Professional Documents

Culture Documents

(Piping Class Petroamazonas) Pam Zno 50 SP 004 0-18-02 - 13

Uploaded by

interx00Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Piping Class Petroamazonas) Pam Zno 50 SP 004 0-18-02 - 13

Uploaded by

interx00Copyright:

Available Formats

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los

especificados

Departamento: Facilidades, Ingeniera y Construcciones

Documento: Standard Specification for Pipe, Valves & Fittings

Cdigo del Documento: PAM-ZN0-50-SP-004

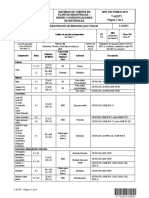

Historial de Revisiones

Revisin: Fecha:

Pginas

revisadas:

Motivo de la revisin:

Control de Distribucin

Ubicacin del Documento: Controlada No Controlada

Departamento de Facilidades y Construcciones X

Departamento de Materiales X

Contratistas X

Revisin: Fecha: Elaborado por: Revisado por: Aprobado por:

0 Feb 2013 P. Corts J. Basantes M. Carvajal

V. Molina D. Guamantica

Standard Specification for Pipe, Valves &

Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 2 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

TABLE OF CONTENTS

1.0 SCOPE

2.0 CODES AND RECOMMENDATIONS

3.0 GENERAL REQUIREMENTS

4.0 MATERIALS

5.0 PIPE SUPPORTS

6.0 WELDING

7.0 INSPECTION

8.0 PRESSURE TESTING

9.0 PAINTING AND COATINGS

10.0 THERMAL INSULATION

11.0 IDENTIFICATION OF PIPING AND VALVES

12.0 BRANCH CONNECTIONS

ATTACHMENT A STRAINERS

ATTACHMENT B ACCESS FITTINGS

ATTACHMENT C INSULATING KITS

ATTACHMENT D BLEED RINGS

ATTACHMENT E GASKETS

ATTACHMENT F STUD BOLTS DIMENSIONS

ATTACHMENT G ANSI PIPE SCHEDULES

ATTACHMENT H INTERNALLY COATED

ATTACHMENT I API FLANGES

ATTACHMENT J U-BOLTS DIMENSIONS

ATTACHMENT K FBE EXTERNAL COATING

ATTACHMENT L GLOSSARY

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 3 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

1.0 SCOPE

This specification defines the minimum requirements for pipe, valves and fittings on process and

utility piping systems. This specification includes materials, fabrication, welding, inspection and

testing and shall apply to all piping installed by or prefabricated for installation by Contractor or to

Contractors order for use on onshore production facilities, which includes: Block 7, Block 15,

Block 18, Block 21 and North Zone.

2.0 CODES AND RECOMMENDATIONS

2.1 Piping shall be designed, constructed and tested in accordance with the latest edition of

ASME B31.3, "PROCESS PIPING", and this specification.

Steam line and Power Generation Systems shall be designed, constructed and tested in

accordance with the latest edition of ASME B31.1, POWER PIPING, and this

specification.

2.2 The following standards (the latest edition) shall apply during preparation of all piping

drawings and during description of materials for Class 150 through Class 2500:

Process Valve Qualification Procedure API RP 591

Specification for Line Pipe API Spec 5L

Specification for Pipeline Valves API Spec 6D

Specification for Fire Test for Valves API Spec 6FA

Fire Test for Check Valves API Spec 6FD

Specification for Quality Programs for the Petroleum, Petrochemical and Natural

Gas Industry

API Spec Q1

Check Valves: Flanged, Lug, Wafer and Butt-welding API Std 594

Valve Inspection and Testing API Std 598

Steel Gate Valves - Flanged and Butt-welding Ends, Bolted Bonnets API Std 600

Steel Gate, Globe and Check Valves for Sizes DN 100 and Smaller API Std 602

Fire Test for Soft-Seated Quarter-turn Valves API Std 607

Metal Ball Valves - Flanged, Threaded and Welding Ends API Std 608

Butterfly Valves: Double-flanged, Lug and Wafer Type API Std 609

Unified Inch Screw Threads, UN and UNR Thread Form ASME B1.1

Pipe Threads, General Purpose (Inch) ASME B1.20.1

Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 ASME B16.5

Factory-Made Wrought Buttwelding Fittings ASME B16.9

Face-to-Face and End-to-End Dimensions of Valves ASME B16.10

Forged Fittings, Socket-Welding and Threaded ASME B16.11

Metallic Gaskets for Pipe Flanges: Ring-Joint, Spiral-Wound, and Jacketed ASME B16.20

Nonmetallic Flat Gaskets for Pipe Flanges ASME B16.21

Buttwelding Ends ASME B16.25

Valves Flanged, Threaded and Welding End ASME B16.34

Orifice Flanges ASME B16.36

Large Diameter Steel Flanges: NPS 26 Through NPS 60 ASME B16.47

Square and Hex Bolts and Screws - Inch Series ASME B18.2.1

Square and Hex Nuts (Inch Series) ASME B18.2.2

Power Piping ASME B31.1

Process Piping ASME B31.3

Welded and Seamless Wrought Steel Pipe ASME B36.10

Stainless Steel Pipe ASME B36.19

Standard Marking System for Valves, Fittings, Flanges and Unions MSS SP-25

Specification for High-Test Wrought, Butt-Welding Fittings MSS SP-75

Class 3000 Steel Pipe Unions Socket Welding and Threaded MSS SP-83

Swage(D) Nipples and Bull Plugs MSS SP-95

Integrally Reinforced Forged Branch Outlet Fittings: SW, THD and BW Ends MSS SP-97

Instrument Valves for Code Applications MSS SP-105

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 4 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

2.3 The following procedures (the latest edition) shall apply during preparation of all piping

drawings and during description of materials for Class 150 through Class 2500:

WPS Approved by B15 B15-ECU-50-PR-023

Structural Steel Skid Mounted Assemblies B15-ECU-20-SP-009

Thermal Insulation B15-ECU-20-SP-015

Manufacture And Installation of Pipes Underground and Aboveground PAM-EC-20-PRC-005

Hydrostatic Test For Process Pipe PAM-EC-20-PRC-007

Coating Specification PAM-EC-50-SP-001

3.0 GENERAL REQUIREMENTS

3.1 Engineering drawings, where provided, indicate the minimum line size, design working

pressure or piping class, valves required, etc.

For services of transportation crude oil and water reinjection, the engineering companies

must confirm the wall thickness with the Hydraulic Calculations of lines.

The maximum design conditions specified in the Piping Class Specifications Note 1 are

separate requirements and neither shall be exceeded.

3.2 Unless otherwise specifically authorized by PETROAMAZONAS EP, the materials

specified in these General Specifications shall be strictly adhered to in the design,

purchasing and fabrication of each piping system. When the specified pipe, valves and

fittings or other materials cannot be obtained, substitution may be permitted with the

written approval of PETROAMAZONAS EP.

3.3 Line marking and identification of valves shall be in accordance with Section 11.0 herein.

Contractors standard markings and identification may be used with the written approval

of PETROAMAZONAS EP.

3.4 Pipe

3.4.1 All pipes shall be marking per API Spec 5L and ASTM-A106: name or mark of the

manufacturer, specification, specified dimensions, grade and class, product

specification level, process of manufacture, heat number and an identification

number.

3.4.2 Pipe wall thickness shall conform to Piping System Specifications.

3.4.3 Piping Class 150 through Class 2500. Piping 1 NPS and smaller may be

threaded, flanged or socket welded as indicated by the Piping System

Specifications. Piping 2 NPS and larger may be threaded (Only Specs HA1 and

HA2), butt welded or flanged as indicated by the Piping System Specifications.

When socket weld piping is used, unions will be installed at accessible locations

to permit removal and replacement of all valves and equipment. With the

exception of vents, drains, samplers and instrument connections, piping 1

NPS and smaller shall be socket welded or flanged for the following services:

3.4.3.1 Hydrocarbon services Class 1500 pressure ratings and above.

3.4.3.2 Hydrocarbon services above 250 F.

3.4.3.3 Hydrocarbon services subject to vibration or pulsation.

3.4.4 Piping shall be located so as not to present overhead or tripping hazards.

Minimum clear headroom for overhead piping shall be 7 foot 0 inches (2.15 m).

Lines which cross shall not touch.

3.4.5 Piping systems shall be designed so that all valves and instruments can be

serviced conveniently. When this is impractical, ladders and platforms designed

in accordance with the Specification of PETROAMAZONAS EP: B15-ECU-20-

SP-009 "STRUCTURAL STEEL SKID MOUNTED ASSEMBLIES, shall be used.

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 5 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

3.4.6 Emergency shutdown valves shall be accessible from deck or floor level and are

to be located in clear areas.

3.4.7 All pipe nipples NPS and smaller shall be a minimum of SCH 160 SMLS steel

pipe. "All-Thread" nipples shall not be used. A nipple shall be defined as any

section of pipe 12 or less in length.

3.4.8 Seal welding of threaded piping shall not be permitted.

3.4.9 Temporary start-up cone or basket-type strainers (screens) shall be provided in

suction lines to mechanical equipment, including, but not necessarily limited to

pumps, compressors and mechanical meters and shall be located as close as

possible to the inlet flange. Such strainers shall have a minimum of 200% of the

line flow area with 1/8 diameter maximum size perforations. For Strainers

Specifications, see ATTACHMENT A.

