Professional Documents

Culture Documents

Coconut Value Added Products Processing Technology

Uploaded by

jsphemil0 ratings0% found this document useful (0 votes)

434 views9 pagesThe document discusses several processes used in shell-based and kernel-based coconut processing technology. It describes the multi-stage processes of producing activated carbon, shell charcoal, coconut shell powder, desiccated coconut, spray dried coconut milk powder, coconut chips, coconut oil, virgin coconut oil, and coconut cream. Key steps involve carbonization, activation, drying, extraction, pressing, filtration, and packaging. A variety of machinery is used including kilns, pulverizers, driers, presses, filters, and packaging equipment.

Original Description:

Processing technology for Coconut Value Added Products

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses several processes used in shell-based and kernel-based coconut processing technology. It describes the multi-stage processes of producing activated carbon, shell charcoal, coconut shell powder, desiccated coconut, spray dried coconut milk powder, coconut chips, coconut oil, virgin coconut oil, and coconut cream. Key steps involve carbonization, activation, drying, extraction, pressing, filtration, and packaging. A variety of machinery is used including kilns, pulverizers, driers, presses, filters, and packaging equipment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

434 views9 pagesCoconut Value Added Products Processing Technology

Uploaded by

jsphemilThe document discusses several processes used in shell-based and kernel-based coconut processing technology. It describes the multi-stage processes of producing activated carbon, shell charcoal, coconut shell powder, desiccated coconut, spray dried coconut milk powder, coconut chips, coconut oil, virgin coconut oil, and coconut cream. Key steps involve carbonization, activation, drying, extraction, pressing, filtration, and packaging. A variety of machinery is used including kilns, pulverizers, driers, presses, filters, and packaging equipment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 9

Processing Technology

Shell Based Products

1. Activated Carbon

Process (Steam Activation)

The process of activation is carried out in two stages. Firstly the coconut shell is

converted into shell charcoal by carbonization process which is usually carried out in

mud-pits, brick kilns and metallic portable kilns. The coconut shell charcoal is activated

by reaction with steam at a temperature of 900oC -1100oC under controlled

atmosphere in a rotary kiln. The reaction between steam and charcoal takes place at the

internal surface area, creating more sites for adsorption. The temperature factor, in the

process of activation is very important. Below 900oC the reaction becomes too slow and

is very uneconomical. Above 1100oC the reaction becomes diffusion controlled and

therefore takes place on the outer surface of the charcoal resulting in loss of charcoal.

Machinery

Jaw crusher Hammer mill Vibratory feeder

Elevator Carbonization kiln Soaking tanks

Cyclones

Rotary kiln with heat

recovery unit

Coolers

Centrifuge Rotary drier Micro pulverizer

Sieving machine Pneumatic filling machine

2. Shell Charcoal

Process (Drum Method)

A M.S. Drum kiln is used for carbonization of shells. The drum consists of three sets of

six 1" dia holes provided at its bottom, middle and upper layers and a lid. A detachable

chimney is provided which is installed on the lid after closing the drum. The

manufacture of charcoal requires optimum carbonization of raw shells in a limited

supply of air so that there is neither unburnt shell nor ash due to complete combustion.

The steel drum is filled with raw shells after placing temporarily a four inch diameter

wooden pole in the centre of the drum. The wooden pole is then removed, leaving a

hollow space in the centre which allows the flow of smoke during carbonization. To start

carbonization, a piece of burning rag is dropped to the bottom of the drum through the

hollow space in the centre. When the fire is well underway, the lid with the chimney is

placed into position and the upper and the middle sets of holes are closed.

Carbonization which starts at the bottom progresses as it goes up as well as radially

from the hollow space. When carbonization is complete in a particular zone, a persistent

glow can be seen in all the six holes of a set. When the bottom most set of holes

indicate this situation, the middle set of holes is opened and the bottom set closed. The

stoppage of air flowing into the bottom region avoids over-carbonization in that region.

