Professional Documents

Culture Documents

Grading and Quality Checks of Dry Cocoa Beans

Uploaded by

CocoaSafe-MalaysiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grading and Quality Checks of Dry Cocoa Beans

Uploaded by

CocoaSafe-MalaysiaCopyright:

Available Formats

STDF - CABI - ICCO PROJECT: TRAINING OF MASTER FACILITATORS

MCB R&D Centre, Teluk Intan, Perak, Malaysia, 7-17 April 2014

Grading and Quality Checks of Dry Cocoa Beans

Introduction

In Accordance to the Malaysian Cocoa Board

Regulations 2012-Regulation 20.(1) :

No Dry Cocoa Beans or semi-processed

products shall be purchased, sold , exported

or imported unless it has been graded in any

manner as the Board may determine.

Objectives

To control the quality of dry cocoa beans from Malaysia with

the common grading and certification system, the quality of

cocoa beans produced by Malaysia is assured.

To improve the quality of Malaysian cocoa bean to enhance

acceptance and fetch better price in the world market.

To produce a complete and systematic procedures of cocoa

grading and certification to eliminate the differences in

quality between consignments and origins of production.

QUALITY REQUIREMENTS

(MALAYSIAN STANDARD MS 293:2005)

QUALITY REQUIREMENTS

The cocoa beans shall be from ripe pods and adequately

fermented, free from smoky smell, free from objectionable or

foreign odour and free from any evidence of adulteration.

The cocoa beans shall be evenly dried throughout. The

moisture content shall be less than or equal to 7.5 %.

The cocoa beans shall be reasonably uniform in size.

The consignment shall be free from bean clusters and

reasonably free from double bean.

The consignment shall contain less than or equal to 2 % waste

by weight.

The consignment shall be free from insects includes mites.

The consignment shall be free from foreign matters.

Quality Requirements

Parameters Standard

Pods

Ripe

Fermentation

Adequately fermented

Smoky smell/Objectionable or

foreign odour

Free

Evidence of adulteration

Free

Moisture Content

7.5%

Bean Size

Reasonably Uniform

Quality Requirements

Parameter Standard

Bean Cluster Free

Double Bean Reasonably Free

Waste content

< 2.0%

Insect infestation

Free

Foreign Matter

Free

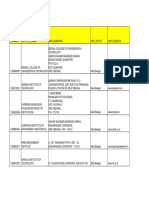

Grade Specifications

(Table 1)

Standard

Malaysian

Cocoa

Grades

Bean Count

(100g)

Mouldy

beans

(% max.)

Slaty

beans

(%max.)

Insects

Damage and

Germinated

Beans

(%max.)

SMC 1

SMC 2

SMC 3

<100

>100 < 110

>110 < 120

< 3%

< 3%

< 3%

< 3%

< 3%

< 3%

< 2.5%

< 2.5%

< 2.5%

NOTES:

All Percentage in the grade specifications are by count . The percentage given

in the last column applies to all the mentioned therein, taken together

DEFINITIONS

Cocoa bean :

The fermented and dried, whole seed

of Theobroma cacao L.

Adulteration

Adulteration of the composition of graded

cocoa beans by any means whatsoever so

that the resulting mixture or combination

is not of the grade prescribed, or affects

adversely the quality, flavour , or alters

the bulk or mass.

DEFINITION

Broken Beans :

Cocoa bean of which a fragment is missing ,

the missing part being equivalent to less than

half of the bean.

Mouldy bean :

Cocoa bean on the internal part of which mould is

visible to the naked eye.

Insect damaged or insect infested bean :

Cocoa bean, of which the internal parts are found to

have been infested by insects which have inflicted

damage visible to the naked eye or contain insect

including mites, at any stage of development

Slaty bean:

Cocoa bean which shows a slaty colour on half or

more of the internal surface

Fermented bean:

Cocoa bean of which the colour of the

cotyledons should range from partly

purple and partly brown to a fully

brown.

Bean cluster :

Bean clump which consists of three or

more beans fused together.

which cannot be separated by hand

Double bean :

Two beans fused together which

cannot be separated by hand.

Germinated bean:

Cocoa bean of which the shell has been pierced,

slit or broken by the growth of the seed germ.

Flat bean:

Cocoa bean of which the cotyledons are too thin

to be cut to give a full length of the cotyledon

surface.

