Professional Documents

Culture Documents

Methodology of WWT Fixed

Uploaded by

Berapi Panas0 ratings0% found this document useful (0 votes)

13 views3 pagesit is about waste water treatment

Original Title

Methodology of Wwt Fixed

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentit is about waste water treatment

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views3 pagesMethodology of WWT Fixed

Uploaded by

Berapi Panasit is about waste water treatment

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Methodology

Preparation of synthetic wastewater

1. Fill a bucket with water for 1 liters. The water represents the streams and rivers that service

wildlife, organisms that live in water and the human population.

2. The type of dye that used in this experiment is acid dyes because it is commonly used in

textile especially in coloring cotton product such t-shirts, socks, underwear and towels.

Moreover, acid dye is soluble in water and possesses affinity for amphoteric fibers compared

to other dyes such as direct dye, azo dyes and anthraquinone.

3. The dye are inserted into the water but the volume of dyes should be 10 % from volume of

water. The concentration of dyes insides water should be 1.0 g/L.

4. Stir it until it dissolved completely on water same on figure 1

Figure 1 The example of the wastewater of acid dyes (Dvju, 2010)

Experimental Procedure

The Jar test is a pilot-scale test of the treatment chemicals used in a particular water plant. It is

stimulates the coagulation process in a water treatment plant and helps operators identify if they

are using the right amount of treatment chemicals which helps them improves the plants

performance (Mohammad et. al, 2010).

1. The laboratory surrounding temperature should be kept below 25C to achieve a great

result. Try avoid any temperature fluctuations as much as possible, except where

indicated in this procedure.

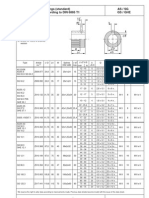

2. Prepare a six paddle stirrer with six beaker apparatus and each beaker (figure 3) should

be contained 150 ml of the prepared dye solution was used in this study.

Figure 3 The Paddle Stirrer and beaker (Mohammad et. al, 2010)

3. Mix the of dye solution with sodium hydroxide (NaOH) for pH adjustment for a period of

1 minute at 60-65 rpm.

4. The initial pH of the dye solutions were measured by the pH meter.

5. The initial turbidity of the dye solution were measured by the turbidimeter

6. Before we add any treatment into wastewater, we should prepare a composition such

a. Lime (10% Sol) + Ferrous Sulphate (5% Sol) + Poly-electrolyte (0.1% Sol)

b. Lime (10% Sol) + Aluminum Chloride (5% Sol) + Poly-electrolyte (0.1% Sol)

c. Caustic (10% Sol) + Ferric Chloride (5% Sol) + Poly-electrolyte (0.1% Sol)

d. Lime (10% Sol) + Alum (5% Sol) + Poly-electrolyte (0.1% Sol)

7. Add composition a into solution, dye solution was stirred for 3 minutes.

(While the stirrer operates, record the appearance of the water in each beaker. Note the

presence or absence of floc, the cloudy or clear appearance of water, and the color of the

water and floc.)

8. It was followed for a further mixing for 1 minute after the addition of polyelectrolyte

(polyelectrolyte functions to stabilize the flocculation procees).

9. The formed flocs were allowed to settle and the settling times( to reach half of the dye

solution height) were recorded. The supernatural of the treated dye solution was taken for

the determination of the colour remained.

10. Reduce the stirring speed to 20 rpm and continue stirring for 30 minutes. Record a

description of the floc in each beaker 10, 20 and 30 minutes after addition of the

chemicals.

11. Stop the stirring apparatus and allow the samples in the beakers to settle for 30 minutes.

Record a description of the floc and turbidity in each beaker after 15 minutes of settling

and again after 30 minutes of settling.

12. Determine the most effective dose of coagulant that gives the least turbid results by

plotting the graph of turbidity.

Reference

Alcoa World Chemicals (2001), Polyaluminum Chloride (PAC). Retrived from

[http://www.alumina.alcoa.com].

Dvju James. (2010). Dyes and dye intermediates. Most polluting industries of India.

SK Al-Dawery and OH Al-Joubori (2010). Preparation and Usage Of Polyaluminum Chloride as

a Coagulating Agent. TJER 2012,vol. 9. 31-36.