The progressive carbonization results in reduction in volume of contents and therefore

more shells are added from the top. When the middle region is carbonized well, the top

set of holes is opened while the middle set is now closed. A further addition of raw

shells is done to fill the volume reduction to maximize capacity for burning. When the

top region is well carbonized, the top set of holes is also closed, resulting in complete

stoppage of air inflow to the drum. The drum is then cooled for about eight hours after

which the product is ready for discharge.

Machinery

Drum kiln with chimney

3. Coconut Shell Powder

Process

Coconut shells free from contamination of coir pith, etc., are broken into small pieces

and fed into a pulverizer. The powder from the pulverizer is fed into a cyclone and the

parallel product is collected in bag filters. The shell powder is then fed into a vibrating

sieving machine and packed according to mesh size requirements for various end uses.

The rejects from the sieving machine can be recycled in the pulverizer for size reduction.

The main requirements for consistent good quality of coconut shell powder, are proper

selection of shell of proper stage of maturity and efficient machinery.

Machinery

Hammer mill

Storage bin

Impact pulverizer

Cyclone

Bag filter

Air blower

Sieving machine

Kernel Based Products

1. Desiccated Coconut

Process

The fresh matured coconuts are de-husked and de-shelled. The de-shelling is done by a

special knife to get the kernel in the form of a ball, which is pared using scrapers to

remove the testa. The pared kernel balls are then cut open to drain off the water and

then washed thoroughly in fresh water to remove the invert sugars from the inner

surface of the kernel. The kernel is then ground into a fine mass using hammer or pin

mills. The ground mass is blanched with live steam for about 20 minutes to bring down

the microbiological counts. The blanched mass is then dried in a hot air drier at a

temperature of 80-90oC for about 10 hours so as to bring down the moisture content to

below 3 per cent. The hot air drier is provided with a drying chamber consisting of a

series of trays, which hold the feed. Hot air is blown into this chamber from an external

source through blowers. The dried mass is tested for moisture, free fatty acid and

microbiological counts. The product is packed in polythene pouches. The brown testa

obtained during paring of kernel can be dried and the oil extracted which is known as

paring oil. The dried brown testa can also be mixed with copra during the extraction of

oil.

Machinery

De-husking, de-shelling and paring tools

Washing tank with spray arrangement

Hot dip blanching tank

Disintegrator provided with screens and aluminum trays

Hot air tray drier with blower

Sieving machine

Storage bins

Heat sealing machine

2. Spray Dried Coconut Milk Powder

Process

The first step is breaking the dehusked nuts into halves. The split nuts are deshelled to

separate the kernel. These two operations usually are done manually. Kernel is washed

and then blanched by immersing in hot water at 80oC for 10 minutes. The next step is

comminution of kernel into small gratings using a hammer mill. The gratings are

subjected to pressing using, continuous screw press to extract the milk. The coconut

milk thus obtained is filtered by passing through a vibrating screen. The coconut milk is

then homogenized and mixed with maltodextrins and other emulsifiers in an additive

mixing tank. The milk mixed with additives is then spray dried into a fine milk powder

using a spray drier. The product is then packed in Aluminum foil packets in various sizes

as per customer requirement.

Machinery

Hammer mill Elevator Screw press

Coconut milk storage tanks Vibrating sieving machine Coconut residue mixer

Additive mixing tank Emulsifier Homogenizer

Pasteurizer Volumetric filling

machine

Exhaust box

Can seaming machine Horizontal rotary retort Spray drier

Agro waste vertical boiler Sterilization tank Coconut residue storage bins

3. Coconut Chips

Process

4. Coconut Oil

Process

Well dried copra with a moisture content not exceeding 6 per cent is cleaned well from

any foreign matter. It is then cut into small chips in a copra cutter. The chips are fed into

steam jacketed kettles and cooked mildly at a temperature of 70oC for 30 minutes. After

proper cooking, the cooked material is fed into the expeller continuously and pressed

twice. The combined oil from the first and the second pressing is collected in a tank

provided separately. This oil is filtered by means of a filter press and stored in MS tanks.

