Professional Documents

Culture Documents

Biomass CHP Catalog Part5

Uploaded by

Michele MionOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biomass CHP Catalog Part5

Uploaded by

Michele MionCopyright:

Available Formats

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

5. Biomass Conversion Technologies

Inthecontextofthisdocument,biomassconversionreferstotheprocessofconvertingbiomass

intoenergythatwillinturnbeusedtogenerateelectricityand/orheat.Theprincipalcategoriesof

biomassconversiontechnologiesforpowerandheatproductionaredirect-fired andgasification systems.

Withinthedirect-firedcategory,specifictechnologiesincludestokerboilers,fluidizedbedboilers,and

cofiring.Withinthegasificationcategory,specifictechnologiesincludefixedbedgasifiersandfluidized

bedgasifiers.Anaerobicdigestersarealsoconsideredabiomassconversiontechnology;however,

extensiveinformationaboutdigestersisreadilyavailablefromEPAsAgSTARProgram

<www.epa.gov/agstar>andtherefore,willnotbediscussedwithinthischapter.

Biomasspowersystemsaretypicallybelow50MWinsize,comparedtocoal-firedplants,which

areinthe100- to1,000-MWrange.Mostoftodaysbiomasspowerplantsaredirect-fired systems. The

biomassfuelisburnedinaboilertoproducehigh-pressuresteamthatisusedtopowerasteamturbine-

drivenpowergenerator.Inmanyapplications,steamisextractedfromtheturbineatmediumpressures

andtemperaturesandisusedforprocessheat,spaceheating,orspacecooling.Cofiring involves

substitutingbiomassforaportionofthecoalinanexistingpowerplantboiler.Itisthemosteconomic

near-termoptionforintroducingnewbiomasspowergeneration.Becausemuchoftheexistingpower

plantequipmentcanbeusedwithoutmajormodifications,cofiringisfarlessexpensivethanbuildinga

newbiomasspowerplant.Comparedtothecoalitreplaces,biomassreducesSO

2

,NO

X

,andcertainother

airemissions.

Biomassgasification systemsoperatebyheatingbiomassinanenvironmentwherethesolid

biomassbreaksdowntoformaflammablegas.Thegasproducedsynthesisgas,orsyngascanbe

cleaned,filtered,andthenburnedinagasturbineinsimpleorcombined-cyclemode,comparabletoLFG

orbiogasproducedfromananaerobicdigester.Insmallersystems,thesyngascanbefiredin

reciprocatingengines,microturbines,Stirlingengines,orfuelcells.Gasificationtechnologiesusing

biomassbyproductsarepopularinthepulpandpaperindustrywheretheyimprovechemicalrecoveryand

generateprocesssteamandelectricityathigherefficienciesandwithlowercapitalcoststhan

conventionaltechnologies.Pulpandpaperindustrybyproductsthatcanbegasifiedincludehoggedwood,

bark,andspentblackliquor.

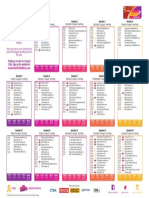

Table 5-1 providesasummaryofbiomassconversiontechnologiesforproducingheatandpower.

Table 5-1. Summary of Biomass CHP Conversion Technologies

Biomass Conversion

Technology

Common Fuel Types Feed

Size

Moisture

Content

Capacity Range

Stokergrate,

underfirestoker

boilers

Sawdust,bark,chips,hog

fuel,shavings,endcuts,

sanderdust

0.252in. 1050% 4to300MW(manyin

the20to50MWrange)

Fluidizedbedboiler Woodresidue,peat,wide

varietyoffuels

<2in. <60% Upto300MW(manyin

the20to25MWrange)

Cofiringpulverized

coalboilers

Sawdust,bark,shavings,

sanderdust

<0.25in. <25% Upto1000MW

Cofiringstoker,

fluidizedbedboilers

Sawdust,bark,shavings,

hogfuel

<2in. 1050% Upto300MW

Fixedbedgasifier Chippedwoodorhogfuel,

ricehulls,shells,sewage

sludge

0.254in. <20% Upto50MW

Fluidizedbedgasifier Mostwoodandagriculture

residues

0.252in. 1530% Upto25MW

Source:BasedonWright,2006.

5.BiomassConversionTechnologies 30

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Modular systems employsomeofthesametechnologiesmentionedabove,butonasmallerscale

thatismoreapplicabletofarms,institutionalbuildings,andsmallindustry.Anumberofmodularsystems

arenowunderdevelopmentandcouldbemostusefulinremoteareaswherebiomassisabundantand

electricityisscarce.

5.1 Direct-FiredSystems

Themostcommonutilizationofsolidfuelbiomassisdirectcombustionwiththeresultinghot

fluegasesproducingsteaminaboileratechnologythatgoesbacktothe19

th

century.Boilerstoday

burnavarietyoffuelsandcontinuetoplayamajorroleinindustrialprocessheating,commercialand

institutionalheating,andelectricitygeneration.Boilersaredifferentiatedbytheirconfiguration,size,and

thequalityofthesteamorhotwaterproduced.Boilersizeismostoftenmeasuredbythefuelinputin

MMBtuperhour(MMBtu/hr),butitmayalsobemeasuredbyoutputinpoundsofsteamperhour.

Becauselargeboilersareoftenusedtogenerateelectricity,itcanalsobeusefultorelateboilersizeto

poweroutputinelectricgeneratingapplications.Usingtypicalboilerandsteamturbinegenerating

efficiencies,100MMBtu/hrheatinputprovidesabout10MWelectricoutput.

Thetwomostcommonlyusedtypesofboilersforbiomassfiringarestokerboilersandfluidized

bedboilers.Eitherofthesecanbefueledentirelybybiomassfuelorcofiredwithacombinationof

biomassandcoal.Theefficiency,availability,operatingissues,equipmentandinstalledcosts,O&M

requirementsandcosts,andcommercialstatusofeachoftheseoptionsarediscussedbelow.

5.1.1 Boilers

Characterization

Stoker Boilers

Stokerboilersemploydirectfirecombustionofsolidfuelswithexcessair,producinghotflue

gases,whichthenproducesteamintheheatexchangesectionoftheboiler.Thesteamisuseddirectlyfor

heatingpurposesorpassedthroughasteamturbinegeneratortoproduceelectricpower.Stoker-fired

boilerswerefirstintroducedinthe1920sforcoal;inthelate1940stheDetroitStokerCompanyinstalled

thefirsttravelinggratespreaderstokerboilerforwood.Mechanicalstokersarethetraditionaltechnology

thathasbeenusedtoautomaticallysupplysolidfuelstoaboiler.Allstokersaredesignedtofeedfuel

ontoagratewhereitburnswithairpassingupthroughit.Thestokerislocatedwithinthefurnacesection

oftheboilerandisdesignedtoremovetheashresidueaftercombustion.Stokerunitsusemechanical

meanstoshiftandaddfueltothefirethatburnsonandabovethegratelocatednearthebaseoftheboiler.

Heatistransferredfromthefireandcombustiongasestowatertubesonthewallsoftheboiler.

Modernmechanicalstokersconsistoffourelements,1)afueladmissionsystem,2)astationary

ormovinggrateassemblythatsupportstheburningfuelandprovidesapathwayfortheprimary

combustionair,3)anoverfireairsystemthatsuppliesadditionalairtocompletecombustionand

minimizeatmosphericemissions,and4)anashdischargesystem.Figure 5-1 illustratesthedifferent

sectionsofastokerboiler.

Asuccessfulstokerinstallationrequiresselectingthecorrectsizeandtypeofstokerforthefuel

beingusedandfortheloadconditionsandcapacitybeingserved.Stokerboilersaretypicallydescribedby

theirmethodofaddinganddistributingfuel.Therearetwogeneraltypesofsystemsunderfeed and

overfeed.Underfeedstokerssupplyboththefuelandairfromunderthegrate,whileoverfeedstokers

supplyfuelfromabovethegrateandairfrombelow.Overfeedstokersarefurtherdividedintotwo

typesmass feed andspreader.Inthemassfeedstoker,fueliscontinuouslyfedontooneendofthegrate

5.BiomassConversionTechnologies 31

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

surfaceandtravelshorizontallyacrossthe

Figure 5-1. Cut-Away View of a Traveling Grate

grateasitburns.Theresidualashis

Stoker Boiler

dischargedfromtheoppositeend.

Combustionairisintroducedfrombelow

thegrateandmovesupthroughtheburning

bedoffuel.Inthespreaderstoker,themost

commontypeofstokerboiler,combustion

airisagainintroducedprimarilyfrom

belowthegratebutthefuelisthrownor

spreaduniformlyacrossthegratearea.The

finerparticlesoffuelcombustin

suspensionastheyfallagainsttheupward

movingair.Theremainingheavierpieces

fallandburnonthegratesurface,withany

residualashremovedfromthedischarge

endofthegrate.Chaingrate,traveling

grate,andwater-cooledvibratinggrate

stokersareotherlesscommon

configurationsthatusevariousmeansto

maintainaneven,thinbedofburningfuel

onthegrate.Otherspecializedstoker

boilersincludebalanceddraft,cyclone-

fired,fixedbed,shakerhearth,tangential-fired,andwall-fired.Practicalconsiderationslimitstokersize

and,consequently,themaximumsteamgenerationrates.Forcoalfiring,thismaximumisabout350,000

poundsperhour(lb/hr);forwoodorotherbiomassfiringitisabout700,000lb/hr.

Underfeed Stokers

Underfeedstokerssupplybothfuelandprimarycombustionairfrombeneaththegratesothatthe

topofthefuelpileisnotcooledbycoldandmoistfuelorcoldair.Thefuelismovedintoahopperand

ontothegratebyeitherascrew- orram-drivenmechanism.Underfeedstokerspushthefuelintothe

bottomofthebedoffuelwhileheatcausesvolatilizationandcompletecombustionofthefuelbythetime

itrisestothetopofthebedasashandisdischarged.Asthefuelmovesoutoverthegratewhereitis

exposedtoairandradiantheat,it

Figure 5-2. Cross Section of Underfeed, Side-Ash

beginstoburnandtransferheatto

Discharge Stoker

thewatertubes.Aswithany

combustionprocess,ashaccumulates

asthefuel,isburned.Thetwobasic

typesofunderfeedstokersare:1)the

horizontal-feed,side-ashdischarge

typeand2)thegravity-feed,rear-ash

dischargetype.Across-sectionofan

underfeed,side-ashdischargestoker

isshowninFigure 5-2.Thedemand

forunderfeedstokershasdiminished

duetocostandenvironmental

considerations.Underfeedstokersare

bestsuitedforrelativelydryfuel

(under40to45percentmoisture.)

Source:ORNL,2002.

Source:ORNL,2002.