3.4.10 Branch Connections

3.4.10.1 Branch connections shall be made per the Standard Branch Connection

Chart for Piping Systems Class 150 through Class 2500.

3.4.10.2 Couplings shall not be used for branch connections.

3.4.10.3 "Stub-in" branch connections shall not be permitted.

3.4.11 During fabrication, installation, sandblasting and painting, care shall be exercised

to keep blast sand, dirt and other foreign matter out of all piping systems prior to

assembly. Prior to acceptance by PETROAMAZONAS EP, the interior of piping

systems shall be thoroughly cleaned by Contractor.

3.4.12 Drain connections and valves shall be provided at all low points in lines. Also,

vent connections and valves shall be provided at all high points where gas may

be trapped. Vent, drain and instrument connections and smaller may be

installed using 3000# or 6000# threadolets, except for high temperature or other

service where sockolets are specified by the Piping System Specifications.

3.4.13 The corrosion coupons connections shall be installed using Access Fittings type

COSASCO. For Access Fittings Specifications, see ATTACHMENT B.

3.4.14 Changes in pressure rating of piping systems shall be made at valves. This valve

shall carry the rating of the higher pressure system.

3.4.15 Laterals (sub-headers) for instrument gas or air systems shall have block valves

at the primary header and branch off from the top of the primary header.

3.4.16 Insulating gaskets shall be installed when joining piping components or dissimilar

metals to prevent galvanic corrosion and/or when there are changes between

underground with cathodic protection and aboveground lines. Only will be

accepted the Insulating Kits VCS PIKOTEK. For Insulating Kits Specifications,

see ATTACHMENT C.

3.4.17 Flow lines piping, between wellhead and manifold, shall be externally coated with

FBE (fusion bonded epoxy). For FBE External Coating Specifications, see

ATTACHMENT K.

3.5 Flanges

3.5.1 All flanges shall be marking per ASME B16.5 and/or MSS SP-25: country of

manufacture, manufacturer's name or trademark, material, rating designation,

conformance with the B16.5 Standard, size, schedule (if applicable) and an

identification number.

3.5.2 Flanges Class 900 and above shall be RTJ. Flanges Class 600 and lower may be

RF or FF, with serrated spiral finish.

3.5.3 Weld neck flanges are required for all flanged piping.

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 6 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

3.5.4 Steel flanges used to mate with equipment having cast iron, ductile iron or

aluminum flanges shall have the faces machined flat (FF).

3.5.5 Flange bolt holes shall straddle the piping horizontal and vertical center lines.

3.5.6 API flanges rated at 2000, 3000 or 5000 PSI shall be Type 6B. For API Flanges

Description, see ATTACHMENT I.

3.6 Fittings

3.6.1 All fittings shall be marking (if applicable) per ASME B16.9, ASME B16.11 and/or

MSS SP-25: country of manufacture, manufacturer's name or trademark,

material, product conformance, size, schedule number or class designation and

an identification number.

3.6.2 All 90 welded elbows shall be long radius (LR), unless restricted by available

space. If short radius welded elbows are used, they shall be derated to 80% of

the calculated allowable working pressure.

3.6.3 Eccentric reducers installed with the straight (flat) side up shall be used when line

size reductions are required for pump suction connections.

3.6.4 Street elbows shall not be used unless approved by PETROAMAZONAS EP.

3.6.5 Bleed rings shall be according to material of pipe, stainless steel or carbon steel.

For Bleed Rings Specifications, see ATTACHMENT D.

3.6.6 All welded elbows related to flow lines, between wellhead and manifold, shall be

externally coated with FBE (fusion bonded epoxy). For FBE External Coating

Specifications, see ATTACHMENT K.

3.7 Valves

3.7.1 Valve materials specified herein are the minimum required by PAM EP. In the

case that there exist the same or better materials with tested performance for the

specific application, their acceptance will be responsibility of the technical

evaluator.

3.7.2 All valves shall be marking per ASME B16.34, API Spec 6D and/or MSS SP-25.

3.7.3 All the valves manufacturers (gate, globe, check and butterfly with exception of

API 6D valves) will have to apply the API RP 591: PROCESS VALVE

QUALIFICATION PROCEDURE. This recommended practice provides

recommendations for evaluation of a construction and quality assurance program

for the purpose of determining a manufacturer's capability to provide new valves

manufactured in accordance with the applicable API standards.

3.7.4 Valves shall be furnished as called out on the Approved Valve Lists. Alternate

valves which are equal to the valve list requirement may be used only after

obtaining the written approval of PETROAMAZONAS EP.

3.7.5 All valves shall be installed in accordance with temperature and pressure ratings

recommended by manufacturer and within limits of the ASME B16.34 Code for

the applicable service. Flanges and flange facings on valves shall match that

specified by the applicable Piping Class Specification. The wall thickness of the

valves gate, globe and check shall be under API 600 and API 602.

3.7.6 All valves for hydrocarbon service shall be steel. Valves 2 and larger shall be

flanged and 1 and smaller may be threaded, flanged or socket welded as

indicated by the Piping Class Specification. Contractor shall not add flanges to

threaded, socket weld or butt weld connections on valves unless specifically

approved. Secondary threaded valves must be easily removable.

3.7.7 The valves for Fire Water System shall be:

Valves 3 and smaller: Cast Bronze body and trim. Threaded ends.

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 7 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

Valves 4 and larger: Cast Iron body and Bronze trim. FF flanged

ends.

3.7.8 Ball valves shall be fire safe design and shall meet the following additional

specifications.

3.7.8.1 Ball valves shall be trunnion mounted with secondary metal seal, as

following:

For Class 150: 8 and larger.

For Class 300: 4 and larger.

For Classes 600, 900, 1500 and 2500: 2 and larger.

All trunnion mounted ball valves shall be supplied with grease fittings for

stem and seals.

3.7.8.2 Secondary metal seal is not required for 1 and smaller ball valves.

3.7.8.3 Manual gear operators shall be furnished on all quarter turn valves in any

application where breakaway torque requirements exceed 50 foot

pounds. Generally:

6 and larger Classes 150 and 300.

4 and larger Classes 600, 900 and 1500.

2 and larger Class 2500.

3.7.8.4 For Hydrocarbon Process and Instruments Air, ball valves 1 and

smaller shall be ASTM-A351 Gr CF8M or 316 SS body, with 316 SS ball

and stem.

3.7.9 Block valves shall be provided downstream of check valves to allow isolating the

check valve for servicing without the need to de-pressurize downstream piping

systems. Vent valves, if applicable, shall be installed to facilitate de-pressuring

piping upstream of check valve and upstream of check valve for leak testing of

check valves.

3.7.10 Check valves can be reduced or full flow, swing check in all cases except for

reciprocating pump or compressor service where ball or piston type check shall

be used or where the piping specification permits wafer type check valves in

utility services.

3.7.10.1 All check valves 2 and larger shall be furnished with bolted

bonnets.

3.7.10.2 All check valves 4 and larger shall be provided with NPT tap

and plug in the body.

3.7.11 Gate, Globe and Check valves shall have hardened (stellite or equal) seats. The

check valve can have removable or integral seats. Globe valves may be straight

or angle type to suit piping configuration

3.7.12 All gate and globe valves shall be OS&Y (outside screw and yoke). Inside screw-

rising stem not will be accepted

3.7.13 Needle valves shall be supplied when shown on the flowsheets and assembly

drawings. Needle valves, except where required for high pressure and/or

temperature service, shall all be soft- seated and all 316 SS.

3.7.14 For ball valves, the ball rotation shall be counter-clockwise when facing the stem

so that the initial valve opening is at the bottom of the pipe.

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 8 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

4.0 MATERIALS

4.1 All materials (Pipe, Fittings, Flanges, etc.) shall include: country of manufacture,

manufacturer's name and/or logo and heat number and be provided with quality

certificates to enable its traceability.

4.2 All materials for Pipe, Valves, Fittings, Flanges, Bolts, Gaskets and Special Parts, shall

be in accordance with Piping Class Specifications.

4.3 The quality management system requirements for the design, development, production,

installation and service of products for the petroleum industry, must be prevailed per API

Spec Q1: Specification for Quality Programs for the Petroleum, Petrochemical and

Natural Gas Industry.

4.4 All Pipe, Valves, Fittings, Flanges, Bolts, Gaskets and Special Parts, supplied by

Contractor shall be new and unused, free of mill scale, dents, cracks, laminations, pits

and detrimental rust or oxidation.

4.5 PETROAMAZONAS EP reserves the right to inspect all Contractor supplied materials

and components, and to reject those deemed unusable for use and not conforming to

these specifications.

4.6 No pipe, valves or fittings of brass, aluminum, cast iron, malleable iron, steel-iron or semi-

steel shall be used in hydrocarbon service. Cast bronze or cast iron body valves will be

used only for Fire Water Systems and foot valves.

4.7 Sealant for threaded piping shall be Teflon tape. Care shall be taken to prevent extension

of the tape into the pipe. Excess tape shall be removed prior to painting.

4.8 All new pipe, flanges and fittings shall be marked with mill and material identification. All

pipes shall be accompanied with mill test reports, and flanges and fittings shall be

accompanied with mill material certifications from manufacturer.

4.9 All threaded galvanized pipe shall be painted after assembly with cold galvanizing.

4.10 The filler material for all gaskets shall be Flexible Graphite (FG) and will only be

accepted from USA and ITALY. For Gaskets Specifications, see ATTACHMENT E.