Bulk packaging is done in tin containers. HDPE containers and polymeric nylon barrier

pouches are used for small consumer packings. The quality of copra is related to the

quality of coconut oil.

The oil cake obtained as a by-product will find a ready market as a cattle feed and in the

manufacture of mixed cattle feeds or as a raw material for the extraction of remaining

oil by solvent extraction method.

Machinery

Copra Cutter

Bucket elevator

Steam jacketed kettle

Oil expeller

Screw conveyor

Crude coconut oil storage tanks

Filter press

Micro filter

Filtered oil storage tanks

Volumetric filling machine

Baby boiler

Wooden storage drums

5. Virgin Coconut Oil

Process

Coconuts are deshelled followed by paring and dewatering. Pared coconuts are

disintegrated by passing through Rotary wedge type coconut cutter having sieve plate

(3mm hole) through which shredded coconut gratings are expressed in a screw/

Slicing of Kernel

Dipping in Osmotic Solution

Heating in Electric Dryer

hydraulic press to extract fresh coconut milk. The coconut milk is filtered and passed

through a high speed centrifuge wherein the coconut oil gets separated from the

coconut milk. The coconut oil is then packed in consumer packs in an automatic

packing machine.

6. Coconut Cream

Process

The first step is breaking the dehusked nuts into halves. The split nuts are deshelled to

separate the kernel. These two operations usually are done manually. Kernel is washed

and then blanched by immersing in hot water at 80oC for 10 minutes. The next step is

comminution of kernel into small gratings using a hammer mill. The gratings are

subjected to pressing using, continuous screw press to extract the milk. The coconut

milk thus obtained is filtered by passing through a vibratory screen. Food additives such

as emulsifiers and stabilizers, are to be added to the milk to obtain a stable consistency

and texture. For this purpose, permitted emulsifiers and stabilizers are mixed with hot

water separately and mixed thoroughly. This is added to the coconut milk and then

subjected to emulsification using a mechanical impeller emulsifier. The emulsified milk

assumes a creamy consistency. The coconut cream is then pasteurized at 95oC for 10

minutes in a plate heat exchanger. The pasteurized coconut cream is hot filled in cans

using a mechanical volumetric filling machine followed by steam exhausting. The cans

are seamed using an automatic can seamer. The seamed cans are sterilized in a rotary

retort at 15 psi for 20 minutes. The cans are then cooled in running water.

The residue obtained after the extraction of milk is dried in a hot air dryer to 3 per cent

moisture level. The residue forms a base for making coconut burfi, coconut cookies,

curry and chutney powders. Other by-products like coconut water and coconut shell

could be processed into value added products. Vinegar and Nata-de-coco can be

manufactured from coconut water. Shell charcoal and shell powder can be

manufactured from coconut shells. The utilization of byproducts would improve the

economic feasibility of the process.

Machinery

Hammer mill

Elevator

Screw press

Coconut milk storage tanks

Vibrating sieving machine

Coconut residue mixer

Additive mixing tank

Emulsifier

Homogenizer

Pasteurizer

Volumetric filling machine

Exhaust box

Can seaming machine

Horizontal rotary retort

Hot air drier

Agro waste vertical boiler

Sterilization tank

Coconut residue storage bins

Coconut Water

1. Preservation & Packing of Tender Coconut Water

Process

Collection of water, filtration, upgradation, pasteurization, and bottling.

Machinery

Mechanical washing system with

conveyor

Automatic boring and sucking

system

Treatment chamber

Can filling machine

Can seaming machine

Bottle sealing machine

Pasteurization unit

Strapping machine

Laminar floor chamber

2. Coconut Vinegar

Process

The matured coconut water consisting of about 3 per cent sugar content is

concentrated to 10 per cent level by fortifying with sugar. The fortified coconut water is

then fermented by inoculating the solution with yeast, Sacharomyces cerviseae. After

alcoholic fermentation for about 4 to 5 days, the clear liquid is siphoned off and

inoculated with mother vinegar containing acetobacter bacteria. The alcoholic ferment

obtained is then fed into a vinegar generator where the feed is uniformly sprayed over

the surface of the porous packing medium (corn cobs). Here the alcoholic ferment is

oxidized to acetic acid. The product is run out from the packing medium by gravity flow

into the receiving vat from where it is recycled into the vinegar generator and the

process of acetification is repeated until a strength of 4 per cent is attained. This

acetified vinegar is then aged before bottling.