5.BiomassConversionTechnologies 32

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Overfeed Stokers

Overfeedstokersaregenerallyclassifiedbythewaythefuelisdistributedandburnedwithinthe

boiler.Theprimarydesignationsaremass-feedorspreaderstokers.Mass-feedstokersintroducefuel

continuouslyatoneendofagrate.Asthefuelmovesintotheboiler,itfallsontothegratebygravity.To

controltheamountoffuelthatenterstheboiler,agatecanbemovedupordown,orthespeedatwhich

thefuelmovesbeneaththegatecanbeadjusted.Insidetheboiler,thefuelburnsasittravelsalongthe

grate.Primarycombustionair

flowsupwardfrombeneaththe

Figure 5-3. Cross Section of Overfeed, Water-Cooled,

grateandthroughtheburning

Vibrating-Grate, Mass-Feed Stoker

bedoffuel,allowingfor

completecombustion.Anyash

thatremainsonthegrateis

thendischargedattheopposite

endofthesystem.Thetwo

primarymass-feedstokersare

1)water-cooledvibratinggrate

and2)moving(chainand

traveling)gratestokers.A

cross-sectionofanoverfeed,

water-cooledvibratinggrate

mass-fedstokerispresentedin

Figure 5-3.

Spreader Stokers

Spreaderstokersarethemostcommonlyusedstokersbecauseoftheirversatility.Theyare

capableofdistributingfuelevenlyandtoauniformdepthovertheentiregratesurfacebyusingadevice

thatpropelstheindividualfuelparticlesintotheairabovethegrate.Methodsusedtopropelthefuel

particlesincludeairinjectionandunderthrowandoverthrowrotors.Asthefuelisthrownintotheboiler,

fineparticlesigniteandburnwhilesuspendedinthecombustionair.Duetosuspensionburning,response

timesofspreaderstokersarebetterthanformassfeedorunderfeedstokers.Thecoarserparticlesthatfall

ontothegrateendupburninginathinbedoffuelonthegrate.Primarycombustionairissuppliedfrom

beneaththegrate.Becausethefuelisevenlydistributedacrosstheactivegratearea,thecombustionairis

uniformlydistributedunderandthroughthegrate.Aportionofthetotalcombustionairisadmitted

throughportsabovethegrateasoverfireair,completingthecombustionprocess.Gratesforspreader

stokersaregenerallydesignedtomoveratherthanremainstationary.Therefore,travelinggrates,air-

cooledvibratinggrates,andwater-cooledvibratinggratesaredesignsthathavebeenusedeffectively.

Modernboilerswithspreaderstokersincorporate:

Equipmentthatdistributesfueluniformlyoverthegrate.

Speciallydesignedair-meteringgrates.

Dustcollectionandreinjectionequipment.

Forceddraftfansforbothundergrateandoverfireair.

Combustioncontrolstocoordinatefuelandairsupplywithsteamdemand.

49

49

ORNL,2002.

Source:ORNL,2002.

5.BiomassConversionTechnologies 33

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Alongwiththefuelfeedsystemandfurnacesectiongeometry,airsystemdesignplaysan

importantroleinefficientandcompletecombustionofbiomassfuelsinstokerboilers.Excessairfor

bark,wood,andmostbiomassfuelsissetat25percentoraboveforstokerfiring.Becausebiomassfuels

aretypicallyhighlyvolatileonadrybasis,areheterogeneousinsize,andmoreoftenburninsuspension

comparedtocoal,biomasscombustionairsystemsaredesignedtoprovidemoreoverfireairthanthose

usedforcoal.Moderndesignsuseundergrateandoverfirequantitiesof40and60percent,respectively.

Fluidized Bed Boilers

Fluidizedbedboilersarethemostrecenttypeofboilerdevelopedforsolidfuelcombustion.The

primarydrivingforcefordevelopmentoffluidizedbedcombustionisreducedSO

2

andNO

x

emissions

fromcoalcombustion.Asthetechnologydeveloped,itbecameapparentthattheprocesscouldefficiently

burnbiomassandotherlow-gradefuelsthataredifficultorimpracticaltoburnwithconventional

methods.

Inthismethodofcombustion,fuelisburnedinabedofhotinert,orincombustible,particles

suspendedbyanupwardflowofcombustionairthatisinjectedfromthebottomofthecombustortokeep

thebedinafloatingorfluidizedstate.Thescrubbingactionofthebedmaterialonthefuelenhancesthe

combustionprocessbystrippingaway

theCO

2

andsolidsresidue(char)that

normallyformsaroundthefuelparticles.

Thisprocessallowsoxygentoreachthe

combustiblematerialmorereadilyand

increasestherateandefficiencyofthe

combustionprocess.Oneadvantageof

mixinginthefluidizedbedisthatit

allowsamorecompactdesignthanin

conventionalwatertubeboilerdesigns.

Naturalgasorfueloilcanalsobeusedas

astart-upfueltopreheatthefluidized

bedorasanauxiliaryfuelwhen

additionalheatisrequired.Theeffective

mixingofthebedmakesfluidizedbed

boilerswell-suitedtoburnsolidrefuse,

woodwaste,wastecoals,andothernon-

standardfuels.Figure 5-4 showsthe

componentsofafluidizedbed

combustionboiler.

Figure 5-4. Cut-Away View of a Fluidized Bed

Combustion Boiler

Source:Babcock&Wilcox,2005.

Thefluidizedbedcombustionprocessprovidesameansforefficientlymixingfuelwithairfor

combustion.Whenfuelisintroducedtothebed,itisquicklyheatedaboveitsignitiontemperature,

ignites,andbecomespartoftheburningmass.Theflowofairandfueltothedensebediscontrolledso

thatthedesiredamountofheatisreleasedtothefurnacesectiononacontinuousbasis.Typically,

biomassisburnedwith20percentorhigherexcessair.Onlyasmallfractionofthebediscombustible

material;theremainderiscomprisedofinertmaterial,suchassand.Thisinertmaterialprovidesalarge

inventoryofheatinthefurnacesection,dampeningtheeffectofbrieffluctuationsinfuelsupplyor

heatingvalueonboilersteamoutput.

Fuelsthatcontainahighconcentrationofash,sulfur,andnitrogencanbeburnedefficientlyin

fluidizedbedboilerswhilemeetingstringentemissionlimitations.Duetolongresidencetimeandhigh

intensityofmasstransfer,fuelcanbeefficientlyburnedinafluidizedbedcombustorattemperatures

5.BiomassConversionTechnologies 34

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

considerablylowerthaninconventionalcombustionprocesses(1,400to1,600Fcomparedto2,200F

foraspreaderstokerboiler).ThelowertemperaturesproducelessNO

x

,asignificantbenefitwithhigh

nitrogen-contentwoodandbiomassfuels.SO

2

emissionsfromwoodwasteandbiomassaregenerally

insignificant,butwheresulfurcontaminationofthefuelisanissue,limestonecanbeaddedtothefluid

bedtoachieveahighdegreeofsulfurcapture.Fuelsthataretypicallycontaminatedwithsulfurinclude

constructiondebrisandsomepapermillsludges.

Fluidizedbedboilersarecategorizedaseitheratmosphericorpressurizedunits.Atmospheric

fluidizedbedboilersarefurtherdividedintobubbling-bedandcirculating-bedunits;thefundamental

differencebetweenbubbling-bedandcirculating-bedboilersisthefluidizationvelocity(higherfor

circulating).Circulatingfluidizedbedboilersseparateandcapturefuelsolidsentrainedinthehigh-

velocityexhaustgasandreturnthemtothebedforcompletecombustion.Atmospheric-pressurebubbling

fluidizedbedboilersaremostcommonlyusedwithbiomassfuels.Thetypeoffluidbedselectedisa

functionoftheas-specifiedheatingvalueofthebiomassfuel.Bubblingbedtechnologyisgenerally

selectedforfuelswithlowerheatingvalues.Thecirculatingbedismostsuitableforfuelsofhigher

heatingvalues.

Inapressurizedfluidizedbedboiler,theentirefluidizedbedcombustorisencasedinsidealarge

pressurevessel.Burningsolidfuelsinapressurizedfluidizedbedboilerproducesahigh-pressurestream

ofcombustiongases.Afterthecombustiongasespassthroughahotgascleanupsystem,theyarefedinto

agasturbinetomakeelectricity,andtheheatinthehotexhaustgasstreamcanberecoveredtoboilwater

forasteamturbine.Therefore,apressurizedfluidizedbedboilerismoreefficient,butalsomore

complicatedandexpensive.Capitalcostsofpressurizedfluidizedbedcombustiontechnologyarehigher

thanatmosphericfluidizedbeds.

Efficiency

Boilerefficiencyisdefinedasthepercentageofthefuelenergythatisconvertedtosteamenergy.

Majorefficiencyfactorsinbiomasscombustionaremoisturecontentofthefuel,excessairintroduced

intotheboiler,andthepercentageofuncombustedorpartiallycombustedfuel.AccordingtotheCouncil

ofIndustrialBoilerOwners(CIBO),thegeneralefficiencyrangeofstokerandfluidizedbedboilersis

between65and85percentefficient.

50

Fueltypeandavailabilityhaveamajoreffectonefficiencybecause

fuelswithhighheatingvaluesandlowmoisturecontentcanyieldefficienciesupto25percenthigher

thanfuelshavinglowheatingvaluesandhigh-moisturecontents.

Biomassboilersaretypicallyrunwithaconsiderableamountofexcessairsothattheycan

achievecompletecombustion,butthishasanegativeimpactonefficiency.ACIBOruleofthumb

indicatesthatboilerefficiencycanbeincreased1percentforeach15percentreductioninexcessair.

51

Table 5-2 comparestheefficiencyofabiomassstokerandafluidizedbedboilerthatareoperated

with50percentexcessairwithafinalfluegasexittemperatureof350F.Theefficienciesareestimated

basedontheheat-lossmethod,whichisawayofdeterminingboilerefficiencybymeasuringthe

individualheatlosses(expressedasapercentofheatinput)andsubtractingthemfrom100percent.As

canbeseeninthetable,thelargestenergylossinaboileristheheatthatleavesthestack.Thislosscould

amounttoasmuchas30to35percentofthefuelinputinolder,poorlymaintainedboilers.Thetable

showsthatdecreasingfuelmoisturecontentfrom30to0percentincreasesthermalefficiencybyabout6

percentagepoints.Thisestimateassumesthattheair-fuelratioismaintainedbyadjustingairinputbased

ontheinputmoisturecontent.Ifthequantityofairisnotreducedwhenwetterfuelenterstheboilerthen

efficiencywilldropevenmoreasfuelmoistureisincreased.

50

CouncilofIndustrialBoilerOwners,1997.

51

ORNL,2002.