4.11 All welded joints related to flow lines, between wellhead and manifold, shall be coated

with 3M Scotchkote 323.

5.0 PIPE SUPPORTS

5.1 Piping shall be supported as necessary to prevent sagging, mechanical stresses and

vibration. Piping shall be adequately supported on racks, stanchions or individual

standoffs.

5.2 Welding of supports directly to the internally coated pipe, except shoes using in thermal

insulating pipe, shall not be permitted unless authorized in writing by PETROAMAZONAS

EP.

5.3 U-Bolts securing pipe to pipe supports shall be galvanized with 1/16 polyethylene sleeve,

flat washers and double nuts. A 1/8 neoprene or polyethylene pad spacer shall be placed

between the pipe support and bottom of pipe. Minimum U-bolt diameter shall be 1/4". For

U-BOLTS Dimensions, see ATTACHMENT J.

5.4 Piping 8 and larger and any smaller piping subject to excessive mechanical vibration or

line pressure pulsations (e.g., rotating equipment piping) shall be fastened to

substantially rigid pipe supports with bolted pipe clamps in lieu of U-bolts. Pipe clamp

bolts shall have double nuts.

5.5 Piping subject to expansion may be either suspended from adjustable or swivel type

hangers or supported from below. If supported from below, steel slip shoes and guides

shall be provided. Anchors and stops shall be provided to maintain movements and

forces within acceptable limits.

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 9 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

6.0 WELDING

6.1 All pipes welding shall be performed in accordance with Procedure B15-ECU-50-PR-023

WPS APPROVED BY B15.

6.2 Welded joints in carbon steel shall be stress relieved in accordance with ASME B31.3

when the nominal pipe wall thickness is greater than . The piping shall be brought to

temperature and cooled in accordance with ASME Section VIII, Paragraph UCS-56.

7.0 INSPECTION

Inspection of all piping shall be performed in accordance with Procedure PAM-EC-20-PRC-005

MANUFACTURE AND INSTALLATION OF PIPES UNDERGROUND AND ABOVEGROUND. If

the inspection is performed in accordance with Contractor Specifications, these procedures shall

be submitted to PETROAMAZONAS EP for approval.

8.0 PRESSURE TESTING

All pressure testing of pipe shall be performed in accordance with ARCH (Regulation and Control

Agency Hydrocarbon) Regulations and Procedure PAM-EC-20-PRC-007 HYDROSTATIC TEST

FOR PROCESS PIPE.

9.0 PAINTING AND COATINGS

9.1 Surface preparation and painting of pipe, valves and fittings shall be performed in

accordance with PETROAMAZONAS EP Specification PAM-EC-50-SP-001 "COATING

SPECIFICATION.

9.2 All flange surfaces and bolt holes, except for flange facings, shall be coated with primer

and intermediate coats prior to assembly. Pipe fittings shall not be primer coated until all

shop fabrication has been completed. Final paint coating shall be performed after piping

has been fully assembled and hydro-tested.

10.0 THERMAL INSULATION

Piping shall be insulated where indicated on the approved for construction AFC drawings.

Insulation shall be applied as specified in PETROAMAZONAS EP Specification: B15-ECU-20-

SP-015 "THERMAL INSULATION".

11.0 IDENTIFICATION OF PIPING AND VALVES

The following nomenclature is to be used in identifying lines and valves designated on the

mechanical flowsheets and process piping drawings.

11.1 Line Identification

11.1.1 Each line on the mechanical flowsheets and process piping drawings shall be

clearly identified to denote the pipe specification and nominal line size.

Following is an example:

3 - GF - 1500 - AA1 00 Special (if required)

Piping Specification

Line Number

Service Identification Letters

Nominal Pipe Size

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 10 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

11.1.2 Line Service

Each line will be denoted by the following abbreviations:

SERVICE ABBREVIATION

Air Instrument AI

Air Utility AU

Air Engine Starter PA

Atmospheric Vent FV

Blow Down (Low Temp to 50 F) BD1

Condensate C

Corrosive Condensate CC

Chemical Injection IL

Circulation Water CW

Combustion air drains AD

Cooling Water RW/SW

Demineralized Water ZW

Diesel DF

Drain Gravity DRG

Drain Overflow DO

Drain Pressure DRP

Fire Water FW

Foam F

Fuel Raw CR

Gas G

Gas Diesel GD

Gas Fuel GF

Gas Fuel (Hot or Dry Service) GF1

Gas Fuel (Wet or Condensing Service) GF2

Gas Liquefied Propane GLP

Gas Process GP

Gas Produced PG

Gasoline GAS

Gas Flare non corrosive HF

Natural Gas NG

Heat Media HM

High Pressure Steam HS

Low Pressure Condensate LC

Low Pressure Steam LS

Lube Oil LO

Oil Dry OD

Oil Fuel Return OFR

Oil Hot Return OHR

Oil Hot Supply OHS

Oil LACT OL

Oil Produced OP

Oil Reject OR

Oil Wet OW

Process Fluid PF

Process Liquids (Chemical Injection) PL

Process Hydrocarbons non-corrosive (gas/liquid) HNC

Process corrosive moderate by CO2 in hydrocarbons (gas/liquid) HMC

Process corrosive strong by CO2 in hydrocarbons (gas/liquid) HSC

Purge Continuous CB

Purge Flashing BB

Purge Water Tower YW

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 11 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

Steam V

Take Samples NS

Treated Water TW

Ventilation Air AV

Water Fireline WFL

Water Fresh WF

Water Heaters HW/IW

Water Hot Return WHR

Water Injection Production (heavy corrosion) WIP

Water Produced WP

Water Raw WR

Water Soft WS

Water Supply BW

Water Utility WU

Water Waste WW

Water Wash WH

11.2 Valve Identification System

Each valve on the mechanical flowsheets and piping drawings will be identified as shown

below to denote its valve size, piping specification, valve type, valve facing and special

valve type. Each valve identification shall be die stamped and/or a stainless steel tag that

shall be secured to the valve with a heave gauge steel wire. Such tags shall remain in

place upon completion of fabrication.

4 AA1 2 R F

Special valve type (if required)

Valve facing

Valve type

Pipe Specification

Valve size

11.2.1 Description

TYPE FACING

SPECIAL VALVE TYPE

If required

1 Gate F Flat face - Standard

2 Ball G Grayloc B Double block and bleed

3 Plug J Ring joint F Full port

4 Globe R Raised face FM FM x FM

5 Check S Threaded (THD) H High temperature

6 Needle U Union L Lug

7 Butterfly W Butt weld LT Low temperature

8 Foot X Special P Piston

9 Gauge, Multiport Y SW x THD S Short pattern

0 Choke (900# - 1500#) Z Socket weld (SW) SG Slab Gate

W Wafer

X Special

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 12 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

11.3 The following piping specification identification is used on the fabrication drawings.

SPEC. ANSI RATING SERVICE IDENTIFICATION MATERIAL CODE

AA1 ANSI 150 RF

AD, AV, BW, C, CR, CW, DO, DF, DRG, DRP, F,

FV, G, GAS, GD, GF, GLP, GP, HF, HM, HNC,

HMC, HSC, HW/IW, LO, NG, OD, OFR, OHR,

OHS, OL, OP, OR, OW, RW/SW, TW, WH, WFL,

WHR, WP, WR, WS, WW

CS ASMEB31.3

AE2 ANSI 150 RF BB, CB, LC CS ASMEB31.1

AL1 ANSI 150 RF BD1 CS ASMEB31.3

AS1 ANSI 150 RF CC, GP 304 SS ASMEB31.3

AS2 ANSI 150 RF GP, PL, C, GF, IL, HF, NS, PF, ZW 316 SS ASMEB31.3

AX1 ANSI 150 RF OP, WP CS Int. Coated ASMEB31.3

BA1 ANSI 300 RF G, GF, GP, OP, WP, DF, NG, HF, HNC, HMC, PA CS ASMEB31.3

BE1 ANSI 300 RF LS CS ASMEB31.1

BL1 ANSI 300 RF BD1 CS ASMEB31.3

BS1 ANSI 300 RF GP 304 SS ASMEB31.3

BS2 ANSI 300 RF CC, GP, PL 316 SS ASMEB31.3

BX1 ANSI 300 RF OP, WP CS Int. Coated ASMEB31.3

CA1 ANSI 600 RF C, G, GF, GP, OL, V CS ASMEB31.3

CS1 ANSI 600 RF GP 304 SS ASMEB31.3

CS2 ANSI 600 RF GP, PL 316 SS ASMEB31.3

CX1 ANSI 600 RF OP, WP CS Int. Coated ASMEB31.3

DA1 ANSI 900 RTJ GP CS ASMEB31.3

DE1 ANSI 600 RF BB, BW, CB, DRP, HS CS ASMEB31.1

DS1 ANSI 900 RTJ GP 304 SS ASMEB31.3

DS3 ANSI 900 RTJ GP Duplex SS ASMEB31.3

EA1 ANSI 1500 RTJ GP, WP CS ASMEB31.3

ES1 ANSI 1500 RTJ GP 304 SS ASMEB31.3

ES3 ANSI 1500 RTJ GP Duplex SS ASMEB31.3

EX1 ANSI 1500 RTJ OP, WP CS Int. Coated ASMEB31.3

FA1 ANSI 2500 RTJ GF1, HSC, WIP CS ASMEB31.3

FS1 ANSI 2500 HUB GF2 304 SS ASMEB31.3

H4 ANSI 2500 HUB PG 304 SS ASMEB31.3

HA1 ANSI 150 RF AI, AU, WF, WU, YW CS Galv. ASMEB31.3

HA2 ANSI 150 RF WF (Deluge system) CS Galv. ASMEB31.3

L ANSI 150 RF FW CS ASMEB31.3

11.4 Conversion Table

This table is the result of the unification of Piping Class used in the B-18 and Piping Class

used in the B-15. In each document existed own nomination for the pipe specification.