Smoky bean:

Cocoa bean which has a smoky smell or taste.

Fragment:

A piece of cocoa bean less than half the original

bean.

Piece of shell :

Part of the shell without adhering cotyledon.

Waste:

flat bean, Piece of shell, dried

placenta , and dried Pulp.

Foreign Matters :

Any Materials and particle other than cocoa

beans and waste

DETERMINATION

OF

GRADE

DETERMINATION OF GRADE

30% Probing Sample Collection

Select 30% randomly

3 Positions Probing on Each Bag

1

st

Top position

2

nd

Middle position

3

rd

Bottom position

Beans collected in Polythene bag

28

Cocoa probing (sample)

QUALITY TOOLS

PROBE :

To collect samples

of cocoa beans by

thrusting a probe

into bags at three

different position

of each bag.

DETERMINATION OF GRADE

(Preliminary Inspection)

Examining Live Insects

To determine the presence of live insects

during sample collection for the

consideration of fumigation requirement.

DETERMINATION OF GRADE

(Preliminary Inspection)

Detecting Off-Flavour

To detect any off-flavour from beans during

sample collection especially on smoky beans.

DETERMINATION OF GRADE

Examining Cocoa Beans

To examine the physical condition of the cocoa

beans such as sizes uniformity, colour and

other general appearance.

QUALITY TOOLS

QUATERING TOOLS

To reduce bulk

sample of cocoa

beans for grading

analysis.

35

DETERMINATION OF GRADE

Each quarter-

Reference/Audit/Exporter/ Grade

Analysis

Quartering Bulk Sample

1 2

3 4

5 6

7 8

9 10

11 12

1

+

4

5

+

8

ANALYSIS TEST

38

GRADING (Analysis Test)

1) Determination Of waste content

2) Determination of Bean Count

3) Conducting the Cut Test

Analysis test : Determining Waste

Content

% WC =

Weight of Sample Weight of

Whole & Broken Beans x 100

divided by Weight Sample

1. Waste content

QUALITY TOOLS

DIGITAL BALANCE

To measure weight

of cocoa bean,

broken bean, waste

and foreign matter.

STEPS

1. SAMPLES

2. WEIGHT EACH QUARTER

(S

1

) = (W)

S

1

S

2

S

3

S

4

W

3. SEPARATE ,WHOLE BEAN,

BROKEN BEAN, WASTE & DOUBLE

BEAN

WASTE

BROKEN

BEAN

WHOLE

BEAN

DOUBLE BEAN

4. WEIGHT - (W1)

WEIGHT WHOLE BEAN

WEIGHT BROKEN BEAN

WEIGHT DOUBLE BEAN

W1

PERCENTAGE OF WASTE :

= W - W1 x 100

W

W = Weight of sample(gm)

W1 = Weight of whole bean, broken bean

and double bean (gm)

Example :

% Waste S

1

= ( 317 312) gm x 100

317 gm

= 1.6 %

Repeat the reading for next quarter

Average % waste = S

1

+ S

2 +

S

3 +

S

4

4

Example = 1.8 +1.8+2.2+ 2.2

4

= 2.0 %

EXAMPLE OF WASTE AVERAGE :

To determine Bean Count

BC/100gm = No. of Whole Beans x 100

divided by Weight of Whole

Bean

% Broken Bean = Weight of 4 quarters Broken

Bean x 100 divided by

Total Weight of 4

2. Bean count

ANALYSIS TEST :

STEPS :

T Take the final quarter sample

Separated the bean and count

Count the whole bean

Weight the whole bean

for each quarter

S

1

S

2

S

3

S

4

Bean Count = Total whole bean x 100

Weight of whole bean

Example :

(S

1

) = 243 bean x 100 gm

238 gm

= 102 bean

Repeat the process for the next

quarter

Calculate the average of the bean count

= S

1

+ S

2 +

S

3 +

S

4

4

100 + 100 + 100 + 100

= 4

= 100

The bean count expresses as number of whole

beans per 100g:

Bean Count = No.Of whole beans x 100 =

Weight of whole beans(g)

Eg 1: 250 x 100 = 98 (SMC 1)

255

Eg 2 : 250 x 100 = 102 (SMC 2)

245

Eg: 3 : 250 x 100 =114 (SMC 3)

220

Gred

SMC

Bean Count/

(100g)

1

2

3

100 or Less

101 - 110

111- 120

Determining the Bean Count

Bean Count : The total number of whole

cocoa beans required to make a weight of

100g

SMC

Grades

Bean Count

(100g)

1

2

3

< 100

>100 < 110

>110 < 120

CUT TEST

The sample of whole cocoa beans from the bean

count is used for the cut test .