Machinery

Feed trough

Vinegar acetifier

Receiving trough

Wooden storage drums

3. Nata-de-coco

Process

Initially coconut water is strained and mixed with sugar and glacial acetic acid in

stipulated proportions. Boil for ten minutes and cool. Add the culture solution and

distribute the mixture in wide mouthed glass or plastic jars, cover the jar with a paper or

a thin cloth to protect from dust. It is then kept aside undisturbed for two to three

weeks. After this period, the white jelly like thick surface growth is harvested, washed

thoroughly to remove all the acids and sliced into cubes. It is then immersed in flavored

sugar solution, again boiled and packed in glass jars or retortable pouches, sterilized

and sealed.

Equipment

Glass Vessels

Glass Jars

Sterilized bottles

Measuring cups

Water bath

Refrigerator

You might also like

- Value Addition in CoconutDocument31 pagesValue Addition in Coconutjsphemil100% (1)

- Virgin Coconut OilDocument23 pagesVirgin Coconut OilLive LikeNo ratings yet

- Coconut and Coconut Based Products Ebrochures 1Document8 pagesCoconut and Coconut Based Products Ebrochures 1Nilamdeen Mohamed Zamil100% (1)

- National Multi Commodity Exchange of India Limited: Report On CopraDocument15 pagesNational Multi Commodity Exchange of India Limited: Report On Coprasurya the greatNo ratings yet

- Blanching of BananaDocument9 pagesBlanching of BananaRaihanul HaqueNo ratings yet

- Growing Demand for Cacao in the Philippines and AbroadDocument34 pagesGrowing Demand for Cacao in the Philippines and AbroadOzzy CaliboNo ratings yet

- Process Optimization For Making Unripe Banana Flour and Its Utilization in VermicelliDocument9 pagesProcess Optimization For Making Unripe Banana Flour and Its Utilization in VermicelliIJASRETNo ratings yet

- Boosting Mindanao's Cassava CompetitivenessDocument113 pagesBoosting Mindanao's Cassava CompetitivenessArnel E. Gonzales75% (8)

- Coconut Milk Powder, Spray DriedDocument3 pagesCoconut Milk Powder, Spray DriedE Delos SantosNo ratings yet

- Desiccated Coconut Coconut Milk or Cream Instant Coconut Milk Powder Coconut Sap and Products. Desiccated CoconutDocument12 pagesDesiccated Coconut Coconut Milk or Cream Instant Coconut Milk Powder Coconut Sap and Products. Desiccated CoconutRajalingamNo ratings yet

- Using Virgin Coconut Oil Waste Products For Chicken and Pig FeedDocument4 pagesUsing Virgin Coconut Oil Waste Products For Chicken and Pig FeedAmalia RahmahNo ratings yet

- Gluten-Free Banana Flour: A Resistant Starch AlternativeDocument2 pagesGluten-Free Banana Flour: A Resistant Starch AlternativeWinna Tapia Tabiosa UbolNo ratings yet

- MangoCultivation PDFDocument10 pagesMangoCultivation PDFcacsniteshNo ratings yet

- CULTIVATION OF TARO: A GUIDEDocument9 pagesCULTIVATION OF TARO: A GUIDEPooja sharmaNo ratings yet

- Coconut Water PreservationDocument15 pagesCoconut Water Preservationgj657No ratings yet

- Coconut Wax Preserves Fruit Freshness for WeeksDocument6 pagesCoconut Wax Preserves Fruit Freshness for WeeksErika Jazmine Ü100% (1)