The Piping Class Unified remains pipe specification from the B-15, and has changed only

the B-18 according to the following conversion table:

CONVERSION TABLE

NEW SPECIFICATION

ZNO

OLD SPECIFICATION

B-18

AA1 AA1-AA2-AA3

AE2 AE2

AG2 AG2

AS2 AK0-AM0-DK0

HA1 AW1-AX1

BA1 BA1-BA2

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 13 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

BE1 BE1

BS1 BM1

DA1 DA1

DE1 DE1

H4 FS2

12.0 BRANCH CONNECTIONS

Piping branch connections shall be installed in accordance with the following Branch Connection

Chart.

STANDARD BRANCH CONNECTION CHART

[INCHES]

BRANCH

24 20 18 16 14 12 10 8 6 4 3 2 1.5 1 .75 .5

R

U

N

24 T RT RT RT RT RT W W W W W W S S S S

20 T RT RT RT RT RT W W W W W S S S S

18 T RT RT RT RT W W W W W S S S S

16 T RT RT RT RT W W W W S S S S

14 T RT RT RT W W W W S S S S

12 T RT RT RT W W W S S S S

10 T RT RT W W W S S S S

8 T RT RT W W S S S S

6 T RT RT W S S S S

4 T RT RT S S S S

3 T RT S S S S

2 T T/S S S S

1.5 SWT SW RT SW RT SW RT

1 SWT SW RT SW RT

.75 SWT SW RT

.5 SWT

LEGEND

T Butt Weld Tee

RT Butt Weld Red Tee

S Sockolet (SOL) / Threadolet (TOL)

W Weldolet (WOL)

T/S Straight Tee BW + Concentric Swage

SWT Socket Weld Tee / Threaded Tee

SW RT Socket Weld Reducing Tee / Threaded Reducing Tee

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 14 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

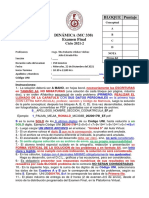

NDICE

1.0 ALCANCE

2.0 CDIGOS Y RECOMENDACIONES

3.0 REQUERIMIENTOS GENERALES

4.0 MATERIALES

5.0 SOPORTES DE TUBERA

6.0 SOLDADURA

7.0 INSPECCIN

8.0 PRUEBA HIDROSTTICAS

9.0 PINTURA Y RECUBRIMIENTOS

10.0 AISLAMIENTO TRMICO

11.0 IDENTIFICACIN DE TUBERA Y VLVULAS

12.0 CONEXIONES DE DERIVACIN

ANEXO A FILTROS

ANEXO B ACCESORIOS DE ENTRADA

ANEXO C KITS DE AISLAMIENTO

ANEXO D ANILLOS DE PURGA

ANEXO E EMPAQUES

ANEXO F DIMENSIONES DE ESPRRAGOS

ANEXO G ESPESORES DE TUBERA ANSI

ANEXO H RECUBRIMIENTO INTERNO

ANEXO I BRIDAS API

ANEXO J DIMENSIONES DE PERNOS U

ANEXO K RECUBRIMIENTO EXTERNO CON FBE

ANEXO L GLOSARIO

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 15 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

1.0 ALCANCE

Esta especificacin define los requerimientos mnimos para tubera, vlvulas y accesorios

utilizados en sistemas de procesos y de utilidades. Esta especificacin incluye materiales,

fabricacin, soldadura, inspeccin y pruebas y se debe aplicar a toda la tubera instalada o

prefabricada para instalarse por el Contratista o por orden de ste para usarse en facilidades de

produccin en tierra, incluidos B7, B15, B18, B21 y Zona Norte.

2.0 CDIGOS Y RECOMENDACIONES

2.1 La tubera debe estar diseada, construida y probada de acuerdo a la ltima edicin de

ASME B31.3, "PROCESS PIPING", y esta especificacin.

La Tubera de Vapor y Sistemas de Potencia de Centrales de Generacin debe estar

diseada, construida y probada de acuerdo a la ltima edicin de ASME B31.1, POWER

PIPING, y esta especificacin.

2.2 Los siguientes estndares (ltima edicin) deben aplicarse durante la preparacin de los

planos de tuberas y la descripcin de materiales para las clases 150 a 2500:

Process Valve Qualification Procedure API RP 591

Specification for Line Pipe API Spec 5L

Specification for Pipeline Valves API Spec 6D

Specification for Fire Test for Valves API Spec 6FA

Fire Test for Check Valves API Spec 6FD

Specification for Quality Programs for the Petroleum, Petrochemical and Natural

Gas Industry

API Spec Q1

Check Valves: Flanged, Lug, Wafer and Butt-welding API Std 594

Valve Inspection and Testing API Std 598

Steel Gate Valves - Flanged and Butt-welding Ends, Bolted Bonnets API Std 600

Steel Gate, Globe and Check Valves for Sizes DN 100 and Smaller API Std 602

Fire Test for Soft-Seated Quarter-turn Valves API Std 607

Metal Ball Valves - Flanged, Threaded and Welding Ends API Std 608

Butterfly Valves: Double-flanged, Lug and Wafer Type API Std 609

Unified Inch Screw Threads, UN and UNR Thread Form ASME B1.1

Pipe Threads, General Purpose (Inch) ASME B1.20.1

Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 ASME B16.5

Factory-Made Wrought Buttwelding Fittings ASME B16.9

Face-to-Face and End-to-End Dimensions of Valves ASME B16.10

Forged Fittings, Socket-Welding and Threaded ASME B16.11

Metallic Gaskets for Pipe Flanges: Ring-Joint, Spiral-Wound, and Jacketed ASME B16.20

Nonmetallic Flat Gaskets for Pipe Flanges ASME B16.21

Buttwelding Ends ASME B16.25

Valves Flanged, Threaded and Welding End ASME B16.34

Orifice Flanges ASME B16.36

Large Diameter Steel Flanges: NPS 26 Through NPS 60 ASME B16.47

Square and Hex Bolts and Screws - Inch Series ASME B18.2.1

Square and Hex Nuts (Inch Series) ASME B18.2.2

Tubera de Vapor y Sistemas de Potencia de Centrales de Generacin ASME B31.1

Tuberas de Proceso de Refineras y Plantas Qumicas ASME B31.3

Welded and Seamless Wrought Steel Pipe ASME B36.10

Stainless Steel Pipe ASME B36.19

Standard Marking System for Valves, Fittings, Flanges and Unions MSS SP-25

Specification for High-Test Wrought, Butt-Welding Fittings MSS SP-75

Class 3000 Steel Pipe Unions Socket Welding and Threaded MSS SP-83

Swage(D) Nipples and Bull Plugs MSS SP-95

Integrally Reinforced Forged Branch Outlet Fittings: SW, THD and BW Ends MSS SP-97

Instrument Valves for Code Applications MSS SP-105

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 16 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

2.3 Los siguientes procedimientos (ltima edicin), deben aplicarse durante la preparacin

de los planos de tuberas y la descripcin de materiales para las clases 150 a 2500:

WPS aprobados por B15 B15-ECU-50-PR-023

Montaje y Ensamblado de Estructuras de Acero B15-ECU-20-SP-009

Aislamiento Trmico B15-ECU-20-SP-015

Fabricacin e Instalacin de Tubera Enterrada y No Enterrada PAM-EC-20-PRC-005

Pruebas Hidrostticas para Tuberas de Proceso PAM-EC-20-PRC-007

Especificacin de Recubrimiento PAM-EC-50-SP-001

3.0 REQUERIMIENTOS GENERALES

3.1 Cuando existan planos de ingeniera, se debe indicar el tamao mnimo de la lnea,

presin de diseo o clase de tubera, vlvulas requeridas, etc.

Para servicios de transporte de petrleo y reinyeccin de agua, las empresas de

ingeniera deben confirmar el espesor de pared con los Clculos Hidrulicos de las

lneas.

Las mximas condiciones de diseo especificadas en el Piping Class Nota 1 son

requerimientos separados y nunca debern excederse.

3.2 Salvo que se tenga una autorizacin por escrito de PETROAMAZONAS EP las

especificaciones de materiales indicadas en esta Especificacin General se deben

respetar estrictamente en el diseo, compra y fabricacin de cada sistema de tuberas.

Cuando la tubera, vlvulas, accesorios, u otro material especificado no se puedan

obtener, se puede permitir la sustitucin de los mismos previa autorizacin por escrito de

PETROAMAZONAS EP.

3.3 La identificacin de las lneas y la identificacin de las vlvulas deben estar de acuerdo

con la seccin 11 de esta especificacin. Se pueden usar estndares de marcado e

identificacin del Contratista con la autorizacin escrita de PETROAMAZONAS EP.

