actively involved in the creation and application of this Training M anual hope that

trough it the new skills acquired by local m asons, supervisors and SEW A m em bers w ill lead

to an better building standard and quality, preventing further loss of lives and property in this

earthquake prone part of India.

Peter Eppler

Program m e C oordinator

Sw iss R ed C ross

5

General Introduction

W hen G ujarat has been hit by the horrifying earthquake in January 2001, international help

for the reconstruction of houses and creation of livelihood w as soon at hand and w arm ly

w elcom ed by the needy one.

The concerned governm ent authorities and non-governm ental organisations launched re-

construction activities w ith an astonishing sw iftness. The resulting focus of construction

activities in G ujarat w as dem anding a huge num ber of skilled construction m anpow er that w as

regrettably not alw ays easy at hand.

This Basic Construction Training Manual for Trainers is tailor m ade for the specific capacity

building / training needs of SEW A for the earthquake reconstruction program m e that is,

financed by the Sw iss Solidarity Fond and im plem ented in partnership w ith Sw iss R ed C ross

and technically coached by Skat_consulting.

This m anual is specifically focussing on the practical im plem entation level and provides a w ide

range of essential inform ation as w ell as dos and donts for trainers to com m unicate to m asons

and supervisors during theoretical and on the job trainings. It also contains photos and sketches

/ draw ings that add clarity to the context. These photos and sketches have been collected from

various reference sources and are therefore, not of uniform character in its present form .

This m anual is divided into five separate m odules. Module one explains the overall and

essential parts of a building. Module two provides inform ation about the quality benchm ark

and testing m ethods of building m aterials that are m ost com m only used in housing construc-

tion in G ujarat. Module three describes the skilled w orking principles for; M ortar, C oncreting,

B rick m asonry, Stone m asonry, C uring, Plastering and Flooring. Module four describes

essential w orking safety m easures to avoid occupational accidents. A nd finally, Module five

provides a list of literature w here useful inform ation regarding earthquake save house designing

and construction principles are described.

The m erit of this m anual lies in the m odular structured docum entation of inform ation from a

practitioner for practitioners that allow s the design of various com bination of required practical

training.

A very tiny fraction of active m asons in G ujarat have received form al m asonry training. Practical

construction skill and inform ation are transferred in an inform al w ay. B ecause of this system ,

som e practices that are actually w rong have now becom e good practice standardand

therefore som e present construction qualities are not up to professional quality standards in

G ujarat.

There is a genuine need and high dem and for form al building construction training by m asons.

SEW A has recognised this as a high priority and expressed the necessity of professional and

practical construction training m aterial for their construction related program m es. This Basic

Construction Training Manual for Trainers is the resulting outcom e of their expression.

5

M

O

D

U

L

E

1

M

O

D

U

L

E

2

M

O

D

U

L

E

3

M

O

D

U

L

E

4

M

O

D

U

L

E

5

M O D U LE 1:

Basic Building Parts ..................................................................7

M O D U LE 2:

Building Material and Quality Standards ..........................19

M O D U LE 3:

Principles of Construction ....................................................33

M O D U LE 4:

Safety ..........................................................................................83

M O D U LE 5:

Earthquake resistant construction practices ..................89

7

7

Various parts of a building (Floor, wall, openings, roof, stair)

Basic Building Parts

M

O

D

U

L

E

1

9

9

M

O

D

U

L

E

1

Basic Building Parts

Content

1. Building......................................................................................................10

1.1. Foundation................................................................................................. 10

1.2 Plinth .......................................................................................................... 11

1.3 Damp proof course (DPC).........................................................................12

1.4 Plinth beam................................................................................................12

1.5 Floor ...........................................................................................................13

1.6 Walls...........................................................................................................13

1.7 Openings.................................................................................................... 14

1.8 Stairs ..........................................................................................................15

1.9 Roof ............................................................................................................16

1.10 Surfaces / Finishes ....................................................................................16

2. Service facilities........................................................................................17

2.1 Water supply..............................................................................................17

2.2 Drainage and sewerage............................................................................17

2.3 Garbage disposal ......................................................................................17

2.4 Electricity....................................................................................................17

10

Basic Construction Training Manual for Trainers

11

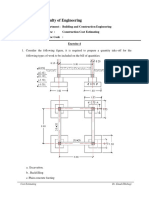

1. Building

A building provides shelter against natural elem ents such as rain, sunshine and w ind. It also

provides security and privacy. A building consists of the follow ing basic parts:

1.1. Foundation

A foundation is necessary to evenly distribute the entire building load on the soil in such

a m anner that no dam aging settlem ents take place. H ence, the foundations need to be

constructed on good/solid ground

The Roof

The Lintel

The Window

The Door

The Cill

The Wall

The Floor

The DPC lies at the

Floor Level right below

the Walls (not under any

openings like Doors)

The Plinth lies between

the Floor and the

Ground

The Foundation is

invisible and lies below

the Ground, just beneth

the Walls

Water Supply

Drainage

10

Basic Construction Training Manual for Trainers

11

Steel reinforcement placing

in foundation excavation

1.2 Plinth

A plinth is norm ally constructed just above the ground level and im m ediately after the

foundation. It raises the floor above the ground level and herew ith prevents surface w ater

from entering the building.

Plinth construction height up to ground floor level

M

O

D

U

L

E

1

Basic Building Parts

12

Basic Construction Training Manual for Trainers

13

1.3 Damp proof course (DPC)

D am p proof course is a layer of w ater proofing m aterial such as asphalt or w aterproof cem ent.

W alls are constructed above the dam p proof course.

D am p proof course prevents surface w ater from rising into the w alls.

D am pness reduces the strength of the w alls and creates unhealthy living conditions. A lso it

affects the paint and plaster and increasing the cost of m aintenance

D am p proofing layer is not required w here a plinth beam is constructed, because the plinth

beam already perform s like a D PC .

Typical DPC type where no concrete plinth has been constructed

1.4 Plinth beam

A plinth beam is constructed depending upon the type of the structure of the building and

nature of the soil. It provides additional stability in regard to settlem ents of the building and

earthquake dam ages.

Completed plinth beam of a building

12

Basic Construction Training Manual for Trainers

13

1.5 Floor

This is the surface on w hich w e do m ost of our activities. Floorings is laid over the filling of the

plinth and on subsequent floors.

Flooring can be done w ith different m aterials, but care m ust be given that the ground below

the floor is w ell com pacted. Flooring is done to prevent dam pness from rising to the top and

to have a firm platform that can be kept hygienic and clean.

Floor construction section, levelling sand, brick layer, cement cover and finishing work

1.6 Walls

W alls are the vertical elem ents on w hich the roof finally rests. They can be m ade of different

m aterials like bricks, stones, m ud, concrete blocks, laterite blocks etc.