With selection of the quarter which contain the

highest number of beans.

To determine the percentage of :

a) Mouldy bean ;

b) Slaty Bean ;

c) Insect damage and germinated Bean

d) To identify the level of fermentation

CUT TEST(Procedure)

P1: Cut all the beans lengthwise through the middle , so as

to expose the maximum cut surface of the cotyledons.

P2: Examine visually both halves of each bean in full

daylight or under an equivalent artificial light for its level

of fermentations and defects.

P3: Count separately the number of defective beans

i.e mouldy beans,slaty beans, insect damaged and

germinated beans. Where beans has multiple defects,

count only one defect which occurs according to the

above.

ANALYSIS TEST

To conduct Cut Test

% Insect Damaged = No. of ID Bean x 100

divided by Total No.

of Bean Cut

% Germinated = No. of Germinated

Bean x 100 divided by

Total No. of Bean Cut

3. Cut test

To conduct Cut Test

% Mouldy = No. of Mouldy Bean x 100

divided by Total No. of Bean Cut

% Slaty = No. of Slaty Beans x 100

divided by Total No. of Bean Cut

58

ANALYSIS TEST

3. Cut test

To conduct Cut Test

% Fully Brown = No. of FB Bean x 100

divided by No. of Bean Cut

% Partly Purple/Brown = No. of PPB Bean x 100

divided by No. of Bean Cut

% Fully Purple = No. of FP Bean x 100

divided by No. of Bean Cut

Analysis test :

4. Fermentation level

The degree of fermentation

(MS 293:2005)

Fermentation Level Category

> 60% of the cut bean

is fully brown

Good

45%-60% of the cut

bean is fully brown

Moderately

< 45% of the cut bean

is fully brown

Fairly Good

STEPS :

Take one quarter which the higher bean

count

Cut the bean and display the surface of

cotyledon

Display all the cotyledon and count the

defeated bean and the colour of fermentation

levels

Defeated Levels :

QUALITY TOOLS

SECATEUR

To cut cocoa bean

lengthwise during

cut test.

64

QUALITY TOOLS

CUT TEST BOARD

To display beans that

have been cut during

cut test in determining

mouldy, slaty, insect

damaged, germinated

and level of

fermentation..

Determining Moisture Content

% MC = Total of 4 MC Readings divided

by Total Number of Readings

66

5. Moisture content

Analysis test :

QUALITY TOOLS

BLENDER

To grind cocoa

bean into powder

for moisture

content

measurement.

67

QUALITY TOOLS

MOISTURE METER

To measure

moisture content

of cocoa bean.

68

Take the 4 reading from

the moisture grain

master meter and find

the average

STEPS:

Take one quarter sample

Grind the beans (40 beans)

Put the grind bean inside the small plastic bag

Repeat the process for the next quarter

Average result for moisture content:

% Moisture Content = Four reading MC

Number of reading

Example: 7.0 + 7.0 + 7.0 + 7.0

4

= 7.0 %

END RESULT OF GRADING

THANK YOU

You might also like

- Miniature Daisy: Crochet Pattern & InstructionsDocument8 pagesMiniature Daisy: Crochet Pattern & Instructionscaitlyn g100% (1)

- Training of Master Facilitators Manual (Malaysia & Indonesia)Document180 pagesTraining of Master Facilitators Manual (Malaysia & Indonesia)CocoaSafe-Malaysia100% (1)

- Training of Master Facilitators Manual (Malaysia & Indonesia)Document180 pagesTraining of Master Facilitators Manual (Malaysia & Indonesia)CocoaSafe-Malaysia100% (1)

- The de Zaan Cocoa Manual: Candy ConfectioneryDocument151 pagesThe de Zaan Cocoa Manual: Candy ConfectioneryTristan75100% (1)

- Cocoa Bean (Also Cacao BeanDocument9 pagesCocoa Bean (Also Cacao BeanVillaci5No ratings yet

- Presentation For CoffeeDocument10 pagesPresentation For Coffeejohn kheNo ratings yet

- CoffeeDocument64 pagesCoffeeparaagpandey100% (6)

