Professional Documents

Culture Documents

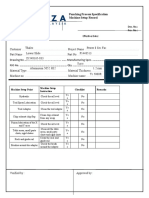

Jigs

Uploaded by

Karuppiah ArunachalamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jigs

Uploaded by

Karuppiah ArunachalamCopyright:

Available Formats

Jig

In metalworking and woodworking, a jig is a type of custom-made tool used to control the location and/or

motion of another tool. A jig's primary purpose is to provide repeatability,accuracy, and interchangeability in

the manufacturing of products.

[1]

A jig is often confused with a fixture; a fixture holds the work in a fixed

location. A device that does both functions (holding the work and guiding a tool) is called a jig.

[citation needed]

An example of a jig is when a key is duplicated; the original is used as a jig so the new key can have the same

path as the old one. Since the advent of automation and computer numerical controlled (CNC) machines, jigs

are often not required because the tool path is digitally programmed and stored in memory. Jigs may be

made for reforming plastics.

Jigs or templates have been known long before the industrial age. There are many types of jigs, and each one

is custom-tailored to do a specific job. Many jigs are created because there is a necessity to do so by

the tradesmen. Some are made to increase productivity through consistency, to do repetitive activities or to

do a job more precisely. Jigs may be well made for frequent use or may be improvised from scrap for a single

project, depending on the task.

Some types of jigs are also called templates or guides. Jigs include machining jigs, woodworking

jigs (e.g. tapering jig), welders' jigs, jewelers' jigs, and many others.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Sheet Metal Interview QuestionsDocument3 pagesSheet Metal Interview QuestionsMayur Panchal100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Mini Project Final ReportDocument37 pagesMini Project Final ReportSamanth Kumar Vasam86% (14)

- Casting Process PDFDocument36 pagesCasting Process PDFArip BudiNo ratings yet

- As 1275-1985Document20 pagesAs 1275-1985caimei89No ratings yet

- Bam LibraryDocument6 pagesBam Librarysaravanan_c1No ratings yet

- Nut Bolt TableDocument1 pageNut Bolt Tablebunta007No ratings yet

- Turbo JetDocument1 pageTurbo JetKaruppiah ArunachalamNo ratings yet

- Turbo FanDocument1 pageTurbo FanKaruppiah ArunachalamNo ratings yet

- Electric GeneratorDocument1 pageElectric GeneratorKaruppiah ArunachalamNo ratings yet

- TurbineDocument1 pageTurbineKaruppiah ArunachalamNo ratings yet

- TurboDocument1 pageTurboKaruppiah ArunachalamNo ratings yet

- Self RelianceDocument3 pagesSelf RelianceKaruppiah ArunachalamNo ratings yet

- PumpDocument1 pagePumpKaruppiah ArunachalamNo ratings yet

- Electric MotorDocument1 pageElectric MotorKaruppiah ArunachalamNo ratings yet

- Numeric ControlDocument1 pageNumeric ControlKaruppiah ArunachalamNo ratings yet

- Machine: Tool Energy Powered Motorized Power Tool ElectronicsDocument1 pageMachine: Tool Energy Powered Motorized Power Tool ElectronicsKaruppiah ArunachalamNo ratings yet

- Rotational Energy Moment of Inertia Rotational Speed TorqueDocument1 pageRotational Energy Moment of Inertia Rotational Speed TorqueNisha SharmaNo ratings yet

- FixturesDocument1 pageFixturesKaruppiah ArunachalamNo ratings yet

- CNC RouterDocument1 pageCNC RouterKaruppiah ArunachalamNo ratings yet

- Introduction To GearsDocument1 pageIntroduction To GearsKaruppiah ArunachalamNo ratings yet

- Basic Sentence Patterns With eDocument1 pageBasic Sentence Patterns With eFazril AminNo ratings yet

- Introduction To ToolsDocument1 pageIntroduction To ToolsKaruppiah ArunachalamNo ratings yet

- Top 100 Engineering Colleges in India 2014Document3 pagesTop 100 Engineering Colleges in India 2014Karuppiah ArunachalamNo ratings yet

- C++ Programming Style GuidelinesDocument28 pagesC++ Programming Style GuidelinesFenil DesaiNo ratings yet

- Thermo FormingDocument1 pageThermo FormingKaruppiah ArunachalamNo ratings yet

- Manufacturing TopicsDocument10 pagesManufacturing TopicsKaruppiah ArunachalamNo ratings yet

- General Studies Indian PolityDocument28 pagesGeneral Studies Indian Politymadhub_17No ratings yet

- Group 2 A Syllabus: PhysicsDocument7 pagesGroup 2 A Syllabus: PhysicsKaruppiah ArunachalamNo ratings yet