If the w alls are very long, colum ns can be provided to carry the roof.

W alls provide privacy and enclosure. W alls also provide security and protection against natural

elem ents such as w ind, rain and sunshine.

O penings are to be provided in w all for access and ventilation.

M

O

D

U

L

E

1

Basic Building Parts

14

Basic Construction Training Manual for Trainers

15

Ongoing brick wall (Rat Trap Bond) construction

1.7 Openings

O penings are norm ally provided in the w alls as door, w indow s and ventilators.

D oors provide access; w indow s and ventilators provide light and ventilation.

Building with many windows providing desired ventilation and light

Lintels are constructed just above the openings. It is norm ally a stone slab or a concrete slab.

Sill is the part of the w all that is just below the w indow .

Lintels are constructed to hold up the w alls above the openings.

In earthquake prone areas a continuous lintel beam is provided all over the w alls.

14

Basic Construction Training Manual for Trainers

15

Continuous sill (direct bellow window)

and lintel (direct above window)

1.8 Stairs

A stair is a sequence of steps and it is provided to afford the m eans of ascent and descent

betw een the floors and landings.

The apartm ent or room of a building in w hich stair is located is called staircase.

The space or opening occupied by the stair is called a stairw ay.

There are different kind of stairs are used in buildings, like R C C stair, w ooden stair, m etal stair,

brick stair etc.

External stair construction, provides safe access to roof area

M

O

D

U

L

E

1

Basic Building Parts

16

Basic Construction Training Manual for Trainers

17

1.9 Roof

The roof provides protection for the building and the people living in it. The roof rests on the

w alls and requires proper anchoring so that w ind and other m echanical im pact cannot destroy

it. A roof can have different shapes but it is alw ays either flat or sloping.

R oof is typically m ade of R C C , stone slab, tiles etc.

Clay tile covered roofs for rural housing scheme

1.10 Surfaces / Finishes

External finishes are the outer m ost layer of protection, w hich protect the structure from

w eathering.

Internal finishes are the layers given on internal faces. They give durability and pleasing

appearance to the inside.

Wall plastering and decorative structure design

16

Basic Construction Training Manual for Trainers

17

2. Service facilities

2.1 Water supply

W ater supply facility is done to provide and distribute clean w ater inside the building.

This can be done through a netw ork of pipes. U sually pipes used are of PVC or G I pipes.

2.2 Drainage and sewerage

This is provided to collect and carry the w astew ater aw ay from the building.

2.3 Garbage disposal

G arbage should be collected and disposed for creating hygienic living conditions.

2.4 Electricity

Electrical connections are done to provide pow er supply for various needs inside the building.

M

O

D

U

L

E

1

Basic Building Parts

19

19

Building material compilation at site (sand, grave, cement, concrete blocks)

M

O

D

U

L

E

2

Building Material and

Quality Standards

21

21

Building Material and Quality Standards

M

O

D

U

L

E

2

Content

Raw materials for masonry works ..........................................................22

1. Bricks..........................................................................................................22

1.1 Classification of bricks ..............................................................................22

1.1.1 Facing bricks..................................................................................23

1.1.2 Solid bricks ....................................................................................23

1.1.3 C avity bricks ..................................................................................23

1.1.4 Special shaped bricks ....................................................................23

1.2 Quality of bricks.........................................................................................23

1.2.1 A A class ........................................................................................24

1.2.2 Soaked bricks ................................................................................24

1.2.3 Structure........................................................................................24

1.2.4 Shape and size ..............................................................................24

1.2.5 Soundness.....................................................................................24

1.2.6 Fall test..........................................................................................24

1.2.7 Scratch test...................................................................................24

2. Stones .......................................................................................................25

2.1 Classification of stones.............................................................................25

2.2 Quality of building stone..........................................................................26

2.2.1 Signs of good quality stones.........................................................26

2.2.2 Q uality tests ..................................................................................26

3. Concrete blocks.........................................................................................27

3.1 Classification of concrete blocks..............................................................27

3.2 Quality of concrete blocks ........................................................................27

4. Sand and aggregates................................................................................28

4.1 Classification of sand and aggregates.....................................................28

4.1.1 C oarse aggregate ..........................................................................28

4.1.2 Sand ..............................................................................................28

4.2 Quality of sand and aggregates...............................................................28

4.2.1 Sand storage .................................................................................29

4.2.2 Testing the sand quality ................................................................29

4.2.3 Sea sand........................................................................................29

5. Cement ......................................................................................................30

5.1 Setting/Hardening......................................................................................30

5.2 Hydration of cement .................................................................................30

5.3 Different types of cement .........................................................................30

5.4 Type and quality........................................................................................30

5.4.1 C em ent storage.............................................................................30

5.4.2 U se of fresh cem ent.....................................................................31

5.5 Testing the cement quality .......................................................................31

6. Water..........................................................................................................32

6.1 Type and quality........................................................................................32

6.1.1 Seaw ater.......................................................................................32

6.1.2 C ollected rainw ater from roofs......................................................32

6.1.3 O ils ................................................................................................32

6.2 Water storage ............................................................................................32

6.3 Testing the water quality ..........................................................................32

22

Basic Construction Training Manual for Trainers

23

Raw materials for masonry works

The raw m aterials required for m asonry w ork, together w ith the skill of the m ason are decisive

factors for the final quality of the m asonry w ork. Therefore, it is im portant that the correct raw

m aterials are used. B asic know -how about the different required raw m aterials is essential for

m asons as w ell as supervisors.

The follow ing m ain raw m aterials for brick m asonry are needed:

n B ricks

n Stones

n C oncrete blocks

n Sand

n C em ent mortar

n W ater

1. Bricks

B ricks m ust be of good quality and w ithout visible cracks for a load-bearing w all. A hard ringing

sound em itted w hen tw o bricks are struck together indicates that they have been burnt satis-

factorily. G enerally, the bricks should be true to size and shape, w ith straight edges and even

surface, so as to facilitate laying them into position w ithout using too m uch m ortar. Inferior

bricks are generally under-burnt and as a consequence are easily broken and are very porous.

These are neither hard nor durable and are incapable of w ithstanding heavy loads.

N ow all over the w orld, nearly all bricks are roughly the sam e shape and size that is approx:

9 x 4 - 1/2 x 3 inches.

1.1 Classification of bricks

These are defined as suitable for general building w ork having no special claim to give an

attractive appearance. The type in use for m ost areas in India is classified as C om m on B ricks.

