Professional Documents

Culture Documents

Jet Pulse Filter (131.170.P21)

Uploaded by

shani55730 ratings0% found this document useful (0 votes)

56 views4 pagesThis document outlines the basic maintenance program for equipment at the Messebo Cement Plant including a jet pulse filter, air sluice, gear box, and filter fan. It lists maintenance activities, their status, lubrication requirements if any, frequency of maintenance, and any remarks. Maintenance includes general cleaning, internal cleaning, checking for leaks, wear, abnormal sounds, lubricating bearings, changing lubricants, checking clearances, tensions, and tightness of fasteners.

Original Description:

Jet Pulse Filter (131.170.P21)

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the basic maintenance program for equipment at the Messebo Cement Plant including a jet pulse filter, air sluice, gear box, and filter fan. It lists maintenance activities, their status, lubrication requirements if any, frequency of maintenance, and any remarks. Maintenance includes general cleaning, internal cleaning, checking for leaks, wear, abnormal sounds, lubricating bearings, changing lubricants, checking clearances, tensions, and tightness of fasteners.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

56 views4 pagesJet Pulse Filter (131.170.P21)

Uploaded by

shani5573This document outlines the basic maintenance program for equipment at the Messebo Cement Plant including a jet pulse filter, air sluice, gear box, and filter fan. It lists maintenance activities, their status, lubrication requirements if any, frequency of maintenance, and any remarks. Maintenance includes general cleaning, internal cleaning, checking for leaks, wear, abnormal sounds, lubricating bearings, changing lubricants, checking clearances, tensions, and tightness of fasteners.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 4

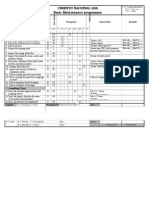

Date Section Depart.

Messebo Cement Plant

Basic Maintenance programme

Form No:Main /ML/4/000

Issue: 1

Page: 1of3

Crusher Mech

Eqpt. No. & Name /

Description of activities

S

t

a

t

u

s

L

u

b

.

/

m

a

i

n

Frequency

O

t

h

e

r

s

Instruction Remark

Jet pulse flter,

131.170.P21

R/S L/M D W F M 3M 6M Y O

1. Carry out general cleaning on & around

the filter

S M O

2. Carry out internal cleaning & clean air

chamber

S M O

3. Check solenoid & membrane ales

function properly

! M O

". Check for presence of isible dust in

the air flo# from stack.

! M O $f dust is isible. Check bags &

!eplace defectie.

%. Check air pressure &' bar( ! M O

'. Condition of compressed air ! M O Dry) clean) free from oil

*. Check function of automatic #ater

separator

! M O

+. Drain #ater from collection pipe. ! M O

,. Check that all inspection hatches &

-oints are tight

S M O $f necessary) replace the rubber

Seals of the hatch.

1.. Check all filter bags after dismantling S M O

11. !eplace the filter cartridge in the

compressed air filter

S M O

12. Check differential pressure

S M O /orking on time base 0000000000

Differential 1ressure base 0000000

13. Check leakage of compressed air. ! M O

1". Check hose & pc pipe condition for #ear S M O

1%. Check suction & deliery ducts for #ear S M O

1'. Check the condition of flap ales &

its securing position

! M O

Legend: R = Running S = Stop Planning cell Entered in Record Sign.

D = Daily W = Weekly F = Fortnightly Sign. Name

M = Monthly Y = Yearly Name Prepared by Checked by

Date Section Depart.

Messebo Cement Plant

Basic Maintenance programme

Form No:Main /ML/4/000

Issue: 1

Page: 2of3 Crusher Mech

Eqpt. No. & Name /

Description of activities

S

t

a

t

u

s

L

u

b

.

/

m

a

i

n

Frequency

O

t

h

e

r

s

Instruction Remark

* Air sluice,

131.170.P23

R/S L/M D W F M 3M 6M Y O

1. 2ubricate bearings ! 2 O

2 points) 2ub.3142)

2. Clean the e5uipment. S M O

3. $nspect housing ! M O

6or rust) corrosion) #ear

". $nspect flanges S M O

6or rust) corrosion) #ear

%. 2eakages any ! M O

'. $nspect impeller S M O

7ane #ear) corrosion) stuck material.

