Professional Documents

Culture Documents

The Ultralight

Uploaded by

Alexandre S. CorrêaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Ultralight

Uploaded by

Alexandre S. CorrêaCopyright:

Available Formats

The Ultralight

Warning: This design has not been tested. Use at your own risk.

The Concept

A shortened version of the Modernistic. Pine framing on the outside. Walls are

1/4" moisture resistant luan. Room in galley for stove. Storage under the counter.

Motorcycle battery under counter. 1 light in galley. 1 light in cabin. 1 shelf in cabin.

Goal is under 500#, tongue weight of 75#. 4 X 8 overall.

Mike Schneider 2006

Mike Schneider 2006

Mike Schneider 2006

Mike Schneider 2006

Mike Schneider 2006

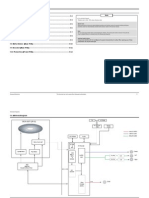

Ultralight Profile using x,y coordinates

X, Y

6 3/4, 0

3 1/4, 3

1 5/16, 6

5/16, 9

0, 12

1/4, 15

7/8, 18

2 1/16, 21

3 5/8, 24

5 13/16, 27

8 5/8, 30

12, 33

16 1/4, 36

21 11/16, 39

24, 40 1/8

27, 41 3/8

30, 42 1/2

33, 43 1/2

36, 44 3/8

39, 45 1/8

42, 45 13/16

45, 46 3/8

48, 46 7/8

51, 47 1/4

54, 47 9/16

57, 47 3/4

60, 47 15/16

63, 48

66, 48

69, 47 5/8

72, 47 1/8

75, 46 3/8

78, 45 1/4

81, 43 7/8

84, 42 1/16

87, 39 3/4

90 5/8, 36

92 5/8, 33

94 3/16, 30

95 1/4, 27

95 7/8, 24

96, 21

95 7/8, 18

95 3/8, 15

94 5/8, 12

93 1/2, 9

92, 6

90, 3

87 7/16, 0

Top of door

X, Y

53, 44.45

57, 44.78

60, 44.93

63, 45

66, 44.94

69, 44.64

72, 44.06

75, 43.2

78, 42

81, 40.43

If you dont like x,y coordinates, Andrew has a drawing for you

Andrew Gibbens 2006

Andrew Gibbens 2006

Andrew Gibbens 2006

Andrew Gibbens 2006

Andrew Gibbens 2006 Andrew Gibbens 2006

A view of the cabinets

There are a couple different options for the tongue. This one uses 2x2x1/4 tubing.

Mike Schneider 2006

Mike Schneider 2006

This one uses the channel that comes with the HF 1175# trailer

Regardless of which tongue option you choose, youll need to reinforce your tounge mounting

with pieces of bar stock, as shown in red in this picture.

Mike Schneider 2006

Mike Schneider 2006

The tongue extends beyond the body by 22.

This allows a maxium of 45 articulation with your automobile.

Mike Schneider 2006

Andrew Gibbens 2006

First you need a sturdy construction table.

Layout the profile and use lengths of dowels with the screw offset to allow fine adjustment to

the line of the profile.

Mike Schneider 2006

Mike Schneider 2006

A Closer look at the lengths of dowels with offset screw..

Mike Schneider 2006

Lay up and glue the strips (1/8 strips) NOTE: 1

st

two strips need to be knot free

Lots of clamps are needed..

Mike Schneider 2006

Mike Schneider 2006

You may want to use a clamp like this to hold the strips down to the table

You may want to use a narrower clamping strip than in this picture.

Mike Schneider 2006

This is what it should look like

A suggested method of smoothing the edges.

Mike Schneider 2006

Mike Schneider 2006

In this picture you can see the part of the framing that is going to be above the

door.

In this picture you can see where the hatch begins... in other words, what you are

looking at is the notch for the hatch insulation...

Mike Schneider 2006

Mike Schneider 2006

And in this picture you can see where the hatch ends...(at the clamp)

With the last two layers of lamination on, there was no springback at all.

Next I take the whole mess outside and run it thru the thickness planer!

Mike Schneider 2006

I've now got the swooshdrop on the plywood side, ready for glue up...

