Professional Documents

Culture Documents

Steptronic X Preparar 2011

Uploaded by

Arnolds FelixOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steptronic X Preparar 2011

Uploaded by

Arnolds FelixCopyright:

Available Formats

Subject Page

E85 Transmissions.................................................................................3

Transm ission C odes................................................................................3

GS6-37BZ Manual Transmission..........................................................6

6 Speed Pow er Flow .............................................................................10

W orkshop H ints.....................................................................................14

Sequential Manual Gearbox (SMG) 6-Speed.....................................15

System C om ponents.............................................................................16

W orkshop H ints....................................................................................21

Review Questions................................................................................24

Table of Contents

E85 Transmissions

2

E85 Transm issions

E85 Transmissions

Model: E85

Production: Start of Production MY 2003

Objectives:

After com pletion of this m odule you w ill be able to:

Identify the four different transm issions available for the E85.

Explain w hy is extrem ely im portant to properly torque the 6 speed m anual transm ission

m ounting bolts to the engine block.

D escribe the changes to the transm ission input shaft.

List the system s influenced by the Sportbutton.

Explain w here SM G system faults can be visually identified.

U nderstand w hy Teaching G earboxm ust be perform ed w ith the D ISplus/G T1.

3

E85 Transm issions

E85 Transmissions

There are 4 different tranm issions offered for the E85:

2 m anual transm issions:

G S5-20B G 5-speed m anual transm ission (know n from the E46 as S5D -250G ). The brief

designation is the B -gearbox.

G S6-37B Z 6-speed m anual transm ission. The brief designation is the H -gearbox.

Autom atic transm ission:

G A5H P19Z autom atic transm ission is available as an option (code 205). This transm is-

sion is know n from the E46 as the A5S-325Z.

Sequential M anual G earbox:

The Sequential M anual G earbox (SM G ) is available as an option (code 206). The basis of

the SM G is the H -gearbox (know n as H -SM G ).

The follow ing table show s the engine/transm ission com binations:

Dynamic Driving Control (if equipped)

For sportydriving, the optional D ynam ic D riving C ontrol function is activated by pushing

the Sportbutton on the center console next to the gearshift lever. W hen this function is

activated, the follow ing control m odules are also influenced:

H -SM G C ontrol M odule - shorter gearshift tim es

EG S C ontrol M odule - Sport shift m ode.

Note: Shifting the Autom atic Transm ission G ear Shift Lever to the left from D into the M S

position activates the Steptronic Transm ission Sport Program .

Engine Manual SMG

(optional)

Automatic

(optional)

M 54B 30 G S6-37B Z H -SM G

G A5H P19Z

(A5S-325Z)

M 54B 25

G S5-20B G

(S5D -250G )

H -SM G

G A5H P19Z

(A5S-325Z)

4

E85 Transm issions

Exam ple - autom atic transm ission:

G A 5 H P 19 Z

M anufacturer:

G = G etrag

J = Jatco

R = R M PT

Z = ZF

M anufacturer's serial num ber

H P = H ydraulic planetary gear

R = R ear w heel drive

T = Transm ission

Alternatively: gearbox type/size/

torque (N m )

N um ber of gears 1 to 9

C = C ontinuously

A = Autom atic gearbox

F = R esearch gearbox

R = R eduction gearbox

Y = H ydrostatic gearbox

G earbox

5

E85 Transm issions

Exam ple - m anual transm ission:

G S 6 - 37 B Z

M anufacturer:

G = G etrag

J = Jatco

R = R M PT

Z = ZF

B = Petrol gear ratio

D = D iesel gear ratio

G earbox type:

37 = "H "

39 = "F"

53 = "G "

20 = "B "

M anual gearboxes:

- = Standard w ith m anual gearshift

S = SM G

X = All-w heel drive w ith m anual gearshift

W = All-w heel drive w ith SM G

N um ber of gears 1 to 9

C = C ontinuously

S = M anual gearbox

F = R esearch gearbox

R = R eduction gearbox

Y = H ydrostatic gearbox

G earbox

6

E85 Transm issions

E85 GS6-37BZ Manual Transmission (if equipped)