- Intro To Pineapple Unit 1Document20 pagesIntro To Pineapple Unit 1mouuNo ratings yet

- Production of Coconut Flour and Virgin Coconut OilDocument10 pagesProduction of Coconut Flour and Virgin Coconut Oilcdwsg254100% (3)

- Project Report Food GrainDocument5 pagesProject Report Food GrainNeel KhandelwalNo ratings yet

- Cassava Starch Production, Physicochemical PropertiesDocument15 pagesCassava Starch Production, Physicochemical PropertiesazwarNo ratings yet

- Maize & Corn Flour Mill Plant Manufacture, Design, and InstallationDocument3 pagesMaize & Corn Flour Mill Plant Manufacture, Design, and InstallationBelong MachineyNo ratings yet

- Oil and Fat Technology Lectures IIIDocument42 pagesOil and Fat Technology Lectures IIIaulger100% (1)

- Market Research Report On Maize and by Products ProcessingDocument9 pagesMarket Research Report On Maize and by Products Processinggaurav24No ratings yet

- Sri Lanka Cassava ProducerDocument15 pagesSri Lanka Cassava ProducerMohamed Farhad67% (3)

- Feasibility Report On Cassava Processing in NigeriaDocument18 pagesFeasibility Report On Cassava Processing in NigeriaOgbesetuyi seun AugustineNo ratings yet

- Coconut ProductionDocument14 pagesCoconut ProductionCharith LiyanageNo ratings yet

- Kwon 2014Document11 pagesKwon 2014restyayuyo50% (2)

- Cassava Training Manual PDFDocument31 pagesCassava Training Manual PDFDidik HariadiNo ratings yet

- Feasibility of Rice Bran Oil PDFDocument248 pagesFeasibility of Rice Bran Oil PDFSajidur Rehman Syed100% (1)

- Chapter One: Proposal On Soap Research ProjectDocument16 pagesChapter One: Proposal On Soap Research ProjectYonael MezmureNo ratings yet

- Pre-Feasibility Study: Potato Starch Manufacturing UnitDocument27 pagesPre-Feasibility Study: Potato Starch Manufacturing UnitosamaNo ratings yet

- Banana CultivationDocument33 pagesBanana Cultivationshashankdatey100% (2)

- Coconut Implementation Guide 2015Document42 pagesCoconut Implementation Guide 2015Sarimanok Sa Punso100% (1)

- Atta FlourDocument4 pagesAtta FloursubhamNo ratings yet

- Production of Spray-Dried CoconutDocument4 pagesProduction of Spray-Dried CoconutIin YahyaNo ratings yet

- Centuries BP 2Document50 pagesCenturies BP 2Dadon4uNo ratings yet

- Eejay Arms: Coconut Cultivator'S GuideDocument22 pagesEejay Arms: Coconut Cultivator'S Guide1979mi100% (1)

- Village Scale Coco Foods Processing Plant Pre Feasibility StudyDocument7 pagesVillage Scale Coco Foods Processing Plant Pre Feasibility StudyGeorge Tumaob Calaor100% (3)

- Downstream Products from VCODocument78 pagesDownstream Products from VCOjosephine mataNo ratings yet

- Banana Plantation: Geographic DistributionDocument7 pagesBanana Plantation: Geographic DistributionJebjeb C. BrañaNo ratings yet

- Mindanao Coconut Oil and VCO Competitiveness StrategyDocument135 pagesMindanao Coconut Oil and VCO Competitiveness StrategyDerwin DomiderNo ratings yet

- Coffee Database in Nepal 2014 PDFDocument66 pagesCoffee Database in Nepal 2014 PDFAnonymous tlMW8s0% (1)

- Milk Processing Industry in IndiaDocument73 pagesMilk Processing Industry in IndiaSameer SippyNo ratings yet

- Pineapple Production Guide for GuyanaDocument17 pagesPineapple Production Guide for GuyanaKaren Lambojon BuladacoNo ratings yet