*. $nspect end coers S M O

6or corrosion) #ear

+. $nspect packing glands S M O

!etighten) if not change packing cord.

,. Change grease from bearings S 2 O

2ub.3142) fill 283

1.. $nspect bearings during grease change S M O

!ust) cracked rack) cage) damage

11. Check for loose bolts S M O

12. Check for abnormal sound ! M O

** Gear Box

Type: Sew euro drive, RF 40 A

1. Check oil leel S M O Oil grade9 Mobil gear '3.

2. Check oil colour and iscosity. S M O Change oil) if polluted

3. Check leakage of oil S M O

". Check temp. of gearbo: ! M O

%. Check for abnormal sound. ! M O

'. Check & clean the breather S M O

*. Check for ibration. ! M O

+. Change lubricant

S 2 O 3ery 2 year

Oil grade9 Mobil gear '3.)5ty9 ..32

** Coupling (Type: Rol. K100)

1.Check the clearance8gap bet#een the coupling hales ! M O

Std ; 2444" mm

<ctual;00000000000

2.Check the plastic fle:ibles for #ear

&Circumferential backlash(

S M O Std ; ' mm

<ctual;00000000

3.Check all fasteners &for tightness( S M O

Legend: R = Running S = Stop Planning cell Entered in Record Sign.

D = Daily W = Weekly F = Fortnightly Sign. Name

M = Monthly Y = Yearly Name Prepared by Checked by

Date Section Depart.

Messebo Cement Plant

Basic Maintenance programme

Form No:Main /ML/4/000

Issue: 1

Page: 3of3 Crusher Mech

Eqpt. No. & Name /

Description of activities

S

t

a

t

u

s

L

u

b

.

/

m

a

i

n

Frequency

O

t

h

e

r

s

Instruction Remark

* Filter fan,

131.170.P26

R/S L/M D W F M 3M 6M Y O

1. Check ibration ! M O

2. Check belt tension & condition S M O

2oad &=( > "2.%?8belt) Sag > 1%mm

3. Check bolts S M O

". Check fan housing S M O 6or #ear

%. Check the impeller S M O 6or #ear & cracks

'. Clean up S M O

*. !eplace lubricating grease S 2 O 2ub.9 3142) 5ty4.."+kg

+. 2ubricate bearings S 2 O 2ub.9 3142

,. Check the temperature of bearings ! M O @y hand. Ma:. '.

.

c.

1.. Check the condition of bearings S M O @acklash) clearance and general

condition.

11. Check for abnormal sound ! M O

12. Check suction duct for #ear S M O

13. Check the condition of cooling disc S M O &$f fitted(

Legend: R = Running S = Stop Planning cell Entered in Record Sign.

D = Daily W = Weekly F = Fortnightly Sign. Name

M = Monthly Y = Yearly Name Prepared by Checked by

You might also like

- Methods of Working Coal and Metal Mines: Planning and OperationsFrom EverandMethods of Working Coal and Metal Mines: Planning and OperationsRating: 3 out of 5 stars3/5 (2)

- Basic Maintenance Programme for Belt ConveyorDocument6 pagesBasic Maintenance Programme for Belt Conveyorshani5573No ratings yet

- Messebo Cement Plant Basic Maintenance programme Form No:Main /ML/4/000Document2 pagesMessebo Cement Plant Basic Maintenance programme Form No:Main /ML/4/000shani5573No ratings yet

- Messebo Cement Plant Blower Maintenance ScheduleDocument5 pagesMessebo Cement Plant Blower Maintenance Scheduleshani5573No ratings yet

- Cimento Nacional Lda Basic Maintenance Programme: Bucket Elevator, Flexible CouplingDocument4 pagesCimento Nacional Lda Basic Maintenance Programme: Bucket Elevator, Flexible Couplingshani5573No ratings yet

- Cimento Nacional Lda Basic Maintenance Programme: BffanDocument2 pagesCimento Nacional Lda Basic Maintenance Programme: Bffanshani5573No ratings yet

- Stage 2 Unit Shutdown ChecklistDocument21 pagesStage 2 Unit Shutdown ChecklistVIBHAVNo ratings yet