Pilling up of common bricks at production site, ready for selling

}

22

Basic Construction Training Manual for Trainers

23

1.1.1 Facing bricks

These bricks are thoroughly burned and uniform in colour, and having plane rectangular faces

and sharp straight right angled edges. They are used in the exposed face of the brickw ork

w ithout any plaster or surface treatm ent. The bricks m ust have sufficient resistance to

penetration by rain and w eathering agencies. In general they are selected from a num ber of

bricks. Facing bricks are also used for R at Trap B ondm asonry w alls.

Facing bricks (second quality) stored at construction site

1.1.2 Solid bricks

A solid brick is a brick w ith less holes or perforations of 25% of its volum e, in w hich frogs do

not exceed 20% of its volum e.

1.1.3 Cavity bricks

A burnt clay hollow block or brick w ith holes larger than 20m m w ide, w hich exceed 20% of its

volum e.

1.1.4 Special shaped bricks

These are usually solid bricks of various shapes suited to a particular construction.

1.2 Quality of bricks

G enerally com m on bricks are grouped into 3 classes:

Description Class 1 Class 2 Class 3

Water absorption M ax. 20% M ax 20% M ax 20%

Crushing strength M in. 105 kg/cm

2

M in. 70 kg/cm

2

M in. 35 kg/cm

2

Building Material and Quality Standards

M

O

D

U

L

E

2

24

Basic Construction Training Manual for Trainers

25

1.2.1 AA class

B ricks w ith crushing strength not less than 140 kg/cm

2

are graded as A A class.

1.2.2 Soaked bricks

The strength of a brick decreases by about 25% w hen soaked in w ater.

1.2.3 Structure

B rick w hen broken should be hom ogeneous in structure, com pact and free from holes, cracks,

fissures, air bubbles, lum ps, pebbles and stones and particles of lim e etc.

1.2.4 Shape and size

The brick should be rectangular w ith straight and sharp edges. A ll bricks should have the sam e

dim ensions and no broken corners or edges.

The size of the bricks varies slightly from region to region in India. Standard size is norm ally

230 x 115 x 70 m m (9 x 4-1/2 x 2-3/4 inch).

N o dim ension of a class 1 brick is allow ed to vary m ore than 3 m m from the standard size.

1.2.5 Soundness

The quality of a brick is good if there is a clear ringing sound w hen tw o bricks are struck

together.

1.2.6 Fall test

A brick should not break w hen dropped flat on hard ground from a height of about one m eter.

1.2.7 Scratch test

A good burned brick has surface so hard that the fingernail cannot scratch it.

24

Basic Construction Training Manual for Trainers

25

2. Stones

B uilding stones are derived from various types of rocks that are found in the crust of the earth.

They are natural products and are used directly, except for their rough sizing and dressing,

before being put in a structure.

Stones are or can be used in alm ost all parts of construction such as foundations, w alls, floors,

roofs, as w ell as for roads, dam s etc.

A s a rough guide, w alls w ith w ell fitting stones laid in cem ent m ortar have a strength of about

75% of an equivalent brick w all, and w alls m ade of rough stones have a strength of about 50%

of the equivalent brick w all.

C rushed and broken stones are used in m aking concrete and artificial stones such as concrete

blocks.

All size bolder stone deposit Sized stone deposit

All size bolder stone try masonry wall Sized stone pillar construction

2.1 Classification of stones

Stones or rocks are divided into three m ain groups:

n Igneous (G ranite)

n Sedim entary (Sand-stone Lim e-stones)

n M etam orphic (Slates, M arble, Laterite)

Building Material and Quality Standards

M

O

D

U

L

E

2

26

Basic Construction Training Manual for Trainers

27

2.2 Quality of building stone

The fundam ental requirem ents of building stones are strength, density and durability com bined

w ith reasonable facility for w orking. A good building stone m ust be hard, tough, com pact

grained and uniform in texture and color.

U sually, crystalline and close-grained stones are durable.

2.2.1 Signs of good quality stones

Colour: Stones should have uniform colour. R ed and brow n shades and

m ottled colour indicate the presence of injurious m aterial.

Weight: B asically, the heavier and com pact grained stones are the stronger and

durable they are.

Water absorption: A stone absorbing less w ater is stronger and m ore durable as it w ill

have less action of rainw ater.

Appearance: A good building stone should be free from decay, flaw s, veins, cracks

and sand-holes

2.2.2 Quality tests

There are several tests possible to define the quality of a stone. H ow ever, in the field there are

basically three tests w here one can define the suitable quality of a stone.

Hammer test

Take a ham m er and check the stone for its sound. A hard ringing sound indicates that the stone

is of good quality and has no m ajor defect such as holes or cracks.

Visible test

C heck the stone for any defects such as cracks, patches w ith soft m aterials, discoloring etc.

Porosity or absorption test

W eight a stone of reasonable size and place it for 24 hrs. into a w ater-bucket. A good building

stone should not absorb m ore than 5% of its w eight of w ater after 24hrs im m ersion.

26

Basic Construction Training Manual for Trainers

27

3. Concrete blocks

C oncrete blocks are now adays very com m on and tim e proofed w alling m aterials. C oncrete

blocks can be produced by hand and by m achine. H and m ade blocks are usually of low er

quality, because m achine m ade blocks are better com pacted by a vibrator table. The specific

use of a concrete block defines its size and the quality. C em ent and coarse sand w ith sm all

size aggregates are used w ith very low w ater/cem ent ratio.

H ollow blocks have better therm al properties than solid blocks of the sam e m aterial and total

thickness.

H ollow blocks have certain advantages over bricks, they are only about 1 3

rd

of the w eight

of the sam e num ber of bricks and they can be laid about four tim es rapidly and are of am ple

strength for all purposes for w hich ordinary bricks are used except under concentrated loads.

They have the advantages of hollow w alls as regards insulation against heat and sound.

Concrete hollow block (CHB)production yard CHB wall construction used in earthquake

resistant house design

3.1 Classification of concrete blocks

C oncrete blocks are classified into tw o m ain groups;

n Solid blocks

n H ollow blocks

3.2 Quality of concrete blocks

The basic quality requirem ent of concrete blocks are; strength, uniform in size and to a certain

degree w ater resistant. A good concrete block is produced and stored under a sunshade,

has an appropriate m ix ratio (not m ore than 1: 6 for hollow blocks and 1: 10 for solid blocks)

contains clean raw m aterials (sand, aggregates and w ater) and fresh cem ent, is properly cured

for 21 days and is handled w ith care up to the point of use for m asonry w ork.