- Cereal Production in PakistanDocument24 pagesCereal Production in PakistananamNo ratings yet

- Groundnut Oil and Oil Cake Manufacturing Project ProfileDocument2 pagesGroundnut Oil and Oil Cake Manufacturing Project ProfileprtmNo ratings yet

- PEANUT PROCESSING: A Profitable Small BusinessDocument8 pagesPEANUT PROCESSING: A Profitable Small BusinesskalaamolNo ratings yet

- Production Technology of Fruit and Plantatin Crops - Teaching Manual-1Document133 pagesProduction Technology of Fruit and Plantatin Crops - Teaching Manual-1yogesh yadavNo ratings yet

- Marketing Plan for Philippine Dried FruitDocument9 pagesMarketing Plan for Philippine Dried FruitJordy Verdadero0% (1)

- AA AvocadoDocument9 pagesAA AvocadoGloria SumariNo ratings yet

- The New Thinking For Philippine AgricultureDocument21 pagesThe New Thinking For Philippine AgricultureGretchel MejalaNo ratings yet

- Prefeasibility Study On Desiccated CoconutsDocument31 pagesPrefeasibility Study On Desiccated Coconutsluanroldan100% (3)

- How To Make Kesong PutiDocument3 pagesHow To Make Kesong PutiMichael Angelo DejandoNo ratings yet

- Sensory Evaluation and Feasibility Report of Plantain Sandwich For Nigerian MarketDocument15 pagesSensory Evaluation and Feasibility Report of Plantain Sandwich For Nigerian MarketKanhiya MahourNo ratings yet

- Soybean: Navigation SearchDocument37 pagesSoybean: Navigation SearchdmelloashleyNo ratings yet

- Rice Bran Refined Oil - RevisedDocument14 pagesRice Bran Refined Oil - ReviseddeeptiachpalyaNo ratings yet

- Industrial Uses of WheatDocument6 pagesIndustrial Uses of Wheatmedkarthik100% (1)

- Desiccated CoconutDocument8 pagesDesiccated CoconutYohanes Slamet WidodoNo ratings yet

- Analysis of annual financial reports (2010-2014Document13 pagesAnalysis of annual financial reports (2010-2014jsphemilNo ratings yet

- Coconut Value ChainDocument1 pageCoconut Value ChainjsphemilNo ratings yet

- Coconut Development Board's schemes to boost productionDocument10 pagesCoconut Development Board's schemes to boost productionjsphemilNo ratings yet

- Continuous Latex FoamDocument7 pagesContinuous Latex Foamjsphemil100% (1)

- How the Talalay and Dunlop Processes Create Different Types of Latex FoamDocument25 pagesHow the Talalay and Dunlop Processes Create Different Types of Latex FoamjsphemilNo ratings yet

- Nutrition for Exercise and Sports PerformanceDocument4 pagesNutrition for Exercise and Sports PerformanceAudrie Allyson GabalesNo ratings yet

- Pas Bahasa Inggris Kelas 2 SMT 2Document4 pagesPas Bahasa Inggris Kelas 2 SMT 2intan norrahmiNo ratings yet

- Test Clasa 4Document2 pagesTest Clasa 4Ruxandra ManescuNo ratings yet

- Ufi-String D PDFDocument4 pagesUfi-String D PDFNermeen ElmelegaeNo ratings yet

- 40 Classic Business TaglinesDocument7 pages40 Classic Business Taglineslanevoj70No ratings yet

- B1 Gerund and Infinitive GI009: Fill in The Correct Form: Gerund or Infinitive (With or Without "TO")Document2 pagesB1 Gerund and Infinitive GI009: Fill in The Correct Form: Gerund or Infinitive (With or Without "TO")zeynepNo ratings yet

- A1 GramatikDocument32 pagesA1 Gramatiklionel messiNo ratings yet

- Rice Fortification Success Stories in 9 Countries PDFDocument16 pagesRice Fortification Success Stories in 9 Countries PDFjavedafridiNo ratings yet