- Service Manual No-Frost Combi-Refrigerator: Models: ERF-366N, 366A ERF-396N, 396A ERF-416N, 416ADocument38 pagesService Manual No-Frost Combi-Refrigerator: Models: ERF-366N, 366A ERF-396N, 396A ERF-416N, 416ATudor FlorianNo ratings yet

- Pomm 9-1005-294-14 Xm177e2 SMG (1967)Document26 pagesPomm 9-1005-294-14 Xm177e2 SMG (1967)pmikel100% (4)

- Mold Flow AnalysisDocument19 pagesMold Flow AnalysisBittuNo ratings yet

- BOE QuestionsDocument4 pagesBOE QuestionsParameswararao BillaNo ratings yet

- PASS M0 - Maintenance Manual - 2GJA600065 (E)Document8 pagesPASS M0 - Maintenance Manual - 2GJA600065 (E)dwas1314No ratings yet

- GeneratorDocument55 pagesGeneratorVlad Iulian100% (3)

- International Maritime Organization: /var/www/apps/conversion/tmp/scratch - 4/207419774Document105 pagesInternational Maritime Organization: /var/www/apps/conversion/tmp/scratch - 4/207419774Viorel AndreiNo ratings yet

- Max pipe span table for carbon steel, stainless steel & individual supportsDocument5 pagesMax pipe span table for carbon steel, stainless steel & individual supportsSeungmin PaekNo ratings yet

- Solutions To Problem in Strength of Materials PDFDocument380 pagesSolutions To Problem in Strength of Materials PDFJohn Baniel90% (40)

- Liquid Turbine Flowmeter User ManualDocument16 pagesLiquid Turbine Flowmeter User ManualJorge RamosNo ratings yet

- Requirement of Compressed AirDocument9 pagesRequirement of Compressed Airsen_subhasis_58100% (1)

- MF-159 Handling Manual and Construction Plan For Oil Heaters PDFDocument8 pagesMF-159 Handling Manual and Construction Plan For Oil Heaters PDFThanh Nghị BùiNo ratings yet

- OH2 REPORTDoc2Document51 pagesOH2 REPORTDoc2Gajanan JagtapNo ratings yet

- Motor Checks & MaintenceDocument5 pagesMotor Checks & Maintenceravi chandra mavuriNo ratings yet

- Damper Guide BookDocument21 pagesDamper Guide Booksbmmla100% (1)

- Juk Mo-6704s 6714S 6716SDocument52 pagesJuk Mo-6704s 6714S 6716SRHoskaNo ratings yet

- MPM 312 03 07Document5 pagesMPM 312 03 07Mousa PetrolNo ratings yet

- Material List: Produced On 3/20/2014 With Xpress Selection V6.6.1 - Database DIL 9.4.1Document9 pagesMaterial List: Produced On 3/20/2014 With Xpress Selection V6.6.1 - Database DIL 9.4.1febimeNo ratings yet

- MEKG-4 Marine Engineering Knowledge ExamDocument3 pagesMEKG-4 Marine Engineering Knowledge ExamBhupender RamchandaniNo ratings yet

- Room Air ZQ08-10 CP08!10!12 SVC Parts Manual 5-06Document24 pagesRoom Air ZQ08-10 CP08!10!12 SVC Parts Manual 5-06Alex M-endoza'No ratings yet

- 69 Camaro AIMDocument489 pages69 Camaro AIMekamm100% (9)

- Full Free MastDocument19 pagesFull Free MastLuca FroliNo ratings yet

- Master List of Records for SPRINTECH DocumentsDocument9 pagesMaster List of Records for SPRINTECH DocumentsSyed Mujtaba Ali BukhariNo ratings yet

- Multi Zone Outdoors Service ManualDocument56 pagesMulti Zone Outdoors Service Manualcmorley505775% (4)

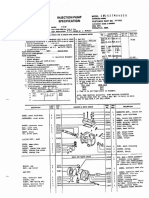

- Injection Pump Specification: IV 25-L0,,t 1. TestDocument2 pagesInjection Pump Specification: IV 25-L0,,t 1. Testjohnny sabinNo ratings yet