But before I can start gluing, I have to pull some wires for the marker lights, and

whatever else I need. Once it's glued, there's no more wire pulling, at least not thru

the sides...

Mike Schneider 2006

Mike Schneider 2006

Cut the groove in the bottom piece for the marker lights and taillights.

Then I glued and clamped that bottom piece down

Mike Schneider 2006

Mike Schneider 2006

Axle support assembly. The vertical piece in the back gets cut off

Mike Schneider 2006

You might also like

- Building A 1/2a Control Line StunterDocument35 pagesBuilding A 1/2a Control Line StunterHeman Lee100% (3)

- Boat Building Simplified - Being a Practical Guide to the 'Ashcroft' Method of Building, Rowing, Sailing and Motor BoatsFrom EverandBoat Building Simplified - Being a Practical Guide to the 'Ashcroft' Method of Building, Rowing, Sailing and Motor BoatsRating: 1 out of 5 stars1/5 (1)

- Weekend TrailerDocument11 pagesWeekend TrailerDavid ReasterNo ratings yet

- Vintage Playground Plans 1950s PDFDocument39 pagesVintage Playground Plans 1950s PDFAlexandre Mello100% (1)

- Build Your Own Go Kart Chassis - Go Kart Frame Plans & MeasurementsDocument15 pagesBuild Your Own Go Kart Chassis - Go Kart Frame Plans & Measurementsandyroads2No ratings yet

- Stitch and Glue MethodDocument61 pagesStitch and Glue Method69x4100% (1)

- The Infinite Oval: Tools For WoodworkingDocument2 pagesThe Infinite Oval: Tools For Woodworkingoqab18No ratings yet

- Kid-Powered "Squaris" WheelDocument6 pagesKid-Powered "Squaris" WheelzebrazeroNo ratings yet

- Čamac Od KedraDocument58 pagesČamac Od KedraБ. А.No ratings yet

- Tent Pitching NotesDocument21 pagesTent Pitching NotessnguidemynahNo ratings yet

- Teardrop TrailerDocument5 pagesTeardrop Trailerlouie duck100% (2)

- Aircarflighttesting: by Angus LaidlawDocument3 pagesAircarflighttesting: by Angus LaidlawJimNo ratings yet

- CLC Northeaster Dory Lug Addendum WebDocument26 pagesCLC Northeaster Dory Lug Addendum Webcipx2100% (3)

- Let's Build A Can Stirling Engine Step 1 - Material Preparation and StructureDocument6 pagesLet's Build A Can Stirling Engine Step 1 - Material Preparation and Structureulises sosaNo ratings yet

- How To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsDocument24 pagesHow To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsJose German Ojeda CruzNo ratings yet

- The Hopper 4X8 PlansDocument22 pagesThe Hopper 4X8 PlansjordannwspNo ratings yet

- Minibeep Mba80bDocument14 pagesMinibeep Mba80bAparecido Nascimento Dos SantosNo ratings yet

- DIY Outdoor Chair - Angela Marie MadeDocument10 pagesDIY Outdoor Chair - Angela Marie MademrcongamanNo ratings yet

- 42SWP22 Lawn SweeperDocument12 pages42SWP22 Lawn SweeperPurpleRyderNo ratings yet

- Camper Plans v1Document12 pagesCamper Plans v1Denis FaureNo ratings yet

- Build Your Own French Doors - Popular Woodworking MagazineDocument34 pagesBuild Your Own French Doors - Popular Woodworking Magazinekostas1977No ratings yet

- One Sheet SampanDocument5 pagesOne Sheet Sampanleather_nunNo ratings yet

- Build MI's Tornado!: by John CapotostoDocument3 pagesBuild MI's Tornado!: by John CapotostoJim100% (1)

- Youngsters T Bucket Frame Plans V1 0Document24 pagesYoungsters T Bucket Frame Plans V1 0weirdbennyNo ratings yet

- DIY TeardropDocument12 pagesDIY TeardropAnonymous MyUcfo100% (1)

- High Performance Polytarp Junk Rig SailDocument10 pagesHigh Performance Polytarp Junk Rig SailScott GieferNo ratings yet

- Upright Trike PlanDocument7 pagesUpright Trike PlanchidoNo ratings yet

- Pico-Light Teardrop Trailer DesignDocument32 pagesPico-Light Teardrop Trailer Designmanolislem100% (3)