5.BiomassConversionTechnologies 35

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Theprimarydifferenceinefficiencybetweenastokerboilerandafluidizedbedboileristhe

amountoffuelthatremainsunburned.AsshowninTable 5-2,theefficiencyoffluidizedbedboilers

comparesfavorablywithstokerboilersduetolowercombustionlosses.Stokerboilerscanhave30to40

percentcarbonintheashandadditionalvolatilesandCOinthefluegases,whilefluidizedbedboiler

systemstypicallyachievenearly100percentfuelcombustion.Theturbulenceinthecombustorcombined

withthethermalinertiaofthebedmaterialprovideforcomplete,controlled,anduniformcombustion.

Thesefactorsarekeytomaximizingthethermalefficiency,minimizingchar,andcontrollingemissions.

Table 5-2. Biomass Boiler Efficiency as a Function of Input Fuel and Combustion Characteristics

Characteristics

Biomass Stoker Biomass Fluidized Bed

Dry As Received Dry As Received

Excessair(%) 50 50 50 50

Dryfluegas(lb/lbfuel) 15.25 10.675 15.25 10.675

Finalexhausttemp(F) 350 350 350 350

Highheatingvalue(HHV)ofthefuel(Btu/lb) 8,500 5,950 8,500 5,950

Moisturecontentoffuel(%) 0 30 0 30

Hydrogenpercentinthefuel(%) 4.59 3.21 4.59 3.21

Efficiency Losses

Dryfluegaslosses(%) 11.63 11.63 11.63 11.63

Moistureinfuel(%) 0.00 5.90 0.00 5.90

Latentheat(%) 5.69 5.69 5.69 5.69

Unburnedfuel(%)(1) 3.50 3.50 0.25 0.25

Radiationandmiscellaneous(%)(2) 2.03 2.03 2.03 2.03

Total Combustion Losses (%) 22.85 28.74 19.60 25.49

Boiler Efficiency HHV Basis (%) 77.15 71.26 80.40 74.51

(1)Estimated

(2)Includesradiation,moistureinair,andothermiscellaneousissues.

Whenconsideringfactorsthatinfluenceboilerperformance,itshouldbenotedthatefficiencyis

notconstantthroughouttheentireoperatingrangeofaboiler.Peakefficiencygenerallyoccursata

particularboileroutputthatisdeterminedbydesigncharacteristics.Wheneverboileroperationsdeviate

fromthisoutput,theresultingperformanceisusuallybelowpeakefficiency.Operatingcontinuouslyat

peakefficiencyisnotpracticalduetoseasonaldemands,loadvariationsandfuelpropertyvariations;

however,operatingatasteadyloadandavoidingcyclicoron-offoperationcanimproveefficiency.

Operating Availability

52

Typically,bothstokerandfluidizedboilersaredesignedforcontinuousoperation,anddesign

performanceisinthe90+percentavailabilityrange.Seasonalvariabilityinfuelavailabilityand/orquality

canaffecttheplantavailability,butthisisafeedstockissue,notanissueofboilerperformance.Awell

52

Theavailabilityofapowergenerationsystemisthepercentageoftimethatthesystemcanoperate,oris

availabletooperate.Bothplannedmaintenanceandunplannedoutageshaveanegativeeffectuponsystem

availability.Thereforeanavailabilityof100%wouldrepresentasystemthatneverbrokedownorneeded

maintenance(impossibletoachieveinrealoperation).

5.BiomassConversionTechnologies 36

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

designedbiomasssteamsystemhasareasonableexpectationofoperatinginthe92to98percent

availabilityrange.

53

Operating Advantages and Disadvantages

Stokerandfluidizedbedboilershavespecificoperatingadvantagesanddisadvantageswith

biomassfuelsdependingonthefuelcharacteristicsandsiterequirements.Biomassfuelsareextremely

variableintermsofheatingvalue,moisturecontent,andotherfactorsthataffectcombustion.Woodand

mostotherbiomassfuelsarecomposedprimarilyofcelluloseandmoisture.Asdiscussedpreviously,the

highproportionofmoistureissignificantbecauseitactsasaheatsinkduringthecombustionprocess.

Thelatentheatofevaporationdepressesflametemperature,takingheatenergyawayfromsteam

production,andcontributingtothedifficultyofefficientlyburningbiomassfuels.Cellulose,inadditionto

containingthechemicalenergyreleasedincombustion,containsfuel-boundoxygen.Thisoxygen

decreasesthetheoreticalairrequirementsforcombustionand,accordingly,theamountofnitrogen

includedintheproductsofcombustion.Afewgeneralguidelinesfordirectfiringofwoodandbiomassin

boilersinclude:

Maintainstablecombustion,whichcanbeachievedinmostwater-cooledboilerswithfuel

moisturecontentsashighas65percentbyweight,asreceived.

Useofpreheatedcombustionairreducesthetimerequiredforfueldryingpriortoignition

andisessentialtospreaderstokercombustionsystems.Designairtemperatureswillvary

directlywithmoisturecontent.

Ahighproportionofthecombustiblecontentofwoodandotherbiomassfuelsburnsinthe

formofvolatilecompounds.Alargeproportionofthecombustionairrequirement,therefore,

isaddedabovethefuelinstokerandotherconventionalcombustionboilersasoverfireair.

Solidcharsproducedintheinitialstagesofcombustionofbiomassfuelsareofverylow

density.Conservativeselectionoffurnacesectionsizeisusedtoreducegasvelocityandkeep

charentrainmentintothefluegasesandpossiblyoutthestackatacceptablelevels.

Toensuresmoothfuelfeeding,biomassfuelshavetobecarefullysizedandprocessed.As

discussedabove,themoisturecontentofwoodandotherbiomasswastecanvaryoverawiderange,from

10percenttomorethan60percent.Toensuresteadyheatinputintotheboilerusingvolumetricfeeders,

efficienthomogenizationoffuelwithdifferentmoisturecontentsatthefuelyardisanecessity.

Biomass-basedfuelscanincreasetheriskofslaggingandfoulingofheattransfersurfacesand,in

somecases,theriskoffiresidecorrosionaswell.Potassiumashcontentisrelativelyhighinfreshwood,

greenparticles,andfast-growingbiomass,whichcausestheashtomeltatlowtemperaturesandleadstoa

tendencyforfoulingandslagging.Additionally,biomassfuelscancontainchlorine,which,togetherwith

alkalis,caninduceaggressivecorrosion.

Table 5-3 providesacomparisonofcombustioncharacteristicsandfuelissuesforstokerand

fluidizedbedboilers.Stokerboilershavebeenaroundforalongtimeandarearelativelybasic

technology,whereasfluidizedbedtechnologyisnewerandmorecomplex,butoffersmoreflexibilityand

operatingcontrol.Fluidizedbedsystemsoffersignificantoperatingflexibilitybecausetheycanoperate

underawiderangeofloadconditions.Thethermalinertiaofthebedmaterialallowsittowithstand

changesinmoistureandheatingcontentofthefuelwithoutnegativeimpacts.Additionally,thelowfuel

53

EnergyProductsofIdaho,acompanythatprovidesfluidizedbedboilers,hasreportedoperatingavailabilitiesof

98percentfortheirunits,<www.energyproducts.com/fluidized_bed_combustors.htm>.

5.BiomassConversionTechnologies 37

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

inventorypresentintheunitmakesitresponsivetovariableloads.Anotheradvantageisthatthefluidized

bedcanalsomaintainefficiencyduringsystemturn-down.Fluidizedbedmanufacturershavereported

thattheoperatingflexibilityoftheirunitshasallowedtheircustomerstotakeadvantageofutility

incentiveprogramsforgenerationthatfollowselectricdemand.

54

Table 5-3. Comparison of Stoker and Fluidized Bed Boilers

Feature

Boiler Type

Stoker Fluidized Bed

Combustion Mechanism

Flowofsolidfuel Transportedonstoker Fluidizedbycombustionairand

circulatedthroughthecombustion

chamberandcyclone

Combustionzone Onthestoker Entireareaofthecombustionfurnace

Masstransfer Slow Activeverticalmovement-massand

heattransfer

Combustion Control

Responsiveness Slowresponse Quickresponse

Excessaircontrol Difficult Possible

Fuel Issues

Applicabilitytovariousfuels Fair High

Fuelpretreatment Generallynotnecessary Lumpsmustbecrushed

Environmental Factors

Lowsulfuroxide(SO

x

)

combustion

In-furnacedesulfurizationnot

possible

Highrateofin-furnacedesulfurization

LowNO

x

combustion Difficult InherentlylowNO

x

Appropriatefacilitysize Small Mediumtolarge

Equipment and Installed Costs

Abiomassboilersystemisacomplexinstallationwithmanyinterrelatedsubsystems.An

integratedsteamsystemwillincludethefuelprep-yardandhandlingequipment,theboileritself,induced

andforcedairfans,controls,andwatertreatmentsystems.Varyinglevelsofemissioncontrolequipment

willnormallybeneededaswell.Mostinstallationswillincludecycloneseparatorstocapturelargefly

ash,abaghouseforfineparticulatematter(PM),andadryscrubbersystem.NO

x

emissionscontrolin

stokerboilersisprovidedbyaselectivenon-catalyticreductionsystemusingureaorammoniathatis

installedinthetopoftheboiler.Othercontrolequipmentincludesacidgasremovalsystem,stack,ash

handling,andcontinuousemissionsmonitoringequipmentifrequired.

Table 5-4 providestotalcapitalcostestimates(equipmentandinstallation)forbothstokerand

circulatingfluidizedbedsteamsystemsforthreebiomassfuelfeedrates:100tons/day,600tons/dayand

900tons/day.Thesefeedratesarecomparabletosteamsystemsproducing20,000;150,000to185,000;

and250,000to275,000lb/hrofsteam,respectively,dependingonsteamtemperatureandpressure.

Installedcostscanvarysignificantlydependingonthescopeoftheequipmentincluded,outputsteam

conditions,geographicalarea,competitivemarketconditions,siterequirements,emissioncontrol

requirements,andprevailinglaborrates.Theestimatespresentedinthetablearebudgetaryestimates

basedonpublisheddataanddiscussionswithequipmentsuppliersanddevelopers.Theestimatesare

54

EnergyProductofIdaho,n.d.

5.BiomassConversionTechnologies 38

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

basedonsteamconditionsthatmightbetypicalforaprocessheating-onlyapplicationinthesmall100

tons/daybiomassunit(250poundspersquareinchgauge[psig]saturatedsteam),andhighersteam

pressures(750psig)forasteamturbineCHPconfigurationinthelargerunits.Therangeofexpectedcost

variationscanbeashighas+/- 35percentdependingonthesiteandsystemvariableslistedabove.Steam

conditionsalsohaveasignificantimpactonboilercost;highertemperaturesandpressuresrequirethicker

tubesandmoreexpensivematerials(seeTable 5-5).