3.4 Tubera

3.4.1 Todas las tuberas debern ser marcadas segn el API Spec 5L y el ASTM-

A106: nombre o marca del fabricante, especificacin, dimensiones, grado y

clase, nivel de especificacin de producto, proceso de manufactura, nmero de

colada y un nmero de identificacin.

3.4.2 El espesor de pared de la tubera debe estar de acuerdo con la Especificacin

del Sistema de Tuberas.

3.4.3 Tubera clase 150 hasta clase 2500. Tuberas de 1 NPS y menores pueden

ser roscadas, bridadas o soldadas (tipo enchufe) de acuerdo a lo indicado en la

Especificacin del Sistema de Tuberas. Tuberas de 2 NPS y mayores pueden

ser roscadas (slo para las especificaciones HA1 y HA2), soldadas a tope o

bridadas de acuerdo a lo indicado en la Especificacin del Sistema de Tuberas.

Cuando se usa soldadura tipo enchufe, las uniones se deben instalar en lugares

accesibles para permitir la remocin y reemplazo de todas las vlvulas y equipos.

Con excepcin de venteos, drenajes, toma muestras y conexiones de

instrumentos, las conexiones de tubera de 1 NPS y menores deben ser

soldadas tipo enchufe o bridadas para los siguientes servicios:

3.4.3.1 Servicio para hidrocarburos con presiones Clase 1500 y superiores.

3.4.3.2 Servicio para hidrocarburos sobre los 250 F.

3.4.3.3 Servicio para hidrocarburos sujeto a vibracin o pulsacin.

3.4.4 La tubera debe estar localizada de tal forma que no presente riesgo de golpes

sobre cabeza ni tropiezos. La mnima altura para tubera sobre cabeza es de 7

pies 0 pulgadas (2.15 m). Las lneas que se cruzan no deben tocarse.

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 17 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

3.4.5 Los sistemas de tubera deben estar diseados de tal forma que todas las

vlvulas e instrumentos puedan ser atendidos convenientemente. Cuando esto

no sea posible, se deben disear escaleras y plataformas de acuerdo con la

especificacin de PETROAMAZONAS EP: B15-ECU-20-SP-009 MONTAJE Y

ENSAMBLADO DE ESTRUCTURAS DE ACERO.

3.4.6 Las vlvulas de parada de emergencia deben estar accesibles desde las

cubiertas o desde el nivel del piso y deben estar localizadas en reas libres.

3.4.7 Todos los neplos de NPS y menores deben ser de tubera de acero sin

costura cdula 160. No se deben utilizar neplos de rosca completa. Se define

como un neplo a una seccin de tubera con una longitud de 12 o menos.

3.4.8 No se permite sellar con soldadura ninguna unin roscada.

3.4.9 Para el arranque de equipos se deben colocar filtros tipo cono o canasta

(pantallas) en las lneas de succin de los equipos, incluyendo, pero no

necesariamente limitado a bombas, compresores y medidores mecnicos y se

colocarn lo ms cerca posible de la brida de succin. Estos filtros deben tener

un rea mnima del 200% del rea de la lnea de flujo con un tamao de

perforacin mximo de 1/8. Para Especificaciones de Filtros, ver ANEXO A.

3.4.10 Conexiones de derivacin

3.4.10.1 Las derivaciones se deben realizar de acuerdo al Cuadro Estndar de

Conexiones de Derivacin para los Sistemas de Tuberas de Clases

150 a 2500.

3.4.10.2 No se deben utilizar acoples para conexiones de derivacin.

3.4.10.3 No se permiten conexiones de derivacin tipo Stub-in.

3.4.11 Durante la fabricacin, instalacin, limpieza y pintura, se debe tener especial

cuidado para mantener la granalla, polvo u otro material extrao fuera del

sistema de tubera antes de la instalacin. Antes de la aceptacin del sistema por

PETROAMAZONAS EP, el interior de la tubera debe limpiarse completamente

por el Contratista.

3.4.12 Las conexiones y vlvulas de drenaje deben colocarse en los puntos ms bajos

de las lneas. As tambin, las conexiones y vlvulas de venteo deben colocarse

en los puntos ms altos donde el gas podra quedar atrapado. Los venteos,

drenajes y conexiones de instrumentos de o menos se deben instalar usando

acoples roscados (threadolets) clase 3000# 6000#, excepto para servicios de

alta temperatura u otros servicios donde se especifique el uso de acoples

soldables (sockolets) por la Especificacin del Sistema de Tuberas.

3.4.13 Las conexiones de cupones de corrosin se deben instalar usando accesorios de

entrada tipo COSASCO. Para Especificaciones de Accesorios de Entrada,

ver ANEXO B.

3.4.14 Los cambios en los ratings de presin de los sistemas de tuberas se harn en

las vlvulas. Esta vlvula deber ser del rating de presin mas alta del sistema.

3.4.15 Las conexiones laterales (cabezales secundarios) para instrumentos en los

sistemas de gas y aire deben tener vlvulas de bloqueo a la salida del cabezal

principal y deben salir de la parte superior del cabezal principal.

3.4.16 Los empaques de aislamiento se deben instalar cuando se unan dos

componentes de tubera o materiales diferentes, para evitar la corrosin

galvnica y/o cuando se den cambios entre lneas enterradas con proteccin

catdica y areas. Slo se aceptan kits de aislamiento VCS PIKOTEK. Para

Especificaciones de Kits de Aislamiento, ver ANEXO C.

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 18 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

3.4.17 La tubera de las lneas de flujo, entre las cabezas de pozo y manifold, deben ser

recubiertas externamente con FBE (fusion bonded epoxy). Para

Especificaciones de Recubrimiento Externo con FBE, ver ANEXO K.

3.5 Bridas

3.5.1 Todas las bridas debern ser marcadas segn el ASME B16.5 y/o MSS SP-25:

pas de fabricacin, nombre o marca del fabricante, material, clase, conformidad

con la norma B16.5, tamao, cdula (si aplicase) y un nmero de identificacin.

3.5.2 Las bridas de clase 900 y mayores deben ser RTJ. Las bridas de clase 600 y

menores pueden ser de caras resaltadas (RF) o de caras planas (FF), con un

terminado estriado espiral.

3.5.3 Bridas de cuello soldable son requeridas para todas las tuberas bridadas.

3.5.4 Las bridas de acero utilizadas para acoplarse con equipos que tienen bridas de

hierro fundido, hierro dctil o aluminio deben tener las caras maquinadas planas

(FF).

3.5.5 Los agujeros para los pernos de las bridas deben estar encuadrados con la

tubera horizontal y con las lneas de centro verticales.

3.5.6 Las bridas API, clasificadas como 2000, 3000 o 5000 PSI deben ser del tipo 6B.

Para descripcin de Bridas API, ver ANEXO I.

3.6 Accesorios

3.6.1 Todos los accesorios debern ser marcados (si aplica) segn el ASME B16.9,

ASME B16.11 y/o MSS SP-25: pas de fabricacin, nombre o marca del

fabricante, material, conformidad con la norma, tamao, cdula o clase y un

nmero de identificacin.

3.6.2 Todos los codos de 90 soldables deben ser de radio largo, a menos que est

restringido por el espacio disponible. Si se utilizan codos soldables de radio

corto, se debe disminuir su clase a un 80% de la presin de trabajo calculada

permitida.

3.6.3 Las reducciones excntricas se deben usar con el lado recto (plano) hacia arriba

cuando se requiera reducir el tamao de la lnea para las conexiones de succin

de las bombas.

3.6.4 Los codos con extremos macho hembra no se deben usar sin la autorizacin

de PETROAMAZONAS EP.

3.6.5 Los anillos de purga deben ser de acuerdo al material de la tubera, acero

inoxidable o acero carbn. Para Especificaciones de Anillos de Purga, ver

ANEXO D.

3.6.6 Todos los codos correspondientes a las lneas de flujo, entre cabezas de pozo y

manifold, deben ser recubiertos externamente con FBE (fusion bonded epoxy).

Para Especificaciones de Recubrimiento Externo con FBE, ver ANEXO K.

3.7 Vlvulas

3.7.1 Los materiales de las vlvulas que se especifican a continuacin son las

mnimas requeridas por PAM EP. En el caso de que existan los mismos

materiales con un mejor rendimiento probado para la aplicacin especfica, su

aceptacin ser responsabilidad del evaluador tcnico.

3.7.2 Todas las vlvulas debern ser marcadas segn el ASME B16.34, API Spec 6D

y/o MSS SP-25.

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 19 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

3.7.3 Todos los fabricantes de vlvulas (compuerta, globo, retencin y mariposa, con

excepcin de las vlvulas API 6D) deben aplicar la recomendacin API RP 591:

PROCESS VALVE QUALIFICATION PROCEDURE. Esta recomendacin

prctica provee recomendaciones para la evaluacin de un programa de

construccin y aseguramiento de calidad con el propsito de determinar la

capacidad del fabricante para proveer vlvulas nuevas fabricadas de acuerdo

con los estndares API aplicables.

3.7.4 Las vlvulas deben ser suministradas de acuerdo a la lista de vlvulas

aprobadas. Vlvulas alternas que cumplen con los requerimientos de la lista de

vlvulas se pueden usar solamente despus de obtener la aprobacin por

escrito de PETROAMAZONAS EP.