- Cocoa ProcessingDocument4 pagesCocoa ProcessingcjachemNo ratings yet

- Production Process of ChocolateDocument12 pagesProduction Process of ChocolateAtul MahaleNo ratings yet

- Palsgaard Troubleshooting Emulsifiers For Ice Cream Coatings 2009Document6 pagesPalsgaard Troubleshooting Emulsifiers For Ice Cream Coatings 2009gutierrez_rgc0% (1)

- Cacao Production GuideDocument13 pagesCacao Production GuideNoli Delos SantosNo ratings yet

- PPTDocument60 pagesPPTShamla Abdul Latheef0% (1)

- Industry-Study Cacao PDFDocument27 pagesIndustry-Study Cacao PDFSila FelixNo ratings yet

- Cocoa ProductionDocument57 pagesCocoa ProductionumeshNo ratings yet

- 1587535182unit III Processing of CocoaDocument8 pages1587535182unit III Processing of Cocoaabdelsalam alhaggarNo ratings yet

- UltimateBeginnerHandbookPigeonRacing PDFDocument21 pagesUltimateBeginnerHandbookPigeonRacing PDFMartinPalmNo ratings yet

- Lecture2 GranulopoiesisDocument9 pagesLecture2 GranulopoiesisAfifa Prima GittaNo ratings yet

- Asean Gap For CocoaDocument16 pagesAsean Gap For Cocoaនិន ម៉ានិតNo ratings yet

- How To Choose Coffee Beans - All You Need To Know: Cupping / TastingDocument8 pagesHow To Choose Coffee Beans - All You Need To Know: Cupping / TastingitounosNo ratings yet

- Cocoa Processing PDFDocument31 pagesCocoa Processing PDFHudaJRas83% (6)

- 5 - Cocoa 2019Document61 pages5 - Cocoa 2019Qiun LeeNo ratings yet

- Ghana CocoaDocument26 pagesGhana CocoaJustice Mensah100% (1)

- Leadership Styles-Mckinsey EdDocument14 pagesLeadership Styles-Mckinsey EdcrimsengreenNo ratings yet

- Chocolate Quality TestingDocument5 pagesChocolate Quality TestingMiruna PetriaNo ratings yet

- Cocoa ProcessingDocument3 pagesCocoa ProcessingCNJSWAMI100% (1)

- Skills Checklist - Gastrostomy Tube FeedingDocument2 pagesSkills Checklist - Gastrostomy Tube Feedingpunam todkar100% (1)

- Cacao Industry Roadmap - Signed March 10, 2017Document34 pagesCacao Industry Roadmap - Signed March 10, 2017Ozzy CaliboNo ratings yet

- Candy Manufacturing Technology and Candy Manufacturing Techniques Are FascinatingDocument7 pagesCandy Manufacturing Technology and Candy Manufacturing Techniques Are FascinatingJorge Meza100% (2)

- Cocoa Training Manual PDFDocument122 pagesCocoa Training Manual PDFOlukunle AlabetutuNo ratings yet

- Effect of Processing Techniques On Flavour 2017Document13 pagesEffect of Processing Techniques On Flavour 2017Mulki Maajid100% (1)

- Commodity Analysis CocoaDocument34 pagesCommodity Analysis CocoaSanket Sakpal100% (1)

- Planting. Coffee Is A Crop That Mostly Grows On Tropical and Subtropical Climates. Usually, TheseDocument8 pagesPlanting. Coffee Is A Crop That Mostly Grows On Tropical and Subtropical Climates. Usually, Theseimo konsensyaNo ratings yet

- Biopesticide For CocoaDocument99 pagesBiopesticide For CocoaAllan AquinoNo ratings yet

- Illustrating An Experiment, Outcome, Sample Space and EventDocument9 pagesIllustrating An Experiment, Outcome, Sample Space and EventMarielle MunarNo ratings yet

- Synthesis, Analysis and Simulation of A Four-Bar Mechanism Using Matlab ProgrammingDocument12 pagesSynthesis, Analysis and Simulation of A Four-Bar Mechanism Using Matlab ProgrammingPedroAugustoNo ratings yet

- Cocoa Study - enDocument76 pagesCocoa Study - enMonica Bîldea100% (2)

- Cocoa ReportDocument78 pagesCocoa Reportmyjoyonline.comNo ratings yet

- Impact of Cocoa Processing Technologies in Free FaDocument7 pagesImpact of Cocoa Processing Technologies in Free FaBunayya Rabbika Firly0% (1)