Kohlschutter HW, Hantelmann P, Diener K, Schilling H (1942), Basic aluminum chlorides.

Zeitschr Anorg, Und allgemeine Chem. 248(4):319-344.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Course Add Drop Form For Ug Course 1718T2 PDFDocument1 pageCourse Add Drop Form For Ug Course 1718T2 PDFArtyomNo ratings yet

- Improvements in Offshore Pipeline Cathodic ProtectionDocument6 pagesImprovements in Offshore Pipeline Cathodic ProtectionEddy Norman Benites DelgadoNo ratings yet

- Coal JourneyDocument2 pagesCoal JourneyasnandyNo ratings yet

- Specification For HDPE MANHOLES PDFDocument4 pagesSpecification For HDPE MANHOLES PDFPipeline EngineerNo ratings yet

- Wwii Aircraft Vol 2Document50 pagesWwii Aircraft Vol 2Virág Árpád100% (5)

- CCNA - Access List QuestionsDocument3 pagesCCNA - Access List QuestionsBaaska214No ratings yet

- Ronalyn AramboloDocument3 pagesRonalyn AramboloRonalyn AramboloNo ratings yet

- Mohit Soni ReportDocument104 pagesMohit Soni ReportMohitNo ratings yet

- PTX PRM PGL T5 750929eDocument382 pagesPTX PRM PGL T5 750929eListiyo Imam SantosoNo ratings yet

- Life-Saving Rules: Tool Box Talk SeriesDocument86 pagesLife-Saving Rules: Tool Box Talk SeriesSalahBouzianeNo ratings yet

- Zf6 6r60 Zip BookletDocument8 pagesZf6 6r60 Zip BookletPablo Farfan Alvarez100% (1)

- IRGC (2021) - Spotlight - Risk Governance and The Rise of DeepfakesDocument4 pagesIRGC (2021) - Spotlight - Risk Governance and The Rise of DeepfakessaidNo ratings yet

- Chapter Four Risk Assessment of NLNGDocument8 pagesChapter Four Risk Assessment of NLNGOkePreciousEmmanuelNo ratings yet

- Particle Packing in Concrete 30-04-20Document49 pagesParticle Packing in Concrete 30-04-20b ramachandraNo ratings yet

- AcknowledgementDocument4 pagesAcknowledgementPurna GuptaNo ratings yet

- Atm MachineDocument7 pagesAtm MachineNguyen TungNo ratings yet

- 23 Electromagnetic Waves: SolutionsDocument16 pages23 Electromagnetic Waves: SolutionsAnil AggaarwalNo ratings yet

- Series: 25 TON (222 KN)Document2 pagesSeries: 25 TON (222 KN)Marius IlcaNo ratings yet

- As / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1Document1 pageAs / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1hadeNo ratings yet

- Solenoid ValvesDocument23 pagesSolenoid ValvesmcsecNo ratings yet

- Washing MachinesDocument6 pagesWashing MachinesAnonymous wK36hLNo ratings yet

- Valspeq 3.80 User Manual EnglishDocument269 pagesValspeq 3.80 User Manual EnglishFaizan AhmedNo ratings yet

- Web Service Integration With SAPDocument7 pagesWeb Service Integration With SAPJoy PatelNo ratings yet

- Operaional Manual: YZBF-120LDDocument16 pagesOperaional Manual: YZBF-120LDMohamed AnwarNo ratings yet

- A30050-X6026-X-4-7618-rectifier GR60Document17 pagesA30050-X6026-X-4-7618-rectifier GR60baothienbinhNo ratings yet

- Chapter 19 Malicious LogicDocument16 pagesChapter 19 Malicious LogicAnita Sofia KeyserNo ratings yet

- Horizontal Cylindrical Steam Autoclave: Main FeaturesDocument2 pagesHorizontal Cylindrical Steam Autoclave: Main FeaturesMahroelNo ratings yet

- 4ghz Low Noise Amplifier For Satellite D ImpDocument5 pages4ghz Low Noise Amplifier For Satellite D ImpAbhishek JajuNo ratings yet

- Lab 1: Basic Cisco Device Configuration: Topology DiagramDocument17 pagesLab 1: Basic Cisco Device Configuration: Topology DiagramnhiNo ratings yet