3.7.5 Todas las vlvulas deben estar instaladas de acuerdo a los rangos de

temperatura y presin recomendadas por el fabricante y dentro de los lmites del

cdigo ASME B16.34 para el servicio correspondiente. Las bridas y las caras de

las bridas deben coincidir con lo especificado por la especificacin de la clase de

tubera correspondiente. El espesor de pared de las vlvulas de compuerta,

globo y retencin debe estar bajo las especificaciones API 600 y API 602.

3.7.6 Todas las vlvulas para servicio de hidrocarburos deben ser de acero. Las

vlvulas de 2 y mayores deben ser bridadas y las de 1 y menores pueden ser

roscadas, bridadas o soldadas (tipo enchufe) tal como lo indica esta

especificacin. El Contratista no debe aumentar bridas en las conexiones

roscadas o soldadas a menos que haya una aprobacin especfica. Vlvulas

secundarias roscadas deben ser fcilmente removibles.

3.7.7 Las vlvulas del Sistema Contra Incendios deben ser:

Vlvulas de 3 y menores: Cuerpo de bronce fundido. Extremos roscados.

Vlvulas de 4 y mayores: Cuerpo de hierro fundido y el asiento de bronce.

Extremos bridados tipo cara plana (FF).

3.7.8 Las vlvulas de bola deben ser diseadas a prueba de fuego y deben cumplir las

siguientes especificaciones adicionales:

3.7.8.1 Las vlvulas de bola deben ser tipo montada sobre muones con sellos

secundarios de metal, de acuerdo a lo siguiente:

Para la Clase 150: 8 y mayores.

Para la Clase 300: 4 y mayores.

Para las Clases 600, 900, 1500 y 2500: 2 y mayores.

Todas las vlvulas tipo montada sobre muones deben ser

suministradas con graseros para el vstago y para los sellos.

3.7.8.2 No se requieren sellos secundarios de metal para vlvulas de 1 o

menores.

3.7.8.3 Se deben suministrar vlvulas con volantes acoplados a sistema de

engranajes para todas las vlvulas de un cuarto de vuelta en cualquier

aplicacin donde el torque inicial exceda las 50 libras pie.

Generalmente:

6 y mayores Clases 150 y 300.

4 y mayores Clases 600, 900 y 1500.

2 y mayores Clase 2500.

3.7.8.4 Para procesos con hidrocarburos y aire de instrumentos, las vlvulas de

bola de 1 y menores deben ser con el cuerpo ASTM-A351 Gr CF8M

o 316 SS, con bola y vstago de 316 SS.

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 20 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

3.7.9 Las vlvulas de bloqueo deben ser colocadas aguas abajo de las vlvulas de

retencin para permitir el aislamiento de stas y poder sacarlas de servicio sin

necesidad de despresurizar el sistema que est aguas abajo. Las vlvulas de

venteo, cuando aplique, deben estar instaladas para facilitar la despresurizacin

de la tubera aguas abajo de la vlvula de retencin y aguas arriba de la vlvula

de retencin para realizar pruebas de fuga en las mismas.

3.7.10 Las vlvulas de retencin pueden ser de flujo completo o flujo reducido, del tipo

clapeta en todos los casos, excepto para uso con bombas reciprocantes o

compresores donde se usan vlvulas de retencin de bola o de pistn o donde

las especificaciones del sistema permitan vlvulas de retencin tipo galleta en los

servicios de utilidad.

3.7.10.1 Todas las vlvulas de retencin de 2 y mayores deben ser

suministradas con las tapas empernadas.

3.7.10.2 Todas las vlvulas de retencin de 4 y mayores deben tener un

agujero con tapn de NPT en el cuerpo.

3.7.11 Las vlvulas de compuerta, globo y retencin deben tener asientos endurecidos

(con stellite o similar). Las vlvulas de retencin pueden tener asientos

removibles o integrales. Las vlvulas de globo pueden ser del tipo recto o

angular de acuerdo a la configuracin de la tubera.

3.7.12 Todas las vlvulas de compuerta y globo deben ser OS&Y (tornillo y vstago

externo). No se aceptan vlvulas del tipo de vstago roscado interno.

3.7.13 Las vlvulas de aguja se deben suministrar de acuerdo a los planos de

fabricacin y de montaje. Las vlvulas de aguja, excepto cuando se requieren en

servicios de alta presin y/o alta temperatura, deben ser de 316 SS con asientos

blandos.

3.7.14 Para vlvulas de bola, la rotacin de la vlvula debe ser en sentido contrario de

las agujas del reloj cuando se mire el vstago de tal forma que la apertura inicial

de la vlvula sea en el fondo de la tubera.

4.0 MATERIALES

4.1 Todos los materiales (Tubera, Accesorios, Bridas, etc.) deben incluir: pas de

fabricacin, nombre y/o logo del fabricante y nmero de colada y contar con certificados

de calidad para permitir su trazabilidad.

4.2 Todos los materiales para Tubera, Vlvulas, Accesorios, Bridas, Pernos, Empaques y

Partes Especiales, deben estar de acuerdo con las especificaciones del Piping Class.

4.3 El sistema de gestin de calidad requerido para el diseo, desarrollo, produccin,

instalacin y servicio de productos en la industria petrolera, debe estar bajo API

especificacin Q1: Specification for Quality Programs for the Petroleum, Petrochemical

and Natural Gas Industry.

4.4 Toda Tubera, Vlvulas, Accesorios, Bridas, Pernos, Empaques y Partes Especiales,

suministrados por el Contratista deben ser nuevos y sin uso, libres de escamas, golpes,

fisuras, laminaciones, agujeros y oxidacin perjudicial.

4.5 PETROAMAZONAS EP se reserva el derecho a inspeccionar todos los materiales y

componentes suministrados por el Contratista, y para rechazar aquellos que considere

inservibles para su uso y no estn conformes con esta especificacin.

4.6 Para servicios de hidrocarburos no se deben instalar tuberas, vlvulas o accesorios de

cobre, aluminio, hierro fundido, hierro maleable, hierro acerado o semi-acero. Vlvulas

con cuerpos de bronce o hierro fundido se usarn solamente para el sistema contra

incendios y vlvulas de pie.

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 21 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

4.7 El material para sellar las roscas de la tubera debe ser cinta de Tefln. Se debe tener

especial cuidado en no colocar la cinta dentro del tubo. Se debe retirar el exceso de cinta

antes de pintar la tubera.

4.8 Toda tubera nueva, bridas y accesorios deben estar marcadas con la identificacin del

material. Todas las tuberas deben estar acompaadas de los reportes de prueba de los

materiales y las bridas y accesorios deben tener el certificado de material del fabricante.

4.9 Todas las roscas galvanizadas se deben pintar despus del montaje, utilizando

galvanizado en fro.

4.10 El material de relleno de todos los empaques debe ser Grafito Flexible (FG) y

solamente se aceptarn de procedencias USA e ITALIA. Para Especificaciones de

Empaques, ver ANEXO E.

4.11 Todas las juntas soldadas asociadas la las lneas de flujo, entre las cabezas de pozo y

manifold, deben ser recubiertas con 3M Scotchkote 323.

5.0 SOPORTES DE TUBERA

5.1 Se debe soportar la tubera para prevenir el pandeo, esfuerzos mecnicos y vibraciones.

La tubera debe estar adecuadamente soportada sobre racks, columnas o soportes

individuales.

5.2 No se permite soldar soportes directamente a la tubera, con excepcin de las zapatas

usadas en tuberas aisladas trmicamente, a menos que se tenga la aprobacin escrita

de PETROAMAZONAS EP.

5.3 Los pernos U para asegurar la tubera deben ser galvanizados con una camisa de

polietileno de 1/16 de espesor, arandelas planas y doble tuerca. Un espaciador de

neopreno o polietileno de 1/8 de espesor se debe colocar entre la tubera y el soporte.

El dimetro mnimo para los pernos U debe ser 1/4. Para Dimensiones de pernos U,

ver ANEXO J.

5.4 Para tuberas de 8 y mayores y para cualquier tubera menor que est sujeta a excesiva

vibracin mecnica o en lneas donde la presin es por pulsos (por ejemplo, en tuberas

de equipos rotativos), sta debe estar firmemente ajustada a soportes de tubera rgidos

con abrazaderas empernadas en lugar de pernos U. Los pernos de las abrazaderas

deben tener doble tuerca.

5.5 La tubera que est sujeta a expansin puede estar suspendida en eslabones giratorios

tipo soportes colgantes o soportadas desde abajo. Si se las soporta desde abajo, se

deben colocar zapatas de acero deslizables y guas. Se deben colocar tambin anclajes

y topes para mantener los movimientos y las fuerzas dentro de lmites aceptables.

6.0 SOLDADURA

6.1 Toda la soldadura de tubera debe realizarse de acuerdo con el Procedimiento B15-ECU-

50-PR-023 WPS APROBADOS POR B15.

6.2 Las juntas soldadas de acero al carbono deben ser tratadas trmicamente (alivio de

tensiones) de conformidad con ASME B31.3 cuando el espesor nominal es mayor a .

La tubera debe ser calentada y luego enfriada de acuerdo con el prrafo UCS-56 de la

seccin VIII, ASME.

7.0 INSPECCIN

La inspeccin de la tubera debe realizarse de acuerdo con el Procedimiento PAM-EC-20-PRC-

005 FABRICACIN E INSTALACIN DE TUBERA ENTERRADA Y NO ENTERRADA. Si se

usan las especificaciones del Contratista, estas deben presentarse a PETROAMAZONAS EP

para su aprobacin.