- Executive Summary-P-5 181.450 To 222Document14 pagesExecutive Summary-P-5 181.450 To 222sat palNo ratings yet

- Café Dine: The Business PlanDocument13 pagesCafé Dine: The Business Planaamir aamiNo ratings yet

- History of CocoaDocument23 pagesHistory of CocoaHyourinmaru BenihimeNo ratings yet

- Planting Cocoa - Challenges and Reality in Malaysia PDFDocument19 pagesPlanting Cocoa - Challenges and Reality in Malaysia PDFscientist786No ratings yet

- How To Improve Quality When Drying Washed Coffees: Coffee Production & FarmingDocument10 pagesHow To Improve Quality When Drying Washed Coffees: Coffee Production & FarmingAdolfusNo ratings yet

- Cake Quality and Evaluation BAKERpaperDocument9 pagesCake Quality and Evaluation BAKERpaperGaganpreet KaurNo ratings yet

- Asean Standard For Coffee BeanDocument8 pagesAsean Standard For Coffee BeanHema HemaNo ratings yet

- Coffee ProductionDocument20 pagesCoffee Productiondhenz00667% (3)

- International Quality Standards of Cacao BeansDocument17 pagesInternational Quality Standards of Cacao BeansPlantacion de Sikwate100% (1)

- Modernizing and Industrializing The Cacao Industry in The PhilippinesDocument17 pagesModernizing and Industrializing The Cacao Industry in The PhilippinesPlantacion de Sikwate100% (4)

- Coffee Roasting ManualDocument20 pagesCoffee Roasting ManualNaeem GherianyNo ratings yet

- Ayeni Deneice Project EditedDocument54 pagesAyeni Deneice Project Editedmercydebby17No ratings yet

- Edita Project: Food Industries S.A.EDocument87 pagesEdita Project: Food Industries S.A.EChemist Mohammed MagdyNo ratings yet

- Chocolate IndustryDocument31 pagesChocolate IndustrySubrahmanyasarma ManthaNo ratings yet

- Yogurt ProductionDocument2 pagesYogurt ProductionFifi Lifia0% (1)

- Centuries BP 2Document50 pagesCenturies BP 2Dadon4uNo ratings yet

- CoffeeDocument391 pagesCoffeeMarc Fiszman100% (1)

- Production, Composition, and Application of Coffee and Its Industrial ResiduesDocument13 pagesProduction, Composition, and Application of Coffee and Its Industrial ResiduesErica González de Torres100% (1)

- Coffee Production BrixDocument23 pagesCoffee Production BrixRuben Dario SortoNo ratings yet

- Litreview CocoaDocument15 pagesLitreview Cocoaapi-534320285No ratings yet

- Godiva PDFDocument2 pagesGodiva PDFsamir100% (1)

- Paper For Coffee Seminar in YangonDocument5 pagesPaper For Coffee Seminar in Yangonသံလံု ငယ္No ratings yet

- Beer Production FinalDocument16 pagesBeer Production FinalMarshall-tendai Zifa-sire Zuku-chibikaNo ratings yet

- Chocolate Fat Bloom ArticleDocument4 pagesChocolate Fat Bloom ArticleClarissa GomezNo ratings yet

- 2.chapter 2 Introduction To ChocolateDocument14 pages2.chapter 2 Introduction To ChocolateTaylor's University Symphony OrchestraNo ratings yet

- Packaging of Sugar ConfectioneryDocument12 pagesPackaging of Sugar ConfectioneryProf C.S.Purushothaman100% (6)

- The Journey From Cacao Pod To ChocolateDocument9 pagesThe Journey From Cacao Pod To Chocolateronalit malintadNo ratings yet

- Specification For Grading Malaysian Cocoa BeansDocument5 pagesSpecification For Grading Malaysian Cocoa BeansOscar Antún Castro HernándezNo ratings yet

- Food Chemistry I Laboratory: TC Haliç University Faculty of Health Sciences Department of Nutrition and DieteticsDocument29 pagesFood Chemistry I Laboratory: TC Haliç University Faculty of Health Sciences Department of Nutrition and Dieteticsmemebeauty220No ratings yet

- The Effects of Calcium Ion On Cooked Dry BeansDocument3 pagesThe Effects of Calcium Ion On Cooked Dry BeansMr. No Jow0% (1)