- BAR Base Shop Data (English, 1943)Document46 pagesBAR Base Shop Data (English, 1943)Ian McCollumNo ratings yet

- DMK RP 3 - 4 - 2Document6 pagesDMK RP 3 - 4 - 2Vlad Stefan CristianNo ratings yet

- Megger Test Report: VESSEL: M/V - DATEDocument2 pagesMegger Test Report: VESSEL: M/V - DATEcatalinNo ratings yet

- Steel Cord - Vulcanized SpliceDocument16 pagesSteel Cord - Vulcanized Splicebogeyman666No ratings yet

- DC9 - Control Surfaces OMDocument83 pagesDC9 - Control Surfaces OMzxcvbnm0078100% (1)

- Electrical Equipment PM SystemDocument7 pagesElectrical Equipment PM Systempankajyadav367No ratings yet

- PDOC 3phase Separator Operation ManualDocument20 pagesPDOC 3phase Separator Operation Manualduazo2009No ratings yet

- Inspecting and Cleaning DiaphragmsDocument4 pagesInspecting and Cleaning DiaphragmsAnonymous zdCUbW8HfNo ratings yet

- Breather ComemDocument12 pagesBreather ComemEd ArenasNo ratings yet

- Air Receiver 1M 3: SR Item Description Item Code UM Tech - Spec. Pur/FMP Usage OLD/New Remarks 1Document6 pagesAir Receiver 1M 3: SR Item Description Item Code UM Tech - Spec. Pur/FMP Usage OLD/New Remarks 1satya1401No ratings yet

- Valves CatalogueDocument30 pagesValves CatalogueRuth Sarai YañezNo ratings yet

- Handbook v1.0Document23 pagesHandbook v1.0Kiran KommireddyNo ratings yet

- Manual Book SICOMA MA02250 - 1500 SDocument61 pagesManual Book SICOMA MA02250 - 1500 SSitumorang David100% (1)

- Failure Analysis of Sheared Shaft of A Brine Recycle Pump...Document12 pagesFailure Analysis of Sheared Shaft of A Brine Recycle Pump...Pd RarNo ratings yet

- Menu Utama Engine Group GuideDocument56 pagesMenu Utama Engine Group GuideHamdi Askar100% (1)

- 8.01 Manufacturer'S Guaranteed Technical Data Schedule For 33/11 KV, 5/6.67 Mva Power TransformerDocument5 pages8.01 Manufacturer'S Guaranteed Technical Data Schedule For 33/11 KV, 5/6.67 Mva Power TransformerfaharaNo ratings yet

- Diseño de PilotesDocument24 pagesDiseño de PilotesmelchorodriguezNo ratings yet

- Ball Mill Checking (Compatibility Mode)Document33 pagesBall Mill Checking (Compatibility Mode)Nael100% (9)

- Newlong DS9 PartslistDocument29 pagesNewlong DS9 Partslisthector_medina_17No ratings yet

- Extract Fan/Exhaust Fan - 3M Task SheetDocument3 pagesExtract Fan/Exhaust Fan - 3M Task Sheetobaidur_rehman_3No ratings yet

- Parts List: Liuki®Document76 pagesParts List: Liuki®That TawooNo ratings yet

- Naomi R Buchwald Financial Disclosure Report For 2009Document20 pagesNaomi R Buchwald Financial Disclosure Report For 2009Judicial Watch, Inc.No ratings yet

- Euro 3 Novus Catalog - 2Document139 pagesEuro 3 Novus Catalog - 2Евгений КосицынNo ratings yet

- Peco Filter CaseDocument11 pagesPeco Filter CaseLuis MaureraNo ratings yet

- Workbook to Accompany Physics for Students of Science and EngineeringFrom EverandWorkbook to Accompany Physics for Students of Science and EngineeringNo ratings yet

- Mustafa Kamal Pasha: Calender For 2011Document4 pagesMustafa Kamal Pasha: Calender For 2011shani5573No ratings yet

- MD20.12 Gear Units Fast Track en Es ItDocument22 pagesMD20.12 Gear Units Fast Track en Es ItJosueNorrisNo ratings yet

- Currency Rate Calculator1Document1 pageCurrency Rate Calculator1shani5573No ratings yet