Table 5-4. Estimated Installed Capital Costs for a Biomass-Fueled Steam Plant

Biomass Fuel Feed (tons/day)

Characteristics 100 600 900

Biomassheatinput(MMBtu/hr) 35.4 297.5 446.3

Steampressure(psig) 275 750 750

Stoker Boiler Integrated Steam Plant

Steamoutput(lb/hr) 20,000 165,000 250,000

Stokerboilerequipmentcost $1,195,000 $7,980,000 $10,790,000

Otherequipmentandinstallation $795,000 $10,020,000 $12,460,000

TotalInstalledBoilerSystemCost $1,990,000 $18,000,000 $23,250,000

TotalInstalledBiomassPrep-Yard* $2,640,000 $5,430,000 $7,110,000

Total Installed Steam Plant Cost $4,630,000 $23,430,000 $30,360,000

UnitCost($/lbsteam) $232 $142 $121

Fluidized Bed Integrated Steam Plant

Steamoutput(lb/hr) 20,000 175,000 260,000

Fluidizedbedboilerequipmentcost $6,175,000 $14,490,000 $19,790,000

Otherequipmentandinstallation $795,000 $10,020,000 $12,460,000

TotalInstalledBoilerSystemCost $6,970,000 $24,510,000 $32,250,000

TotalInstalledBiomassPrep-Yard* $2,640,000 $5,430,000 $7,110,000

Total Installed Steam Plant Cost $9,610,000 $29,940,000 $39,360,000

UnitCost($/lbsteam) $480 $171 $151

*Prep-Yardcostsareestimatedbasedonthecapitalcostcurvedevelopedinsection4.1.5

Source:BasedondatafromAntaresGroup,Inc.,2003;discussionwithequipmentsuppliersanddevelopers.

AsshowninTable 5-4,theprep-yardandfuelhandlingsystemrepresentsasignificantportionof

thetotalsteamsystemcosts,rangingfrom15to25percentofthetotalsteamsystemcostsforthelarger

sizedunitsand25to50percentofthetotalcostofthe100tons/daysteamsystem.Fluidizedbedboiler

equipmentcostsarehigherthanthesimplerstokertechnology;thefluidizedbedboileritselfismorethan

threetimesasexpensiveasastokerboilerinthesmallestsizeshown;inthelargersizes,thefluidizedbed

boileris35to40percentmoreexpensive.Theunitcapitalcosts($/lbsteam)forabiomass-fueledsteam

plant,includingtheprep-yardcosts,are20to25percentmoreexpensiveforthelargerfluidizedbed

systems.Aportionofthehighercapitalcostisoffsetbythehigheroutputduetohigherefficiency.

ThecostoftheboilerisalsoafunctionofthesteamoutputconditionsasshowninTable 5-5.

Generatinghigherpressureandtemperaturesteamrequiresspecialandmoreexpensivealloysandthicker

watertubes.Boilersproducingveryhighpressuresteamcanbemorethantwiceasexpensiveasboilers

generatinglowpressuresteam.

5.BiomassConversionTechnologies 39

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Table 5-5. Effect of Steam Output Conditions on Boiler Capital Costs

Steam Conditions Boiler Cost Factor

150250psig 1.0

600750psig 1.151.25

1,2501,500psig 1.52.0

Source:Matches,2003.

O&M Costs

Estimatednon-fuelO&McostsforstokerandfluidizedbedboilersystemsareprovidedinTable

5-6 forthethreesteamsystemsizes,basedonpublisheddataanddiscussionwithmanufacturers.The

O&Mcostsareevaluatedwithinthecontextofanintegratedplant.TotalO&Mcostsincludethelaborfor

theprep-yard,andlabor,materials,andpartsfortheboilersystemitself.BoilersystemO&Mestimates

werebasedonanannualnon-laborcomponentforsparepartsandmaintenanceequipmentassumedtobe

2percentofboilercapitalcosts.Variablecostsforchemicals,water,andelectricityneededtorunblowers

andauxiliaryequipmentwereassumedtobeapproximately$0.20to$0.25perthousandpoundsofsteam

output.

Table 5-6. Annual O&M Costs for a Biomass-Fueled Steam Plant

Biomass Fuel Feed (tons/day)

Characteristics 100 600 900

Stoker Boiler Integrated Steam Plant

Steamoutput(lb/hr) 20,000 165,000 250,000

Prep-yardlabor $400,000 $320,000 $320,000

BoilersectionO&M $160,000 $1,095,000 $1,110,000

Total Annual O&M $560,000 $1,415,000 $1,430,000

Total Annual O&M ($/1,000 lb Steam)* $3.55 $1.09 $0.73

Fluidized Bed Integrated Steam Plant

Steamoutput(lb/hr) 20,000 175,000 260,000

Prep-yardlabor $400,000 $320,000 $320,000

BoilersectionO&M $260,000 $1,190,000 $1,205,000

Total Annual O&M $660,000 $1,510,000 $1,525,000

Total Annual O&M, ($/1,000 lb Steam)* $4.19 $1.09 $0.74

*Basedon90to95percentsteamsystemcapacityfactor.

Source:BasedondatafromAntaresGroup,Inc.,2003;discussionswithdevelopers.

AsshowninTable 5-6,thetwoboilertypesareassumedtohavetheidenticalprep-yardlabor

requirementforthesameoutput.The100tons/dayplantusesalessautomatedsystem,sothelabor

requirementishigherthanforthelargerplantsusinganautomatedprep-yard.Onaunitcostbasis,O&M

costsarehigherforthefluidizedbedboilerinthe100tons/daysize,butequaltothestokerboilerO&M

costsforthetwolargersizes.

Commercialization Status

Stokerboilershavelongbeenastandardtechnologyforbiomassaswellascoal,andareoffered

5.BiomassConversionTechnologies 40

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

byanumberofmanufacturers.Fluidizedbedboilersareamorerecenttechnology,butarealso

commerciallyavailablethroughanumberofmanufacturers.Untilrecently,however,fluidizedbedboiler

usehasbeenmorewidespreadinEuropethantheUnitedStates,andmanyofthesuppliersareEuropean-

based.

AsshowninTable 5-6, whenevaluatedwithinthecontextofanintegratedplantonaunitcost

basis,O&Mcostsarehigherforasmallercirculatingfluidizedbedprocessing100tons/day,butlower

thanthestokerboilerforthetwolargersizesevaluatedinthisstudy.

Overall Cost and Performance Characteristics

AsummaryofthecostandperformanceoftypicalbiomasssteamsystemsisshowninTable 5-7.

Table 5-7. Summary of Biomass Combustion Boiler System Cost and Performance

Biomass Fuel Feed (tons/day)

System 100 600 900

BiomassFuelCharacteristics

Energycontent(dry)(Btu/lb) 8,500 8,500 8,500

Moisturecontent(%) 50 30 30

Energycontent(asreceived)(Btu/lb) 4,250 5,950 5,950

Stoker Boiler Integrated Steam Plant

Steamoutput(lb/hr) 20,000 165,000 250,000

Boilerefficiency(zeromoisture)(%) 77 77 77

Boilerefficiency(moistureadjusted)(%) 63 71 71

Heatinputtoboiler(MMBtu/hr) 35.4 297.5 446.3

Heatinputtosteam(MMBtu/hr) 22.5 212.0 318.0

Capacityfactor(%) 95 95 95

Cost Factors

Totalinstalledboilercosts $1,990,000 $18,000,000 $23,250,000

Totalinstalledsteamsystemcosts $4,630,000 $23,430,000 $30,360,000

Unitcapitalcost($/lbsteam) $232 $142 $121

Non-fuelO&Mcost($/1,000lbsteam) $3.55 $1.09 $0.73

Fluidized Bed Integrated Steam Plant

Steamoutput(lb/hr) 20,000 175,000 260,000

Boilerefficiency(zeromoisture)(%) 80 80 80

Boilerefficiency(moistureadjusted)(%) 67 75 75

Heatinputtoboiler(MMBtu/hr) 35.4 297.5 446.3

Heatinputtosteam(MMBtu/hr) 23.6 221.7 332.5

Capacityfactor(%) 95 95 95

Cost Factors

Totalinstalledboilercosts $6,970,000 $24,510,000 $32,250,000

Totalinstalledsteamsystemcosts $9,610,000 $29,940,000 $39,360,000

Unitcapitalcost($/lbsteam) $480 $171 $151

Non-fuelO&Mcost($/1,000lbsteam) $4.19 $1.09 $0.74

Source:NREL,2003.

5.BiomassConversionTechnologies 41

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

5.1.2 Cofiring

Oneofthemostcosteffectiveandeasilyimplementedbiomassenergytechnologiesiscofiring

withcoalinexistingcoal-firedboilers.Cofiringreferstothepracticeofmixingbiomasswithafossilfuel

inhigh-efficiencyboilersasasupplementaryenergysource.Inbiomasscofiring,biomasscansubstitute

forupto20percentofthecoalusedintheboiler.Cofiringistypicallyusedwheneitherthesupplyof

biomassisintermittentorwhenthemoisturecontentofthebiomassishigh.Atlargeplants,biomassis

cofiredwithcoal,andmorecoalistypicallyusedthanbiomass.Atsmallplants,biomassiscofiredwith

naturalgas,andmorebiomassistypicallyusedthannaturalgasbecausethenaturalgasisusedto

stabilizecombustionwhenbiomasswithhigh-moisturecontentisfedintotheboiler.

Characterization

Figure 5-5 showsaprocessdiagramforastandardcoal-basedcofiringplant.Biomasshasbeen

cofiredwithcoaleconomicallyincommercialplants,whichisprincipallyviewedasafuelcostreduction

strategy.Incertainsituations,cofiringhasprovidedopportunitiesforutilitiestogetfuelfromwood

manufacturingandotherbusinessesatzeroornegativecost.Overallproductioncostsavingscanalsobe

achievedbyreplacingcoalwithinexpensivebiomassfuelsourcessuchaswoodwasteandwastepaper.

Typically,biomassfuelsuppliesshouldcostatleast20percentless,onathermalbasis,thancoalsupplies

beforeacofiringprojectcanbeeconomicallyattractive.

Figure 5-5. Biomass Cofiring in Coal Power Plant

Source:AntaresGroup,Inc.,2003.

Biomasscofiringismainlyaretrofitapplication.Abasicprincipleofcofiringisthatsignificant

changestotheboilerarenotrequiredbeyondsomeminorburnermodificationsoradditionsnecessaryto

introduceandburnthesupplementalfuel.Tomeetthisobjective,cofiringbiomassfuelsisusuallydone

onalimitedbasis,withtheamountofbiomassrangingfrom5to15percentofthetotalheatinputtothe

boiler.