- Auto Restoration Rotisserie PlansDocument26 pagesAuto Restoration Rotisserie PlansbeegoodNo ratings yet

- Barton skiff plans for 15ft experimental skiffDocument9 pagesBarton skiff plans for 15ft experimental skiffStanlei FernandaNo ratings yet

- Simplified Steam Engine and Boiler 1937Document5 pagesSimplified Steam Engine and Boiler 1937Anghel Curty Jr.100% (1)

- Three Trailers in One - Box, Car and Flat Top. The Box Top TrailerDocument10 pagesThree Trailers in One - Box, Car and Flat Top. The Box Top TrailerDavidNo ratings yet

- Barrelback BookletDocument26 pagesBarrelback BookletManousos LImbe100% (2)

- Camp TrailerDocument6 pagesCamp TrailerGreg Phillpotts100% (3)

- CNCinst SherlineDocument72 pagesCNCinst SherlineDejan StalovicNo ratings yet

- Build Your Own Mini Bike PlansDocument8 pagesBuild Your Own Mini Bike Plansmawan_jogjaNo ratings yet

- GraderDocument2 pagesGraderFrenchwolf420No ratings yet

- Vista Teardrop Trailers: Cab-Forward Design Provides Big ViewsDocument10 pagesVista Teardrop Trailers: Cab-Forward Design Provides Big ViewsDeák Gábor100% (1)

- HTC Multi-Fence System ManualDocument8 pagesHTC Multi-Fence System Manualanilr008No ratings yet

- BrockwayfullDocument38 pagesBrockwayfullrajagula100% (1)

- MBA80 Manual - Sneak PeekDocument14 pagesMBA80 Manual - Sneak PeekJo Alex100% (1)

- Vought V-143 FighterDocument9 pagesVought V-143 FighterAviation/Space History LibraryNo ratings yet

- Easy To Build Desk Top 3 Axis CNC Milling MachineDocument17 pagesEasy To Build Desk Top 3 Axis CNC Milling Machinemarandan85No ratings yet

- Mistral HullDocument5 pagesMistral HullmikeNo ratings yet

- Building a Model Boat HullDocument19 pagesBuilding a Model Boat HullAlexander Florin100% (1)

- Toy Box: Kreg JigDocument4 pagesToy Box: Kreg Jigtoro17No ratings yet

- By Emile Alline: Technical Art by Fred WolffDocument4 pagesBy Emile Alline: Technical Art by Fred WolffJim100% (3)

- Build your own vehicle frame with XYZ SPACEFRAME VEHICLESDocument12 pagesBuild your own vehicle frame with XYZ SPACEFRAME VEHICLESLornaLFryeNo ratings yet

- Pod Yak FlatDocument3 pagesPod Yak Flattwinscrewcanoe100% (1)

- Struck Dozers - CubCadetManDocument4 pagesStruck Dozers - CubCadetManNaveen BansalNo ratings yet

- Pedal Car Construction: Chassis DesignDocument4 pagesPedal Car Construction: Chassis DesignanilbabuNo ratings yet

- DIY Folding Step LadderDocument23 pagesDIY Folding Step Ladderdeni971No ratings yet

- Lasercut RC PakWagenDocument51 pagesLasercut RC PakWagenJack DaielsNo ratings yet

- SLA 3d PrinterDocument80 pagesSLA 3d Printerbitu&piutaNo ratings yet

- Family Handyman Ultimate 1 Day ProjectsFrom EverandFamily Handyman Ultimate 1 Day ProjectsRating: 5 out of 5 stars5/5 (1)

- Voron B - The ManualDocument63 pagesVoron B - The ManualDaniel Leonardo AlbeNo ratings yet

- American Woodworker: OCTOBER 2002Document9 pagesAmerican Woodworker: OCTOBER 2002JvlValenzuelaNo ratings yet

- $75 DIY Slider PDF GuideDocument53 pages$75 DIY Slider PDF GuideĐorđe Radić100% (1)

- 1-18 Easy Fix Double Glazing Counter Price ListDocument16 pages1-18 Easy Fix Double Glazing Counter Price ListChris PaceyNo ratings yet