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 22 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

8.0 PRUEBAS HIDROSTTICAS

Todas las pruebas hidrostticas a tuberas deben ser realizadas de acuerdo con las regulaciones

de la ARCH (Agencia de Regulacin y Control Hidrocarburfero) y el Procedimiento PAM-EC-20-

PRC-007 PRUEBAS HIDROSTTICAS PARA TUBERAS DE PROCESO

9.0 PINTURA Y RECUBRIMIENTOS

9.1 La preparacin de la superficie y pintura de la tubera, vlvulas y accesorios debe ser

realizada de acuerdo a la especificacin de PETROAMAZONAS EP: PAM-EC-50-SP-

001 "ESPECIFICACIN DE RECUBRIMIENTO.

9.2 Toda la superficie de las bridas y de los agujeros para los pernos, excepto las caras de

las bridas, deben estar recubiertas con primer y con la capa intermedia antes del

montaje. Los accesorios de tubera no deben ser pintados con el primer hasta que se

haya terminado la prefabricacin en el taller. La capa final de la pintura debe aplicarse

una vez que el sistema de tuberas haya sido totalmente ensamblado y probado

hidrostticamente.

10.0 AISLAMIENTO TRMICO

La tubera debe tener aislamiento trmico donde indiquen los planos AFC (aprobados para

construccin). El aislamiento se debe aplicar de acuerdo a lo indicado en la especificacin de

PETROAMAZONAS EP: B15-ECU-20-SP-015 "AISLAMIENTO TRMICO".

11.0 IDENTIFICACIN DE VLVULAS Y TUBERA

La siguiente es la nomenclatura que se utilizar en la identificacin de lneas y vlvulas

diseadas en los planos mecnicos y en los diagramas de proceso de tubera:

11.1 Identificacin de lneas

11.1.1 Cada lnea en los planos mecnicos y en los diagramas de proceso de tubera

debe estar claramente identificada indicando la especificacin de la tubera y el

tamao nominal de la lnea.

A continuacin se tiene un ejemplo:

3 - GF - 1500 - AA1 - 00 Especial (si se requiere)

Especificacin de la tubera

Nmero de lnea

Letras de identificacin del servicio

Tamao nominal de la tubera

11.1.2 Servicio de la lnea

Cada lnea debe estar indicada con las siguientes abreviaciones:

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 23 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

SERVICIO ABREVIATURA

Air Instrument AI

Air Utility AU

Air Engine Starter PA

Atmospheric Vent FV

Blow Down (Low Temp to 50 F) BD1

Condensate C

Corrosive Condensate CC

Chemical Injection IL

Circulation Water CW

Combustion air drains AD

Cooling Water RW/SW

Demineralized Water ZW

Diesel DF

Drain Gravity DRG

Drain Overflow DO

Drain Pressure DRP

Fire Water FW

Foam F

Fuel Raw CR

Gas G

Gas Diesel GD

Gas Fuel GF

Gas Fuel (Hot or Dry Service) GF1

Gas Fuel (Wet or Condensing Service) GF2

Gas Liquefied Propane GLP

Gas Process GP

Gas Produced PG

Gasoline GAS

Gas Flare non corrosive HF

Natural Gas NG

Heat Media HM

High Pressure Steam HS

Low Pressure Condensate LC

Low Pressure Steam LS

Lube Oil LO

Oil Dry OD

Oil Fuel Return OFR

Oil Hot Return OHR

Oil Hot Supply OHS

Oil LACT OL

Oil Produced OP

Oil Reject OR

Oil Wet OW

Process Fluid PF

Process Liquids (Chemical Injection) PL

Process Hydrocarbons non-corrosive (gas/liquid) HNC

Process corrosive moderate by CO2 in hydrocarbons (gas/liquid) HMC

Process corrosive strong by CO2 in hydrocarbons (gas/liquid) HSC

Purge Continuous CB

Purge Flashing BB

Purge Water Tower YW

Steam V

Take Samples NS

Treated Water TW

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 24 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

Ventilation Air AV

Water Fireline WFL

Water Fresh WF

Water Heaters HW/IW

Water Hot Return WHR

Water Injection Production (heavy corrosion) WIP

Water Produced WP

Water Raw WR

Water Soft WS

Water Supply BW

Water Utility WU

Water Waste WW

Water Wash WH

11.2 Sistema de identificacin de vlvulas

Cada vlvula en los planos mecnicos y en los diagramas de proceso de tubera debe

estar identificada tal como se muestra a continuacin para indicar el tamao,

especificacin, tipo de vlvula, caras de la vlvula y tipo especial de vlvula. Cada

vlvula debe tener la especificacin estampada y/o una etiqueta de acero inoxidable

asegurada a la vlvula mediante un alambre de acero calibrado. Esta etiqueta debe

permanecer en su lugar hasta completar la fabricacin.

4 AA1 2 R F

Tipo especial de vlvula (si se requiere)

Caras de la vlvula

Tipo de vlvula

Especificacin de la tubera

Tamao de la vlvula

11.2.1 Descripcin

TIPO EXTREMOS

VLVULA ESPECIAL

Si es requerido

1 Compuerta F Cara plana - Estndar

2 Bola G Conector Clamp B Doble bloqueo y purga

3 Tapn J Junta de anillo F Paso completo

4 Globo R Cara resaltada FM Hembra x Hembra

5 Retencin S Roscada H Alta temperatura

6 Aguja U Unin L Oreja

7 Mariposa W Soldada a tope LT Baja temperatura

8 Pie X Especial P Pistn

9 Calibracin Y Enchufe x roscado S Modelo corto

0 Estranguladora (900# - 1500#) Z Enchufe SG Compuerta plana

W Galleta

X Especial

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 25 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

11.3 La siguiente identificacin de especificaciones de tuberas es usada en planos de

fabricacin.

ESPEC RATING ANSI IDENTIFICACIN DE SERVICIO MATERIAL CDIGO

AA1 ANSI 150 RF

AD, AV, BW, C, CR, CW, DO, DF, DRG, DRP, F,

FV, G, GAS, GD, GF, GLP, GP, HF, HM, HNC,

HMC, HSC, HW/IW, LO, NG, OD, OFR, OHR,

OHS, OL, OP, OR, OW, RW/SW, TW, WH, WFL,

WHR, WP, WR, WS, WW

CS ASMEB31.3

AE2 ANSI 150 RF BB, CB, LC CS ASMEB31.1

AL1 ANSI 150 RF BD1 CS ASMEB31.3

AS1 ANSI 150 RF CC, GP 304 SS ASMEB31.3

AS2 ANSI 150 RF GP, PL, C, GF, IL, HF, NS, PF, ZW 316 SS ASMEB31.3

AX1 ANSI 150 RF OP, WP CS Int. Coated ASMEB31.3

BA1 ANSI 300 RF G, GF, GP, OP, WP, DF, NG, HF, HNC, HMC, PA CS ASMEB31.3

BE1 ANSI 300 RF LS CS ASMEB31.1

BL1 ANSI 300 RF BD1 CS ASMEB31.3

BS1 ANSI 300 RF GP 304 SS ASMEB31.3

BS2 ANSI 300 RF CC, GP, PL 316 SS ASMEB31.3

BX1 ANSI 300 RF OP, WP CS Int. Coated ASMEB31.3

CA1 ANSI 600 RF C, G, GF, GP, OL, V CS ASMEB31.3

CS1 ANSI 600 RF GP 304 SS ASMEB31.3

CS2 ANSI 600 RF GP, PL 316 SS ASMEB31.3

CX1 ANSI 600 RF OP, WP CS Int. Coated ASMEB31.3

DA1 ANSI 900 RTJ GP CS ASMEB31.3

DE1 ANSI 600 RF BB, BW, CB, DRP, HS CS ASMEB31.1

DS1 ANSI 900 RTJ GP 304 SS ASMEB31.3

DS3 ANSI 900 RTJ GP Duplex SS ASMEB31.3

EA1 ANSI 1500 RTJ GP, WP CS ASMEB31.3

ES1 ANSI 1500 RTJ GP 304 SS ASMEB31.3

ES3 ANSI 1500 RTJ GP Duplex SS ASMEB31.3

EX1 ANSI 1500 RTJ OP, WP CS Int. Coated ASMEB31.3

FA1 ANSI 2500 RTJ GF1, HSC, WIP CS ASMEB31.3

FS1 ANSI 2500 HUB GF2 304 SS ASMEB31.3

H4 ANSI 2500 HUB PG 304 SS ASMEB31.3

HA1 ANSI 150 RF AI, AU, WF, WU, YW CS Galv. ASMEB31.3

HA2 ANSI 150 RF WF (Deluge system) CS Galv. ASMEB31.3

L ANSI 150 RF FW CS ASMEB31.3

11.2 Tabla de Conversiones

Esta tabla es el resultado de la unificacin del Piping Class utilizado en el B-18 y del Piping Class

del B-15. En cada documento exista su propia designacin para la especificacin de la tubera

(Piping Specification).