55

Biomassfuelsthathavebeensuccessfullycofiredincludewoodandpelletizedwastepaper.

Interestisgrowingincofiringbiomassamongelectricutilitiesandotherusersofcoalboilers,chieflydue

totheneedtoimproveairemissionsfromcoal-burningfacilities,aswellastodiversifyfuelsupplies.

Table 5-8 givesasenseofthesizeoftypicalutilitycofiringpowerplants,thepercentageof

biomassfuelused(generallyabout10percent,butupto50percent),andthetypesofbiomassfeedstock

used(wood,woodwaste,woodresidues,andsawdust).

55

FehrsandDonovan,1999.

5.BiomassConversionTechnologies 42

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Table 5-8. Utility Cofiring Biomass With Coal (Continuous Operation)

Plant Name Location Biomass

Feedstock

Total Plant

(MW)

Biomass

(MW)

Boiler

Type

6thStreetAlliantEnergy CedarRapids,IA

Agriculturaland

woodwaste

85 6.5

Fluidized

bed

BayFrontNorthern

States

Ashland,WI Woodresidues 34 5.0 Stoker

ColbertTennesseeValley

Authority

Tuscumbia,AL Woodresidues 190 3.0

Pulverized

coal

GreenridgeAES

Corporation

Dresden,NY Woodresidues 108 10.0

Pulverized

coal

KingNorthernStates

Power

Bayport,MN Sawdust 560 10.0 Cyclone

TacomaSteamPlant#2 Tacoma,WA Wood 25 12.5

Fluidized

bed

WillowIslandAllegheny

Energy

Pleasants,WV

Sawdust,tire-

derivedfuel

188 2.3 Cyclone

YatesSouthern

Co./GeorgiaPower

Newnan,GA Woodresidues 150 2.0

Pulverized

coal

Source:AntaresGroup,2003

Efficiency

Usually,nomajorchangesinboilerefficiencyresultfromcofiring.However,somedesignand

operationalchangesmightbeneededtomaximizeboilerefficiencywhilemaintainingacceptableopacity,

baghouseperformance,andotheroperatingrequirements.Withouttheseadjustments,boilerefficiency

andperformancecandecrease.Forexample,atabiomassheatinputlevelof10percent,boilerefficiency

lossesof2percentweremeasuredduringcofiringtestsatafacilitywithapulverizedcoalboilerwhenno

adjustmentsweremade.

56

Numerouscofiringprojectshavedemonstratedthatefficiencyandperformance

lossescanbeminimizedwithproperawarenessofoperationalissues.

Operating Availability

Theavailabilityofbiomassandcoalcofiredboilersissimilartothatofregularcoalboilers,if

propermodificationsaremadetothesystem.Ifsomeofthepotentialoperatingissuesmentionedinthe

nextsectionmanifest,thenavailabilitymightbenegativelyaffected.

Operating Advantages and Disadvantages

Typically,cofiringbiomassinanexistingcoalboilerrequiresmodificationsoradditionstofuel

handling,processing,storage,andfeedsystems.Slightmodificationstoexistingoperationalprocedures,

suchasincreasingoverfireair,mightalsobenecessary,aswellasincreasingfuelfeederratesto

compensateforthelowerdensityandheatingvalueofbiomass.

AscoveredinChapter4,fuelcharacteristicsandprocessingcangreatlyaffecttheabilitytouse

biomassasafuelinboilers.Woodchipsarepreferabletomulch-likematerialforcofiringwithcoalin

stokerboilersbecausethechipsaresimilartostokercoalintermsofsizeandflowcharacteristics.This

56

Tillman,2000.

5.BiomassConversionTechnologies 43

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

similarityminimizesproblemswithexistingcoalhandlingsystems.Whenusingamulch-likematerialor

abiomasssupplywithahighfractionoffineparticles(sawdustsizeorsmaller),periodicblockageoffuel

flowopeningsinvariousareasoftheconveying,storage,andfeedsystemscanoccur.Theseblockages

cancausesignificantmaintenanceincreasesandoperationalproblems;therefore,fuelshouldbeprocessed

toavoiddifficultieswithexistingfuelfeedingsystems.

Anotherfuelconsiderationwhendealingwithbiomassisthepotentialforproblemswith

slagging,fouling,andcorrosion.Somebiomassfuelshavehighalkali(principallypotassium)orchlorine

contentthatcanleadtounmanageableashdepositionproblemsonheatexchangeandash-handling

surfaces.Chlorineincombustiongases,particularlyathightemperatures,cancauseacceleratedcorrosion

ofcombustionsystemandfluegascleanupcomponents.Theseproblemscanbeminimizedoravoidedby

screeningfuelsuppliesformaterialshighinchlorineandalkalis,limitingthebiomasscontributionto

boilerheatinputto15percentorless,usingfueladditives,orincreasingsoot-blowing.Themost

troublesomebiomassresourcetendstobeagriculturalresidues,includinggrassesandstraws,whichhave

highalkaliandchlorinecontents.Incontrast,mostwoodymaterialsandwastepapersarerelativelylowin

alkaliandchlorineandshouldnotpresentthisproblem.

Currently,about25percentoftheflyashfromcoal-firedpowerplantsisusedasafeedstockfor

cementandconcreteproduction,whileanother15percentisusedasafeedstockinotherapplications.

57

Accordingtocurrentindustrystandards,

58

onlyflyashfromcoalcombustionqualifiesforusein

cement/concreteapplications.Cofiringbiomassinacoalpowerplantwouldkeeptheflyashfrom

meetingthecurrentstandard.Similarly,coalflyashwillsometimesnotmeetthecurrentstandardwhen

certainemissionscontroltechniquesareused,suchasammoniainjection.Thoughtheserestrictionscan

impacttheeconomicsofbiomasscofiring,thevalueoffindingaproductiveuseforflyashandothercoal

combustionproductsisprimarilytheavoidanceofaroughly$20/tonlandfillfee.Forcoalwith10percent

ashcontent,thisvaluewouldbeworthabout$2/tonoftheinputfuelcost.Whilethecurrentrestrictions

areabarriertoconsideringcofiringinsomeapplications,otherusesofflyasharenotaffected,and

researchersarecurrentlystudyingtheimpactofusingflyashfrombiomassandbiomass/coalcofiringon

concretecharacteristics.Earlyresultsshowthatbiomassandcofiredfuelsdonotadverselyaffectthe

usefulnessofflyashincementandconcrete,andinfactmighthavesomeadvantages.

59

Itislikelythat

thisworkwilleventuallyleadtoareevaluationofthestandardandinclusionofflyashfromcofiringasan

acceptablecement/concretefeedstockashasalreadyhappenedinEurope.

60

Equipment and Installed Costs

Cofiringtypicallydoesnotinvolveaddedinvestmentfortheboilerequipmentthatisalreadyin

placeforthecoal-firedplant.Thereareadditionalcostsfornewfuelhandlingandprocessingequipment,

boilermodifications,controls,engineeringfees,andcontingency.Forblendedfuelinputsystems,in

whichthebiomassisaddedupstreamofthecoalfuelpreparationequipment,thecostsfortheaddedfeed

preparationareontheorderof15to30percentofthecostsshownintheprevioussectioninTable5.4for

adedicatedbiomasssystem.Forsystemsusingaseparatefuelfeedsystem,thecostsarecomparableto

thecosts($/tonofbiomassfeed)foradedicatedbiomassplant.

57

AmericanCoalAshAssociation,n.d.

58

ASTMC-618.

59

Wang,2007.

60

In2004,EuropeanStandardEN450dealingwithflyashspecificationsforuseinconcretewasapprovedfor

modificationtoincludeflyashfromawiderangeofcofiredbiomassandwastefeedstocks.Thesechangesareinthe

processofbeingadoptedbytheEuropeanUnionmembercountries.

5.BiomassConversionTechnologies 44

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

O&M Issues

Asdiscussedundercapitalcosts,additionalO&Mtotheboilersectionattributabletotheaddition

ofbiomassforcofiringisminimal.Maintenancerequirementsforboilerscofiringbiomassandcoalare

similartothoseforcoal-onlyboilers.However,slightchangestopreviousoperationalprocedures,suchas

increasingoverfireairandfuelfeederspeeds,mightbeneeded.IncreasesinO&Mcostsforbiomass

cofiringwithcoalarealmostentirelyforthebiomassreceivingandfeedpreparation.Forablended

system,theadjustmentstofeedpreparationO&Marealsoontheorderof15to30percentofthecostofa

dedicatedbiomassplant.

Commercialization Status

Organizationssuchaselectricutilities,DOE,andtheElectricPowerResearchInstitute(EPRI),

haveconductedresearchandfieldtestsonbiomasscofiringinsmall- andlarge-scaleutilityboilersfora

numberofyears.Thesetestshaveshownthatcofiringwithbiomasshasbeensuccessfullyaccomplished

inawiderangeofboilertypes,includingcyclone,stoker,pulverizedcoal,andbubblingandcirculating

fluidizedbedboilers.AccordingtotheFederalEnergyManagementProgram,atleast182separateboilers

andorganizationsintheUnitedStateshavecofiredbiomasswithfossilfuelsalthoughthisnumberisnot

comprehensive.Ofthe182cofiringoperations,114(or63percent)havebeenatindustrialfacilities,32at

utility-ownedpowerplants,18atmunicipalboilers,10ateducationalinstitutions,andeightatfederal

facilities

61

.

5.2 GasificationTechnologies

Biomassgasificationforpowerproductioninvolvesheatingsolidbiomassinanoxygen-starved

environmenttoproducealowormediumcalorificgas.Dependingonthecarbonandhydrogencontentof

thebiomassandthegasifiersproperties,theheatingvalueofthesyngas,canrangeanywherefrom100to

500Btu/cubicfoot(10to50percentthatofnaturalgas).Theheatingvalueofsyngasgenerallycomes

fromCOandhydrogenproducedbythegasificationprocess.Theremainingconstituentsareprimarily

CO

2

andotherincombustiblegases.Biomassgasificationofferscertainadvantagesoverdirectlyburning

thebiomassbecausethegascanbecleanedandfilteredtoremoveproblemchemicalcompoundsbeforeit

isburned.Gasificationcanalsobeaccomplishedusingchemicalsorbiologicaction(e.g.,anaerobic

digestion);however,thermalgasificationiscurrentlytheonlycommercialornearcommercialoption.