- Manual Transistor PDFDocument4 pagesManual Transistor PDFAlexandre S. CorrêaNo ratings yet

- Optical Comp Exp - Edu SilvaDocument6 pagesOptical Comp Exp - Edu SilvaAlexandre S. CorrêaNo ratings yet

- F e A T U R e SDocument2 pagesF e A T U R e SAlexandre S. CorrêaNo ratings yet

- Manual 2016 Nitro g5Document2 pagesManual 2016 Nitro g5Alexandre S. CorrêaNo ratings yet

- Vistabule 2014 Feb Brochure LRDocument10 pagesVistabule 2014 Feb Brochure LRAlexandre S. CorrêaNo ratings yet

- CCE TV HPS-2071B Diagrama EsquematicoDocument1 pageCCE TV HPS-2071B Diagrama EsquematicoDaniel AvecillaNo ratings yet

- 1947 Trailer For TwoDocument7 pages1947 Trailer For TwoAlexandre S. CorrêaNo ratings yet

- Build "Wild Goose": A Sturdy Overnight TrailerDocument7 pagesBuild "Wild Goose": A Sturdy Overnight TrailerAlexandre S. CorrêaNo ratings yet

- Sansung CL21A551MLDocument9 pagesSansung CL21A551MLleno2No ratings yet

- Modular CNC Router 2009v1 FREE PLANSDocument10 pagesModular CNC Router 2009v1 FREE PLANSModularCNC57% (7)

- Schematic Diagrams: Special NoteDocument12 pagesSchematic Diagrams: Special NoteAlexandre S. Corrêa100% (1)

- 4HD D0049.0611 - 06FDocument104 pages4HD D0049.0611 - 06FCarlosLimaNo ratings yet

- Schematic Diagram DVD-P370Document8 pagesSchematic Diagram DVD-P370Alexandre S. Corrêa0% (1)

- Cold Cold HOT HOT: QFP80 QFP80Document1 pageCold Cold HOT HOT: QFP80 QFP80Jone Ferreira Dos SantosNo ratings yet

- XR-A550 XR-A330: Stereo CD Cassette Deck ReceiverDocument82 pagesXR-A550 XR-A330: Stereo CD Cassette Deck ReceiverAlexandre S. CorrêaNo ratings yet

- 74573Document4 pages74573jamesrychurdNo ratings yet

- ICL7106 and ICL7107 VoltmeterDocument16 pagesICL7106 and ICL7107 VoltmeterAntonino ScordatoNo ratings yet

- Yamaha Receiver Rxv-595 SchematicDocument7 pagesYamaha Receiver Rxv-595 SchematicMauricio Bumba100% (1)

- Tip41-2 20wDocument3 pagesTip41-2 20wAlexandre S. CorrêaNo ratings yet

- 74688Document4 pages74688Alexandre S. CorrêaNo ratings yet

- 74574Document6 pages74574Alexandre S. CorrêaNo ratings yet

- Ta 8403 KDocument5 pagesTa 8403 KFlorenz RemasteredNo ratings yet

- DC Da90Document24 pagesDC Da90Alexandre S. CorrêaNo ratings yet

- Datasheet 7400Document9 pagesDatasheet 7400gab50No ratings yet

- TL 074Document10 pagesTL 074Alexandre S. CorrêaNo ratings yet

- TDA2002 10wDocument21 pagesTDA2002 10wAlexandre S. CorrêaNo ratings yet

- Build Your Own VAWT by David MussellDocument17 pagesBuild Your Own VAWT by David MussellMr Void100% (9)

- 802Document4 pages802BooksNo ratings yet

- 74VHCU04Document6 pages74VHCU04Alexandre S. CorrêaNo ratings yet

- Titanvene Lldpe-LctnDocument4 pagesTitanvene Lldpe-LctnRifan HarfaniNo ratings yet

- Xtract V 3 0 8Document72 pagesXtract V 3 0 8Don Ing Marcos LeónNo ratings yet

- Novajet Refference GuideDocument74 pagesNovajet Refference GuideoralbnetworkNo ratings yet

- Fire Drencher System - Base-Engineer PDFDocument2 pagesFire Drencher System - Base-Engineer PDFpequenita34100% (1)