- List of Countries in The WorldDocument5 pagesList of Countries in The WorldDan MihaitaNo ratings yet

- Transfer MoldingDocument1 pageTransfer MoldingKaruppiah ArunachalamNo ratings yet

- Just in TimeDocument1 pageJust in TimeKaruppiah ArunachalamNo ratings yet

- Manufacturing: Manufacturing Is The Production of Goods For Use or Sale Using LaborDocument1 pageManufacturing: Manufacturing Is The Production of Goods For Use or Sale Using LaborKaruppiah ArunachalamNo ratings yet

- Material Requirements PlanningDocument1 pageMaterial Requirements PlanningKaruppiah ArunachalamNo ratings yet

- Me TrologyDocument1 pageMe TrologyKaruppiah ArunachalamNo ratings yet

- Strength of MaterialsDocument1 pageStrength of MaterialsKaruppiah ArunachalamNo ratings yet

- Creating Larger Forces With Differential Roller Screws: Carlos GonzalezDocument1 pageCreating Larger Forces With Differential Roller Screws: Carlos GonzalezfbahsiNo ratings yet

- 7.5m MMCD DavitDocument1 page7.5m MMCD Davitduda_sekaNo ratings yet

- Hard Chrome Plating - Industrial ChromeDocument3 pagesHard Chrome Plating - Industrial ChromeNirav DesaiNo ratings yet

- Machine Setup Check List CNC003Document2 pagesMachine Setup Check List CNC003zulfahmyNo ratings yet

- Advantages and Application of PCD and CBN ToolsDocument14 pagesAdvantages and Application of PCD and CBN ToolsMark EnriquezNo ratings yet

- Adaptive Control Systems For MachiningDocument10 pagesAdaptive Control Systems For MachiningRaj JhaNo ratings yet

- Experiment 1: Aim: Study and Practice of Orthogonal & Oblique Cutting On A Lathe. Apparatus: Lathe Machine TheoryDocument20 pagesExperiment 1: Aim: Study and Practice of Orthogonal & Oblique Cutting On A Lathe. Apparatus: Lathe Machine Theorykapil.scribdNo ratings yet

- Grinding MachineDocument4 pagesGrinding MachineSridhar BhagavatullaNo ratings yet

- Lab Report 3Document7 pagesLab Report 3mamoona noreen100% (1)

- CNC Milling Labsheet - DJJ40142Document8 pagesCNC Milling Labsheet - DJJ40142tonik 66No ratings yet

- Cleaning, Casting Defects and Die Castings. CleaningFettling of CastingsDocument70 pagesCleaning, Casting Defects and Die Castings. CleaningFettling of Castingsmecaunidos7771No ratings yet

- Instruction - Macroscopic Testing: 1. ScopeDocument2 pagesInstruction - Macroscopic Testing: 1. ScopeMohammed Ady GanjarNo ratings yet

- Current Online CatalogDocument1 pageCurrent Online CatalogamandaNo ratings yet

- HQ126EN Balinit® LATUMADocument4 pagesHQ126EN Balinit® LATUMAMari BraatzNo ratings yet

- Anyang Xinheng Machine Tool Co., LTDDocument27 pagesAnyang Xinheng Machine Tool Co., LTDYorvin OrtegaNo ratings yet

- Bolted Joints: ME 423: Machine Design Instructor: Ramesh SinghDocument41 pagesBolted Joints: ME 423: Machine Design Instructor: Ramesh SinghManjunath AithalNo ratings yet

- AASHTHO Road DesignDocument7 pagesAASHTHO Road DesignDilbert ScottNo ratings yet

- Assignment Engine BlockDocument7 pagesAssignment Engine Blocksaad100% (1)

- Miyano Model Lz-02Ry2 Quick Loading CNC Lathe Turning Center W/Y - Axis and Revolving Tool AttachmentDocument18 pagesMiyano Model Lz-02Ry2 Quick Loading CNC Lathe Turning Center W/Y - Axis and Revolving Tool AttachmentFidel Eduardo Luque Percka100% (1)

- HERFDocument9 pagesHERFDhiraj RauniyarNo ratings yet

- Dievar D20140715Document16 pagesDievar D20140715Keattikhun ChaichanaNo ratings yet

- Complete EDM Handbook - 4Document7 pagesComplete EDM Handbook - 4Prahlad GargNo ratings yet

- Weld Test Stand Assembly ManualDocument9 pagesWeld Test Stand Assembly ManualLUIS CORDOVA ZANCHESNo ratings yet

- CH 21Document45 pagesCH 21Anonymous p0mg44xNo ratings yet