Thefueloutputfromthegasificationprocessisgenerallycalledsyngas, thoughincommonusage

itmightbecalledwood gas,producer gas, orbiogas.Syngascanbeproducedthroughdirectheatingin

anoxygen-starvedenvironment,partialoxidation,orindirectheatingintheabsenceofoxygen.Most

gasificationprocessesincludeseveralsteps.Theprimaryconversionprocess,calledpyrolysis,isthe

thermaldecompositionofsolidbiomass(inanoxygen-starvedenvironment)toproducegases,liquids

(tar),andchar.Pyrolysisreleasesthevolatilecomponentsofthebiomassfeedataround1,100Fthrough

aseriesofcomplexreactions.Biomassfuelsareanidealchoiceforpyrolysisbecausetheyhavesomany

volatilecomponents(70to85percentondrybasis,comparedto30percentforcoal).Thenextstep

involvesafurthergasificationprocessthatconvertstheleftovertarsandcharintoCOusingsteamand/or

partialcombustion.Incoalgasification,pureoxygenoroxygen-enrichedairispreferredastheoxidant

becausetheresultingsyngasproducedhasahigherheatingvalue,andtheprocessismoreefficient.In

biomassgasification,oxygenisgenerallynotusedbecausebiomassashhasalowermeltingpointthan

coalash,andbecausethescaleoftheplantsisgenerallysmaller.

61

DOE,2004.

5.BiomassConversionTechnologies 45

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Veryhightemperatureprocessesinvolvingpassingthebiomassthroughaplasmaarchavebeen

developedandtestedprimarilyforwasteremediation,contaminatedwastes,andMSW.Plasmaprocesses

arenotdiscussedinthisreport.

Comparedwithdirect-firedbiomasssystems,gasificationisnotyetanestablishedcommercial

technology.Thereisgreatinterest,however,inthedevelopmentanddemonstrationofbiomass

gasificationforanumberofreasons:

Agaseousfuelismoreversatilethanasolidfuel.Itcanbeusedinboilers,processheaters,

turbines,enginesandfuelcells,distributedinpipelines,andblendedwithnaturalgasorother

gaseousfuels.

Gasificationcanremovefuelcontaminantsandreduceemissionscomparedtodirect-fired

systems.

Gasificationcanbedesignedtohandleawiderangeofbiomassfeedstocks,fromwoodyresidues

toagriculturalresiduestodedicatedcrops,withoutmajorchangesinthebasicprocess.

Gasificationcanbeusedtoprocesswastefuels,providingsaferemovalofbiohazardsand

entrainmentofheavymetalsinnon-reactiveslag.

Agaseousfuelcanbeusedinahigh-efficiencypowergenerationsystem,suchasagasturbine-

combinedcycleorfuelcells,provideditiscleanedofcontaminants.Whenequipmentisaddedtorecover

theheatfromtheturbineexhaust,systemefficienciescanincreaseto80percent.

Likethedirectcombustionprocessesdescribedintheprevioussection,twoprincipaltypesof

gasifiershaveemerged:fixedbedandfluidizedbed.Fixedbedgasifiersaretypicallysimpler,less

expensive,andproducealowerheatcontentsyngas.Fluidizedbedgasifiersaremorecomplicated,more

expensive,andproduceasyngaswithahigherheatingvalue.

5.2.1 Gasifiers

Characterization

Fixed Bed Gasifiers

Fixedbedgasifierstypicallyhaveafixedgrateinsidearefractory-linedshaft.Thefreshbiomass

fuelistypicallyplacedontopofthepileoffuel,char,andashinsidethegasifier.Afurtherdistinctionis

basedonthedirectionofair(oroxygen)flow:downdraft(airflowsdownthroughthebedandleavesas

biogasunderthegrate),updraft(airflowsupthroughthegrateandbiogasiscollectedabovethebed),or

crossflow(airflowsacrossthebed,exitingasbiogas).Schematicsoftheprimarysectionofthefixedbed

gasifiertypesareshowninFigure 5-6.

5.BiomassConversionTechnologies 46

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Figure 5-6. Fixed Bed Gasifier Types

Source:Bain,2006.

Table 5-9 comparesfixedbedgasifiertypes.Table 5-10 providestypicalphysicalcharacteristics

ofafixedbedgasifier.Fixedbedgasifiersareusuallylimitedincapacity,typicallyusedforgeneration

systemsthatareabletoproducelessthan5MW.Thephysicsoftherefractory-linedshaftreactorvessel

limitsthediameterandthusthethroughput.Developershaveidentifiedagoodmatchbetweenfixedbed

gasifiersandsmall-scaledistributedpowergenerationequipment.However,thevariableeconomicsof

biomasscollectionandfeeding,coupledwiththegasifierslowefficiency,maketheeconomicviabilityof

thetechnologyparticularlysite-specific.

5.BiomassConversionTechnologies 47

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Table 5-9. Comparison of Fixed Bed Gasification Technologies

Type of Gasifier

Downdraft Updraft Crossflow

Operation

Biomassisintroduced

fromthetopandmoves

downward.Oxidizer(air)is

introducedatthetopand

flowsdownward.Syngas

isextractedatthebottom

atgratelevel.

Biomassisintroducedfrom

thetopandmoves

downward.Oxidizeris

introducedatthebottom

andflowsupward.Some

dryingoccurs.Syngasis

extractedatthetop.

Biomassisintroducedfrom

thetopandmoves

downward.Oxidizeris

introducedatthebottomand

flowsacrossthebed.

Syngasisextractedopposite

theairnozzleatthegrate.

Advantages

Tarsandparticulateinthe

syngasarelower,allowing

directuseinsome

engineswithoutcleanup.

Thegrateisnotexposed

tohightemperatures.

Canhandlehigher-moisture

biomass.Higher

temperaturescandestroy

sometoxinsandslag

mineralsandmetal.Higher

tarcontentaddstoheating

value.

Simplestofdesigns.

Strongercirculationinthe

hotzone.Lower

temperaturesallowtheuse

oflessexpensive

constructionmaterials.

Disadvantages

Biomassmustbeverydry

(<20percentmoisture

content).Thesyngasis

hotandmustbecooledif

compressionorextensive

cleanupisrequired.About

4to7percentofthe

carbonisunconvertedand

remainsintheash.

Highertarcontentcanfoul

enginesorcompressors.

Thegrateisexposedto

hightemperaturesand

mustbecooledor

otherwiseprotected.

Morecomplicatedto

operate.Reportedissues

withslagging.Highlevelsof

carbon(33%)intheash.

Table 5-10. Typical Characteristics of a Fixed Bed Gasifier

Parameter Fixed Bed, Downdraft

Fuelsize(inches) 0.4-4

Fuelashcontent(%weight) <6

Operatingtemperature(F) 1450-2550

Control Simple

Turn-downratio 4:1

Constructionmaterial Mildsteel+refractory

Capacity(MW

thermal

)(tonsbiomass/day) <5(<30)

Start-uptime Minutes

Operatorattention Low

Tarcontent(lb/MMBtuproductgas) <1.2

Heatingvalue(Btu/scf)HHV 130

Source:GasNet,n.d.

5.BiomassConversionTechnologies 48

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Fluidized Bed Gasifiers

Fluidizedbedgasifiersutilizethesamegasificationprocessesandofferhigherperformancethan

fixedbedsystems,butwithgreatercomplexityandcost.Similartofluidizedbedboilers,theprimary

gasificationprocesstakesplaceinabedofhotinertmaterialssuspendedbyanupwardmotionofoxygen-

deprivedgas(Figure 5-7).Astheamountofgasisaugmentedtoachievegreaterthroughput,thebedwill

begintolevitateandbecomefluidized.Sandoraluminaisoftenusedtofurtherimprovetheheat

transfer.Notablebenefitsoffluidizedbeddevicesaretheirhighproductivity(perareaofbed)and

flexibility.Fluidizedbedgasifierscanalsohandleawiderrangeofbiomassfeedstockswithmoisture

contentsupto30percentonaverage.

Figure 5-7. Fluidized Bed Gasifier

Source:Bain,2006.

Therearethreestagesoffluidizationthatcanoccuronthegasifierdependingonthedesign:

bubbling,recirculating,andentrainedflow.Atthelowerendoffluidization,thebedexpandsandbegins

toactasafluid.Asthevelocityisincreased,thebedwillbegintobubble.Withafurtherincreasein

airflow,thebedmaterialbeginstoliftoffthebed.Thismaterialistypicallyseparatedinacycloneand

recirculatedtothebed.Withstillhighervelocities,thebedmaterialisentrained(i.e.,pickedupand

carriedoffintheairflow).

Fluidizedbedgasifierscanbedesignedtouseaportionofthepyrolysisgasestogeneratetheheat

todrivetheprocess,ortheycanbeexternallyfired.Operatingthegasifierathigherpressuresincreases

thethroughput;however,thisalsoincreasesthegasifierscomplexityandcost.Intheseunits,thebiomass

isfullyconvertedaftergoingthroughthepyrolysisandcharconversionprocesses.

Byreducingthequantityofairandprocesstemperature,itispossibletooperatefluidizedbed

boilersasgasifiers.Inthisoperatingmode,thegasifiersproduceagaswithaheatingvalueofslightly

morethan100Btu/cubicfoot(ft

3

).Thisgasisburnedabovethebedasadditionalairsupplyisinjected

upstreamoftheboilertubesection.

Table 5-11 providestypicalphysicalcharacteristicsofafluidizedbedgasifier.Anumberof

advanced-conceptfluidizedbedgasifiersaimingtoproduceasyngaswithaheatingvaluebetween250

and400Btu/ft

3

areunderdevelopment.Thistypeofsyngaswouldbemoreappropriateforuseingas

5.BiomassConversionTechnologies 49

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

turbines,fuelcells,andreciprocatinginternalcombustionengines;however,theseadvancedconcept

gasifiershavenotreachedthepointwheretheyareprovenincommercialoperation.

Table 5-11. Typical Characteristics of a Fluidized Bed Gasifier

Parameter Fluidized Bed

Fuelsize(inches) 0-0.8

Fuelashcontent(%weight) <25

Operatingtemperature(F) 1,350-1,750

Control Average

Turn-downratio 3

Constructionmaterial Heat-resistantsteel

Capacity(MW

thermal

)(biomasstons/day) 5andup(>30)

Start-uptime Hours

Operatorattention Average

Tarcontent(lb/MMBtuproductgas) <2

Heatingvalue(Btu/scf)HHV 150

Source:GasNet,n.d.