- HVCB Timing ApplicationDocument52 pagesHVCB Timing Applicationbhuban mohanNo ratings yet

- 1998 CAT 3126 Oper & Maint ManualDocument93 pages1998 CAT 3126 Oper & Maint Manualbatuhan kılıç100% (2)

- Bel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Document5 pagesBel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Palani AppanNo ratings yet

- ASTM E92-17 Standard Test Methods For Vickers Hardness and Knoop Hardness of Metallic MaterialsDocument27 pagesASTM E92-17 Standard Test Methods For Vickers Hardness and Knoop Hardness of Metallic MaterialsCarlos Pinto Pradilla88% (8)

- DWTS, WDWTS: Improving MRI Image Reconstruction with Directional Wavelet ThresholdingDocument1 pageDWTS, WDWTS: Improving MRI Image Reconstruction with Directional Wavelet ThresholdingSumit ChakravartyNo ratings yet

- Advanced clutter options for radio propagation modelingDocument40 pagesAdvanced clutter options for radio propagation modelingLaura VillarrealNo ratings yet

- SYMAP UsersManual E PDFDocument98 pagesSYMAP UsersManual E PDFRafaqatAliNo ratings yet

- 2020 Can Am Off Road - Apache Track Kits Leaflet - enDocument7 pages2020 Can Am Off Road - Apache Track Kits Leaflet - enNicolas VillamayorNo ratings yet

- PartesDocument136 pagesPartesFernando Erazo NavarreteNo ratings yet

- Ricoh 2090Document832 pagesRicoh 2090cosmin176100% (1)

- CPU Vs vCPUDocument14 pagesCPU Vs vCPUainseanNo ratings yet

- BRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualDocument28 pagesBRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualLuis Daniel ContrerasNo ratings yet

- CHM096-Tutorial 1 (Alkanes & Alkenes)Document4 pagesCHM096-Tutorial 1 (Alkanes & Alkenes)Anonymous RD1CrAINo ratings yet

- PI Digital Panel Indicator - B0Document7 pagesPI Digital Panel Indicator - B0dtoxidNo ratings yet

- Scallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesDocument3 pagesScallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesJanuel BorelaNo ratings yet

- c600 17lookinsideDocument6 pagesc600 17lookinsideИван МинчевNo ratings yet

- Zw3d2022 Lite Vs Cadbro 2022Document4 pagesZw3d2022 Lite Vs Cadbro 2022Carlos LimaNo ratings yet

- GEC - Sample Resume For StudentsDocument2 pagesGEC - Sample Resume For StudentsNiketNo ratings yet

- Maxxi Report FinalDocument7 pagesMaxxi Report FinalDepanshu Gola100% (1)

- Ricoh 301 PARTS CATALOGDocument68 pagesRicoh 301 PARTS CATALOGbefremdenNo ratings yet

- Instructions For Installation, Operating and Maintenance InstructionDocument30 pagesInstructions For Installation, Operating and Maintenance InstructionmilacronNo ratings yet

- Using Semi Circular Bending Test To Evaluate Low Temperature Fracture Resistance For Asphalt ConcreteDocument10 pagesUsing Semi Circular Bending Test To Evaluate Low Temperature Fracture Resistance For Asphalt Concreteappu140688No ratings yet

- A Rope of Mass 0.65 KG Is Stretched Between Two Supports 30 M Apart. If The Tension in The Rope Is 120 N, How Long Will It Take A Pulse To Travel From One Support To The Other?Document6 pagesA Rope of Mass 0.65 KG Is Stretched Between Two Supports 30 M Apart. If The Tension in The Rope Is 120 N, How Long Will It Take A Pulse To Travel From One Support To The Other?peyying12No ratings yet

- Company Profile 2021Document18 pagesCompany Profile 2021Hamza FaheemNo ratings yet

- DESIGN II - ChemTran General Reference GuideDocument332 pagesDESIGN II - ChemTran General Reference GuideDebabrata MitraNo ratings yet

- WWW - Incar.tw-Kobelco SK 75 Service ManualDocument5 pagesWWW - Incar.tw-Kobelco SK 75 Service Manualpurnomo0% (1)