The G S6-37B Z 6-speed m anual transm ission (H -gearbox) is used in the E85 w ith the

M 54B 30 engine. The gearbox is designed by Zahnradfabrik Friedrichshafen (ZF) and built

and supplied by ZF and G etrag. This is w hy the gearbox designation bears the endings of

both "Z" and "G ." The changes to the G S6-37B Z com pared w ith m anual transm issions cur-

rently used in B M W s are:

Flanged dam ping block

Alum inium bolts (connecting to engine block)

Alum inium bolt (connecting case halves)

Input shaft m ounting in dual-m ass flyw heel

Involute input shaft teeth

Shift gate for guiding the selector shaft

External shift w ithout play in neutral position

N ew dual-m ass flyw heel

Components

The transm ission consists of the follow ing:

Transm ission case (front and rear half)

Transm ission shafts

G ear sets

G ear synchronizers

Shift m echanism

1. Selector sleeve, 5th/6th gear 6. Reverse gear 11. 6th gear

2. Selector sleeve, 3rd/4th gear 7. 1st gear 12. 5th gear (direct 1:1)

3. Selector sleeve, 1st/2nd gear 8. 2nd gear 13. Countershaft

4. Selector sleeve, reverse gear 9. 4th gear 14. Input shaft

5. Output shaft 10. 3rd gear

and the engine-side com ponents:

D ual-m ass flyw heel (ZM S)

C lutch

7

E85 Transm issions

Transmission Case

The casing is m anufactured from diecast alu-

m inium and flanged m ounted w ith alum inium

bolts to the engine block (arrow s).

The front half of the casing is also bolted to the

rear half w ith alum inium bolts. The casing is

secured at the rear w ith 4 bolts to the dam ping

block.

Note: Refer to TIS for correct tightening torque! For

additional and updated information, refer to the Repair

Instructions.

The bolted dam ping block (1) increases the transm is-

sion application for different vehicles. M odifying the

acoustic dam ping to different vehicle types is achieved

by changing the dam ping block.

Dual-mass Flywheel (ZMS)

A specially developed dual-m ass flyw heel is used

w ith the H -gearbox. B ecause the 6-speed m anual

transm ission has m ore gears, the flyw heel is m od-

ified to com pensate for vibration and noise.

In this flyw heel, the 2 m asses are connected via

inner and outer dam pers (rubber like dam ping

m aterial).

The m asses are now supported by a plain bearing

(no longer in a ball bearing). The plain bearing

requires less space and enables an additional inner

dam per to be used.

The transm ission input shaft is supported through the flyw heel in a

needle bushing w ith a roller pilot bearing. The flyw heel is connect-

ed to the crankshaft flange w ith Torx socket bolts.

Clutch: 03/2003 w ill introduce new heavy m etal-free friction linings

w hich satisfy the requirem ents of used car regulations.

8

E85 Transm issions

Input Shaft

The input shaft is approx. 25 m m shorter than

that in the 5-speed. The input shaft longitudinal

splines have an involute shape.

Involute Toothing: This denotes the special

shape (m athem atical curve) of the toothed seg-

m ents of the input shaft splines (22 teeth total).

This creates linear contact (dots show n to the

right) w ith the toothed segm ents to the clutch

drive plate center splines. The reduced friction

of the linear contact provides easier declutching

operation.

The splined clutch drive plate hub and guide sleeve form a seal to decrease contam ination

of the input shaft. The involute shaped splines m ake it easier to rem ove and install the trans-

m ission.

Transmission Shift Mechanism

The short shifttravel of the E85 gearshift handle required a m odification to the selector

forces of the internal gearshift m echanism . This changed the internal shift gate and shift-

gate finger. The shift gate finger is perm anently attached to the selector shaft and engages

the shift gate. The shift gate and finger precisely guide the selector shaft, conveying a pre-

cise gearshift sensation to the driver. This also provides a passive lockw hich prevents 2

gears from being sim ultaneously engaged.