En el Piping Class Unificado se mantiene la especificacin de la tubera del B-15, y se ha

modificado nicamente la del B-18, de acuerdo a la siguiente tabla de conversin:

TABLA DE CONVERSIONES

ESPECIFICACIN NUEVA

ZNO

ESPECIFICACIN ANTERIOR

B-18

AA1 AA1-AA2-AA3

AE2 AE2

AG2 AG2

AS2 AK0-AM0-DK0

HA1 AW1-AX1

BA1 BA1-BA2

Standard Specification for

Pipe, Valves & Fittings

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 26 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

BE1 BE1

BS1 BM1

DA1 DA1

DE1 DE1

H4 FS2

12.0 CONEXIONES DE DERIVACIN

Las derivaciones de tuberas deben ser instaladas de acuerdo con el siguiente Cuadro de

Conexiones de Derivacin.

TABLA DE CONEXIONES DE DERIVACIN

[PULGADAS]

DERIVACIN

24 20 18 16 14 12 10 8 6 4 3 2 1.5 1 .75 .5

P

R

I

N

C

I

P

A

L

24 T RT RT RT RT RT W W W W W W S S S S

20 T RT RT RT RT RT W W W W W S S S S

18 T RT RT RT RT W W W W W S S S S

16 T RT RT RT RT W W W W S S S S

14 T RT RT RT W W W W S S S S

12 T RT RT RT W W W S S S S

10 T RT RT W W W S S S S

8 T RT RT W W S S S S

6 T RT RT W S S S S

4 T RT RT S S S S

3 T RT S S S S

2 T T/S S S S

1.5 SWT SW RT SW RT SW RT

1 SWT SW RT SW RT

.75 SWT SW RT

.5 SWT

LEYENDA

T Te soldable a tope

RT Te reducida soldable a tope

S Sockolets (SOL) / Threadolet (TOL)

W Weldolet (WOL)

T/S Te recta soldable + reduccin concntrica

SWT Te soldable Socket Weld / Te roscada

SW RT Te soldable Socket Weld con reduccin / Te roscada con reduccin

Standard Specification for Pipe,

Valves & Fittings

Piping Specification AA1

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 27 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

CLASS: ANSI 150#

CS, RF

SERVICE: AD, AV, BW, C, CR, CW, DO, DF, DRG, DRP, F, FV, G, GAS, GD, GF, GLP, GP,

HF, HM, HNC, HMC, HSC, HW/IW, LO, NG, OD, OFR, OHR, OHS, OL, OP, OR, OW,

RW/SW, TW, WH, WFL, WHR, WP, WR, WS, WW

SIZE 1/2 3/4 1 1 1/2 2 3 4 6 8 10 12 16 20 24

PIPE

SCH 160 SCH 80 STD

THD/PE BE, SMLS / ERW-HFI

ASTM-A106 GR B ASTM-A106 GR B, API-5L GR B

FLANGES

150# RF Flange Bore to Match Pipe Wall

THD/SW 150# RF/FF, WN

ASTM-A105

FITTINGS

3000# Wall Thickness to Match Pipe

THD/SW BW, SMLS

ASTM-A105 ASTM-A234 GR WPB

BRANCH

(OLETS)

3000# SCH 80 STD

THD/SW BW

ASTM-A105

V

A

L

V

E

S

GATE CA1-1S AA1-1R

BALL CA1-2S, CA1-2SF AA1-2R, AA1-2RF

PLUG N/A

GLOBE CA1-4S AA1-4R

CHECK CA1-5S AA1-5R

NEEDLE

DA1-6S

DA1-6SFM

N/A

BUTTERFLY N/A AA1-7RL, AA1-7RW

FOOT N/A AA1-8F

GAUGE DA1-9S N/A

BOLTING

(Note 3)

Bolts: ASTM-A193 GR B7, Fluorocarbon Coated Threaded and dimensions per

ASME B16.5 Nuts: ASTM-A194 GR 2H, Fluorocarbon Coated Heavy Hex Nuts

GASKETS

150# RF, Thk 1/8, 316 SS Spiral Wound, filler material: Flexible Graphite

(FG) with CS outer ring (Flexitallic Style CG, Lamons Style WR, Garlock

Style RW ONLY USA. Carrara Style SWC - ONLY ITALY)

150# FF, Thk 1/8", Comp. Non-asbestos, Synthetic fiber with NBR binder

(Flexitallic, Lamons, Garlock - ONLY USA)

PRESS./TEMP. RATINGS

F PSIG

REF. ASME B16.5

NOTES: -20/100 285

1. Maximum design conditions: 250

F - 245 PSIG (Group 1.1) 200 260

2. Piping 1 or smaller subject to vibration or pulsation shall be SW or flanged 250 245

3. For Bolts dimensions, see ATTACHMENT F

4. For ANSI Pipe Schedules, see ATTACHMENT G

5. TDH/SW for smaller diameters is the responsibility of the designer to choose the

appropriate connection endpoints for the service

Standard Specification for Pipe,

Valves & Fittings

Piping Specification AA1

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 28 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

TYPE SYMBOL SIZE DESCRIPTION

ACCEPTABLE

BRANDS

GATE CA1-1S

1 and

Smaller

Class 800# (1975# CWP), CS body and

bonnet, (ASTM-A105), Trim 8, HF stellited

seats, threaded ends per ASME B1.20.1,

OS&Y, bolted bonnet, solid wedge gate.

Hand wheel operated. Design per API

602. Test per API 598

Bonney Forge

DHV

DSI

Newco

Smith

Velan

Vogt

AA1-1R 2 4 Class 150#, CS body and bonnet (ASTM-

A216 Gr WCB or ASTM-A105), Trim 8, HF

stellited seats. RF flanged ends per ASME

B16.5, OS&Y, bolted bonnet, flexible

wedge gate, Hand wheel operated.

Design per API 600. Test per API 598

Bonney Forge

Crane

DHV

DSI

MTS

Newco

Velan

Vogt

Walworth

AA1-1R 6 and Larger Class 150#, CS body and bonnet (ASTM-

A216 Gr WCB or ASTM-A105), Trim 8, HF

stellited seats. RF flanged ends per ASME

B16.5, OS&Y, bolted bonnet, flexible

wedge gate, Gear operated. Design per

API 600. Test per API 598

BALL CA1-2S

1 and

Smaller

1440 PSI @ 100 F, SS body (ASTM-

A351 Gr CF8M or ASTM-A182 F316), 316

SS ball and stem, filled Teflon seats,

threaded ends per ASME B1.20.1,

reduced port, lever operated. Fire safe.

Design per API 608. Test per API 598

AOP

Balon

KF

MTS

Nibco

Nutron

PBV

Quadrant

Velan

Warren

WKM

CA1-2SF

1 and

Smaller

1440 PSI @ 100 F, SS body (ASTM-

A351 Gr CF8M or ASTM-A182 F316), 316

SS ball and stem, filled Teflon seats,

threaded ends per ASME B1.20.1, full

port, lever operated. Fire safe. Design per

API 608. Test per API 598

AA1-2R 2 6 Class 150#, CS body (ASTM-A216 Gr

WCB or ASTM-A105), CS 1 mil ENP ball

and stem. RF flanged ends per ASME

B16.5, reduced port, lever or gear (6)

operated, Floating ball. Fire safe. Design

per API 608. Test per API 598

AOP

Balon

Cameron

DHV

Grove

KF

MTS

Nibco

Nutron

PBV

Quadrant

TK

Velan

WKM

AA1-2RF 2 6 Class 150#, CS body (ASTM-A216 Gr

WCB or ASTM-A105), CS 1 mil ENP ball

and stem, RF flanged ends per ASME

B16.5, full port, lever or gear (6)

operated. Floating ball. Fire safe. Design

per API 608. Test per API 598 , and

ASME 16.34

Standard Specification for Pipe,

Valves & Fittings

Piping Specification AA1

Departamento: FIC

Cdigo No.: PAM-ZNO-50-SP-004

Revisin : 0

Pgina No.: 29 de 160

La informacin del presente documento es propiedad exclusiva de PETROAMAZONAS EP y no deber ser usada para otros propsitos distintos a los especificados

TYPE SYMBOL SIZE DESCRIPTION

ACCEPTABLE

BRANDS

BALL AA1-2R 8 and Larger Class 150#, CS body (ASTM-A216 Gr

WCB or ASTM-A105), CS 1 mil ENP ball

and stem, RF flanged ends per ASME

B16.5, reduced port, gear operated.

Trunnion mounted, double block and

bleed and sealant injection fittings. Fire

safe. Design and test per API 6D

AOP

Balon

Cameron

DHV

Grove

KF

MTS

Nibco

Nutron

PBV

Quadrant

TK

Velan

WKM

AA1-2RF 8 and Larger Class 150#, CS body (ASTM-A216 Gr

WCB or ASTM-A105), CS 1 mil ENP ball

and stem, RF flanged ends per ASME

B16.5, full port, gear operated. Trunnion

mounted, double block and bleed and

sealant injection fittings. Fire safe. Design

and test per API 6D

GLOBE CA1-4S

1 and

Smaller

Class 800# (1975# CWP), CS body and

bonnet (ASTM-A105), Trim 8, HF stellited

seats, threaded ends per ASME B1.20.1,

OS&Y, bolted bonnet. Hand wheel

operated. Design per API 602. Test per

API 598

Bonney Forge

DHV

DSI

Newco

Smith

Velan

Vogt

AA1-4R 2 and Larger Class 150#, CS body and bonnet (ASTM-

A216 Gr WCB or ASTM-A105), Trim 8,

HF stellited seats, RF flanged ends per

ASME B16.5, OS&Y, bolted bonnet. Hand