Description Solid blocks

Hollow blocks

(non load bearing w alls)

Hollow blocks

(load bearing w alls)

Density > 1800 kg/cum > 1500 kg / cum > 1500 kg/cum

Crushing strength

(after 28 days)

M in. 5 N /m m

2

M in.2.8 N /m m s M in. 3.5 N /m m

2

Building Material and Quality Standards

M

O

D

U

L

E

2

28

Basic Construction Training Manual for Trainers

29

4. Sand and aggregates

Sand and aggregates are very essential building construction raw m aterials and deserve special

attention.

4.1 Classification of sand and aggregates

M aterial retained on a 4.75 m m IS (Indian Standard) sieve is classified as coarse aggregate,

and below that size as fine aggregate or sand. The m aterial passing a 75-m icron IS sieve is

generally considered to be clay, fine silt or fine dust in an aggregate.

Sand, w hich contains 90% of particles of size greater than 0.06 m m and less than 0.2 m m , is

fine sand.

Sand, w hich contains 90% of particles of size greater than 0.6 m m and less than 2 m m is

coarse sand.

4.1.1 Coarse aggregate

There are m ainly three sources from w here coarse aggregates originate nam ely:

n N atural deposits

n C rushed stones

n B rick aggregates

4.1.2 Sand

There are m ainly four types of sand nam ely:

n Pit sand

n Sea sand

n R iver sand

n C rushed sand

Pit sand deposit

28

Basic Construction Training Manual for Trainers

29

4.2 Quality of sand and aggregates

The quality of the m ortar is directly linked to the characteristics and condition of the sand. Sand

and aggregates m ust be free from clay, loam , vegetables and any other organic m aterial.

C lay or dirt coating on aggregates prevents adhesion of cem ent to aggregate, slow s dow n the

setting and hardening process and reduces the strength of the m ortar.

Therefore, clay and silt content should not exceed 10% , otherw ise the sand needs to be

w ashed.

4.2.1 Sand storage

The sand should be stored preferably under a shade. The sand should be sufficiently protected,

such that no im purity from anim als, agricultural w aste, children, trees, etc. is possible.

4.2.2 Testing the sand quality

There are tw o m ain sand quality-testing m ethods, nam ely:

Visible test

C heck the sand for im purities such as organic m aterials (m ud, leaves, roots etc.) R em ove them

before using the sand.

Clay and silt content test

The clay and silt content test can be in tw o w ays:

Hand test

The sand sam ple is rubbed betw een dam p hand. A clean sand w ill leave the hands only slightly

stained. If the hands stay dirty, it indicates the presence of too m uch silt or clay.

Bottle test

Take a bottle and fill in the sand until it is half full. Fill in clean w ater until the bottle is three-

quarters full. Shake up vigorously and leave it to settle for about one hour. C lean sand w ill

settle im m ediately, silt and clay w ill settle slow ly on top of the sand. The thickness of the clay

and silt layer should not exceed one-tenth or 10% of the sand below .

This test is also called decantation test. This test is not applicable to crushed stone sands!!

D irty sand should never be used in m asonry because it w ill reduce the adhesive value of the

m ortar considerably.

4.2.3 Sea sand

Sea sand is unsuitable for m ortar as it contains salts, w hich attract and retain m oisture. In

addition the salt content in the m ortar w ill produce a w hitish pow der of efflorescence, w hich

discolors the brickw ork or m asonry.

Building Material and Quality Standards

M

O

D

U

L

E

2

30

Basic Construction Training Manual for Trainers

31

5. Cement

C em ent is a m ixture of 60 to 67% lim e, 17 to 25% silica and 3 to 8% alum ina, w hich are

intim ately m ixed together w ith w ater to form into a slurry, w hich is subsequently heated, dried,

calcined and ground to a very fine pow der. A sm all proportion of gypsum is added before

grinding in order to control the rate of setting.

5.1 Setting/Hardening

The term s setting and hardening have different m eanings. Setting is the process w hich changes

a fluid concrete to a solid but w eak state. H ardening is the process by w hich the w eak set

concrete attains strength.

5.2 Hydration of cement

W hen w ater is added to cem ent, the cem ent hydrates and during the chem ical reactions, w hich

take place w hile the cem ent is setting, an increase in tem perature occurs and a considerable

quantity of heat is generated

5.3 Different types of cement

There are total five different kinds of cem ents. C em ents are classified by their properties and

chem ical com position. The nam es of these five kinds of cem ents are:

n O rdinary Portland C em ent

n R apid hardening C em ent

n Q uick setting C em ent

n B last furnace Slag C em ent

n H igh A lum ina C em ent

5.4 Type and quality

For ordinary brick m asonry w ork it is recom m ended to use ordinary Portland cem ent. In order

to achieve a good m ortar in strength and durability, it is essential that the follow ing rules and

regulations be follow ed:

5.4.1 Cement storage

C em ent can be safely stored in bags for a few m onths if kept in a dry room . Paper bags are

better for storing than jute bags because paper bags perform better in regard to quality dete-

rioration due to m oisture. D uring the m onsoon tim e, the cem ent storage plays an even m ore

im portant role, since the relatively higher hum idity accelerates the deterioration process of the

cem ent.

C em ent bags should be stored on a raised w ooden platform (e.g. tim ber pallets) about 15 to

20 cm above the floor level and about 30 to 50 cm aw ay from w alls.

The cem ent stack should not be m ore than 10 bags high. The bags should be placed close

together to reduce circulation of air.

A cem ent bag should never be opened until its im m ediate use for m ixing.

30

Basic Construction Training Manual for Trainers

31

5.4.2 Use of fresh cement

O rdinary Portland cem ent, w hich has been stored for over six m onths, should not be used for

m asonry w ork.

The average reduction of strength in a 1:2:4 m ix as a result of storage is:

Fresh cement strength 100%

C em ent after 3 m onths, strength reduced by 20%

C em ent after 6 m onths, strength reduced by 30%

C em ent after 12 m onths, strength reduced by 40%

C em ent after 24 m onths; strength reduced by 50%

5.5 Testing the cement quality

The indication of dam aged cem ent is given by the presence of large lum ps of set cem ent.

These lum ps of set cem ent should not be used, not even if screened again.

The freshness of cem ent can be tested as per follow ing description:

Lump test:

C heck the cem ent for any sm all or large lum ps. R em ove them .

Rubbing test:

W hen cem ent is rubbed betw een fingers and thum b it should feel like a sm ooth pow der such

as flour.

Setting test:

If you are uncertain about your cem ent quality you can m ake a sim ple setting test.

M ake a stiff paste of neat cem ent and w ater and form it into a cake about 75 m m diam eter

and 12 to 15 m m thick. The cake should com m ence to set in about 30 to 60 m inutes. In 18 to

24 hours the cake should have hardened sufficiently so that it does not effortlessly scratch the

surface w ith a thum bnail.