1. Shift finger, 5/6 gear

2. Shift finger, 3/4 gear

3. Passive lock

4. Shift finger, 1/2 gear

5. Shift gate finger

6. Shift gate

7. Shift finger, reverse gear

9

E85 Transm issions

The gears are shifted by selector forks. The design dictates that the selector fork for 1st

and 2nd gears is transm itted as follow s: W hen the selector shaft is pushed forw ards

(engagem ent of 1st gear), the selector fork forced is m ultiplied as it m oves backw ards to

engage 1st gear.

The cham feredshift gate precisely guides

diagonal gearshifts (2nd to 3rd, 4th to 5th and

vice-versa).

1. Selector sleeve, 1/2 gear

2. Shift gate

3. Shift gate finger

A further function of the shift gate and the shift gate finger is to absorb "m isuse forces" cre-

ated by the driver at the gearshift lever (previously transm itted via the selector shaft to the

selector forks). A reduction of selector forces is achieved by low pretension springs at the

5/6 gutter, reverse gear and 1/2 gutter (helical coiled spring).

1. Spring, 5/6 gutter

2. Helical coiled spring, 1/2 gutter

3. Shift finger, 5/6 gear

4. Spring, reverse gear

Note: A correctly operating selector force m ech-

anism ensures that the gearshift lever is w ithout

play in neutral.

Notes:

10

E85 Transm issions

Transmission Gear Sets

The G S6-37B Z is designed for 5th gear to be direct and 6th gear as an overdrive.

Gear Synchronizers

A triple-taper synchronizer is installed for 1st and 2nd gears. A double-taper synchronizer

unit is installed for 3rd and 4th gears. A single-taper synchronizer unit is installed for 5th,

6th and reverse gear.

6-Speed Transmission Power Flow

The individual gear pow er flow s for the M 54B 30 engine are illustrated in the next few pages.

The pow er flow s illustrated are applicable to an input torque of 300 N m at a speed of 3500

rpm . The step-up ratio from the input shaft to the countershaft is 1.38. The input torque at

the countershaft is 390 N m .

Power flow in 1st gear

An input torque of 300 N m produces an output torque of 1226 N m .

Gear Ratios

1 2 3 4 5 6 R

4.350 2.496 1.665 1.234 1:1 0.851 3.926

11

E85 Transm issions

Power flow in 2nd gear

An input torque of 300 N m produces an output torque of 704 N m .

Power flow in 3rd gear

An input torque of 300 N m produces an output torque of 470 N m .

12

E85 Transm issions

Power flow in 4th gear

An input torque of 300 N m produces an output torque of 347 N m .

Power flow in 5th gear

The transm ission output torque is equal to the input torque (1:1 direct).

13

E85 Transm issions

Power flow in 6th gear

An input torque of 300 N m produces an output torque of 240 N m (overdrive).

Power flow in reverse gear

An input torque of 300 N m produces an output torque of 1107 N m (reverse rotation).

14

E85 Transm issions

Workshop Hints

Removing Transmission

The case is flanged m ounted w ith alum inium bolts to the engine block (arrow s). The front

half of the case is also bolted to the rear half w ith alum inium bolts. These aluminium bolts

may only be used 3 times.

Note: Refer to TIS for correct tightening torque!

For additional and updated information, refer to

the Repair Instructions.

The shortened input shaft w ith the involute teeth

m ake it easier to rem ove and install the trans-

m ission.

Installing Transmission

A special lubrication procedure is required for the

involute teeth on the input shaft. Lubrication is

carried out w ith tw o special tools:

C arefully slide the grease scraper sleeve

(P/N 21 2 220) over the input shaft up to the

guide tube. This rem oves any previous lubri-

cation and debris.

C arefully slide the grease application sleeve

(P/N 21 2 221) over the input shaft up to the

guide tube.

U sing a brush, spread the grease evenly on

the teeth and the profile base up to the grease

application sleeve.

C arefully pull back the grease application

sleeve over the shaft. This provides an equal

distribution over the entire spline contact sur-

faces.