- Revision For The First Term Test (English 11) (2022-2023)Document11 pagesRevision For The First Term Test (English 11) (2022-2023)Nhan NamNo ratings yet

- ANCW30011 - Topic 7 ReadingsDocument41 pagesANCW30011 - Topic 7 ReadingsfaithNo ratings yet

- Analisa Kandungan Nitrit Daging Burger Di Pasar Kecamatan Duren Sawit Jakarta TimurDocument8 pagesAnalisa Kandungan Nitrit Daging Burger Di Pasar Kecamatan Duren Sawit Jakarta TimurRisma WerdaningsihNo ratings yet

- Brownie Recipe - Preppy Kitchen PDFDocument2 pagesBrownie Recipe - Preppy Kitchen PDFclearNo ratings yet

- Better VocabularyDocument13 pagesBetter VocabularyalvaroNo ratings yet

- Phenylketonuria: Dietary Information For The Treatment ofDocument13 pagesPhenylketonuria: Dietary Information For The Treatment ofLuz Del ValleNo ratings yet

- THI THU LAN 3 TH-TRUONG TH CAO NGUYEN-ĐẠI HỌC TAY NGUYENDocument5 pagesTHI THU LAN 3 TH-TRUONG TH CAO NGUYEN-ĐẠI HỌC TAY NGUYENTài LêNo ratings yet

- Licenses Required For Opening A Microbrewery in India - Ipleaders PDFDocument24 pagesLicenses Required For Opening A Microbrewery in India - Ipleaders PDFanilks3No ratings yet

- Discussion, Inference, Lexis. McDonalds Around The WorldDocument11 pagesDiscussion, Inference, Lexis. McDonalds Around The WorldIan JamesNo ratings yet

- Zuppa Toscana - Google SearchDocument1 pageZuppa Toscana - Google SearchAndrea CsekeNo ratings yet

- Doosan Excavator Dx300lc 5 20001 Up Operation Maintenance Manual 2017 enDocument22 pagesDoosan Excavator Dx300lc 5 20001 Up Operation Maintenance Manual 2017 enericathompson051194gdy100% (128)

- Business PlanDocument7 pagesBusiness PlanJaye Ric GonzalesNo ratings yet

- Jas T 102161384633800Document9 pagesJas T 102161384633800Oki ArdiyansahNo ratings yet

- Bovine Milk: Taurus (See Animals That Produce Dairy Foods: Major Bos Taurus Breeds Minor and Dual-Purpose Bos TaurusDocument6 pagesBovine Milk: Taurus (See Animals That Produce Dairy Foods: Major Bos Taurus Breeds Minor and Dual-Purpose Bos TaurusELI ALEXIS GONZALEZ HERNANDEZNo ratings yet

- Rainforest Deforestation Sudent WorksheetDocument2 pagesRainforest Deforestation Sudent WorksheetAlejandro Posada PenagosNo ratings yet

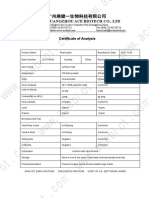

- COA of ResveratrolDocument1 pageCOA of ResveratrolPan EmmaNo ratings yet

- Prom 2015: The Great GatsbyDocument14 pagesProm 2015: The Great GatsbyMaple Lake MessengerNo ratings yet

- High-quality silage from Patanjali ForagesDocument26 pagesHigh-quality silage from Patanjali ForagesShravankumar GaddiNo ratings yet

- Program Design SampleDocument2 pagesProgram Design SampleBfp Rsix Maasin FireStation100% (1)

- Grade 8 - Unit 9Document4 pagesGrade 8 - Unit 9Minh Hien DoNo ratings yet

- Herald of The Harrowing - Dark Tides of BilgewaterDocument14 pagesHerald of The Harrowing - Dark Tides of BilgewaterIvisonVinicyusNo ratings yet

- 2012 EsuDocument129 pages2012 EsuNaumia DarojahNo ratings yet