Building Material and Quality Standards

M

O

D

U

L

E

2

32

Basic Construction Training Manual for Trainers

33

6. Water

The w orkability of a m ortar increases as the w ater content of the m ix is increased. W ater

lubricates the m ixture. H ow ever, increased w ater content w ill cause a decrease in strength,

produce cracks (shrinkage) and decrease density.

Therefore, not only the quality, but equally im portant the quantity of the w ater is im portant for

producing a good m ortar and brick m asonry w ork.

6.1 Type and quality

A lm ost any natural w ater that is drinkable and has no pronounced taste or odor can be used as

m ixing w ater for m aking cem ent m ortar. W ater suitable for m aking cem ent m ortar, how ever,

m ay not be fit for drinking.

6.1.1 Seawater

Seaw ater should not be used as m ixing w ater for cem ent m ortar.

6.1.2 Collected rainwater from roofs

R ainw ater collected from roofs can be used for m ixing m ortar or concrete.

6.1.3 Oils

Various kinds of oil are occasionally present in m ixing w ater. W ater m ixed w ith any kind of oil

shall not be used for m ixing m ortar or concrete.

6.2 Water storage

W ater should be stored w here no contam ination is possible. W ater stored in clean drum s

or covered tanks is preferred. The age of the w ater, or the storage tim e does not affect the

cem ent m ortar quality in any w ay.

6.3 Testing the water quality

W ater of questionable suitability can be used for m aking cem ent m ortar cubes. The w ater in

question should achieve the strength in 7 and 28 days equal to at least 90% of com parable

specim ens m ade w ith drinkable w ater.