15

E85 Transm issions

E85 SMG 6-Speed Sequential Manual Gearbox (if equipped)

The optional Sequential M anual G earbox (H -SM G ) is a further developm ent of the E85

G S6-37B Z 6-speed m anual (H -gearbox). C om pared to previous SM G technology,

changes include:

C om pletely new transm ission

M ounting positions of the hydraulic com ponents and the sensors on the transm ission

housing.

In com bination w ith the SM G option, the custom er also obtains the D ynam ic D riving

C ontrol function. This function provides a Sporteffect on driving by influencing the Engine

M anagem ent, Transm ission (SM G and EG S) and Electronic Pow er Steering (EPS) control

system s. This function is activated w ith the Sportbutton.

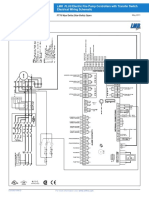

System Overview

- Inputs/Outputs

1. Power distribution box

2. Instrument cluster

3. Gearshift lever

4. Illuminated shift gate

5. EWS III

6. MS45 ECM

7. Dynamic Driving Control

Sport button

8. SMG assembly on transmission

Hydraulic unit

Shift travel sensor

Selection angle sensor

Input speed sensor

Clutch control travel sensor

9. Reverse light relay

10. Starter motor

11. PT-CAN

12. Diagnosis Bus- DISplus/GT1

13. SMG steering wheel with

shift paddles

14. General Module - GM5

15. Brake light switch

16. SMG Control Module

16

E85 Transm issions

System Components

The H -SM G system is m ade up of the follow ing com ponents:

SM G gearshift lever

SM G steering w heel w ith shift paddles

Sportbutton (D ynam ic D riving C ontrol)

SM G hydraulic system

SM G C ontrol M odule

R everse light relay

Transm ission

D isplays/indications in Instrum ent C luster

SMG Gearshift Lever

The design of the lever and the shift gate is sim ilar to the previously used SM G shift lever.

The shift gate depicted on the gearshift knob features the D sym bol instead of the C

sym bol for cruise m ode. The lever is connected to the transm ission by electric leads only

and the gearshift lever positions are m onitored by 7 H all sensors.

Operation

A dow nshift is perform ed w hen the lever is pressed forw ard.

An upshift is perform ed w hen the lever is pulled backw ard.

The gearshift lever position display (indicated w ith LED s) is integrated in the gearshift lever

center console trim , behind the gearshift lever.

SMG Steering Wheel with Shift Paddles

A gear change can also be perform ed using the

shift paddles on the steering w heel.

Operation

An upshift is perform ed w hen either shift pad-

dle is pulled backw ard

A dow nshift is perform ed w hen either shift

paddle is pressed forw ard.

17

E85 Transm issions

Sport Button

Pressing the Sportbutton (1) activates the

D ynam ic D riving C ontrol function and selects

sportier transm ission perform ance (shorter

gearshift tim es). This function can also be

selected in cruise m ode.

The request signal is m onitored by the M S45

EC M w hich transm its the signal to the SM G and

EPS C ontrol M odules.

If there are no faults in the C ontrol M odules, the

EPS C ontrol M odule illum inates the function

light in the Sport button.

SMG Hydraulic System

The clutching operation and the gear shift is perform ed autom atically by the SM G hydraulic

system . The H -SM G hydraulic system has sim ilar com ponents and functions as the previ-

ous SM G hydraulic system .

Installation location

In com parison w ith the previous SM G , the m ounting positions of the hydraulic system com -

ponents in the H -SM G have undergone significant changes, as can be seen in the follow -

ing 5 illustrations:

1. Shift/selector actuator

2. Pressure accumulator

3. Connections for:

Shift travel sensor

Selection angle sensor

4. Clutch control travel sensor

5. Clutch actuator

Left Side View

18

E85 Transm issions

1. Hydraulic pump

2. Transmission input speed sensor

3. Expansion tank

4. Valve block

5. Shift/selection actuator

1. Selection angle sensor 6. Pressure accumulator

2. Shift travel sensor 7. Selector shaft connection

3. Shift/selection actuator mounting hole

4. Expansion tank 8. Clutch actuator with

5. Valve block control travel sensor

1. Shift/selection actuator 4. Hydraulic pump

2. Valve block 5. Pressure accumulator

3. Expansion tank 6. Valve block guard

Right Side View

Top Rear View Bottom Rear View

19

E85 Transm issions

1. Shift/selection actuator

2. Expansion tank

3. Valve block

4. Hydraulic pump

5. Pressure accumulator

6. Clutch actuator with clutch control

travel sensor

C om pared w ith the previous SM G hydraulic system , the H -SM G hydraulic system is slight-

ly m odified in the follow ing areas:

The electrom echanical reverse light sw itch has been om itted.

The valve block is located underneath the transm ission.

The expansion tank is located on the right side of the transm ission w ith new m in/m ax fill

level m arkings.

The electrohydraulic pum p is located on the right side of the transm ission.

O n the left side of the transm ission, below the clutch actuator, is a central connector for

the valve block (solenoid valves EV0 to EV3, pressure sensor, voltage and ground sup-

ply to the valves).

Flexible high pressure hydraulic lines w ith quick-connect couplings are used.

Rear View

20

E85 Transm issions

1. Shift/selection actuator

2. Shift travel sensor

3. Selection angle sensor

4. Pressure accumulator

5. Clutch actuator with clutch control travel sensor

6. Hydraulic pump

7. Transmission input speed sensor

8. Expansion tank

9. Valve block

SMG Control Module

The SM G C ontrol M odule is located in the electronics box at the front left in the engine

com partm ent. It is positioned next to the EC M , in place of the EG S C ontrol M odule.

1. Engine Control Module (ECM)

2. SMG Control Module

3. ECM (main) relay

4. Fuel injector relay

5. SMG hydraulic pump relay

21

E85 Transm issions

Displays/Indications

The selected drive positions are displayed in 2 segm ents in the instrum ent cluster. The

selected gear position (1-6) is displayed in the right segm ent (2).

The drive m ode is displayed in the left segm ent (1), "D " for autom atic m ode. N o sym bol

appears in the left segm ent w hen the m anual drive program is selected. O nly the selected

gears are displayed in the right segm ent.

A fault can also be displayed in the left segm ent w ith "F." A serious gearbox

fault is indicated by an indicator light in the instrum ent cluster.

Workshop Hints

Central Connector

To sim plify access, a sm all central connector is located on the left side of the gearbox below

the clutch sensor. The central connector incorporates the circuit connections for the fol-

low ing hydraulic unit com ponents:

W iring for hydraulic valves

Signal line for pressure sensor

Voltage and ground supply for pressure sensor

G round connection for hydraulic valves

The gearshift lever accom m odates a M icro-Q uadlock system w ith a 12 pin pin tray. Tw o

pins are additionally assigned in the U S version. They are the outputs for the illum inated

gearshiftlever position indicator, w hich is located on the driver's side next to the gearshift

lever on the center console.

22

E85 Transm issions

SMG Bus System Overview

Diagnosis

D iagnosis corresponds to E46 diagnostics and contains the follow ing:

R ead identification

R ead fault m em ory

D elete fault m em ory

D iagnosis request

Programming

The SM G C ontrol M odule is program m able. Program m ing m ust be perform ed w henever

the SM G C ontrol M odule has been replaced.

Notes:

23

E85 Transm issions

Working on Hydraulic System

Note: Prior to any work on the hydraulic system, the system pressure must be reduced with

the service function "Before working on hydraulic system" in the DISplus/GT1.

The hydraulic pum p relay m ust be rem oved to prevent the hydraulic pum p from activat-

ing. The relay m ust not be reconnected for the entire duration of the repair w ork.

The service function "After w orking on hydraulic system " m ust be im plem ented w ith the

D ISplus/G T1 (to vent the hydraulic system ).

The service function "Teach gearbox" m ust be im plem ented w ith the D ISplus/G T1. The

hydraulic pum p m ust not run w hen dry!

After w ork is com pleted on the hydraulic system , the hydraulic fluid level m ust be

checked and topped up if necessary. The hydraulic pum p relay can be reinstalled. The

hydraulic fluid level m ust be checked again.