Efficiency

Bothfixedandfluidizedbedbiomassgasificationusessimilartypesofequipmentasdirect

combustion.Thebiomassfuelisfedintoacombustion/reactionvesselwitheitherafixed,fluidized,or

movingbed.Thethermodynamicsofheatlossaresimilar,butgasificationconditionsaredifferentfrom

directcombustion.Indirectcombustion,10to14timestheweightofthefuelisintroducedasair.In

gasification,theairenteringthereactor,ifany,isonlyonetotwotimestheweightofthefuel.This

differencereducesheatlossesfromthereactionzone.Ontheotherhand,thesyngasexitsthegasification

reactoratveryhightemperatures(1,200to1,500F);someofthisheatlosscanberecoveredeither

directlythroughtheuseofheatexchangersinthegascoolingsection,orindirectlythroughtheuseofheat

recoveryfromthecombustionofthesyngasinthepowergenerationsection.Totheextentthatheatis

usedtopreheatincomingair,introducehigh-temperaturesteam,ordrytheincomingbiomass,the

efficiencyofbiomasstosyngasconversionwillbeincreased.Heatthatisrecoveredfromthehotgas

coolingsectioncanalsobeaddedtotheCHPheatrecovery.Inthiscase,theintermediateefficiencyvalue

ofsyngasconversionisnotincreasedbuttheoverallCHPefficiencyis.Thesedifferencescombineto

producebiomasstosyngasefficiencies(heatingvalueofthesyngasdividedbytheheatingvalueofthe

biomass)of60to80percent.Inintegratedconfigurations,however,additionalsteamcanbegenerated

fromcoolingthehotsyngasexitingthereactorpriortocleanup.

Operating Availability

Duetothefactthatcommercializationofbiomassgasificationplantsisinitsearlystages,no

facilitysurveyinformationwasfoundontheiravailabilityorreliability.Plantsaredesignedfor

continuousoperation,anddesignperformanceisinthe90+percentrange.Actualexperiencewith

emergingtechnologytendstoresultinloweravailabilitythanisexperiencedduringbroadcommercial

use,asmaterialshandlingproblems,controlissues,andcomponentfailurescausemorefrequent

unplannedoutagesthanareseenafteraccumulatingadditionaloperatingexperience.Withanewly

establishedsupportinfrastructure,outagesalsotendtolastlongerbeforebeingfixedorsolved.Awell

5.BiomassConversionTechnologies 50

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

designedsystem,however,hasareasonableexpectationofoperatinginthe85to95percentavailability

range.

Operating Issues

Asdiscussedabove,moisturecontent,gascleanup,andoperatingpressurecanallaffectoperation

ofagasifier.Thereareanumberofoperatingissuescommontothedifferenttypesofgasification

systems.

Moisture Content

Greenbiomass,definedasfreshlyharvestedplantmaterial,cancontainasignificantamountof

waterbyweight(upto60percent).Thiswaterdoesnotcontributetotheheatcontentofthesyngaswhile

consumingasignificantamountofenergyingasification.Eventhoughwatercannotbeburned(oxidized)

atelevatedtemperatures,itwilldissociateintoitselementalcomponentshydrogenandoxygen.The

hydrogenwillcontributetothecalorificvalueofthesyngas.Thisreactionisverytemperature-sensitive,

andthehydrogenandoxygenwillusuallyrecombineintowatervaporasthesyngascools.Therefore,the

moisturecontentofbiomassmustbestrictlylimited.Ifthereisexcessmoisture,thegasificationprocess

cannotsustainitselfwithoutanexternalsourceofheat.Asthemoisturecontentofthebiomassincreases,

thenetenergyavailableinthesyngasdecreases.Fixedbedgasifiersthatuseinternalcombustionofthe

syngastypicallyutilizebiomasswithlessthan20percentmoisturecontent.Fluidizedbedgasifiers

typicallyrequirelessthan30percentmoisturecontent.

Greenbiomassisthemostreadilyavailableandinexpensivebiomassproduct.Thedryingprocess

requiresaconsiderableadditionalcapitalinvestmentandincreasestheO&Mcosts.Unfortunately,the

costofthedryingequipment(equipmentcostandO&Mcost)seldomcoversthecostsavingsofusing

greenbiomass.

Gas Cleanup

Assyngasleavesthegasifier,itcontainsseveraltypesofcontaminantsthatareharmfulto

downstreamequipment,ashhandling,andemissions.Thedegreeofgascleanupmustbeappropriately

matchedtoitsintendeduse.Foruseinreciprocatingengines,gasturbines,andespeciallyfuelcells,a

verycleangasisrequired.AsdiscussedinTable 5-12,theprimarycontaminantsinsyngasaretars,

particles,alkalicompounds,andammonia.Thetypesofcontaminantsthatareobserveddependonthe

biomassfeedstockandthegasificationprocessused.

Table 5-12. Gas Cleanup Issues

Contaminant Description Treatment

Tar

Tars(creosote)arecomplexhydrocarbonsthat

persistascondensablevapors.

Wetscrubbers,electrostaticprecipitators,barrier

filters,catalysts,orcombustion.

Particles

Particlesareverysmall,solidmaterialsthat

typicallyincludeashandunconvertedbiomass.

Cycloneseparators,fabricfilters,electrostatic

precipitators,andwetscrubbers.

Alkali

compounds

Potassium,alkalisalts,andcondensedalkali

vaporsarepartofthechemicalcompositionof

biomass.

First,coolsyngasbelow1,200F,causingthe

alkalivaporstocondense.Second,usecyclone

separators,finefabricfilters,electrostatic

precipitators,andwetscrubbers.

Ammonia

Ammoniaisformedfromnitrogen(fuel-bound

andinair)andhydrogen(infuelandin

moisturecontent).Whensyngasisburned,

ammoniaisconvertedtoNOx.

Catalysts,hydrocarbonreforming,orwet

scrubbing.

5.BiomassConversionTechnologies 51

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Becausegasificationoccursatanelevatedtemperature,syngascanhaveasmuchasathirdofits

totalenergyinsensibleheat.Cleaningthegaswhileitishotwouldbeadvantageousfromanenergyuse

perspective,butthistaskiscurrentlydifficulttoaccomplish.Researchisongoingregardinghotgas

filters,whichcanbeappliedincoalgasification,aswellasotherhigh-temperatureprocesses.Wet

scrubbersarecurrentlyoneofthemostreliableandleastexpensiveoptionsforgascleanup,eventhough

theysacrificealargeportionofthesensibleheatofthesyngas.Coolingthehotsyngascanprovidea

sourceofsteamforthecleaningprocess,powergeneration,orend-use.

Operating Pressure

Gasifierscanbeoperatedateitheratmosphericorelevatedpressures.Air-blown,atmospheric

gasifiersproduceaverylowBtugas110to170Btu/scf.Tointroducethisgasintoagasturbineinthe

powergenerationsectionoftheplantrequiresconsiderablecompressionenergy,uptoathirdofthe

turbinesoutput.Therefore,itwouldbeadvantageoustoproducethesyngasatahighpressuresothatit

canbeintroduceddirectlyintothecombustionsectionofagasturbinewithoutadditionalcompression.

Pressurizedreactors,however,doneedtocompressanycombustionairoroxygenthatisintroducedinto

thereactorandmaintainapressuresealonthebiomassinputandashremovalsystems.

Advantages and Disadvantages

Fixedbedandfluidizedbedgasifiershavespecificoperatingadvantagesanddisadvantageswith

biomassfuelsdependingonthebiomasscharacteristicsandsiterequirements.Table 5-13 providesa

qualitativecomparisonofgasifiercharacteristicsandoperatingissuesforfixedbedandfluidizedbed

systems.

Table 5-13. Relative Advantages/Disadvantages of Gasifier Types

Gasifier Advantages Disadvantages

Updraftfixedbed Matureforheat

Small-scaleapplications

Canhandlehighmoisture

Nocarboninash

Feedsizelimits

Hightaryields

Scalelimitations

LowBtugas

Slaggingpotential

Downdraftfixedbed Small-scaleapplications

Lowparticulates

Lowtar

Feedsizelimits

Scalelimitations

LowBtugas

Moisture-sensitive

Bubblingfluidbed Large-scaleapplications

Feedcharacteristics

Direct/indirectheating

CanproducehigherBtugas

Mediumtaryield

Higherparticleloading

Circulatingfluidbed Large-scaleapplications

Feedcharacteristics

CanproducehigherBtugas

Mediumtaryield

Higherparticleloading

Entrainedflowfluidbed Canbescaled

Potentialforlowtar

Potentialforlowmethane

CanproducehigherBtugas

Largeamountofcarriergas

Higherparticleloading

Particlesizelimits

5.BiomassConversionTechnologies 52

Section

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Equipment and Installed Costs

Themaincostforthegasificationtrainistheprimarygasificationreactoritself.Supplementary

processingcanoccurinatarcracker.Indirectgasifiershaveseparatecharcombustorstosupplyheat.The

nextmajorpartisthegascleanupsection,whichincludesashremoval,quench,bagfilter,wetscrubber,

andheatexchangerstocoolthesyngasandprovideheattootherpartsoftheprocessortocontributeto

theCHPheatutilization.Capitalcostsforthegasificationsectionandforabiomass-to-syngasplantare

showninTable 5-14.Thesecostsareestimatedbasedonpublishedestimates(AntaresGroup,Inc.,2003)

anddiscussionswithequipmentsuppliers.Theunitcostsdonotshowauniformdecliningtrendasa

functionofsize,butinsteadvarydependingontheprocessconsidered.

Table 5-14. Biomass Gasification Capital Costs to Produce Syngas

Gasifier Cases

Atmospheric

Gasification

Atmospheric

Gasification

Atmospheric

Gasification

High-Pressure

Gasifier

Gasifiertype Fixed Fluidized Fluidized Fluidized/

high-pressure

Tons/day(asreceived) 100 260 450 1,200

Gasifierequipment $1,225,000 $10,050,000 $15,158,000 $34,682,000

Installation $612,000 $5,024,000 $7,578,000 $17,338,000

Total Installed Gasification $1,837,000 $15,074,000 $22,736,000 $52,020,000

BiomassPrepYard* $2,639,700 $3,947,400 $4,972,000 $9,685,766

Total Installed Capital Cost $4,476,700 $19,021,400 $27,708,000 $61,705,766

UnitCost($/MMBtu/hr)(syngas) $127,164 $209,425 $174,130 $161,270

*Prep-Yardcostsareestimatedbasedonthecapitalcostcurvedevelopedinsection4.1.5

Source:BasedondatafromAntaresGroup,Inc.,2003;discussionwithequipmentsuppliersanddevelopers.

O&M Costs

Non-fuelO&McostsforgasificationincludeO&Mlabor,supervisorylabor,water,ashremoval,

insurance,taxes,royalties,andotheroperatingmaterials.ThesecostsareestimatedinTable 5-15 based

onpublishedestimatesanddiscussionswithequipmentsuppliers.