- Methods and Instruments Used in Brewing Control - Selected QuestionsFrom EverandMethods and Instruments Used in Brewing Control - Selected QuestionsNo ratings yet

- Procedure of Shallow Bos FermentationDocument1 pageProcedure of Shallow Bos FermentationCocoaSafe-MalaysiaNo ratings yet

- Procedure of Shallow Box FermentationDocument1 pageProcedure of Shallow Box FermentationCocoaSafe-MalaysiaNo ratings yet

- Dry Cocoa Beans Storage PracticesDocument1 pageDry Cocoa Beans Storage PracticesCocoaSafe-MalaysiaNo ratings yet

- Pesticide Application TechnologyDocument48 pagesPesticide Application TechnologyCocoaSafe-Malaysia100% (1)

- Photo List TOF of Participants in SabahDocument4 pagesPhoto List TOF of Participants in SabahCocoaSafe-MalaysiaNo ratings yet

- Photos List TOMF ParticipantsDocument2 pagesPhotos List TOMF ParticipantsCocoaSafe-MalaysiaNo ratings yet

- List TOF Participants in JengkaDocument1 pageList TOF Participants in JengkaCocoaSafe-MalaysiaNo ratings yet

- List TOF Participants in SarawakDocument4 pagesList TOF Participants in SarawakCocoaSafe-MalaysiaNo ratings yet

- Delonghi Esam Series Service Info ItalyDocument10 pagesDelonghi Esam Series Service Info ItalyBrko BrkoskiNo ratings yet

- WAQF Podium Design Presentation 16 April 2018Document23 pagesWAQF Podium Design Presentation 16 April 2018hoodqy99No ratings yet

- Latched, Flip-Flops, and TimersDocument36 pagesLatched, Flip-Flops, and TimersMuhammad Umair AslamNo ratings yet

- Case Study 2Document5 pagesCase Study 2api-247285537100% (1)

- Canon Powershot S50 Repair Manual (CHAPTER 4. PARTS CATALOG) PDFDocument13 pagesCanon Powershot S50 Repair Manual (CHAPTER 4. PARTS CATALOG) PDFRita CaselliNo ratings yet

- Clark SM 616 Service ManualDocument20 pagesClark SM 616 Service Manualenid100% (55)

- Injections Quiz 2Document6 pagesInjections Quiz 2Allysa MacalinoNo ratings yet

- Oxford EAP B1 Pre-Intermediate Student - S Book 2Document167 pagesOxford EAP B1 Pre-Intermediate Student - S Book 2Thư Dương Thị AnhNo ratings yet

- Pityriasis VersicolorDocument10 pagesPityriasis Versicolorketty putriNo ratings yet

- Implementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorDocument11 pagesImplementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorChristie YohanaNo ratings yet

- Export Management EconomicsDocument30 pagesExport Management EconomicsYash SampatNo ratings yet

- Teaching Profession - Educational PhilosophyDocument23 pagesTeaching Profession - Educational PhilosophyRon louise PereyraNo ratings yet

- (Jones) GoodwinDocument164 pages(Jones) Goodwinmount2011No ratings yet

- EqualLogic Release and Support Policy v25Document7 pagesEqualLogic Release and Support Policy v25du2efsNo ratings yet

- Week 4 - Theoretical Framework - LectureDocument13 pagesWeek 4 - Theoretical Framework - LectureRayan Al-ShibliNo ratings yet

- WBDocument59 pagesWBsahil.singhNo ratings yet

- Cloud Comp PPT 1Document12 pagesCloud Comp PPT 1Kanishk MehtaNo ratings yet

- Peer PressureDocument13 pagesPeer PressuremightymarcNo ratings yet

- Algoritm BackTracking EnglezaDocument6 pagesAlgoritm BackTracking Englezaionutz_67No ratings yet

- Final Project Strategic ManagementDocument2 pagesFinal Project Strategic ManagementMahrukh RasheedNo ratings yet

- Assignment of Chemistry For B.sc-B.ed First Semester Session 2019-2023-1Document2 pagesAssignment of Chemistry For B.sc-B.ed First Semester Session 2019-2023-1Payal sahaNo ratings yet

- Physics Education Thesis TopicsDocument4 pagesPhysics Education Thesis TopicsPaperWriterServicesCanada100% (2)