Teaching Gearbox

The service function "Teaching gearbox" m ust be im plem ented w ith the D ISplus/G T1 w hen

the follow ing com ponents are replaced:

SM G C ontrol M odule

SM G Transm ission

C lutch

C lutch sensor

Note: The SM G control system learns the clutching characteristic during the drive off oper-

ation. There m ay be im paired com fort during the initial gearshift operations.

24

E85 Transm issions

Review Questions

1. List the four different transm issions available for the E85.

2. W hy is extrem ely im portant to properly torque the 6 speed m anual transm ission m ount-

ing bolts to the engine block?

3. W hat does the term Involute Toothingrefer to?

4. The Sportbutton can influence w hat three system s in an E85?

5. W here can SM G system faults be visually identified by the driver?

6. W hat procedure m ust be perform ed after replacing any of the follow ing com ponents:

SM G C ontrol M odule, SM G transm ission, clutch, clutch sensor?

You might also like

- enDocument60 pagesenRegistr Registr100% (3)

- U140eand U241Document25 pagesU140eand U241yosergey80% (5)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- VW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFDocument68 pagesVW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFlucafelicianioanNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Testing and AdjustingDocument20 pagesTesting and AdjustingAlexandra Yupanqui sarmiento100% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Re5r05a Nissan ArmadaDocument201 pagesRe5r05a Nissan ArmadaJorge Suarez75% (4)

- FS5A Shop ManualDocument192 pagesFS5A Shop ManualDorkDork08100% (1)

- WheelHorse Eaton Model 7 Service ManualDocument40 pagesWheelHorse Eaton Model 7 Service ManualKevins Small Engine and Tractor Service71% (7)

- 9-Speed ManualDocument214 pages9-Speed ManualFusoTech93% (15)

- Manual de Transmisiones Chrysler Años 90 PrincipalmenteDocument188 pagesManual de Transmisiones Chrysler Años 90 PrincipalmenteMarbelmen100% (1)

- 5hp19e 130209063629 Phpapp02Document54 pages5hp19e 130209063629 Phpapp02Luis Miguelo80% (10)

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- VOLVO G930B MOTOR GRADER Service Repair Manual PDFDocument16 pagesVOLVO G930B MOTOR GRADER Service Repair Manual PDFsekfsekmddde75% (8)

- Saab 900 5 SpeedDocument63 pagesSaab 900 5 Speedmnbvqwert100% (2)

- 6W105 Part BookDocument102 pages6W105 Part Bookbapsi01100% (1)

- BMW E60 M5 SMG PDFDocument31 pagesBMW E60 M5 SMG PDFtalyerautoshop5432100% (2)

- U341E GearDocument18 pagesU341E Gearpalaboy88875% (12)

- 10 Automatic Transaxle SystemDocument35 pages10 Automatic Transaxle SystemYun ZhenNo ratings yet

- Cajas en InglesDocument25 pagesCajas en InglesJose sQ100% (1)

- Technical Information About Steering Gears and Steering PumpsDocument37 pagesTechnical Information About Steering Gears and Steering PumpsVictor BalasNo ratings yet

- Automatic Transaxle GuideDocument194 pagesAutomatic Transaxle Guidebravo6d78% (9)

- Sistema 4X4: - EST (Transfer Con Cambio Eléctrico) - ATT (Transferrencia de Par Activa)Document0 pagesSistema 4X4: - EST (Transfer Con Cambio Eléctrico) - ATT (Transferrencia de Par Activa)julio797No ratings yet

- MPS6Document4 pagesMPS6noe dela vega50% (2)

- Hyundai Crawler Excavator Service GuideDocument227 pagesHyundai Crawler Excavator Service Guidemohammed barghothi100% (3)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Control Hidraulico de La Transmision D6NDocument7 pagesControl Hidraulico de La Transmision D6NDavid manjarresNo ratings yet