32

Basic Construction Training Manual for Trainers

33

Bad brick wall construction resulting into corner collapse / damage

Principles of Construction

M

O

D

U

L

E

3

35

35

Principles of Construction

M

O

D

U

L

E

3

Content

1. Principles of mortar .................................................................................38

1.1 What is mortar?.........................................................................................38

1.2 Type of mortars .........................................................................................38

1.3 Cement mortar...........................................................................................38

1.4 Lime mortar ...............................................................................................38

1.5 Cement lime mortar ...............................................................................38

1.6 Mortar sand granulation...........................................................................38

1.7 Mixing mortars..........................................................................................39

1.7.1 W eight m ethod..............................................................................39

1.7.2 Volum etric m ethod ........................................................................39

1.8 Categorization of mortars and its mix ratio............................................39

1.9 Dos and donts ..........................................................................................40

2. Principles of concreting............................................................................42

2.1 What is concrete?......................................................................................42

2.1.1 O ther ingredients ..........................................................................42

2.1.2 H ydration begins ...........................................................................42

2.1.3 The form s of concrete...................................................................43

2.2 Functions and requirements of concrete ingredients.............................43

2.2.1 Functions of cem ent......................................................................43

2.2.2 Functions of sand ..........................................................................43

2.2.3 C oarse aggregate ..........................................................................44

2.2.4 W ater.............................................................................................44

2.3 Reinforced concrete .................................................................................44

2.4 Reinforcement ..........................................................................................44

2.4.1 Type and characteristics of steel bars ..........................................44

2.4.2 C ategories & purpose of reinforcem ent........................................45

2.4.3 B asic rules for steel reinforcem ent...............................................45

2.5 Type of concrete .......................................................................................46

2.5.1 H igh strength concrete..................................................................46

2.5.2 M edium strength concrete............................................................46

2.5.3 Low strength concrete ..................................................................46

2.5.4 M ixing proportion of concrete .......................................................46

2.6 Cover in concrete......................................................................................47

2.7 Requirements of concrete.........................................................................47

2.7.1 Strength.........................................................................................47

2.7.2 W orkability.....................................................................................47

2.8 Factors influencing concrete quality........................................................47

2.8.1 C em ent..........................................................................................47

2.8.2 W ater C em ent ratio ....................................................................47

2.8.3 R aw m aterials................................................................................47

2.8.4 Fineness of fine aggregate............................................................48

2.8.5 Placing the concrete......................................................................48

2.8.6 C om paction ...................................................................................49

2.8.7 C uring ............................................................................................49

2.8.8 Effect of aging ...............................................................................49

2.9 Mixing of concrete....................................................................................49

2.9.1 H and m ixing ..................................................................................49

2.9.2 M achine m ixing ............................................................................50

2.10 Dos and donts ..........................................................................................50

2.11 Form work..................................................................................................53

2.12 Removal of the forms ...............................................................................54

36

Basic Construction Training Manual for Trainers

37

3. Principles of brick masonry......................................................................55

3.1 Brick overlap between layers ...................................................................55

3.2 Size of bricks..............................................................................................55

3.2.1 N am es of parts of a brick..............................................................56

3.3 Rules for joints ..........................................................................................57

3.3.1 H orizontal joints.............................................................................57

3.3.2 Vertical joints .................................................................................57

3.4 Selection of bricks.....................................................................................58

3.5 Brick cuttings .............................................................................................58

3.6 Brick soaking..............................................................................................58

3.7 Maximum brick wall height per day........................................................59

3.8 Curing.........................................................................................................59

3.9 Pointing......................................................................................................59

3.10 Most common bonds................................................................................60

3.10.1 Flem ish bond (O ne brick thick)......................................................60

3.10.2 Flem ish bond (O ne and half brick thick)........................................60

3.10.3 English bond (O ne brick thick).......................................................61

3.10.4 English bond (O ne and half brick thick ..........................................61

3.10.5 R at trap bond.................................................................................62

3.10.6 Stretcher bond...............................................................................63

3.10.7 H eader bond..................................................................................64

4. Principles of stone masonry....................................................................65

4.1 Stone surfaces...........................................................................................65

4.2 Rules for stone shaping............................................................................65

4.2.1 Line stones....................................................................................66

4.2.2 C ornerstones.................................................................................66

4.2.3 A rch stones ..................................................................................67

4.3 Unsquared rubble masonry ....................................................................67

4.3.1 U ncoursed rubble ..........................................................................67

4.3.2 R andom coursed rubble ................................................................68

4.3.3 C oursed rubble ..............................................................................68

4.4 How to build with shaped stones ............................................................68

4.5 Bonding......................................................................................................70

4.6 Curing.........................................................................................................70

4.7 Pointing......................................................................................................70

4.8 Dos and donts ..........................................................................................71

5. Principles of curing...................................................................................72

5.1 What is curing?..........................................................................................72

5.2 Type of curing............................................................................................72

5.2.1 W ater curing ..................................................................................72

5.2.2 Vapor curing ..................................................................................73

5.2.3 Steam curing .................................................................................73

36

Basic Construction Training Manual for Trainers

37

Principles of Construction

M

O

D

U

L

E

3

6. Principles of plastering.............................................................................74

6.1 What is plastering? ................................................................................... 74

6.2 Requirements of good plaster ................................................................ 74

6.3 Types of mortars for plastering................................................................ 74

6.3.1 C em ent m ortar..............................................................................74

6.4 Number of coats of plaster....................................................................... 74

6.4.1 B ackground ....................................................................................75

6.4.2 Tw o coat plaster............................................................................75

6.4.3 Three coat plaster.........................................................................75

6.4.4 Single coat plaster ........................................................................75

6.5 Preparation of background ......................................................................75

6.6 Recommended mortar mixes ................................................................... 76

6.7 Defects in plastering .................................................................................77

6.7.1 B listering of plastered surface.......................................................77

6.7.2 C racking.........................................................................................77

6.7.3 C razing...........................................................................................77

6.7.4 Efflorescence ...............................................................................77

6.7.5 Flaking ...........................................................................................77

6.7.6 Peeling...........................................................................................77

6.7.7 Popping..........................................................................................77

6.7.8 R ust stains ....................................................................................78

6.7.9 U neven surface .............................................................................78

7. Flooring......................................................................................................79

7.1 What is flooring?.......................................................................................79

7.2 Components of flooring ..........................................................................79

7.2.1 Sub floor........................................................................................79

7.2.2 Floor finish.....................................................................................79

7.3 Types of floors...........................................................................................79

7.3.1 B rick bat floor ...............................................................................79

7.3.2 C oncrete floor................................................................................80

7.3.3 O ther com m on types of floors......................................................81

38

Basic Construction Training Manual for Trainers

39

1. Principles of mortar

1.1 What is mortar?

M ortar m ay be defined as a m aterial com posed of fine aggregate and cem ent, w hich form s a

hardened m ass after m ixing w ith w ater. It is used in the beds and side joints of m asonry w ork,

in order to bind the stones, bricks or blocks together and distribute the pressure throughout

the block-w ork.

M ortar is further used also for plastering w ork, pointing w ork, flooring and topping w ork.

G ood m ortar used for m asonry consists of cem ent, sand and w ater in the correct proportions.

W hen the m aterials are freshly m ixed, m ortars have a plastic consistency, w hich could be

easily w orked w ith trow els to fill the joints in m asonry or to render the surfaces of w alls by

plastering etc. B y the virtue of the setting properties of the binding m aterial used (cem ent,

lim e) they set and becom e hard subsequently.

1.2 Type of mortars

G enerally there are three com m on types of m ortars in use for m asonry and plastering w ork,

nam ely:

n C em ent m ortar

n Lim e m ortar

n C em ent lim e m ortar

1.3 Cement mortar

C em ent m ortar is now adays the m ost com m only used m ortar for brick as w ell as stones

or concrete block m asonry w ork. It provides high strength properties. M ix proportion varies

according to requirem ents of the m asonry structure.

1.4 Lime mortar

This is a m ixture of quicklim e (burnt lim estone) and sand in the proportion of 1 part lim e and 3

parts sand, in addition to w ater. Lim e m ortar w as once the principal m aterial used for bedding

and jointing bricks and stones. It is used less frequently now as it develops strength very

slow ly and is not easily available in the m arket.

1.5 Cement lime mortar

This w as the m ost usual general-purpose m ortar com prising 1 part cem ent 2 parts lim e and 9

parts sand. The addition of lim e im proves the w orkability and m akes it easier to use. C em ent

lim e m ortar is m ainly used for internal w ork.

1.6 Mortar sand granulation

The sand used for every kind of m ortar m ust be clean and free from clay and other organic

m atters.

For getting a proper m ortar, the granulation of the sand needs to be correct. Sand w ithout fines

(below 0.5m m ) gives a harsh m ortar w ith a low com pressive strength and a bad w orkability.

C em ent m ortar gives the best result w hen the sand com prises of the follow ing:

38

Basic Construction Training Manual for Trainers

39

0 - 0.5 m m (60% 0-0.2 m m ) 1 part

0.5 - 2 m m 1 part

2 - 4 m m 1 part

1.7 Mixing mortars

The sand is placed on a clean platform , the correct am ount of cem ent is added to it, both, sand

and cem ent are thoroughly m ixed before w ater is added and the m ass gradually w orked up into

a plastic condition. The general rule is that sand and cem ent are m ixed dry together at least 3

tim es before w ater is added. This is im portant for achieving the proper plasticity.

Flatten the dry mix with a trowel, if properly

mixed a uniform gray color is visible.

Add water only once a uniform gray color is

visible.

1.7.1 Weight method

M ortar m ixtures are also expressed in kg of cem ent per 1 m

3

of cem ent m ortar. For exam ple

PC 250 m eans that 250 kg of Portland C em ent (PC ), approx. 1000 liters of sand and 120 liters

of w ater are used to obtain about 1 m

3

m ortar. This m ethod is m ainly used for large construc-

tions in cities for bridges, hotel and shopping com plexes etc.

1.7.2 Volumetric method

U sually on sm all and rural construction sites the m ore practical volum e batching m ethod is

applied. The volum etric m ethod is a very appropriate w ay to m ix raw m aterials. Special care

m ust be given to ensure that the w orkers m easure each tim e the sam e volum e.

1.8 Categorization of mortars and its mix ratio

M ortars are categorized in m ainly three groups, nam ely:

Group 1

H ighly stressed m asonry incorporating height strength structural units as used in m ultistory

load bearing buildings.

G roup 1 batching

Cement Sand

1 4

Bucket Buckets

Principles of Construction

M

O

D

U

L

E

3

40

Basic Construction Training Manual for Trainers

41

Group 2

N orm al load bearing applications such as external house w alls, parapets, and balustrades,

retaining structures, freestanding garden w alls and other w alls exposed to severe dam pness.

G roup 2 batching

Cement Sand

1 6

Bucket Buckets

Group 3

Lightly stressed non-structural w alls

G roup 3 batching

Cement Sand

1 8

Bucket Buckets

1.9 Dos and donts

Dos:

U se alw ays-clean sand for m ortar.

Why?

C ontam inated sand (e.g. roots, leaves, plastic parts, saw dust, anim al and hum an excreta etc

w ill not bind w ith cem ent, hence is w eakening the m ortar. A lso sand w ith high percentage of

clay or silt w ill w eaken the m ortar, because the clay or silt contains too m any fines that needs

to be covered by cem ent for proper binding, hence, the m ortar becom es w eak.

Sand deposit properly covered and protected from being contaminated

40

Basic Construction Training Manual for Trainers

41

Dos:

A lw ays use fresh and lum p free cem ent for m ortar

Why?