- Year-End Tax Planning Calculator1Document18 pagesYear-End Tax Planning Calculator1shani5573No ratings yet

- Design Calculations For Pressure VesselsDocument73 pagesDesign Calculations For Pressure Vesselsshani5573No ratings yet

- Process Systems Process System - Introduction: System Levels in Ore / Minerals ProcessingDocument12 pagesProcess Systems Process System - Introduction: System Levels in Ore / Minerals ProcessingepaccoyNo ratings yet

- Pile Load Test: (Source: Pile Design and Construction by M.J. Tomlinson, 1994)Document4 pagesPile Load Test: (Source: Pile Design and Construction by M.J. Tomlinson, 1994)Arvin BhurtunNo ratings yet

- 1UIADocument7 pages1UIAshani5573No ratings yet

- Pile LOad Test AADocument1 pagePile LOad Test AAshani5573No ratings yet

- A4-P 1.0 enDocument4 pagesA4-P 1.0 enshani5573No ratings yet

- Conveyor Belt Installtion SplicingDocument71 pagesConveyor Belt Installtion SplicingMatthew Butler75% (4)

- Marvelous FishesDocument51 pagesMarvelous FishesMushtaq M.ChinoyNo ratings yet

- Gear BoxDocument4 pagesGear Boxshani5573No ratings yet

- On 17Document2 pagesOn 17shani5573No ratings yet

- MT French Vocabulary Course PDFDocument48 pagesMT French Vocabulary Course PDFsuigeneris11No ratings yet

- MT French AdvancedDocument64 pagesMT French AdvancedperacNo ratings yet

- SHUTDODocument13 pagesSHUTDOshani5573No ratings yet

- A4-P 1.0 enDocument4 pagesA4-P 1.0 enshani5573No ratings yet

- Vibration Analysis On BearingsDocument67 pagesVibration Analysis On BearingsronfrendNo ratings yet

- Virus Signature DatabaseDocument1 pageVirus Signature Databaseshani5573No ratings yet

- Alternative Mixed: Cost /ton $ Cost /ton $ Cost /ton $ Cost /ton $Document3 pagesAlternative Mixed: Cost /ton $ Cost /ton $ Cost /ton $ Cost /ton $shani5573No ratings yet

- Blue Book Cor Us 20041011Document960 pagesBlue Book Cor Us 20041011ccbserialk100% (1)

- Knowledge ManagementDocument298 pagesKnowledge Managementshani5573No ratings yet

- Arrangement of EquipmentDocument4 pagesArrangement of Equipmentshani5573No ratings yet

- Equipment - Elect Kiln 2Document26 pagesEquipment - Elect Kiln 2shani5573No ratings yet

- Calculation Sheet: Padeye Calculations LoadsDocument15 pagesCalculation Sheet: Padeye Calculations Loadsshani5573No ratings yet

- Square FootingDocument9 pagesSquare Footingshani5573No ratings yet

- Lucky Cement Limited Karachi Project: SR No. Date LINE Equipments Defect/Deficiencies/ProblemsDocument4 pagesLucky Cement Limited Karachi Project: SR No. Date LINE Equipments Defect/Deficiencies/Problemsshani5573No ratings yet

- Army Welfare Trust Nizampur Cement Plant: Electrical DepartmentDocument18 pagesArmy Welfare Trust Nizampur Cement Plant: Electrical Departmentshani5573No ratings yet

- 2nd Line Presentation Dated 12-07-2003Document5 pages2nd Line Presentation Dated 12-07-2003shani5573No ratings yet

- Megohm Insulation TestDocument3 pagesMegohm Insulation TestArunkumar MyakalaNo ratings yet

- A404 / A413 / A470 / A670: FWD 3 SpeedDocument6 pagesA404 / A413 / A470 / A670: FWD 3 SpeedRaffa ChávezNo ratings yet

- Fan Drive System: Systems OperationDocument5 pagesFan Drive System: Systems Operationallan lariosaNo ratings yet

- BMW 318-Series 1991Document9 pagesBMW 318-Series 1991Piotr JaworskiNo ratings yet

- MY19 Mattoc Comp Service Guide and Travel Change 1Document31 pagesMY19 Mattoc Comp Service Guide and Travel Change 1Anonymous DabMRntnNo ratings yet