- Four Bar LinkageDocument9 pagesFour Bar LinkageAliceAlormenuNo ratings yet

- TM Management G330Document60 pagesTM Management G330Eka SayangNo ratings yet

- 5.1 - Brakes (OCR)Document90 pages5.1 - Brakes (OCR)mnbvqwertNo ratings yet

- At PDFDocument200 pagesAt PDFchory_1100% (1)

- Plano 2 Hidra.374fDocument2 pagesPlano 2 Hidra.374fIlder NavizNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Lenksysteme NKW eDocument40 pagesLenksysteme NKW eKabilan Muthukannan100% (2)

- Symbol Plant-3d-Isometrics PDFDocument9 pagesSymbol Plant-3d-Isometrics PDFEvaldo BritoNo ratings yet

- 05 E85 Driveline PDFDocument24 pages05 E85 Driveline PDFZakaria KalomarNo ratings yet

- D65e P-12Document10 pagesD65e P-12Raphael Ruiz Ramos100% (1)

- Seven-Speed Dual-Clutch Gearbox 0B5/S TronicDocument11 pagesSeven-Speed Dual-Clutch Gearbox 0B5/S TronicChristian Pach100% (1)

- Commercial Vehicles Catalogue PDFDocument516 pagesCommercial Vehicles Catalogue PDFAlexe Cristiana100% (1)

- Hyundai HD78 Transmission M2S5, M3S5Document42 pagesHyundai HD78 Transmission M2S5, M3S5Bigfair HD78100% (1)

- Circuit DiagramsDocument63 pagesCircuit DiagramsMax RojasNo ratings yet

- Caja de Cambios EATON FS6209Document145 pagesCaja de Cambios EATON FS62097sergio950% (2)

- 05 E85 DrivelineDocument24 pages05 E85 Drivelineabraham silva hernandezNo ratings yet

- 05 E85 Driveline PDFDocument24 pages05 E85 Driveline PDFfulltransmissionNo ratings yet

- Gear Box ReportDocument39 pagesGear Box ReportNisar HussainNo ratings yet

- Shift MaticDocument68 pagesShift MaticUrszula WalczewskaNo ratings yet

- Precione de Trasmicion D6eDocument14 pagesPrecione de Trasmicion D6efranklin oliverosNo ratings yet

- Peugeot Workshop ManualDocument39 pagesPeugeot Workshop ManualLerner VadimNo ratings yet

- Steering SystemDocument22 pagesSteering SystemAlexanderNo ratings yet

- Express 3Document5 pagesExpress 3api-312620075No ratings yet

- 1971-1972 ALSPORT Snowmobile ManualDocument4 pages1971-1972 ALSPORT Snowmobile ManualtimmckennaNo ratings yet

- Compression Brake: Operación de SistemasDocument4 pagesCompression Brake: Operación de SistemasA Nadie ZelaNo ratings yet

- The Gearbox (Transmission) : B A A B A B B A A BDocument12 pagesThe Gearbox (Transmission) : B A A B A B B A A BVijay PanchalNo ratings yet

- TM 9-1750 Power Train Unit, Three-Piece Differential Case, For Medium Tanks, M3, M4, and Modifications 1942Document117 pagesTM 9-1750 Power Train Unit, Three-Piece Differential Case, For Medium Tanks, M3, M4, and Modifications 1942RobertLockieNo ratings yet

- Testing and AdjustingDocument53 pagesTesting and AdjustingAlexandra Yupanqui sarmiento100% (1)

- Rolls-Royce Silver Cloud Workshop Manual Chapter on Braking SystemsDocument35 pagesRolls-Royce Silver Cloud Workshop Manual Chapter on Braking SystemsAniket SankpalNo ratings yet

- Addendum To The Catalog: Synchronous Servo GearmotorsDocument0 pagesAddendum To The Catalog: Synchronous Servo GearmotorsVictor FriasNo ratings yet

- Stepper Motors Synchronous Motors Technical AppendixDocument5 pagesStepper Motors Synchronous Motors Technical AppendixCARLOSWAR101No ratings yet

- Localizacion SolenoidesDocument3 pagesLocalizacion SolenoidesEdgarNo ratings yet