O ld cem ent is loosing its strength property. E.g. cem ent that has been stored for about 6

m onths is gaining 30% less strength than fresh cem ent. For good m asonry w ork, strength is

im portant as it influences the overall building quality.

Improperly stored cement results in

loss of quality

Dos:

A lw ays m ix the dry ingredients (sand & cem ent) together before adding w ater.

Why?

W et sand particles have the tendency to stick together and are therefore hindering that cem ent

can cover them . This results in an un-uniform m ix that is reducing the m ortar quality, because

each sand particle should ideally be fully covered w ith cem ent.

Further, adding w ater together w ith sand and cem ent in one go m akes m ixing the m ortar

extrem ely difficult for the laborers.

Dos:

A lw ays protect the m ortar-m ixing place from w ind, rain and sunshine.

Why?

W ind and sunshine is entraining the w ater from the m ortar and is accelerating the hardening

process before it is being used. This is m akes the m ortar useless for any purpose. R ain is

adding w ater and the m ortar becom es unusable too.

Donts:

D o not use or re-use m ortar that has already hardened. A s cem ent m ortar sets relatively quickly

(approx. 30 m inutes), it should never be m ixed in huge quantities.

Why?

In hardened m ortar, the hydration process of the cem ent has started and re-m ixing it is

destroying the bond betw een cem ent and sand. This bond cannot regain strength again by

sim ply adding fresh w ater to the m ortar.

Principles of Construction

M

O

D

U

L

E

3

42

Basic Construction Training Manual for Trainers

43

2. Principles of concreting

2.1 What is concrete?

In its sim plest form , concrete is a m ixture of paste and aggregates. The paste, com posed of

portland cem ent and w ater, coats the surface of the fine and coarse aggregates. Through a

chem ical reaction called hydration, the paste hardens and gains strength to form the rock-like

m ass know n as concrete. W ithin this process lies the key to a rem arkable trait of concrete: its

plastic and m alleable w hen new ly m ixed, strong and durable w hen hardened. These qualities

explain w hy one m aterial, concrete, can build skyscrapers, bridges, sidew alks and superhigh-

w ays, houses and dam s. The key to achieving a strong, durable concrete rests in the careful

proportioning and m ixing of the ingredients. A concrete m ixture that does not have enough

paste to fill all the voids betw een the aggregates w ill be difficult to place and w ill produce

rough, honeycom bed surfaces and porous concrete. A m ixture w ith an excess of cem ent paste

w ill be easy to place and w ill produce a sm ooth surface; how ever, the resulting concrete is

likely to shrink m ore and be uneconom ical.

A properly designed concrete m ixture w ill possess the desired w orkability for the fresh

concrete and the required durability and strength for the hardened concrete. Typically, a m ix

is about 10 to 15 percent cem ent, 60 to 75 percent aggregate and 15 to 20 percent w ater.

Entrained air in m any concrete m ixes m ay also take up another 5 to 8 percent.

Portland cem ents chem istry com es to life in the presence of w ater. C em ent and w ater form a

paste that coats each particle of stone and sand. Through a chem ical reaction called hydration,

the cem ent paste hardens and gains strength. The character of the concrete is determ ined

by quality of the paste. The strength of the paste, in turn, depends on the ratio of w ater to

cem ent. The w ater-cem ent ratio is the w eight of the m ixing w ater divided by the w eight of

the cem ent. H igh-quality concrete is produced by low ering the w ater-cem ent ratio as m uch

as possible w ithout sacrificing the w orkability of fresh concrete. G enerally, using less w ater

produces a higher quality concrete provided the concrete is properly placed, consolidated, and

cured.

2.1.1 Other ingredients

A lthough m ost drinking w ater is suitable for use in concrete, aggregates are chosen carefully.

A ggregates com prise 60 to 75 percent of the total volum e of concrete. The type and size of

the aggregate m ixture depends on the thickness and purpose of the final concrete product.

A lm ost any natural w ater that is drinkable and has no pronounced taste or odor m ay be used

as m ixing w ater for concrete. H ow ever, som e w aters that are not fit for drinking m ay be

suitable for concrete. Excessive im purities in m ixing w ater not only m ay affect setting tim e

and concrete strength, but also m ay cause efflorescence, staining, corrosion of reinforcem ent,

volum e instability, and reduced durability.

R elatively thin building sections call for sm all coarse aggregate, though aggregates up to six

inches (150 m m ) in diam eter have been used in large dam s. A continuous gradation of particle

sizes is desirable for efficient use of the paste. In addition, aggregates should be clean and free

from any m atter that m ight affect the quality of the concrete.

2.1.2 Hydration begins

Soon after the aggregates, w ater, and the cem ent are com bined, the m ixture starts to harden.

A ll portland cem ents are hydraulic cem ents that set and harden through a chem ical reaction

w ith w ater. D uring this reaction, called hydration, a node form s on the surface of each cem ent

particle. The node grow s and expands until it links up w ith nodes from other cem ent particles

or adheres to adjacent aggregates. The building up process results in progressive stiffening,

42

Basic Construction Training Manual for Trainers

43

hardening, and strength developm ent. O nce the concrete is thoroughly m ixed and w orkable

it should be placed in form s before the m ixture becom es too stiff. D uring placem ent, the

concrete is consolidated to com pact it w ithin the form s and to elim inate potential flaw s, such

as honeycom bs and air pockets. For slabs, concrete is left to stand until the surface m oisture

film disappears. A fter the film disappears from the surface, a w ood or m etal handfloat is used

to sm ooth off the concrete. Floating produces a relatively even, but slightly rough, texture

that has good slip resistance and is frequently used as a final finish for exterior slabs. If a

sm ooth, hard, dense surface is required, floating is follow ed by steel trow eling. C uring begins

after the exposed surfaces of the concrete have hardened sufficiently to resist m arring. C uring

ensures the continued hydration of the cem ent and the strength gain of the concrete. C oncrete

surfaces are cured by sprinkling w ith w ater fog, or by using m oisture-retaining fabrics such

as burlap or cotton m ats. O ther curing m ethods prevent evaporation of the w ater by sealing

the surface w ith plastic or special sprays (curing com pounds). Special techniques are used for

curing concrete during extrem ely cold or hot w eather to protect the concrete. The longer the

concrete is kept m oist, the stronger and m ore durable it w ill becom e. The rate of hardening

depends upon the com position and fineness of the cem ent, the m ix proportions, and the

m oisture and tem perature conditions. M ost of the hydration and strength gain take place w ithin

the first m onth of concretes life cycle, but hydration continues at a slow er rate for m any years.

C oncrete continues to get stronger as it gets older.