- Turolla Catalog Group 2 Gear PumpsDocument48 pagesTurolla Catalog Group 2 Gear Pumpsvut73 aNo ratings yet

- Mobel SofaDocument55 pagesMobel SofaNikhil R KNo ratings yet

- Speakers Mini x3 Wireless Bluetooth Speaker Manual OriginalDocument4 pagesSpeakers Mini x3 Wireless Bluetooth Speaker Manual OriginalKei OnderNo ratings yet

- A Textbook of Automobile Engineering by Navy FerozDocument161 pagesA Textbook of Automobile Engineering by Navy Ferozumesh1374100% (2)

- ATV600 Getting Started Annex EAV64300 12Document8 pagesATV600 Getting Started Annex EAV64300 12rabia akramNo ratings yet

- ARM7,9,11 ProcessorDocument34 pagesARM7,9,11 Processorharshad lokhandeNo ratings yet

- P200h2-P220he2 (1) 001Document4 pagesP200h2-P220he2 (1) 001Carlos José Barrios InfanteNo ratings yet

- There Are A Number of Effective Ways To Test An Arrester in The Field Without Necessarily Having To Rely On Sophisticated EquipmentDocument5 pagesThere Are A Number of Effective Ways To Test An Arrester in The Field Without Necessarily Having To Rely On Sophisticated EquipmentShahriar AhmedNo ratings yet

- Mastering Measurement with a MultimeterDocument51 pagesMastering Measurement with a MultimeterSebastian TataranNo ratings yet

- SM411 Technical RF (Eng Ver10.0 CS14.11)Document212 pagesSM411 Technical RF (Eng Ver10.0 CS14.11)jeemaxNo ratings yet

- BOSCH Vikakoodit Maalampopumppu 7001i 7800i LW LWMDocument32 pagesBOSCH Vikakoodit Maalampopumppu 7001i 7800i LW LWMHeikki SyrjämäkiNo ratings yet

- Crystal Resonator Oscillator - The Key DifferencesDocument4 pagesCrystal Resonator Oscillator - The Key DifferencesSatish MoorthyNo ratings yet

- 365-390 Pelle CaterpillarDocument4 pages365-390 Pelle Caterpillarait mimouneNo ratings yet

- PTCL Vendor Registration FormDocument30 pagesPTCL Vendor Registration FormHarisAslam100% (1)

- Injector and Ignition Driver For Automotive ApplicationsDocument25 pagesInjector and Ignition Driver For Automotive ApplicationsAnonymous 4IEjoc100% (2)

- Technote: Series vs. Parallel Connection of Multipulse RectifiersDocument2 pagesTechnote: Series vs. Parallel Connection of Multipulse Rectifiersmkashkooli_scribdNo ratings yet

- Dre80m4 PDFDocument2 pagesDre80m4 PDFRamiro Sew EurodriveNo ratings yet

- RC Ultra Hi-Lo 850 ManualDocument34 pagesRC Ultra Hi-Lo 850 ManualWojciech StasiewiczNo ratings yet

- Chapter 2newDocument134 pagesChapter 2newBelayneh TadesseNo ratings yet

- Filed Inspection Report: Quality Control FormDocument2 pagesFiled Inspection Report: Quality Control FormHesham HelalNo ratings yet

- The Intel 4004 Microprocessor, Which Was Introduced in 1971 Was The First MicroprocessorDocument21 pagesThe Intel 4004 Microprocessor, Which Was Introduced in 1971 Was The First MicroprocessorPraise PhillipsNo ratings yet

- DPB181 Bandsaw Instruction ManualDocument13 pagesDPB181 Bandsaw Instruction ManualHD QuanNo ratings yet

- SEBU7926 - Operation & Maintenance Manual (C7 Urban Transit Bus Engines)Document228 pagesSEBU7926 - Operation & Maintenance Manual (C7 Urban Transit Bus Engines)Rodolfo WongNo ratings yet

- Data Manual: PCI2050BDocument88 pagesData Manual: PCI2050BapurvNo ratings yet

- Lexus NX 200tDocument28 pagesLexus NX 200tSopheak LimNo ratings yet