62

62

AntaresGroupInc.,2003

5.BiomassConversionTechnologies 53

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Table 5-15. Gasification O&M Cost Estimates for Syngas Production

Gasifier Cases

Atmospheric

Gasification

Atmospheric

Gasification

Atmospheric

Gasification

High-Pressure

Gasifier

Gasifiertype Fixed Fluidized Fluidized Fluidized/

high-pressure

Tons/day(asreceived) 100 260 450 1,200

Netcapacity,MMBtu/hr 35.2 90.8 159.1 382.6

Prep-yardlaborcosts $400,000 $320,000 $320,000 $400,000

GasifiersectionO&M $502,000 $634,500 $789,500 $2,235,800

Total Annual O&M

(to syngas) $902,000 $954,500 $1,109,500 $2,635,800

GasificationO&M($/MMBtu) $3.250 $1.333 $0.884 $0.874

Source:BasedondatafromAntaresGroup,Inc.,2003;discussionwithequipmentsuppliersanddevelopers.

Asummaryofthecostandperformancefortherangeofbiomassgasificationsystemsconsidered

isprovidedinTable 5-16.

Table 5-16. Biomass Gasification Cost and Performance

Gasification Technologies

Atmospheric

Gasification

Atmospheric

Gasification

Atmospheric

Gasification

High-

Pressure

Gasifier

Gasifiertype Fixed Fluidized Fluidized Fluidized/

high-pressure

Tons/day(asreceived) 100 260 450 1,200

Feedstock Characteristics

Energycontentdry(Btu/lb) 8,500 8,500 8,500 8,476

Moisturecontent(%) 30 30 30 38

Energycontentasreceived(Btu/lb) 5,950 5,950 5,950 5,255

Biomass Conversion

Gasifierefficiency

(moistureadjusted)(%)

65 71 71 72

Biomassfuelvaluetogasifier

(MMBtu/hr)

49.6 127.9 224.1 531.9

Fuelproduced(MMBtu/hr) 32.2 90.8 159.1 382.6

Heatingvalue(Btu/scfHHV) 110.0 110.0 110.0 128.8

Fuelpressure(psig) Atmospheric Atmospheric Atmospheric Pressurized

Plantcapacityfactor(%) 90 90 90 90

Capital Costs

Gasifierequipment $1,225,000 $10,050,000 $15,158,000 $34,682,000

Installation $612,000 $5,024,000 $7,578,000 $17,338,000

Total Installed Gasification Section

$1,837,000 $15,074,000 $22,736,000 $52,020,000

BiomassPrep-Yard $2,639,700 $3,947,400 $4,972,000 $9,685,766

Total Installed Capital Cost

$4,476,700 $19,021,400 $27,708,000 $61,705,766

UnitCost($/MMBtu/hr)(syngas) $127,164 $209,425 $174,130 $161,270

Source:BasedondatafromAntaresGroup,Inc.,2003;discussionwithequipmentsuppliersanddevelopers.

5.BiomassConversionTechnologies 54

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Commercial Status

Themajorityofcommercialgasificationprojectsusecoalorpetroleumcokeasafeedstock.

Biomassgasificationtechnologieshavebeenasubjectofcommercialinterestforseveraldecades.Bythe

1990s,CHPhadbeenidentifiedasapotentialnear-termtechnology.Researchanddevelopment

concentratedonintegratedgasificationcombinedcycleandgasificationcofiringdemonstrations,which

ledtoanumberofcommercial-scalesystems.IntheUnitedStates,projectsmostlyprocessedhard-to-

managefeedstockslikebagasseandalfalfa.Low-energygasifiersarenowcommerciallyavailable,and

dozensofsmall-scalefacilitiesareinoperation.

AreviewofgasifiermanufacturersinEurope,theUnitedStates,andCanada

63

identified50

manufacturersofferingcommercialgasificationplantsinwhich75percentofthedesignswerefixedbed

downdrafttype;20percentofthedesignswerefluidizedbedsystems.Theactualnumberofbiomass

gasificationsystemsinoperationworldwideisunknown,butisestimatedtobebelow50basedon

literaturereviewanddiscussionswithindustrysources.Thereareonlyahandfulofcommercially

operatingbiomassgasificationsystemsintheUnitedStatesatthistime,andmanyofthesearepartially

government-fundeddemonstrationunits.Incomparison,therearecurrentlymorethan100biomass-fueled

fluidizedbedboilersinoperationaroundtheworld.

Thereisstillaconsiderableamountofdevelopmentactivityunderwaytoaddressexisting

technicalandoperationalissues:

GasificationSomegasificationtechnologiesusingbiomassandblackliquorhave

developedtothepointoflarge-scaledemonstration.However,gasifiersystemshavenot

reachedwidespreadcommercialavailabilityforsystemssuitableforintegrationwith

hydrogenseparationtechnologiesforfuelcellsorfuelsynthesis.Thisisdueinparttoareas

offuelchemistrythatarenotestablishedenoughtosupportthecommercialdemonstration

programsandfacilitatethedevelopmentandscale-upofadvancedgasifiersandgascleanup

systems.

Syngas cleanup and conditioningTherawgasesfrombiomasssystemsdonotcurrently

meetstrictqualitystandardsfordownstreamfuel,chemicalsynthesiscatalysts,orthosefor

somepowertechnologies.Thesegaseswillrequirecleaningandconditioningtoremove

contaminantssuchastar,particulates,alkali,ammonia,chlorine,andsulfur.Available

cleanuptechnologiesdonotyetmeettheneededcost,performance,orenvironmentalcriteria

neededtoachievecommercialimplementation.

Sensors and controlsDevelopmentofeffectiveprocesscontrolsisneededtomaintain

plantperformanceandemissionsattargetlevelswithvaryingload,fuelproperties,and

atmosphericconditions.Newsensorsandanalyticalinstrumentsareunderdevelopmentto

optimizecontrolsystemsforthermochemicalsystems.

Process integrationAswithallnewprocesstechnologies,demonstratingsustained

integratedperformancethatmeetstechnical,environmental,andsafetyrequirementsat

sufficientlylargescaleisessentialtosupportingcommercialization.Applicationssuchas

blackliquorintegrationinpapermillshastheaddedcomplexityofbeingattachedtoan

existingcommercialprocesswheretheunitoperationsassociatedwithsteamproduction,

power,pulping,andchemicalrecoverymustallbeintegrated.

63

EuropeanBiomassIndustryAssociation,n.d.

5.BiomassConversionTechnologies 55

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Containment (materials of construction)Experiencewithexistinggasifiersindicatesthat

gasificationreactionsaredifficulttocontainandthatmaterialsdevelopmentforreactorshells

andinternals,refractorymaterialstolinecontainmentvessels,vesseldesign,andincreased

knowledgeofbedbehaviorandagglomerationwillimproveperformanceoverthelongterm.

5.3 ModularSystems

Modularbiomass-fueledCHPsystemsaredefinedassmallsystems,lessthan5MW,though

typicallysmaller,withthemainoperatingcomponentscominginoneormorepre-engineeredand

packagedmodulesforsimpleinstallationattheuserssite.Thesystemstypicallyincludeafuelprocessor

(combustionorgasification),necessaryintermediatefuelcleanup,anelectricgenerator,andheatrecovery

fromboththepowergenerationandenergyconversionsections.Anautomaticfuelstorageanddelivery

systemmustbeaddedforacompleteoperatingsystem.

Smallmodularbiomasssystemscansupplyelectricitytoruralareas,farms,businesses,and

remotevillages.Thesesystemsuselocallyavailablebiomassfuelssuchaswood,cropwaste,animal

manure,andLFG.Developmentofbiomass-fueledmodularpowersystemsisofgreatinterest

internationallyasameanstobringpowertoisolatedcommunitiesinareaslackingpowerandfuel

infrastructure.IntheUnitedStates,thereisinterestinsmallsystemstoutilizeopportunityfuelsfroma

localarea,suchascropwastesorfirecontrolforestthinnings.

Apartiallistingofspecificdeveloper/manufacturermodularsystemsisprovidedinAppendixD.

Characterization

Modularsystemsareessentiallyscaleddownversionsoflargersystems.Therearesystemsthat

usedirect-firedtechnologywithsteampower,andsystemsthatusegasificationtechnologyandgaseous

fuelburningpowertechnologies(discussedinChapter6)suchasinternalcombustionengines,

microturbines,andStirlingengines.TherearealsodirectfiredsystemsthatuseStirlingenginesforpower

production,aswellassystemsthatemploygasification,whereinthehotrawgasiscombustedtoraise

steam.

Modular Gasification Systems

Figure 5-8 showsaschematicofa75-kWmodularbiomassgasificationsystemthatis

representativeofsystemsunderdevelopment.Thefigureshowsthatthereareeightsubmodulesincluded

inthebasicsystemandthatthestorageandfeedsubmodulesarenotincluded.

BasicPackageModules

1. Automaticbiomassfeedsystem.

2. Dryertoreducethefeedstockmoisturecontent.

3. Chipsorterforsizing.

4. Heatexchangerthatextractsheatfromthegasifierforuseinthedryerandforonsitethermal

applications.

5. Gasifierfeeder.

6. AdowndraftgasifierproducinglowBtugas(heatingvalueofabout110Btu/scfHHV).

5.BiomassConversionTechnologies 56

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

7. Filteringstagesthatremoveparticulates.

8. Thepower modulethis can bean internal combustion engine designed to run on lowBtu

fuel, a microturbine, a Stirling engine, or even a fuel cell. Thepower modulealso has heat

recoveryequipmenttoprovideadditionaluseablethermalenergyforonsiteuse.Becausethe

gasisofsuchalowBtucontent,propaneornaturalgasisrequiredonsystemstart-up.After

start-up,thesystemcanrunonthesyngasalone.

Systemssuchasthesewillrequirefeedstockstoragewithanin-placedeliverysystem.Anin-

groundstoragebunkerwithamovingbedwouldallowdirectdeliveryoffuelloadsintotheautomated

system.Thiscanconsistofapermanentlyinstalledlivebottomvanintowhichdumptruckscandelivera

sizedfuelsupply.

Figure 5-8. Example Modular Biomass Gasification System

Source:CommunityPowerCorporation,n.d.

Modular Combustion Systems

64

Directcombustioninfixedbedcombustorsisacommercialtechnologyinlargersizes.Inthese

largersystems,ascharacterizedpreviously,powerisgeneratedbysteamturbines.Inmodularsystems,

otherpowersystemsarebeingdevelopedthataremoresuitableforsmall-sizedapplications.Thetypical

powerandheatcyclesbeingemployedorexploredforuseareasfollows:

Steamcycle

OrganicRankinecycle(ORC)

Braytoncycle,hotairturbine

64

Exampleshown,BioMax,isdevelopedbyCommunityPowerCorporation.

5.BiomassConversionTechnologies 57

EPACombinedHeatandPowerPartnership BiomassCHPCatalog

Entropiccycle,asdefinedbyitsdeveloper,similartoOrganicRankinecyclebutwitha

highertemperaturedifferentialproducinghigherefficiencies

StirlingEngine,externalcombustion

ModularpowerandheatcyclesthatcanbedrivenbybiomasscombustionareshowninFigure 5-9.