2.1.3 The forms of concrete

C oncrete is produced in four basic form s, each w ith unique applications and properties. Ready

mixed concrete. Its batched at local plants for delivery in the fam iliar trucks w ith revolving

drum s. Precast concrete products are cast in a factory setting. These products benefit from

tight quality control achievable at a production plant. Precast products range from concrete

bricks and paving stones to bridge girders, structural com ponents, and panels for cladding.

Concrete masonry, another type of m anufactured concrete, m ay be best know n for its con-

ventional 8 8 16 - inch block. Todays m asonry units can be m olded into a w ealth of shapes,

configurations, colors, and textures to serve an infinite spectrum of building applications and ar-

chitectural needs. C em ent-based m aterials represent products that defy the label of concrete,

yet share m any of its qualities. C onventional m aterials in this category include m ortar, grout,

and terrazzo. Soil-cem ent and roller-com pacted concrete-cousinsof concrete-are used for

pavem ents and dam s. O ther products in this category include flow able fill and cem ent-treated

bases. A new generation of advanced products incorporates fibers and special aggregate to

create roofing tiles, shake shingles, lap siding, and countertops. A nd an em erging m arket is the

use of cem ent to treat and stabilize w aste.

2.2 Functions and requirements of concrete ingredients

2.2.1 Functions of cement

n It fills up the voids in the fine and coarse aggregates.

n M ake the concrete im perm eable.

n It provides strength to concrete on setting and hardening.

n It binds the aggregates into a solid m ass by virtue of its setting.

n H ardens w hen m ixed w ith w ater.

2.2.2 Functions of sand

n Sand fills the voids existing in the coarse aggregates.

n It reduces shrinkage of concrete

n Sand helps in hardening of cem ent by allow ing the w ater through its voids.

Principles of Construction

M

O

D

U

L

E

3

44

Basic Construction Training Manual for Trainers

45

2.2.3 Coarse aggregate

n It m akes solid and hard m ass of concrete w ith cem ent and sand.

n It reduces the cost of concrete, since it occupies m ore volum e.

2.2.4 Water

n W ater w ets the surface of aggregates

n It facilities the spreading of cem ent over the aggregates and m akes the m ix w orkable.

n It initiates the hydration process of the cem ent, subsequently starts the setting and

hardening process

n It controls the heat generated by the hydration process of the cem ent

2.3 Reinforced concrete

C oncrete can support heavy loads in com pression, but its tensile strength is relatively low .

(A bout one tenth of the com pressive) To com pensate for the low tensile strength property of

the concrete, steel bars w ith a very high tensile strength is com bined w ith concrete.

B y em bedding steel bars in the concrete, advantage is taken of these properties to im prove

the load carrying capacity of the structure. The steel is placed in the concrete that is subjected

to tension but also to avoid cracks due to shrinking.

2.4 Reinforcement

2.4.1 Type and characteristics of steel bars

Steel is a high strength m aterial and for reinforced concrete w ork m ild steel, m edium tensile

steel, high tensile steel and hard draw n steel is com m only used.

D ifferent size of reinforcem ent & their w eights:

Sr.No. Size of Steel (dia in mm) Weight per Rm.

1.

2.

3.

4.

5.

6.

7.

6

8

10

12

16

20

25

0.22 kg

0.39 kg

0.62 kg

0.89 kg

1.58 kg

2.47 kg

3.85 kg

44

Basic Construction Training Manual for Trainers

45

The various form s in w hich steel is used as reinforcem ent in R .C .C . w orks are round bars,

deform ed bars, tw isted bars, square bars and flats. Som e tim es expanded m etal fabrics m ade

by w elding steel w ire in the form square m esh, are also used as reinforcem ent in slabs.

M ild steel and m edium tensile steel bars of round sections are m ost com m only used in R .C .C .

w ork. The diam eters of round bars used in norm al building w ork are 6, 8,10, 12, 16,18, 20, 22,

25 and 32 m m .

D eform ed bars or high yield strength deform ed bars are furnished w ith lugs, ribs or other form

of surface deform ations for the purpose of increasing their bond strength w ith concrete.

2.4.2 Categories & purpose of reinforcement

There are tw o m ain categories and purposes of reinforcem ent by steel.

The main reinforcement, to take care for the tension forces.

Distribution reinforcement, to spread the load and to keep the m ain reinforcem ent in

position during casting.

2.4.3 Basic rules for steel reinforcement

The m ain reinforcem ent should alw ays be at the place w here tension occurs. It should

adequately covered by concrete to avoid corrosion of the reinforcem ent. Steel bars of plain

surface (m ild steel) need to be hooked at the ends to obtain better adhesion, and therefore

create a greater strength for the structure. H ooking is not necessary for steel bars w ith ribbed

surface (Tor-steel).

A proper bond betw een the steel rods and the concrete is the m ost im portant for reinforced

concrete. The surface of the rod has to be clean. In order to provide a proper bond the rods

have to be surrounded com pletely by the concrete. Therefore, the reinforced concrete has to

be properly vibrated. Plain bars m ust have ends w ith hooks, w hich, should be anchored, in

the pressure zone. D eform ed bars w ith ribbed projections can have straight ends but then the

anchorage has to be in the pressure zone of the structure.

If rods have to be overlapped the follow ing rules show the m inim um overlap length:

R od w ith hook - 45 tim es diam eter of the rod

Straight - 65 tim es diam eter of the rod

Important:

The proper placing of reinforcem ent for structures of high quality concrete requires a w orking

draw ing or reinforcem ent plan, containing all the necessary inform ation. A structural engineer

w ill m ake this reinforcem ent plan only.

Principles of Construction

M

O

D

U

L

E

3

46

Basic Construction Training Manual for Trainers

47

2.5 Type of concrete

The strength of the concrete depends on m ix proportions and should suit the w ork being done.

D ifferent applications require different strengths of concrete. Three different strength categories

w ith typical applications are outlined below

2.5.1 High strength concrete (M 300 M350)

H igh strength concrete should be used for suspended structural beam s and slabs, precast

item s (stairs) and heavy-duty floors.

2.5.2 Medium strength concrete (M 200 M250)

M edium strength concrete is suitable for reinforced foundations and slabs, light duty house

floors, paths, steps, drivew ays and garage doors.

2.5.3 Low strength concrete (M100 M150)

Low strength concrete is suitable for unreinforced foundations for houses and freestanding

w alls.

2.5.4 Mixing proportion of concrete

Concrete Type Proportion of Cement Proportion of Sand Proportion of Aggregates

M 100

M 150

M 250

M 350

1

1

1

1

4

4

3

2

6

4

3

2

46

Basic Construction Training Manual for Trainers

47

2.6. Cover in concrete