- Hydraulic Motor (Radial Piston, Multi-Stroke) : RE 15 208/10.94 1/8 Replaces: 15 217Document8 pagesHydraulic Motor (Radial Piston, Multi-Stroke) : RE 15 208/10.94 1/8 Replaces: 15 217Timon2005No ratings yet

- Pitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939From EverandPitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939No ratings yet

- Metrics For MechanicsDocument63 pagesMetrics For Mechanicseduardorojas007No ratings yet

- 7432 DatasheetDocument6 pages7432 DatasheetSergio GuerraNo ratings yet

- Vin Camion CNGDocument3 pagesVin Camion CNGArnolds FelixNo ratings yet

- SaeDocument184 pagesSaehariprasanNo ratings yet

- Gear Pump (B5501-34022) (22 MM Dia. Shaft) - 853Document2 pagesGear Pump (B5501-34022) (22 MM Dia. Shaft) - 853walterNo ratings yet

- LMR PLUS Electric Fire Pump Controller Wiring SchematicDocument1 pageLMR PLUS Electric Fire Pump Controller Wiring SchematicHydro Energy GroupNo ratings yet

- Electric Actuator Butterfly Valve ZIPDocument5 pagesElectric Actuator Butterfly Valve ZIPwoodali9115991100% (1)

- 17 - Trouble DiagnosisDocument18 pages17 - Trouble DiagnosisFrederikusNo ratings yet

- Unit Iii Bevel Worm and Cross Helical GearsDocument3 pagesUnit Iii Bevel Worm and Cross Helical GearsAyush SinghalNo ratings yet

- Hydraulic Fluid Power Parts CatalogDocument14 pagesHydraulic Fluid Power Parts CatalogEng-Mohammed SalemNo ratings yet

- Southern Cross 125 X 80 - 200Document1 pageSouthern Cross 125 X 80 - 200supriNo ratings yet

- Si-204EN Somas Butterfly Valve VSSDocument4 pagesSi-204EN Somas Butterfly Valve VSStamaa andriNo ratings yet

- Bevel GearDocument1 pageBevel Gearahmad rifaiNo ratings yet

- Manual Transmission Components and Operation ExplainedDocument38 pagesManual Transmission Components and Operation ExplainedsayedNo ratings yet

- Spare Parts Proposal Kit: Boyles C5CDocument6 pagesSpare Parts Proposal Kit: Boyles C5CRafael Castillo LimachiNo ratings yet

- Chapter 9-SPUR GEARS AND GEAR TRAINSDocument64 pagesChapter 9-SPUR GEARS AND GEAR TRAINSMohammed Al-OdatNo ratings yet

- Lab 5 Maintennace of Actuator DriveDocument18 pagesLab 5 Maintennace of Actuator DriveNatNo ratings yet

- SM WA450-3 SN 53001-Up SEBM015501.PDF-part-6Document47 pagesSM WA450-3 SN 53001-Up SEBM015501.PDF-part-6Anyelo BravoNo ratings yet

- KOM Final 13 May 2020Document5 pagesKOM Final 13 May 2020Nilesh GhugeNo ratings yet

- SAMSON PositionerDocument60 pagesSAMSON PositionerJaco SerfonteinNo ratings yet

- Oliver 480 Sakurai MachineDocument4 pagesOliver 480 Sakurai MachinedominicomondyNo ratings yet

- Valvulas JisDocument48 pagesValvulas Jisanon_387758396No ratings yet

- Engine Mechanical (5Vz-Fe) : SST (Special Service Tools)Document3 pagesEngine Mechanical (5Vz-Fe) : SST (Special Service Tools)marran almarranyNo ratings yet

- Allison 5000/6000 Series Off-Highway Transmissions Parts CatalogDocument3 pagesAllison 5000/6000 Series Off-Highway Transmissions Parts CatalogMaya OlmecaNo ratings yet

- Huong Dan Lap Dat Va Su Dung Van Chong Va PDFDocument4 pagesHuong Dan Lap Dat Va Su Dung Van Chong Va PDFDONGTA123No ratings yet